10/22/2020 For quite a long time in Russia there was no GOST standard for laminated plywood. Russian manufacturers produced it based on their own specifications, which were adapted to the requirements of the buyer's countries. The first (and current today) GOST appeared only in 2010. This is GOST R 53920-2010 “Coated plywood. Technical conditions".

Important

The document describes the requirements for plywood laminated with a film of thermosetting polymers. Veneered plywood, metal coated plywood, etc. are not subject to GOST and are produced according to internal specifications.

Plywood laminated mesh

For ease of work, the surface of the plywood is marked in the form of a grid, which simplifies cutting sheets and laying reinforcement, significantly reducing labor costs and increasing the productivity of construction work. At the same time, this type of surface, such as the smooth mesh of laminated plywood, retains high wear resistance after repeated use. The plywood laminated mesh has a pitch of 25, 50 and 100 mm, which simplifies the procedure for cutting extensions, flanging and cutting right angles. This material is most widely used in the installation of removable and permanent formwork, but is also widely used in interior and exterior decoration, furniture and decorative production. On the outside, the sheets are mostly brown or black, but depending on the density, the color may vary.

Technical characteristics of laminated mesh plywood

| Format | 2440x1220, 2500x1250, 3000x1500, 3050x1525 |

| Thickness, mm | 6 — 40 |

| Surface color | black, dark brown (F) / Black (W) |

| Surface type | smooth / mesh (F/W) |

| Film density, g/m2 | 125 (black)/120 (dark brown) |

| Wear resistance, speed according to Taber test | not less than 2600 |

| Formaldehyde emission class | E1 |

| Water resistance | high |

| Density, kg/m3 | 640 -7 00 |

| Humidity, % | ≤14 |

| End processing | coloring on request |

Application of laminate

To obtain a laminated surface, thin protective films are placed on the plywood, which are pressed at a temperature of 136 ℃.

The time for applying the protective layer of the laminate depends on the thickness of the plywood layer and the type of polymer agent. To obtain coatings the following is used:

- melamine compounds;

- phenol-formaldehyde macromolecules;

- vinyl chloride polymers.

The process is carried out quickly. The maximum amount of time required for recording is 10 minutes. After heating, the thermosetting coating hardens completely and irreversibly.

On some types of plywood, the protective function is performed by paper oiled or impregnated with resins and secured using presses.

After receiving the laminated surface, they begin to process the ends, which must be done to ensure the durability of the plywood. They are usually coated with acrylic compounds.

Laminated birch plywood

Laminated birch plywood combines the best qualities of the wood itself and the final product made from it. Peeled birch veneer is glued together under pressure using moisture-resistant glue and melamine resins, which makes the product stronger and denser throughout the structure, while maintaining flexibility. In addition to moisture resistance, one can note the absence of odor and safety for health in accordance with class E0. Additional advantages include resistance to warping, the presence of a perfectly smooth structure of the birch base, aesthetic light color, ease of processing and good compatibility with other materials. Plywood Agro is one of the leading organizations involved in manufacturing and supplying a unique range of moisture resistant laminated birch, poplar and softwood plywood to our clients. It is made from high quality hardwood and is one of the best in the country. The inner layer and outer surface are made of premium quality wood using formaldehyde resin. We supply this plywood as per the client's requirements in terms of design, pattern, size, etc. The main competitive advantages of our company are high quality products, timely delivery, and competitive prices. Laminated birch plywood is the most common building material due to its successful combination of price and quality.

Technical characteristics of birch laminated plywood

| — | Value (mm) | Tolerance |

| Length | 1525 | +-4 |

| Width | 3050 | +-4 |

| Thickness | 6,5 | +-4 |

| Thickness | 8 | +-0,5-0,7 |

| Thickness | 10, 12 | +-0,5-1,2 |

| Thickness | 15, 18, 21, 24 | +-1 |

| Thickness | 27, 30 | +-1-1,5 |

Assortment

The FOB assortment is determined by the external characteristics and quality of processing of the outer layer, which is expressed in the presence of various types of defects. The state standard determines the indicators for FOB I, II and III grades.

- Grade I - visible damage to the outer layer is excluded, spots up to 25x25 mm in size are possible at the rate of 1 pc/sq.m, point distortions of the structure, film swelling, pressure from slabs and debris are unacceptable;

- Grade II - overlaps are allowed, the absence of up to 1% of the outer film coating, signs of defects in the internal layers of veneer, spots and stripes, painted over chips, a change in structure not exceeding 10% without signs of damage to the veneer;

- Grade III - possible absence of facing and overlay films, presence of stains and stripes, adhered fragments of film on top, scratches, prints from debris, chips.

Color laminated plywood

The greatest demand is for anti-slip laminated plywood mesh, white, black, green, grey, brown, light - most often used for decorative finishing. In its production, PVC films of various densities, textures and colors are used, on one or both sides, depending on the client’s needs. Most often used for making interior items. The advantage of this option is that it does not require additional painting, the choice of colors is quite wide, does not fade, looks aesthetically pleasing, is easy to process, and is not afraid of moisture. Plywood Agro is a company that is well known in the market of manufacturing, supplying and exporting Colored Anti Slip Mesh Laminated Plywood. We export quality tested timber from certified suppliers, regular black laminated plywood is manufactured as per industry standards. Plywood sheets are available in various sizes and shapes. It is suitable for wall and floor coverings, used in the interior of houses, hotels and restaurants. Known for its high strength and fine finish, our 2500 x 1250 Color Laminated Plywood is popular in the market.

