Wood cutter for a manual router - what is it and what is its purpose

A cutter for a manual electric router is a small-sized cutting tool. Consists of three simple parts:

- shank;

- supporting body;

- cutting knives fixed in the supporting body.

A lot depends on the quality of the cutter. As experienced craftsmen say, it is not so important what kind of router is used, what matters is the quality of the cutter.

However, it is better to work with a high-quality, convenient router. During operation, the cutter rotates at enormous speeds, due to which cleanliness, speed and quality of processing are achieved. The electric motor of the milling cutter, through an overdrive gearbox, gives the cutter a rotation speed from 10,000 to 30,000 rpm. The more revolutions the router can produce, the better.

What can you do with a hand router with different cutters?

A brief overview of cutters will give a complete understanding of what can be done with a hand-held wood router and how it can be used at home and in a carpentry workshop. The main types often used in woodworking include groove, edge and combination cutters.

Types of groove cutters and their purpose

As the name suggests, groove cutters can be used to make grooves using a hand router. And also used for applying decorative milling on the front parts of furniture.

- Straight grooved. A simple cylindrical shape allows you to make a rectangular groove, the width of the groove is determined by the diameter of the cutter. Suitable for thicknessing.

- Disk groove. The width and thickness of the disk determines the depth and width of the groove, which can be made with a hand router. Also used for thicknessing of workpieces.

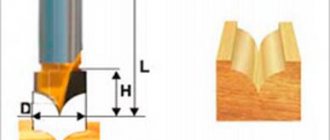

- Fillet groove . Depending on the shape of the cutter, rounded or V-shaped, you can make a rounded or triangular groove of different widths with a hand-held wood router.

- Structural groove. Provides a stronger and more stable joinery joint, T-joint or dovetail joint depending on the cutter shape.

- Shaped groove. Used for decorative design of facades and other front blanks.

Types of combined cutters and their purpose

In order to make a tongue-and-groove joint with a wood router, you may need two cutters at once, which are called “combined” in the set. There is also an option to make a “tenon and groove” using one cutter, by moving one workpiece relative to the other by the width of the tenon and groove.

Single combination cutters allow you to increase the length of a workpiece from short remains by flipping one part relative to the other (so that the tongue-and-groove joint meets).

Double combination tenon and mortise cutters are used to make wood paneling and other siding panels with specified joinery. The kit comes with a couple of different positions, you should be careful when using it. Some types involve turning the workpiece over, others require working in one plane so that the joint comes together.

Feeder combination cutters are designed for decorative design of the façade of furniture. Using a federation horizontal cutter, you can use a router to make a relief along the plane of the facade, and with a vertical cutter, you can shape the base (plinth) in height. A double-sided horizontal cutter allows you to make decorative carvings for subsequent assembly into a groove with a panel.

Please note that this type is equipped with a bearing so that you can mill not only along a straight line, but also along a radius, a template of any curved shape.

Type of shank diameter

The shank of a cutter is a round metal rod, the same as that of a drill. But unlike a drill press, drill or screwdriver, the cutter shank is clamped not in a 3-jaw chuck, but in a collet clamp (collet).

This clamp is much more compact than the chuck; it is easier to tighten one nut than the jaws on the chuck with a special wrench. This is important given the design of this tool. The disadvantage of this clamp is that you can only use shanks that are suitable in size. This differs from a chuck, in which you can clamp the shank of a drill with a size of, for example, from 1 to 10 mm.

Modern routers use collets to clamp three main shank standards: 6 mm, 8 mm, 10 mm and 12 mm. Many models come with replaceable collets. For example, for 6 and 8 mm shanks.

The cutter rotates at enormous speeds, so it must always be securely tightened when working. If the collet clamp fails, you cannot use the tool, it is dangerous.

The collet is tightened with a special wrench included in the kit or with another spanner (open-end) wrench of similar size. To tighten and unscrew, the shaft is locked either by pressing the lock provided in the design, or with another key, if the shaft has edges for a second key for fixing.

