This article was born as a by-product when creating another article. But I think it will be interesting as a way out of a situation where there is no time or opportunity to go to a construction store.

While creating another Mozgochin project, I discovered that I had run out of dowels. It was late, plus it was pouring rain outside, so I didn’t see any point in going to the store. It was decided to make the dowels ourselves.

Wooden dowels are used in furniture production for positioning and connecting parts made of chipboard, MDF, plywood, solid wood and other materials to each other.

So, to make dowels we need:

- slats, glazing beads or production waste of a suitable size;

- die;

- drill;

- sandpaper.

We take scraps of suitable size (left over from making the legs of the ironing board). We clamp them in the drill chuck.

And we drive it through a die clamped in a vice.

In principle, this is already a semi-finished product, but you can go over it with sandpaper to make it smooth.

Although most of the time I don't do this. When driving the dowels, the “thread” becomes wrinkled, and only makes the connection stronger. Yes, and the glue is absorbed better.

Now all that remains is to cut it into the necessary pieces. For marking, I made this device.

It seems a little expensive to drive a circular engine for them, but a turbine is just the thing.

In total, we have a bunch of dowels quickly and without much effort.

A universal furniture dowel is a special fastening device made of wood, which is used in the manufacture and assembly of furniture. It has a cylindrical elongated shape and has corrugations on the surface. In some cases, a dowel not only replaces metal fasteners, but also works better than them. At the same time, the price of the dowel is more affordable.

How to make a wooden dowel with your own hands

If necessary, dowels and dowels can be made at home, but production will require a lathe. The process of making wooden fasteners is as follows:

- For work, take a harvest of wood of the selected species. The block must be of high quality, without cracks, wormholes, knots, or irregularities. Use quality seasoned wood. When drying, the parts can become deformed and crack, as a result of which the cross-section of the wooden furniture chopper changes.

- Place the workpiece on the lathe and begin removing chips, gradually reducing the diameter.

- Having reached the required section, remove the chamfers and cut the workpiece.

Note! In factory conditions, the length of the dowels is up to 200 centimeters. After processing, the workpiece is removed and cut into fasteners of the required length

Varieties and sizes

Purpose of a furniture damper, nuances of choice

Such fastening is in demand in the furniture industry due to a number of advantages:

- corrugated surface - notches on the parts allow you to fix the elements well, increasing the adhesion area;

- presentability - when assembling furniture, fasteners are immersed in the base material, so they are not visible (unlike screws, bolts and other screwed-in parts);

- wide range - the consumer can choose the required length and diameter of the element depending on the design of the furniture.

There are also disadvantages, for example, such rods cannot be used if it is necessary to fasten vertical planes. For this purpose, it is better to use screws, nails and other fasteners that ensure reliable alignment. Furniture dowels can be wooden (they are more popular), as well as plastic, which are used in rare cases.

Tips for repairing furniture depending on the type of damage

Wood

Most often, furniture is made from solid wood, MDF, plywood, chipboard. Products made from hardwood are used for its assembly. Notch options may be different:

- Straight vertical is the universal and most common type.

- Helical - located at an angle from the vertical axis, making it difficult to loosen.

- Complex - has both transverse and longitudinal cuts. Designed for structures subject to high loads that require strong connections.

- Horizontal - secures different parts as much as possible; it is not recommended for use in cases where disassembling furniture may be required.

- Smooth - made completely without corrugation, it allows you to resist the shift of structural elements due to exposure to moisture and temperature. When deformed, such a rod, also called a dowel, bends and subsequently provides high resistance to loads.

The assortment includes rods with a circumference from 4 to 30 mm, length sizes vary from 15 to 200 mm. They are often made to order when assembling designer items, since not every element will fit unique items. Wooden dowels are resistant to temperature changes and reliable. They have no shortcomings as such.

Plastic

The plastic version is used for connecting parts of prefabricated cabinet panel furniture, as well as for transforming products. It is produced by casting, the material used is impact-resistant plastic that does not collapse under physical impact. The options for notches on plastic dowels are the same as in the case of wooden ones. They have similar sizes. The disadvantage of this type of fastener is that it is not as common as wooden ones; it cannot be found in any department with furniture fittings.

In addition to plastic ones, there are metal dowels, which are considered stronger and last much longer. They are indispensable when assembling tables, as they provide maximum structural stability. However, such products do not prevent material shrinkage, and their cost is much higher than that of any other fastener.

