Natural moisture content of wood

This parameter is used to measure humidity on a still growing or freshly cut tree. Based on the natural humidity indicator, the method of drying the timber is selected. If this parameter is determined incorrectly, the wood may not be dried or may be overdried.

Natural humidity ranges from 30% to 80% and depends on the following factors:

- The environmental conditions in which the tree grew - in winter the humidity of the tree is lower than in summer, because in the cold season, the plant “sleeps” and does not absorb water from the soil;

- Trunk structure - deciduous trees have lower moisture levels than coniferous trees;

- Porosity;

- Species: humidity of birch is 78%, oak – 70%, pine – 88%, fir – 101%.

The main task of companies involved in logging is to reduce the natural moisture content of the tree as much as possible. Otherwise, building materials lose their wear resistance.

In addition, dried preparations are smaller in weight and dimensions. At the same time, overdried wood is very fragile and unsuitable for construction, because cracks quickly appear on it.

To bring natural humidity to 15%, the following methods are used:

- Lay out the boards in an open area at a short distance from each other. The gap is necessary for all-round air circulation. To prevent precipitation from interfering with drying, the structure is covered with film or roofing felt on top. The bottom is covered with spruce branches or moisture-resistant material. Natural drying is best done in the shade or under a canopy. Otherwise, the scorching sun will quickly dry out the wood and it will crack.

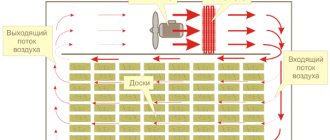

- Chamber drying in a closed space allows you to reduce natural humidity below 15%. This process is more labor-intensive than the first, so the material will cost more. It is worth considering that kiln-drying boards are not very suitable for construction. It is best used for making furniture.

Logs and beams for building a house

At “MariSrub” you can order the construction of wooden houses only from high-quality and carefully selected dried materials. We independently produce logs and beams for the design of a wooden house, bathhouse, gazebo or garage. Choose an individual design or modification of a ready-made option, which you will see in the company’s catalog.

During production we use condensation drying, we comply with GOST requirements, storage and transportation standards. We carry out antiseptic treatment and control every stage of production, which allows us to obtain durable and high-quality lumber. Due to this treatment, the wood retains its original color and natural properties for a long time. It does not rot or darken or become moldy. The materials are resistant to moisture and cold, wind and insects, and temperature changes.

We build wooden houses from timber and logs from the manufacturer. Own production is a guarantee of quality and low prices for lumber! We offer turnkey construction, which includes the creation of a project and installation of a timber or log frame, construction of a foundation and roof, finishing inside and outside the house, installation and commissioning of utility networks. We guarantee quality construction on time!

Equilibrium humidity

This parameter is measured during long-term storage. Determined by long-term exposure of the material to certain conditions. Since wood easily absorbs moisture when environmental conditions change, this indicator is constantly changing.

Excess moisture leads to wood rotting, fungus and mold. In addition, the workpieces, absorbing or releasing water, increase and decrease in size accordingly.

Incorrect calculations of the equilibrium moisture level lead to incorrect calculations of the required amount of building materials.

Based on the percentage of moisture, the following types of logging are distinguished:

- Dry – humidity below 25%;

- Semi-dry – humidity from 25 to 35%;

- Damp – humidity above 35%.

How to dry lumber correctly

Today, several industrial methods are practiced, and in some workshops different technologies are actively combined. The classification is based on the method of heat transfer to wood; there are several types of lumber drying:

- conductive (contact);

- convective (chamber, atmospheric);

- liquid (hydrophobic oils);

- radiation (infrared irradiation);

- dielectric (and vacuum-dielectric);

- induction (electromagnetic).

The feasibility of the method is determined by the complexity of the process. To dry lumber, it is preferable to choose a technology with the lowest energy consumption.