Fixation with a second key is more reliable, since the internal latches sometimes break off. Therefore, on high-quality branded models, key fasteners are often used. This is an advantage, not a disadvantage.

The collet nut is tightened with force until it stops, but without unnecessary zeal, so as not to strip the threads, or the edges of the nut and the key.

Classification

In accordance with the generally accepted classification, cutters of the shapes shown in the table are used for processing wood.

| Types of wood cutters | Main types of work |

| End | End surface processing |

| Cone-shaped | Processing any type of wood at different angles |

| V-shaped | Engraving, 45° chamfering and V-grooving |

| Disk | Making horizontal grooves of various sizes for cutting work |

| Profile | Decoration of products |

| Folded | Quarter milling |

| Mouldings | Rounding edges |

| bird home | Making tenon joints of various types |

| Curvy | Processing the edges of panel parts |

| Fillet | Creating fillets (grooves) on the edges of products |

There are various subspecies that differ in design, blade shape, and application.

Thus, using a ball (spherical or spherical with a round head) tool, you can perform artistic wood carving. There are special-purpose products used for cutting laminate flooring, furniture parts, handles, and handrails.

The combined type is a combination of a groove cutter and a tenon cutter, used for merging boards.

Plunge tools are used for milling grooves. To obtain neat grooves, models with an extended shank are produced.

Main types of structures

Without exaggeration, hundreds of milling cutters of various purposes, profiles and designs are offered on the modern market. By design, there are three main groups of this cutting tool.

Prefabricated

The simplest and most common type. It consists of a shank, a supporting body and cutting knives attached to it. All three parts are made of different alloys. The knives are made of special cutting steel, everything else is made of cheaper metals. They are called prefabricated because different parts are assembled during production. Further, it is impossible to disassemble or assemble the elements of such equipment; everything is tightly secured.

Some profiles are equipped with bearings that can be removed.

Monolithic

This is practically the same equipment as the three-piece prefabricated ones described above. Nothing changes or is rearranged. The difference from the prefabricated version is that the entire cutter is made of the same alloy. In another way, such cutters are called backed ones.

With replaceable cutting edges

Such designs allow you to remove or rearrange individual cutting elements, obtaining the desired cutting profile. As an example, in the image below there is a groove/tenon cutter.

When using two cutting edges, a tenon-shaped cut is obtained. If you unscrew the nut, remove one cutting element and adjust the height of the cutter to the desired size, you can get a groove for this tenon.

The same type includes cutters with double-sided knives. They are not tightly fixed in the case, but are screwed on. When one side becomes dull, the knives are turned over and the other side is used.

An example of such equipment:

Shell cutters with replaceable knives are also used on stationary milling machines. This is a drum for attaching knives, similar to those found on conventional electric planes. But instead of the usual flat ones, figured knives with different profiles can be inserted into it.

Classification of cutters by shank size, type of design and cutting part

Cutting tools for a manual milling machine are classified primarily according to the following three criteria:

- Tail dimensions.

- Type of construction – prefabricated, replaceable blades, monolithic, attachment/set-on.

- Material and method of sharpening the cutting edge.

Let's look at these parameters in more detail.

Set of cutters for woodworking Source instrumentgid.ru

Tail dimensions

In the characteristics of the tail section, the unit of diameter is of paramount importance. The designation must coincide with a similar parameter of the collet - the place where the cutter is mounted in the machine. As a rule, there are only two standards for this value:

- Millimeter. The most common sizes are 6, 8 and 12 mm.

- Inch. There are two main types - half and quarter inches, denoted - ½ and ¼, respectively.

When comparing two measurement systems, it turns out that products with similar diameters differ only by a small amount in size. Thus, 6 mm and ¼ or 6.35 mm cutters and 12 mm and ½ or 12.7 mm cutters look almost the same - however, the holder of a hand router is not adapted to securely hold any type of tool, like a drill chuck.