Features, means and methods for restoring different types of furniture

Width joining

Used to increase the width of the product

When using bonding methods, it is important to pay attention to the location of the tree’s annual rings. It is important to alternate the boards depending on their direction. The payment options are:

The payment options are:

- Butt-to-end - parts need to be trimmed and jointed using a square.

- In tongue and groove - the height and width of the ridge is equal to 1/3 of the thickness of the board.

- Using a hacksaw - the edges need to be cut at an acute angle to the wide plane of the board.

- With a comb with a height of 1/3 to half of the board.

- A quarter with a ledge equal to half the thickness of the board.

- In a tongue and groove with slats - in each board, select grooves into which you need to insert a rail that is twice as wide as the depth of the groove.

Installation and removal methods

Types and installation of furniture footers

Furniture dowels make it possible to significantly increase the strength of connections. But this is not as simple a method as it might seem at first: the connection cannot be secured if any hole is displaced. Depending on the size of the offset, the result will be unsatisfactory.

As a rule, tabletops on dining tables and desks are secured with a dowel. Put them in working position like this:

- The parts are first marked on the end side, and then holes are drilled to the required depth. The same holes are made in the countertops. They must match;

- A cylindrical fastener is installed in the end hole, the upper end protrudes at a distance equal to the depth of the hole in the covering part;

- To strengthen the dowel in the hole, it is generously lubricated with glue, fixing it in the desired position. Sometimes glue is poured into the holes, where the fastener is then inserted - this will completely cover its ribbed surface with glue, improving the adhesion strength of the elements;

- The second part of the design is superimposed on the installed dowel.

Drilling the material

Hammering the dowel

Connect with glue

The work is ready

There are 3 main problems in assembling furniture using dowels:

It is possible to assemble an edge-to-edge connection, but in this case, the planes of the structural parts do not coincide. Solution: The drill guide holes were not aligned with the center edges of the parts. The device must be constantly aligned with the reference planes of the two parts being fastened. Even in the absence of a central location of holes in the connection, no shifts or sagging are formed; Holes in one part do not line up with another. Solution: to align the holes, use special markers designed specifically for connections. Initially, holes are made in one part with a drill. A marker is then inserted into each hole and the two pieces are pressed together as they should be when assembled. This way, the second part will have marks with markers in the places where you should drill; The holes are made in the right places, but the installation of the dowels is not correct: the fasteners do not fit through or, on the contrary, fall out

Solution: It is important to make sure that the diameter of the fasteners matches the diameter of the holes. Factory fasteners are mass produced and may have a diameter slightly larger or smaller than stated

In addition, wood can swell or shrink with changes in humidity. When the diameter is verified and it is identical, then the problem is the wear of the drilling jig and, as a consequence, the deviation of the drill. This leads to deformation. It is enough to change the bushings or purchase a new device.

To correctly assemble furniture parts onto a dowel, you will need to learn three basic rules:

- To mark, use a sharp pencil or knife. A pencil with a thick lead will not make marks accurately;

- When drilling holes, you need to use drills with a central point. Twist drills with conical sharpening can deviate to the sides during work, setting the wrong direction;

- To ensure uniform hole depths, a locking ring is placed on the drill and firmly fixed. The depth of the hole is made 2 - 3 mm greater than the length of the dowel.

We mark with a pencil

Use center point drills

Use a retaining ring

You can make cylindrical mounts yourself. Here is a short instruction on how to make dowels: To do this, take birch logs and split them into many pieces - you get square blanks. Next, they need to be trimmed by hand or on a lathe to give them a cylindrical shape and the required diameter. Fasteners can also be made using a circular saw.

The correct solution is to take a drill of a smaller diameter and drill in the center of the fragment. Then, using a screwdriver, chisel or chisel, break up the remaining debris and remove it from the hole. If difficulties arise, you can use photo instructions - there are a lot of them on the Internet.

So, when used correctly, a furniture dowel is a universal fastening that guarantees reliability. It is used for assembling different types of furniture in combination with other types of fasteners.

Variations on a theme

Feel free to experiment with different combinations of wood species for frames, overlays and decorative stoppers. Or try some of the examples shown here.