Absolute humidity

Absolute humidity is designated by the sign – W. It is equal to the ratio of the amount of moisture to the amount of dry wood. The absolute humidity of dry wood is zero.

To calculate, the dry mass is subtracted from the mass of freshly cut wood, the resulting difference is divided by the mass of the dry workpiece and multiplied by one hundred.

Bibliographic link

Nadyrova A.R., Velichkin P.S., Stepanova O.A. CHANGE IN WOOD HUMIDITY DURING THE DRYING PROCESS // International Student Scientific Bulletin. – 2015. – No. 3-1.;URL: https://www.eduherald.ru/ru/article/view?id=12031 (date of access: 09/25/2018).

Sources:

- tehnopost.kiev.ua

- 1poderevu.ru

- dekormyhome.ru

- www.eduherald.ru

There are no similar posts, but there are more interesting ones.

Relative humidity

The indicator is inaccurate. The calculation is based on the ratio of the actual weight of the material to the dry weight.

To calculate this indicator you need:

- Cut a small sample.

- Weigh it and record the data.

- Dry the workpiece and take measurements again.

- Subtract the second from the first value. This gives the mass of water in the sample.

- Then divide the mass of water by the mass of the sample when cutting and multiply the resulting value by 100. The resulting figure is the percentage of absolute humidity.

Buy or restore?

Again, returning to the topic of modernization, it should be noted that there is not always a need to buy a new drying chamber, demolish the old one and build a new one. If the condition of the drying chamber enclosing structures is in satisfactory condition, then reconstruction or equipping the dryer with modern equipment is a good option. Of course, if serious restoration is required, then the cost of reconstruction may be the same amount as the construction of a new drying chamber, then reconstruction is not advisable.

Often the need for reconstruction is dictated not only by the wear and tear of equipment or the destruction of fences, but by the task of reducing energy costs and improving the quality of drying or increasing the productivity of the dryer.

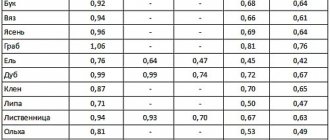

Humidity of different rocks

The moisture content of lumber depends on the type of wood. Certain breeds absorb moisture faster and therefore have a higher percentage of natural moisture. Others absorb water quickly and dry out quickly.

Oak absorbs little water, so its humidity percentage is lower. Pear and beech quickly absorb and release water.

Trees with a porous structure are saturated with moisture faster and are more susceptible to mechanical damage and cracks. Coniferous trees are wetter than deciduous trees. Moreover, the percentage of natural moisture in deciduous trees is the same throughout the entire structure of the trunk. And in conifers, the percentage of moisture is higher towards the core.

Calorific value of wet wood

The calorific value of wood is directly dependent on its moisture content.

The moisture content of firewood is a determining indicator of its quality. That dry wood burns better than wet wood is known to many, if not everyone. And everyone knows that wet firewood can always be dried, and dry firewood, on the contrary, can be wetted.

Accordingly, the quality of the fuel will change – improve or deteriorate. But is this really important for modern heating equipment? For example, wood-burning pyrolysis boilers allow you to burn wood with a humidity of up to 50%, and even up to 70%!

The table shows generalized indicators of the calorific value of wood for each degree of its moisture content.

Wood humidity (%) Mass working calorific value, kcal/kg Degree of humidity 04400 Absolutely dry wood 7…183980-3750 Room-dry wood25…303630-3120 Air-dry wood33…502870-1860 Freshly cut wood50…701800 and less Driftwood 70 and more Practically does not burn Driftwood

The table shows that the lower the moisture content of the wood, the higher its calorific value. For example, air-dried wood has a working calorific value almost twice as high as freshly cut wood, not to mention wet wood.

Wood with a humidity of 70% or higher practically does not burn. The ideal option for wood heating is to use firewood at a room-dry humidity level. Such firewood provides the maximum amount of heat.