Therefore, a 12 mm cutter loaded into a ½-inch collet will not sit securely in the chuck and can easily fly out during processing. Likewise, if you load a ½-inch tool into a 12-mm holder, it may jam so much that you will have to come and repair the machine later.

The packaging indicates the size and other main parameters of the cutters Source goods.ru

The second important characteristic is the length of the shank. However, often when choosing the right tool in terms of shape, design, diameter and other parameters, it turns out that it is impossible to find one suitable for the processing conditions of the required length. In this case, special extension adapters come to the rescue.

It should also be remembered that such “helpers” should be used as a last resort and with caution. Since under loads, speeds and revolutions characteristic of modern machines, such a device will always have the property of a “weak link”.

Important! Metric and imperial cutting attachments are not interchangeable. And their use in this capacity can lead not only to damage to the workpiece or machine, but also risks injury to the operator.

See also: Catalog of companies that specialize in garden furniture and storage systems

Type of construction – prefabricated, replaceable blades, monolithic, attachment/set-on

According to the design features of wood cutters, there are 4 main types:

- Prefabricated. It is made by soldering, using refractory solders, the cutting edge to a monolithic base - the shank and the head. They are distinguished by simplicity and accessibility of production.

Example of a prefabricated cylindrical cutter Source atis-market.com

- With replaceable blades. The cutting edge is a separate element, fixed to the head with screws and which the user can replace or sharpen as necessary. Some products have up to 4 working surfaces - which significantly increases the working life of the tool.

- Monolithic. The cutting part is formed directly on the base itself - by analogy with a drill. The advantage is the minimal risk of blade tearing off. However, for prolonged use it must be periodically sharpened, which over time changes the original geometry, impairs performance and leads to the need for replacement.

- Mounted/set-on. The cutting head is connected to the shank in a movable manner. This allows you to change the distance between elements and their sequence for more varied processing of workpieces.

Recommendation! To gain experience and become familiar with processing techniques, a novice user only needs to purchase prefabricated cutters. For the more experienced and professional, kit tools are the best option.

Milling cutter with replaceable blades Source prostanki.com

Material and method of sharpening the cutting edge

The large number of revolutions and the resulting high temperature in the processing zone force tool developers to use the following 2 types of metal alloys as cutting edge materials for wood cutters for hand routers:

- Tool steel. It is marked - HSS. Designed for processing low-density wood at maximum speeds. Disadvantage: when it gets into a denser environment, the cutting edge instantly becomes dull. Therefore, it is not suitable for cutting chipboard, MDF and other similar materials.

- Carbide brazing. Designated - NM. Used for processing dense wood at medium and low speeds. Can also be used for finishing machining with high cutting edge quality. However, it is often impossible to achieve the ideal degree of smoothness when finishing with an average cutter of this type.

Frame cutters with carbide-tipped blades Source zubr-rus.ru

Types of cutter blades

The shape of the profile of the cutting edge (blades) of the cutter determines what kind of sample will be obtained in the end. There are several main types.

Grooved

The purpose corresponds to the name - equipment for making grooves. In turn, there are varieties of groove cutters.

End groove

“End” means that the sampling is performed not only by the side, but also by the end part (lower end) or only by the end part. Example in the image below:

Such cutters can be of different diameters. There are options with a bearing located at the top for making a groove (rebate or quarter) on the side of the workpiece.

Slotted structural with side cutting edge

This cutter can be used in different ways. So, as shown above, along a full profile, or to make a simple straight groove on the side of the workpiece to the desired depth, set using a rip fence.

Fillet groove cutters make a groove with a semicircular groove

This is the main cutter for applying decorative patterns and surface wood carvings. With its help, you can apply drawings and patterns both along the intended lines and using a compass or patterns.

We also recommend reading an interesting article about artistic carving with a jigsaw.