A. Leave a spacer about 12 mm wide between the cuts. Then cut the jumper using a band saw or by hand.

B. These overlays are cut to a thickness that is 0.5 mm greater than the depth of the folds at the corners of the frame.

C.Remove excess trim material with a band saw and then sand the face and edges using an orbital sander.

D. Place the plugs at equal distances from the joint line of the frame parts. The size and location of the plugs must match the frame and overlays.

E. Using a fine-toothed flexible-blade hacksaw for this operation, guide it parallel to the grain of the lining to avoid leaving rough scratches.

In preparing the article, materials from the wonderful publication for woodworkers WooDMaster were used

How to arrange a connection between furniture parts

Types of furniture pipes, nuances and tips for their use

The procedure for attaching parts to a wooden nail is not complicated. By following the instructions below, you can connect the parts and assemble the furniture without much effort. The assembly diagram looks like this:

- Holes are drilled in the parts to be joined if they were not made at the factory. The diameter of the recesses should be slightly larger than the diameter of the chopper, and the length should be 1-2 mm longer than the dowel. The presence of gaps in this case is by no means a disadvantage. They prevent fasteners from jamming and help compensate for temperature and humidity deformation.

- The protruding part is filed down if necessary.

- Using a mallet, hammer a dowel into the hole so that its surface is slightly below the plane of the part. If you need to connect the furniture frame, then the dowel is driven in half. The protruding part of the wooden furniture chopper is smeared with glue and, having laid the end part of the furniture or facade on top, it is seated on the mount.

At first glance, it seems that this technique does not provide reliable fixation of the structure, but in practice it turns out that when using high-quality, well-dried dowels, furniture, log houses and timber are durable and stable.

Dowels, dowels, choppers, metal fasteners are types of fastening elements used for reliable connections. Without their use it is impossible to imagine the house-building industry and the furniture industry.

Corrugation of the side surfaces of the dowel

Dowels (either wooden or plastic) can have longitudinal grooves on the side surface - grooves, either straight, located along (parallel) to the cylinder axis, or helical.

The riffles serve to allow air to escape when installing dowels into the part. Since wooden elements are most often placed on glue, this improves adhesion and speeds up hardening.

Types of corrugation on the side surfaces of dowels (in the figure on the right - from top to bottom):

| Corrugation of the side surfaces of dowels |

- straight corrugations - corrugation for dowels for universal use. The most common option.

- helical riffles - located at an angle from the vertical axis. Makes it difficult to loosen.

- complex corrugations - (in this case, screw and transverse corrugations) corrugations for dowels intended for reinforced adhesive connections. Designed for structures subject to high loads that require a strong connection.

- transverse riffles - secures different parts as much as possible. Not recommended for use in cases where furniture may need to be disassembled.

- smooth dowel - made completely without corrugation and allows you to resist the shift of structural elements due to exposure to moisture and temperature.

Some types of plastic dowels have “roughness” on the side surfaces, i.e. they are equipped with projections. This surface prevents the dowel from falling out when disassembling furniture, securely fixing it in the main fabric.

Installation sequence

When assembling furniture, dowels allow you to create strong connections. But the main problem is the exact alignment of the holes on individual parts. Otherwise, they simply will not be able to connect, so measurements must be taken with special care.

The most common use of dowels is to secure a tabletop to a table base. If we take this as an example, we get the following sequence of actions:

- Holes are made at the end of the base parts. With exact matching they perform drilling and table tops, to a depth of approximately 2/3 of the total thickness of the material. The dowel axes must completely coincide; it is recommended to check this before starting to connect the elements.

- A dowel is installed in the base part, and its length is selected in such a way as to fully correspond to the depth of the hole in the tabletop. If it is larger, the material will either not come together or damage will occur at the contact point. With a shorter length, the reliability of the fastener decreases.

- If you plan to create non-separable furniture, wood glue is used at the time of joining. It can either be applied to the dowel itself, or pre-filled into the holes.

- The tabletop is placed on the base and fixed with a weight while the glue hardens.

Wooden fasteners

Design of dowels and their varieties

The wooden dowel is perhaps the oldest type of fastener. Pins are wooden pins that are driven into pre-drilled holes and secure parts due to the natural elasticity of the material.