But, since drying firewood to such a state is associated with additional energy costs, the most optimal option for heating would be to use air-dried wood. Bringing firewood to an air-dry state is relatively easy. To do this, it is enough to prepare them for future use and store them in a dry, ventilated area.

Finally, I would like to note that the moisture contained in firewood not only worsens its calorific value. Increased moisture content in fuel negatively affects the combustion process itself. Excess water vapor serves as the basis for creating an aggressive environment, which causes premature wear of the heating unit and chimneys.

Manufacturers of modern heating equipment recommend using air-dry wood as fuel, with a humidity of no more than 30-35%

Wood moisture content | Drovana tehnopost.kiev.ua

When wood moisture content is less than 30%, putrefactive fungal processes in it stop and such wood is considered suitable for long-term storage

Alternative Heating: woodwoodwoodcalorific valueheatheatingwood

Wherever wood raw materials are intended to be used - in construction, in the manufacture of furniture or carpentry blanks - its moisture content will be the main indicator of the quality and durability of the finished product. Wood has the natural property of hygroscopicity, that is, the ability to absorb moisture well and release it just as quickly when the temperature and humidity of the environment changes. As a result of these processes, a significant increase or decrease in the volumetric size of the material occurs in various directions, leading to complete unsuitability of the structure or object. In order to understand how to properly dry wood, you need to know some rules that allow you to carry out this process professionally, and be able to determine the moisture content in wood.

Scheme for drying wood under atmospheric conditions.

Percentage of humidity for various breeds (table)

| Breed | % humidity |

| Spruce | 90 |

| Scots pine | 87 |

| Cedar pine | 91 |

| Larch | 81 |

| Birch | 70 |

| Oak | 52 |

| Beech | 65 |

| Aspen | 83 |

| Poplar | 90 |

| Linden | 62 |

Why is winter material still better?

If the moisture content of winter lumber is not lower than that of summer lumber, then why is it in greatest demand? The reason is that in summer, wooden products are susceptible to fungus. Under the influence of heat, microflora is activated, and a damp board will become a favorable environment for mold.

GOST prescribes treating wood with antiseptics before summer drying. Antiseptic periods are influenced by regional climatic conditions. According to GOST in Moscow and the Moscow region, materials collected from April 1-15 to October 1-15 must be processed.

In winter, mold does not multiply, so the board can be dried.

Methods for determining humidity

The choice of method for determining humidity depends on the environment and the type of wood. However, the most commonly used methods are gravimetric and electrical.

Weight

To determine you will need:

- Saw;

- Ruler;

- Board;

- Accurate scales.

It is necessary to cut a piece of 2-3 cm in size from the middle of the board. It is important to take a sample from the middle part, because at the edges the humidity level will be lower.

Then the sample needs to be cleaned of bark residues and other contaminants, and then weighed. Record the result.

In a drying machine, the board is dried at a temperature of 100°C until completely dry.

- 4-6 hours after drying, the sample is re-weighed and the indicator is recorded. Then it is left in natural conditions for another 2-3 hours. Weigh.

- Leave for the same period. The bar is weighed so many times until the indicators on the scales are the same. This figure is fixed.

- Then the last one is subtracted from the first weight, and the resulting difference is divided by the last weight multiplied by 100%.

To more accurately determine humidity, the procedure must be repeated on several samples.

Electric

The electric method takes less time than the weight method, and the indicator will be more accurate.

To measure, you will need a special moisture meter. It measures the timber's resistance to electrical impulses.

The ends of the wires are installed in different parts of the board opposite each other.

The moisture meter shows the percentage of humidity in one segment. In order for the indicators to be accurate, measurements must be taken on several samples.

TechLib SPB UVT

Wood is a capillary-porous material (heterocapillary system), which consists mainly of hydrophilic components, and therefore it constantly contains more or less water. A living tree needs water to ensure its life. Water content is characterized by wood moisture content . Humidity is one of the main characteristics of wood.