Edge

Designed for processing side edges. Their main difference is the presence of a ball bearing at the bottom of the shank. This makes work simple and convenient. The bearing prevents the cutter from going deep inside and damaging the workpiece; it rotates along the surface of the workpiece, making the tool move easily and smoothly.

The edges are processed with a variety of profiles. Therefore, cutters of this type may include slotted, figured (profile), tenon, rebated cutters for selecting quarters and other cutters with bearings.

If necessary, the bearing can be removed and the cutter can be used in another way. For example, for sampling a profile in the middle of a workpiece after a fillet or simple direct sampling, setting the desired depth. In this case, preliminary selection is necessary, since edge cutters with bearings are not end cutters; they do not have knives at the very end, at the bottom end.

Combined

Combined cutters are called cutters for a “complex groove/tenon” connection. The peculiarity of this connection is that the joined edges have the same groove, and not a groove and tenon, as on the lining. You can see what such cutters and connections look like in the following video:

This image also well illustrates the capabilities of such equipment:

If a groove/tenon connection (like a lining or tongue-and-groove floor plank) requires passage with two different profiles (groove and tenon), then a combined cutter makes a compatible connection on both sides.

Curvy

These are large cutters with different complex profiles, a combination of wide semicircles, rounded grooves, etc. The result of their work can be seen on paneled doors (the panel is selected with them) and curly baseboards.

Of course, long-length moldings (the same as skirting boards) are made not with hand milling machines, but with powerful milling machines. But small amounts of work - several doors, 10-30 running meters. skirting boards can also be made using a hand router with a power of at least 1.5 kW. To cut moldings, a hand router is sometimes secured in the table upside down (with the cutter facing up).

An example of a classic figurine cutter specifically for a manual router in the image:

The next image shows a more complex double (double-leaf) figurine cutter.

In one pass, she makes not only a door or furniture panel, but also a tenon for fastening it into the groove of an adjacent part.

Other types

A special type of cutter is Forstner drill. By design these are cutters. But since they perform the function of a drill, that is, they make round holes, they are called both cutters and drills. Their functional difference from classic spiral drills with a conical tip is the following - they form a flat, rather than conical, bottom of a non-through hole. This is often important. For example, when planting round elements of furniture fastenings, hinges, etc.

The image shows a Forstner drill:

Forstner drills are available in a wide range of diameters, from 10 mm to 56 mm, sometimes more, both individually and in sets. The cutting element consists of three main parts:

- Scoring lateral incisors. Due to them, the edges of the holes do not tear, the hole is drilled cleanly.

- The lower incisors are strictly perpendicular to the axis of rotation. Therefore, the bottom of the hole is smooth.

- The third element, centering the peak in the middle, allows you to accurately orient the drill along the mark; when entering the workpiece, it does not jump or move.

Carbide cutters with tungsten carbide or other metals make it possible to use such equipment for drilling chipboard, MDF and other materials with hard adhesive resins, which is important in the manufacture of cabinet furniture from such materials.

A separate type includes cutters for soft metals, plastics and other non-wooden materials. As a rule, knives made of harder alloys are used for such cutters.

Rating of the best cutters for a hand router for 2022

10th place - FIT set 6 pcs. (36566)

FIT IT 36566 attachments process wooden workpieces and various grooves. The set includes a plywood case for storage and transportation. Good as a first set for beginners. Milling cutters with carbide cutting inserts.

Equipment (mm.):

- groove 6;

- groove 12;

- groove 16;

- fillet 12.7;

- dovetail 12.7;

- "V-shaped" for an angle of 90°.

Specifications:

| Options | Characteristics |

| Kit type | kit |

| Cutter type | terminal |

| Type of cutter | fillet, dovetail, groove |

| Shank type | cylindrical |

| Shank diameter | 6 mm |

| Processing material | tree |

FIT 6 pcs. (36566)

Advantages:

- good price/quality ratio;

- rare shank diameter;

- convenient storage box;

- not bad blade sharpening;

- carbide brazing.