Square bars for connecting logs

Today, a variety of types of such parts are used in construction:

| Sign by which classification is carried out | Varieties |

| Wood species | Typically, dowels are made from hardwood. The following parts are used in construction:

|

| Part shape | To connect logs, as a rule, two types of products are taken:

|

| Size | Traditionally, the minimum diameter of the dowel is 25 mm. At the same time, when connecting large beams or logs, fasteners with a cross-section of 50 mm or more can be used. |

Dowels of different shapes and sizes

Analogues of dowels in carpentry are wooden dowels. In most cases, they are smooth or grooved rods (just with a smaller diameter), which are driven or glued into holes made in the parts to be joined.

Production and use of wooden dowels

If necessary (and also, of course, if you have a lathe), dowels and dowels are quite easy to make with your own hands:

Finished goods

- For work, we take a blank from the selected wood. The block must be smooth and intact, without large knots, cracks, wormholes, etc.

- It is advisable to use well-dried wood, since otherwise, when drying, the dowel/dowel may become deformed and its cross-section will change.

- We place the workpiece in the lathe and begin to remove chips, gradually reducing the diameter.

- When the desired section is achieved, we remove the chamfers and cut the workpiece.

Drilling a hole for the dowel

The process of attaching parts to a wooden nail is also not difficult.

The instructions for setting up the connection are as follows:

- We drill holes in the parts to be joined, the diameter of which is equal to or slightly greater than the diameter of the dowel, and the depth is approximately 1-2 mm greater than the length of the dowel. The presence of gaps helps prevent jamming of fasteners and provides compensation for temperature and humidity deformations.

- We hammer the dowel into the hole with blows of a mallet so that its upper part is slightly below the plane of the part.

- If necessary, cut off the protruding part.

One may decide that this technique does not provide reliable fixation, but practice shows that when using sufficiently high-quality dried dowels, log houses made of timber and logs assembled using this technology are quite stable and durable.

Fixing the fastener

Increase in height

From the name it is clear that the essence is to lengthen the beams or logs in the vertical direction. The axes of the elements are on the same vertical line. Types of extensions are:

- End-to-end extension. To absorb random loads, a barbed pin is inserted on the sides.

- Extension with one or two spikes. The width and height of one tenon must be at least one third of the thickness of the timber. The depth of the nest is slightly greater than the height of the thorn.

- Half-tree extension. The ends of both logs need to be cut to half their thickness by 3-3.5 diameters in length.

- Tongue building. In one beam you need to cut a fork into which you need to insert the correspondingly cut end of another piece. The connection itself must be wrapped in tin.

Making dowels

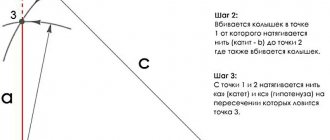

You can make dowels at home quite simply. They will have a horizontal helical cross-section applied to them, which will allow such fasteners to reliably fix the parts being connected. A minimal set of tools is used for this; the process does not look labor-intensive.

As a form, you can use dies for cutting threads, called dies. The set usually has several diameters, which will allow you to choose the most suitable one. A wooden blank is pre-made, made in the form of a rod with a diameter slightly larger than the future dowels.

The die is fixed in a vice, and the workpiece is fixed in a conventional drill. The limitation of the dowel diameter is the maximum capabilities of its cartridge. It is not recommended to make workpieces that are too strong, as they may break from twisting during the grooving process. The workpiece is completely passed through the lathe, which leads to its turning to the required diameter and the application of a notch.

After this, it is enough to cut it using a hacksaw or jigsaw into fragments of the required length and the wooden dowels for the timber, made by yourself, are ready. The process is quite fast and allows you to save a lot of money, since you can use wood scraps and trimmings to make them.

Characteristics and dimensions

Dowels may vary in length and diameter. Diameter sizes range from 4 to 30 mm, and lengths from 15 to 200 mm. At the buyer's request, they are manufactured in any variations, where D is the diameter and L is the length of the product.

The dowel is a popular fastener, and therefore professionals try to purchase parts in bulk in advance, so as not to waste time and money on constant purchases. The advantages of fasteners include:

- Corrugation of the surface on the rod - this helps to securely fix the parts, ensuring their strong adhesion;

- Improved appearance of furniture, because the fastenings are completely hidden from view;

- Possibility of selecting the diameter and length required for assembly of the product, in accordance with the design features.