The moisture content of wood is the amount of water it contains. Wood moisture content affects the properties of wood and the suitability of wood for construction purposes. The moisture content of wood is understood as the percentage ratio of the mass of water to the dry mass of wood. Wood moisture content is the ratio of the mass of moisture contained in wood to the mass of absolutely dry wood, expressed as a percentage.

The moisture content of wood and the interaction of wood and its components with water are important for the mechanical and chemical technology of wood, for example, for the impregnation of wood with solutions of chemical reagents, antiseptics, fire retardants, etc., when rafting and storing timber in water.

Water plays a role in activating cellulose before chemical reactions occur. The interaction of cellulose with water in the paper pulp during grinding and the subsequent removal of water during the formation of a paper sheet causes the formation of strong interfiber bonds in the paper.

The properties of wood directly determine the properties of wooden products. When there is excess or insufficient humidity, wood usually absorbs or releases moisture, increasing or decreasing in volume accordingly. When indoor humidity is high, wood can swell, and when there is a lack of moisture, it tends to dry out, so all wooden products, including flooring, require careful care. To prevent deformation of the floor covering in the room, it is necessary to maintain a constant temperature and humidity.

There are two concepts - relative humidity of wood and absolute humidity of wood.

Relative humidity of wood is the mass fraction of water expressed as a percentage relative to the mass of wet wood.

Absolute humidity of wood (moisture content) is the mass fraction of water, expressed as a percentage relative to the mass of absolutely dry wood. The absolute moisture content of wood is the ratio of the mass of moisture contained in a given volume of wood to the mass of absolutely dry wood. According to GOST, the absolute humidity of parquet should be 9% (+/- 3%).

Absolutely dry wood is conventionally called wood that has been dried to constant weight at a temperature of (104±2)°C. Values of relative humidity of wood are needed for analyzing wood when calculating the mass fractions of its components as a percentage relative to absolutely dry wood. The absolute humidity of wood (moisture content) is used to quantitatively characterize wood samples when comparing them by water content.

According to the degree of moisture content, wood is divided into the following types:

- Wet wood. Its humidity is more than 100%. This is only possible if the wood has been in water for a long time.

- Freshly cut. Its humidity ranges from 50 to 100%.

- Air dry. Such wood is usually stored in air for a long time. Its humidity can be 15-20%, depending on climatic conditions and time of year.

- Room-dried wood. Its humidity is usually 8-10%.

- Absolutely dry. Its humidity is 0%.

Wood moistening schedule: 1 – hot water; 2 – saturated steam; 3 – cold water

Water in a tree is distributed unevenly: roots and branches contain more water than the trunk; the butt and apex are larger than the middle part of the trunk; sapwood of coniferous species - more than sound and mature wood. In deciduous wood, water is distributed more evenly across the cross-section of the trunk, and in some tree species (for example, oak) the core moisture content is much higher than in coniferous species. In the bark, the moisture content of the bast is significantly (7...10 times or more) higher than that of the crust.

Freshly cut wood has a moisture content of 80 - 100%, while the moisture content of driftwood reaches up to 200%. In conifers, the moisture content of the core is 2-3 times lower than the moisture content of the sapwood.

In construction practice, wood is usually classified according to its moisture content:

- freshly cut wood with an average absolute humidity of 50 to 100% depending on the time of felling (the water content is much higher in the spring and least in the winter), as well as the tree species and growing conditions;

- air-dried wood is wood that has been dried in air until its moisture content is in equilibrium with the relative humidity of the air; the absolute humidity of such wood depends on the relative humidity of the air and is usually 16...21%;

- room-dry wood - wood kept in a heated room and having an absolute humidity of 9...13%; wet wood, resulting from prolonged exposure to water, with an absolute humidity above 100% (up to 200% or more).

There are two forms of water found in wood - bound (hygroscopic) and free (capillary). These add up to the total amount of moisture in the wood. Bound (or hygroscopic) moisture is contained in the cell walls of wood, and free moisture occupies the cells and intercellular spaces. Free water is removed more easily than bound water and has less effect on the properties of wood.