Flaws:

- there are vibrations during operation;

- There are no overrunning nozzles with bearings.

9th place - Bat FIT 36692

The scope of application of FIT 36692 is the spot machining of recesses on small chamfers, the placement of seals and the formation of tongue-and-groove structures. Works with hand milling machines and machines. The nozzle is made of hardened steel with carbide blades. Sold in blister packs. Two cutting elements. It differs favorably from sets by the possibility of individual purchase. Medium quality.

Specifications:

| Options | Characteristics |

| Kit type | piece |

| Cutter type | terminal |

| Type of cutter | disk |

| Cutter diameter | 32 mm |

| Shank type | cylindrical |

| Shank diameter | 8 mm |

| Working height | 6 mm |

| total length | 36 mm |

| Cutter material | carbide |

| Processing material | tree |

Bit FIT 36692

Advantages:

- cuts the groove well;

- sold individually, packed in plastic packaging;

- comfortable for storage.

Flaws:

- short, not always convenient to work;

- bearing is missing.

8th place — Set CALIBER 0504 (8 mm, 5 pcs.)

Used for working with wooden structures. The bits effectively machine surfaces made of soft and hard materials. Sold in a wooden case. It is in great demand among novice carpenters. The low price allows you not to save on consumables. The quality is at the level of previous sets. Unlike others, it has a popular shank.

Equipment (mm.):

- R 4.76;

- edge diameter 12.7;

- edge length 12.7;

- bit R 6.35;

- diameter 6.

Specifications:

| Options | Characteristics |

| Kit type | kit |

| Cutter type | terminal |

| Shank diameter | 8 mm |

| Processing material | tree |

CALIBER 0504 (8 mm, 5 pcs.)

Advantages:

- compact and in convenient packaging;

- there is a coating that protects against corrosion;

- processes fiberglass;

- shank diameter 6 mm will fit milling cutters from different manufacturers;

- are delivered already sharpened and ready for use;

- during transportation, the cutting edge is not damaged by the case, thanks to the soft backing;

- reasonable cost;

- Despite the low price there are no chips.

Flaws:

- There are no combination bits included;

- the box doesn't have a handle.

7th place - Total TACSR 1121

Set for working on wood, PVC and other materials. Used for finishing wooden blanks. Provides the ability to select grooves of various configurations. Plywood case for transportation and storage. The advantage of the set is greater functionality due to the number of bits and the presence of bearings. A little play.

Complete set (pcs., mm.):

- 1 groove fillet;

- 1 edge molding with ball bearing;

- 1 groove “Dovetail”;

- 1 edge cone with ball bearing;

- 1 edge straight with ball bearing;

- 1 slot straight 16;

- 1 curtain rod with ball bearing;

- 1 slot straight 12;

- 1 groove straight line 6;

- 1 curtain rod with ball bearing D 28.6;

- 1 “V – shaped” for 90° angles;

- 1 curtain rod with ball bearing R 4.0;

- case.

Specifications:

| Options | Characteristics |

| Amount in a package | 12 pcs. |

| Kit type | kit |

| Cutter type | terminal |

| Shank diameter | 8 mm |

| Processing material | tree |

Total TACSR 1121

Advantages:

- functional;

- minimal backlash;

- blade geometry error 0.03 mm;

- bearings do not knock;

- affordable price.

Flaws:

- not suitable for hard materials.

6th place - Metabo 631039000

The Metabo set consists of 15 bits with an 8mm shank. Designed for decorative wood processing. Unlike competitors above, it has better sharpening. Types of milling:

- chamfer;

- cutting profiles;

- mold.

Equipment:

- straight, grooved 4 pcs.;

- edge-seam;

- fillet-groove 2 pcs.;

- fillet-groove, “V-shaped” with a tip 90⁰;

- moulding-edging 4 pcs.;

- straight, edged;

- cone-edge 45⁰;

- “dovetail” 14⁰.