Determining the size of the dowel

Dimensions

Length splicing

This type of joining of wooden parts has some nuances. At its core, this is the elongation of elements in the horizontal direction. Splicing can be:

- Butt-end - the ends are cut at right angles and aligned with each other. A bracket is hammered into both beams (logs).

- Oblique butt - the cuts are made at an angle, and the ends are fastened with a pin or nail.

- End butt with ridge.

- Direct overlay - the length of the cutting is 1.5-2 times greater than the thickness of the timber (log).

- Oblique trim - the ends are cut at an angle and secured with bolts.

- Overlay with an oblique cut - at the ends of the parts, end ridges are made, having a width and length of one third of the thickness of the beam.

Varieties

In fact, a dowel is a small spike - it is a hidden type of furniture fastener. In appearance, it resembles a cylinder-shaped rod, with slightly rounded or simply truncated ends on both sides. Sometimes, to assemble furniture on dowels, not only wooden elements are used, but also plastic ones. They have slightly different purposes:

- Wooden ones are needed for positioning and connecting furniture parts made of MDF, chipboard, plywood, and solid wood;

- Plastic ones mainly connect parts when installing prefabricated panel furniture.

Wooden

Plastic

There are also metal products. They have improved strength characteristics; they are also called dowels or dowels. But the most commonly used are wooden dowels measuring 30 by 8, that is, the length is 30 mm and the diameter is 8 mm. There is also a smaller diameter - 6 mm. You can purchase different types in construction stores or markets. If you wish, you can make dowels yourself.

There are different grooves on wooden dowels:

- Straight vertical;

- Helical – located at a slight angle to the vertical axis;

- Complex ones - there are transverse and longitudinal recesses - they also allow you to make the adhesive joint stronger;

- Horizontal – help to make the adhesive joint as strong as possible;

- Smooth - do not have corrugation.

Corrugation helps air pass during the installation of dowels, improving the adhesion of the glue with the “glue” method of connecting parts.

Vertical straight lines

Complex

Smooth

Common mistakes

Errors when using dowels in assembling furniture occur mainly among beginners. They can be avoided by considering the main difficulties:

If the diameter of the dowels corresponds to the declared one, the problem is in the drill, namely in the drilling jig, due to wear of which the drill deviates. You should change the bushings or purchase a new tool.

These are the main problems that can arise with the installation of furniture on dowels. In order for the assembly to be successful, you also need to take into account a number of rules:

For high-quality assembly of cabinets, sofas and other structures, you can use special fasteners - furniture dowels of various sizes and configurations. It is best to give preference to wooden elements, for which holes are created in the canvases, and the rods themselves are attached with wood glue. You should first measure all furniture elements and parts, check the equipment and apply approximate markings. This will allow you to use fasteners as accurately as possible with the smallest error.

Installation methods

Such products are inherently designed for the most durable connection of different furniture elements. However, their installation is not as simple as it might seem. One important nuance must be taken into account - fastening will not succeed if the holes prepared in advance are displaced.

Before making or assembling furniture using dowels, you need to familiarize yourself with the proven diagram:

- At the end of the canvas, points are marked where the holes for the rods will be located.

- Using a drill, drill a hole in the furniture half the length of the dowel. The same must be done in the covering tabletop.

- A rod is inserted into the end - its upper part should protrude to a distance that corresponds in depth to the hole in the covering element.

- The dowel is lubricated with glue, then tightly fixed in the required position. Experts advise pouring glue directly into the hole and only then installing the fastener. This will allow the composition to be distributed more evenly over the entire surface.

- The top part is carefully placed on the protruding dowel. For the best fixation, it is recommended to lubricate the second hole so that the glue secures both sides of the rod.

Preparing holes for dowels

Dowels must be driven in as carefully as possible

Additionally, you can attach the part with glue

Which fastening hardware to choose for certain types of material

Modern manufacturers make furniture not only from chipboard, but also from other materials.