Free (capillary) moisture is contained in the cavities of the cells, and bound moisture is contained in the walls of the wood cells. The gradual saturation of dry wood with water initially occurs due to bound moisture, and only when the cell walls are completely filled does a further increase in moisture occur due to free moisture. Therefore, it is obvious that it is the change in bound moisture that affects the processes of shrinkage and warping of wood, as well as its strength and elastic properties. An increase in free moisture has practically no effect on the properties of wood.

Water absorption of wood is the ability of wood to absorb water in direct contact with it. Wood is a natural material that is susceptible to fluctuations in temperature and humidity. Its main properties include hygroscopicity , that is, the ability to change humidity in accordance with environmental conditions.

They say that wood “breathes,” that is, it absorbs air vapor (sorption) or releases it (desorption), reacting to changes in the microclimate of the room. The absorption or release of vapors occurs due to the cell walls. Given a constant state of the environment, the moisture level of wood will tend to a constant value, which is called equilibrium (or stable) moisture.

In wood, moisture is contained in wood cells, in the intercellular space, in the channels of blood vessels and it is called free moisture. The moisture contained in cell membranes is called hygroscopic (bound) moisture.

The hygroscopicity of wood is the ability of wood to change humidity depending on changes in the temperature and humidity state of the surrounding air. Hygroscopicity for most breeds is 30% at 20°C.

The maximum amount of bound moisture is called

the hygroscopic limit or fiber saturation limit.

At a temperature of 20°C, the hygroscopicity limit is 30%. As the temperature rises, part of the bound moisture turns into free moisture and vice versa. Free and hygroscopic moisture is removed from wood by drying. Moisture can be contained in wood in the form of chemically bound moisture in the form of substances that make up wood; this type of moisture can be removed during chemical processing of wood.

The maximum amount of hygroscopic moisture is almost independent of the type of wood. The percentage of the weight of water to the weight of absolutely dry wood is usually 30% at a temperature of 20°. This moisture content of wood is called the saturation point of the cell membranes, or the saturation point of the fibers. A further increase in humidity occurs due to free moisture filling the voids in the wood.

When humidity changes from zero to the point of saturation of the cell membranes, the volume of wood changes and it swells. When humidity decreases, wood dries out.

Dimensional changes are always observed in the transverse direction and almost do not appear in the longitudinal direction; denser wood has a higher volumetric weight, therefore, more shrinkage and swelling. Late wood is denser.

Wood contains free (in cell cavities and intercellular spaces) and bound (in cell walls) water. The saturation limit of cell walls Wn,H is on average 30%. A decrease in the bound water content causes to shrink .

The ability to absorb moisture is affected not only by the microclimate of the room, but also by the type of wood. The most hygroscopic species include beech, pear, and kempas.

They respond most quickly to changes in humidity levels.

In contrast, there are stable species, for example, oak, merbau, etc. These include the bamboo stem, which is very resistant to unfavorable climatic conditions. It can even be installed in the bathroom.

Different types of wood have different moisture levels. For example, birch, hornbeam, maple, and ash have low humidity (up to 15%) and, when dry, tend to form cracks. The moisture content of oak and walnut is moderate (up to 20%). They are relatively resistant to cracking and dry less quickly. Alder is one of the most drying-resistant species. Its humidity is 30%.

When testing wood to determine its physical and mechanical properties, it is brought to normalized humidity (on average 12%) by conditioning at a temperature of (20±2)°C and relative air humidity <= (65±5)%.

DETERMINATION OF WOOD MOISTURE

There are several ways to determine wood moisture content. At home, they use a special device called an electric moisture meter. The operation of the device is based on changes in the electrical conductivity of wood depending on its humidity. The needles of an electric moisture meter with electrical wires connected to them are inserted into the wood and an electric current is passed through them, while the moisture content of the wood is immediately marked on the scale of the device in the place where the needles are inserted.