Specifications:

| Options | Characteristics |

| Kit type | kit |

| Cutter type | terminal |

| Type of cutter | figured, seam, fillet, tenon, groove, edge |

| Shank diameter | 8 mm |

| Processing material | tree |

Metabo 631039000

Advantages:

- good wooden case;

- sit firmly on the instrument;

- smooth sharpening;

- good set for beginners;

- sharp sharpening.

Flaws:

- some of the attachments are not balanced, there is some play;

- quickly become dull;

- for small carpentry work;

- not for hard wood.

5th place - STAYER 2992-H12 kit

The 2992-H12 STAYER kit is suitable for hardwood and softwood. With the help of bits, high-quality products are made. There are nozzles of edge, groove and profile types. Supplied in a practical plywood box.

Equipment (mm.):

- straight groove 6;

- straight groove 12;

- straight groove 16;

- straight fillet 12.7, R 6.3;

- “dovetail” 14⁰, D 12.7;

- cone-edge 45⁰, D 32;

- straight edge D 12.7;

- fillet-groove, V-shaped 90⁰, D 12.7;

- moulded-edge, D 22, R 6.3.;

- moulded-edge D 22, R 6.3;

- moulded-edge D 28.6, R 9.5;

- moulding-edge D 25, R 4.

Specifications:

| Options | Characteristics |

| Kit type | kit |

| Cutter type | terminal |

| Shank type | cylindrical |

| Shank diameter | 6 mm |

| Cutter material | carbide |

| Processing material | tree |

STAYER 2992-H12

Advantages:

- inexpensive price, set with a wide range of functions;

- smooth and sharp sharpening;

- for a 6 mm collet.

Flaws:

- for home workshop only;

- scuffing during use;

- some bits are larger than stated size;

- operate at low speeds.

4th place — Set Hammer 222-005, No. 2, 12 pcs. (58595)

Consumables made of hard alloy, effectively cut chamfers. They are resistant to elevated temperatures, cope well with loads, and have good wear resistance.

The cutting edges of the blades are sharpened on high-precision machines. Increased performance and protection against burns. High production technologies guarantee that the geometry will be preserved during operation. The 8 mm shank makes it possible to use bits with popular tool models.

Equipment:

- 2 fillets;

- 3 slotted;

- 3 edge-moulders;

- 1 for flush operation;

- 1 dovetail;

- 1 cone;

- 1 V-groove.

Specifications:

| Options | Characteristics |

| Kit type | kit |

| Cutter type | terminal |

| Type of cutter | fillet, molding, conical, groove, edge |

| Shank type | cylindrical |

| Shank diameter | 8 mm |

| Cutter material | carbide |

| Processing material | tree |

Hammer 222-005, No. 2, 12 pcs. (58595)

Advantages:

- provides wide functionality;

- handles inch boards well;

- price-quality ratio;

- The bearings rotate easily, without jamming or play.

Flaws:

- Average quality storage box.

3rd place — Set SKRAB 37090

Cylindrical nozzles made of high-strength steel 33090 SKRAB have a diameter of 3 mm. Heads of chrome-molybdenum alloy of various shapes are attached to the shank. Metal cutters are used with machine tools and hand tools. Work with pneumatic drills. The only representative of the rating for metal processing, it is necessary to use a power tool with a high rotation speed. SKRAB works with materials:

- copper;

- brass;

- bronze;

- cast iron;

- alloy steel up to 60 HRC;

- carbon alloys;

- chromium-nickel alloys;

- stainless alloys;

- titanium.

Type of work:

- chamfer;

- cuts edges;

- polishes burrs;

- bores holes and grooves;

- processes flat surfaces;

- preparing metal for welding;

- grinding of welds.