Thanks to the wide range of fittings, you can choose fasteners for any type of furniture

Table 6. Selection of fasteners based on the furniture material.

| Material | Description |

| Glass | Fasteners such as self-tapping screws (of the “quick installation” type) are used, which are screwed into the wall. Usually this is a thin self-tapping screw with a plastic attachment. Also, fasteners can have a special adhesive composition and a rubber gasket. They provide fixation of shelves and glass surfaces, while the furniture coating is not damaged. Glass doors on a cabinet can be installed using regular furniture hinges. |

| Metal | Screw fasteners are ideal for connecting metal parts. They can be fixed to the stand using a screwdriver/drill. To prevent the furniture from losing its aesthetic appearance, the head of the fasteners can be closed with a plug. |

| Plastic and chipboard | To fix such furniture, you can use any fasteners that are designed for chipboard. |

Telescopic guides for drawers are modern fittings that allow you to effortlessly open even massive structures. Would you like to learn in detail about the installation of telescopic guides and the correct calculation for their installation? Read the special article.

How to arrange a connection between furniture parts

The procedure for attaching parts to a wooden nail is not complicated. By following the instructions below, you can connect the parts and assemble the furniture without much effort. The assembly diagram looks like this:

- Holes are drilled in the parts to be joined if they were not made at the factory. The diameter of the recesses should be slightly larger than the diameter of the chopper, and the length should be 1-2 mm longer than the dowel. The presence of gaps in this case is by no means a disadvantage. They prevent fasteners from jamming and help compensate for temperature and humidity deformation.

- The protruding part is filed down if necessary.

- Using a mallet, hammer a dowel into the hole so that its surface is slightly below the plane of the part. If you need to connect the furniture frame, then the dowel is driven in half. The protruding part of the wooden furniture chopper is smeared with glue and, having laid the end part of the furniture or facade on top, it is seated on the mount.

At first glance, it seems that this technique does not provide reliable fixation of the structure, but in practice it turns out that when using high-quality, well-dried dowels, furniture, log houses and timber are durable and stable.

Dowels, dowels, choppers, metal fasteners are types of fastening elements used for reliable connections. Without their use it is impossible to imagine the house-building industry and the furniture industry.

All photos from the article

In carpentry and joinery work, a variety of types of fasteners are used: these are staples, dowels, wood grouse, wooden dowels, and many other products. Each of them has its own scope of application, and therefore in our article we will provide an overview of those parts that are not used as often as common nails or self-tapping screws.

Inset

A mortise, or notch, is a corner or middle connection with which you can securely fasten two boards or wooden beams together. One part is attached end-to-end to the other. The insertion technique is based on a butt connection. Make a cutout in the plastic for the end and then proceed to the main part of the work.

PHOTO: YouTube.com This fastening method is most often used in box or frame connections, for example when assembling a cabinet or frame for building a house

The main types of connections using notches are T-notches, corner in the dark or corner in the rebate. Each of these connection methods has its own characteristics. If you decide to make a corner fold, you need to make a larger recess ─ two-thirds of the workpiece.

What is

Before you find out the installation details, you will need information about what a dowel is. This is the name for fasteners that allow you to securely fix different parts of furniture. It looks like a small cylindrical rod with rounded ends. The dowel does not complicate the disassembly of objects, but at the same time can withstand even heavy loads. Any material can be used for its manufacture: plastic, metal, wood. For a tighter fit, its surface should be corrugated (straight, helical, transverse).

The optimal circumference of the furniture dowel would be equal to no more than a third of the wall thickness; this will make the assembly reliable and maximally resistant to high loads. The length is selected individually, taking into account the base. Such parts are used both in the production of factory furniture and in self-assembly of the structure.

Application

These products have been used for a long time and are widely used in metalworking. Thus, many machines are equipped with conductors. The need for templates for dowels in the woodworking industry is due to the prevalence of closed furniture joints. In this industry, the devices in question are used both in mass production and during assembly. In the latter case, furniture jigs are used to drill holes for dowels.

In addition to the above-mentioned areas, such devices are in demand in construction, mechanical engineering, and household work.

The scope of application is determined by the type of conductor. Thus, overhead devices are used for processing flat parts, chipboard and MDF boards. Corner ones are applicable both for furniture and for chipboard and MDF boards. Rotary products are designed for making holes in cylindrical parts. Universal models are suitable for small-scale furniture production. Tilting options are designed for simultaneous processing in several planes. Clip-on and sliding jigs are most suitable for home use. In addition, the latter are incompatible with single-spindle machines.

Rigid models are designed for making holes in objects with an uneven surface, such as pipes. In this case, they are secured using a clamp, but this method is not suitable for furniture, since deformation of the surface is possible.

The use of conductors simplifies and speeds up the work due to the fact that it eliminates the need for manual measurements and calculations.