Knowing the types of wood, its density and other physical properties, it is possible to determine the moisture content of wood by mass, by the presence of cracks at the end or along the wood fibers, by warping and other signs. By the color of the bark, its size and the color of the wood, you can recognize ripe or freshly cut wood and the degree of its moisture content. When processing a semi-finished plane with a plane, its thin shavings, compressed by hand, are easily crushed, which means the material is wet. If the chips break and crumble, this indicates that the material is dry enough. When making transverse cuts with sharp chisels, also pay attention to the shavings. If they crumble or the wood of the workpiece itself crumbles, this means that the material is too dry. Very wet wood is easy to cut, and a wet mark from the chisel is noticeable at the cutting site. But it is unlikely that cracking, warping and other deformations will be avoided.

The moisture content of wood is determined in various ways: by drying samples of wood, wood chips or sawdust until completely dry; distillation of water in the form of an azeotropic mixture with non-polar solvents that are immiscible with water; chemical methods (titration with Fischer reagent); electrically.

The moisture content of lumber is determined by the formula

W = (mc - mo) / mc,

where mс and mо are the mass of the sample in the initial and dried states, respectively.

In fact, wood moisture content is determined by control weighing or using an electric moisture meter.

Humidity of drift wood is 200%, freshly cut wood is 100%, air-dry is 15-20%.

DRYING WOOD

Wood abalization is the process of removing moisture from wood to a certain percentage of moisture content.

Wood grain is the ability of the wood surface to reflect light rays directionally.

Gloss depends on the type of wood, the degree of smoothness of the surface and the nature of the lighting. The radial surfaces of maple, sycamore, beech, elm, oak, dogwood, white acacia, ailanthus wood are distinguished by their shine. rocks in which a significant part of the surface is occupied by medullary rays consisting of small cells. The shine of wood is a decorative property and is taken into account when determining species.

Dielectric properties of wood are properties that are characterized by dielectric constant and dielectric loss tangent.

Wood swelling coefficient is the average swelling of wood when the bound moisture content increases by 1% moisture content.

Wood shrinkage coefficient is the average wood shrinkage when the bound moisture content decreases by 1% moisture content. Wood deformability (warping) is the ability of wood to change its size and shape under external influences of load, humidity, and temperature.

Transverse warping is associated with different shrinkage (swelling) of wood in the radial and tangential directions.

Its character depends on the location of the annual layers, determined by the cross-sectional shape of the assortment, as well as the place where it is cut from the log. Longitudinal warping is associated with certain wood defects, such as large knots, tilting, and tilting of the fibers.

The consequence of warping is a wood defect - warping (transverse, longitudinal along the face and along the edge, wingedness).

Transverse and longitudinal warping also occurs due to an imbalance of residual stresses in dried lumber during mechanical processing: one-sided milling, rib division of thick boards into thin ones.

Longitudinal warping of the boards is observed during sawing; a change in the cross-sectional shape of samples cut from different parts of the log during drying.

Dry wood has high strength, warps less, is not susceptible to rotting, is easy to glue, is better finished, and is more durable. Any wood of various species reacts very sensitively to changes in environmental humidity.

This property is one of the disadvantages of timber. At high humidity, wood easily absorbs water and swells, but in heated rooms it dries out and warps.

Indoors, wood moisture content is sufficient up to 10%, and outdoors - no more than 18%. There are many ways to dry wood.

The simplest and most accessible type of drying is natural - atmospheric, air . Wood should be dried in the shade, under a canopy and in a draft. When dried in the sun, the outer surface of the wood quickly heats up, but the inner surface remains damp.