General information

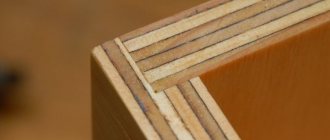

The basic process of making laminated plywood does not have any special features - the logs are cut into veneer, which is subsequently treated with glue, placed in bags and pressed. However, after receiving the finished sheets, they are additionally laminated, i.e. covered with film.

The film is a thick paper impregnated with mixed melamine-formaldehyde or phenolic resins.

This coating has the following properties:

- good strength;

- water resistance;

- wear resistance;

- antiseptic effect;

- density.

Options for the appearance of laminated plywood

It should be noted that during the lamination process, the ends of the boards are treated with acrylic waterproof paint, which also makes the material less vulnerable to moisture.

In addition, we can highlight other positive properties of laminated plywood acquired as a result of such processing:

- crack resistance and high strength;

- resistance to temperature fluctuations;

- immunity to aggressive chemicals, including fuels and lubricants;

- resistance to decay and other biological influences.

As for the disadvantages, they include a higher price. In addition, the material becomes less environmentally friendly.

Note! If the sheet is cut, the cut area must be treated with a protective compound yourself, otherwise the water resistance of the material will decrease.

Example of exterior use of laminated plywood

Colored plywood

| colored plywood blue | green plywood | yellow plywood | red plywood |

| white laminated plywood |

Laminated plywood GOST 53920 2010

The Plywood Agro company offers high quality anti-slip laminated plywood GOST 53920 2010, with a higher degree of surface finish and improved shear strength, using glue that ensures perfect adhesion. Available in multiple surface types, finishes and color shades, our range of colors effectively caters to numerous customer requirements. Mesh laminated plywood GOST 53920 2010 is extremely durable, cost-effective and easy to maintain. Apart from this, our regular customers can benefit from very economical as well as customer oriented prices.

Conclusion

Laminated plywood has high technical characteristics, especially regarding its strength and moisture resistance. Therefore, it is often an indispensable material for outdoor work. However, when choosing, you should take into account that there are quite a few types of it on the market, differing in some important properties.

The video in this article contains additional information on the topic discussed. If you have any questions while reading the material, you can leave them in the comments, and we will be happy to answer them.

Technical characteristics of laminated plywood

| Moisture-resistant plywood laminated birch GOST 53920 2010 Format: length x width, mm (ft) | 1220x2440x1220 (4x8x4) 1250x2500x1250 (4x8x4) 1500/1525x2500 (5x8) 1500/1525x3000/3050 (5x10) |

| Thickness, mm | 6-40 |

| Plywood grade | I |

| Film surface type | Smooth (F/F), smooth/mesh (F/W) |

| End processing | Waterproof acrylic paint |

| Base for lamination | Birch plywood brand FSF |

| Formaldehyde emission class | E1 |

| Density, kg/m3 | 640-700 |

| Humidity, % | 5-10 |

| Tensile strength, MPa, not less | when chipping along the adhesive layer | 1,5 |

| with static bending along the fibers of the outer layers | 25 | |

| when stretched along the fibers | 30 | |

| Modulus of elasticity, MPa, not less | with static bending along the fibers | 7000 |

Laminated plywood sizes, grades

According to the material used for lamination:

- Melamine is a material consisting of pressed melamine-formaldehyde resins

- Phenol - resins based on phenol or formaldehyde

- Polyvinyl chloride - PVC - the most non-toxic material

By surface color: colored or transparent film, by surface type: (F) smooth, (W) embossed, by type of ends: untreated or treated with acrylic-based hydrophobic paint, lamination with plastic is possible Laminated plywood dimensions: 2440x1220, 2500x1250, 3000x1500 Laminated grades plywood: 1/1, 2/2, 3/3

Application of laminated plywood

- formwork for walls, floors, foundations, columns, bridges and tunnels

- loading docks and bridges

- outbuildings

- fencing and fencing

- agricultural buildings

- warehouses

- partitions and doors

- scaffolding

- non-slip floor

- wall panels and window sills

- sound and heat insulating partitions

- educational institutions, classrooms and laboratories

- conference rooms and concert halls

- decoration of bars and restaurants

- finishing of medical institutions and pharmacies

- partitions in massage and beauty salons

- finishing of laundries, beach houses, showers

- seats for spectators in stadiums and sports grounds

- gates, body trim, floors of trucks, vans, pickups, trailers

- buses and trolleybuses (smooth grid)

- containers and trailers

- railway carriages

- finishing of yachts, boats and ships

- seats on boats, small craft, catamarans and passenger ships

- trade equipment, counters and racks

- warehouse cladding

- information desks

- fitting cabins

Advantages

- very high wear resistance and strength

- quick to install and easy to process

- increased water resistance

- combines well with other materials

- There are types with smooth and embossed surfaces

- wide range of colors and film densities

- large sheet format

Certificates

Sheet cutting services

Our company cuts sheets using modern equipment, accurately and accurately, taking into account the specifics of the material. Black plywood laminated mesh or smooth / mesh is also sawn at the request of the client in accordance with the technical specifications. task.

Scope of application

Areas of use of laminated veneer sheets:

- Construction works. The sheets are suitable for installation of formwork, cladding of temporary storage areas, cladding of facades of residential and technical facilities. The used material can be laid on scaffolding.

- Finishing processes. The panels are used for constructing partitions and leveling walls. Laying on horizontal and vertical bases as a rough and finishing layer is allowed.

- Furniture manufacturing. Due to its reliability and strength, the material is significantly superior to laminated chipboard.

- Mechanical engineering. The product is an ideal solution for body cladding and is also used for interior decoration of railway cars and ships.

Laminated plywood has high performance characteristics, so the range of applications for this material is very wide.

The popularity of plywood is limited by its high price.