Due to the difference in stress, cracks form and the wood quickly warps. Boards, timber, etc. are stacked on metal, wooden or other supports with a height of at least 50 cm. The boards are stacked with their inner layers facing up to reduce their warping. It is believed that boards placed on the edges dry faster, since they are better ventilated and moisture evaporates more intensely, but they also warp more, especially material with high humidity.

It is recommended to compact a stack of p/m, prepared from freshly cut and live trees, with a heavy load on top to reduce warping. During natural drying, cracks always form at the ends; to prevent cracking and preserve the quality of the boards, it is recommended to carefully paint the ends of the boards with oil paint or soak them in hot drying oil or bitumen to protect the pores of the wood. The ends must be processed immediately after cross-cutting into the cut.

If the wood is characterized by high humidity, then the end is dried with a blowtorch flame, and only then painted over. The trunks (ridges) must be debarked (cleared of bark), only small collars-muffs 20-25 cm wide are left at the ends to prevent cracking. The bark is cleaned so that the tree dries out faster and is not affected by beetles. A trunk left in the bark in relative heat with high humidity quickly rots and is affected by fungal diseases. After atmospheric drying in warm weather, the wood moisture content is 12-18%.

There are several other ways to dry wood.

The method of evaporation or steaming has been used in Russia since ancient times. The blanks are cut into pieces, taking into account the size of the future product, placed in ordinary cast iron, sawdust from the same blank is added, filled with water and placed in a heated and cooled Russian oven for several hours, “languishing” at t = 60-700C.

In this case, “leaching” occurs - evaporation of wood; Natural juices come out of the workpiece, the wood is painted, acquiring a warm, thick chocolate color, with a pronounced natural texture pattern. Such a workpiece is easier to process, and after drying is less likely to crack and warp.

Waxing method . The blanks are dipped into melted paraffin and placed in an oven at t=400C for several hours. Then the wood dries for a few more days and acquires the same properties as after steaming: it does not crack, does not warp, the surface becomes tinted with a distinct texture pattern.

Method of steaming in linseed oil. Wooden utensils steamed in linseed oil are very waterproof and do not crack even with everyday use. This method is still acceptable today. The workpiece is placed in a container, filled with linseed oil and steamed over low heat.

Warping: 1—transverse; 2 - longitudinal along the surface; 3 - longitudinal along the edge; 4 – wingedness of logs due to residual internal growth stresses.

Linear shrinkage of wood is a reduction in the size of wood in one direction when bound water is removed from it. Linear swelling of wood is an increase in the size of wood in one direction with an increase in the content of bound water in it.

Normalized wood moisture content is the equilibrium wood moisture content acquired at a temperature of 20 ± 2 ° C and a relative humidity of 65 ± 5%.

Volumetric shrinkage of wood is a decrease in the volume of wood when bound water is removed from it.

Volumetric swelling of wood is an increase in the volume of wood with an increase in the content of bound water in it.

Relative humidity of wood is the ratio of the mass of moisture contained in wood to the mass of wood in a wet state, expressed as a percentage. Wood is a hygroscopic material, and the humidity to which it tends under given temperature and humidity conditions is called equilibrium. For example, at a temperature of 20°C and air humidity of 100%, the equilibrium moisture content of wood is W = 30%.

A rapid change in bound moisture and uneven drying in different directions leads to warping or, conversely, swelling of the wood.

In massive elements, due to uneven drying, shrinkage cracks form. Therefore, in the production of lumber, great importance should be attached to the organization of drying, and when operating wooden structures, large and sudden changes in temperature and humidity should be excluded. Wood is characterized by a certain inertia of moisture exchange processes.

Wood shrinkage: 1 – shrinkage; 2 – cracking; 3 – transverse warping; 4 – the same, longitudinal

The amount of shrinkage is different in different directions: it is greater in the tangential (6 - 12%) and less in the radial (3 - 6%) direction of the cross section of the trunk. Due to such uneven shrinkage, warping of the boards appears when drying. When humidity increases above the saturation point of the fibers, further swelling does not occur.

With a sharp change in the temperature and humidity conditions in a room, internal stresses arise in the wood, which lead to cracks and deformations. The optimal temperature in a room with parquet flooring should be approximately 200C, and the optimal air humidity should be 40-60%. Hydrometers are used to control indoor temperature, and relative humidity in the room is maintained using humidifiers.

Deformation of wood during drying

Wood for building parts (windows, doors, floors, etc.), especially for glued structures, should contain no more than 8-15% moisture. Hence the need to dry the wood. Natural drying takes a long time; for example, to dry a board 50 mm thick in the summer in central Russia to a humidity of 20%, it takes 30 - 40 days. Artificial drying in conventional dryers reduces the drying time of such boards to 5 - 6 days, and drying at elevated temperatures (>100°) can be carried out in 3 - 4 hours.

The final moisture content of the wood must correspond to the humidity under operating conditions.

During prolonged drying, water evaporates from the wood, which can lead to significant deformation of the material. The process of moisture loss continues until the moisture level in the wood reaches a certain limit, which directly depends on the temperature and humidity of the surrounding air. A similar process occurs during sorption, that is, absorption of moisture. A decrease in the linear volume of wood when bound moisture is removed from it is called shrinkage. Removing free moisture does not cause shrinkage.

Shrinkage is not the same in different directions. On average, complete linear shrinkage in the tangential direction is 6-10%, and in the radial direction - 3.5%.

With complete drying (that is, one in which all bound moisture is removed), the moisture content of the wood is reduced to the limit of hygroscopicity, that is, to 0%. If moisture is unevenly distributed during drying of wood, internal stresses can form in it, that is, stresses that arise without the participation of external forces. Internal stresses can cause changes in the size and shape of parts during mechanical processing of wood.

Schemes for the development of deformations during convective drying

The process of convective drying of wood is accompanied by an uneven distribution of moisture throughout its volume. This causes its uneven shrinkage, which in turn causes the formation of internal stresses.

Let us consider how internal stresses arise and develop in wood, without yet taking into account its anisotropic structure, i.e., assuming the shrinkage in the tangential and radial directions to be the same. For simplicity, we will also assume that the movement of moisture in the material occurs only along its thickness. This will allow us to depict moisture distribution curves on a cross-sectional drawing of the dried assortment.

Let's consider the moisture distribution curves along the thickness for the most characteristic moments of the process: 0 - the moment of the beginning of drying; 1 - the moment when the moisture content of the surface layers has dropped below the saturation limit of the cell walls Wn, and there is still free water inside the assortment; 2 - the moment when the humidity across the entire section became below WH, but a significant difference in humidity across the thickness is still observed; 3 - the moment of the end of the process, when the humidity has become approximately the same throughout the entire cross-section, close to stable humidity.

At the initial moment of the process there is still no shrinkage and tension is obviously absent. After some time, the moisture content of the surface layers will drop below Wn (moment) and they will tend to dry out. However, this desire cannot fully manifest itself due to the resistance of the internal layers, the shrinkage of which has not yet begun. It is possible to identify the beginning of shrinkage by cutting out an end plate, the so-called section, from the dried assortment along its entire cross-section, and dividing it into a number of layers according to thickness.

Photos of the best wood species

Sun drying

Many mistakes are made when organizing the drying of lumber on your own. To speed up the process, the stacks are placed in areas of direct sunlight. This should not be done; directed sunlight does not ensure uniform drying. Exposure to rays leads to an increase in temperature in one area, while another area of lumber does not heat up. As a result, the part exposed to the rays dries faster, while the area hidden from the sun's heat takes longer to dry. The lumber begins to pull apart, cracks may appear on it, and the products bend and twist.

If drying takes place in the warm season, it is recommended to cover the ends of the lumber with paint. The end in stacks dries faster, while the core remains damp. this can lead to deformation of wooden products. The paint will slow down the drying of the ends and make the drying process more uniform.