Equipment (mm.):

- A 6x12x3;

- C 6x12x3;

- D 6x5x3;

- E 6x11x3;

- F 6x14x3;

- G 6x14x3;

- H 6x14x3;

- L 6x14x3;

- M 6x14x3;

- N 6x8x3.

Specifications:

| Options | Characteristics |

| Kit type | kit |

| Cutter type | terminal |

| Type of cutter | fillet, molding, conical, groove, edge |

| Shank type | cylindrical |

| Shank diameter | 8 mm |

| Cutter material | carbide |

| Processing material | tree |

SKRAB 3709

Advantages:

- reliable, wear-resistant, cuts well;

- process forged products.

Flaws:

- the need to apply lubricant during operation;

- high average price.

2nd place - Groove Bosch 2608628392

The scope of use of Bosch 2608628392 is the production of grooves and grooves in wood of various species. Used for mobile and stationary tools. Greater penetration of the nozzle into the material is achieved by greater power of the tool. The bat is made of high-quality alloys and has a well-designed blade geometry.

Specifications:

| Options | Characteristics |

| Kit type | piece |

| Cutter type | terminal |

| Type of cutter | grooved |

| Cutter diameter | 25 mm |

| Shank type | cylindrical |

| Shank diameter | 8 mm |

| Working height | 19.6 mm |

| total length | 51 mm |

| Cutter material | carbide |

| Processing material | tree |

Groove Bosch 2608628392

Advantages:

- carbide steel is suitable for working with any wood;

- sold individually;

- plastic box;

- not a high price compared to analogues;

- symmetrical blades have no serrations.

Flaws:

- There is a play of up to 1 mm, which leads to additional vibration.

1st place - BOSCH 12 NM SET 8MM-ХВ

Bosch 12 NM SET 8MM-ХВ nozzles are designed for wood, plexiglass, lining and other materials. They are used by construction companies for renovations and furniture makers for decoration and leveling the surface. Bosch 2607019466 are stored in a case, which allows you to keep the set in order. The best set deserves its place due to its sharp sharpening, wear-resistant alloy and wide functionality.

Equipment:

- 3 pcs. for making grooves;

- 1 chamfers;

- profile;

- 2 cornices;

- 1 “V-shaped” groove type;

- "dovetail";

- for flush sampling;

- 2 fillets.

Specifications:

| Options | Characteristics |

| Amount in a package | 12 pcs. |

| Kit type | kit |

| Cutter type | terminal |

| Type of cutter | fillet |

| Shank diameter | 8 mm |

| Cutter material | carbide |

BOSCH 12 NM SET 8MM-ХВ

Advantages:

- Sold in a case that can be placed on the wall, consumables are always at hand and safe;

- Processes plywood, hardwood and softwood;

- Used on manual and tabletop machines;

- The bits are well sharpened.

Flaws:

- the set contains rarely used bits;

- large box.

Popular manufacturers

Milling cutter manufacturers today can be divided into two groups:

- milling cutter manufacturers who produce accessories for their power tools and compatible tools from other manufacturers;

- manufacturers of cutting equipment who specialize in this and do not produce power tools themselves.

The former produce products of fairly good quality, since they are interested in ensuring that their instrument works successfully. But they are not interested in their equipment working forever so that sales are not one-time. From time to time, such cutters are replaced with new ones.

The most widespread and popular manufacturers are Encore, Bosch, Fit, Corvette and others.

The latter try to maintain a reputation for the quality of their products and produce professional products with a long service life. However, among them there may be “nameless” products of poor quality of unknown origin.

How to choose

The quality and durability of a cutter can only be determined through actual work. It is impossible to do this by inspection or other means before purchasing. If you need to buy a large set of different profiles for a significant amount, you can check the quality without lengthy work in the following way:

- buy one cutter from the selected manufacturer;

- the reverse side of the cutting edge is trial sharpened with an ordinary file with a fine notch;

- if sawdust is removed, the alloy is not strong enough. (Easy to sharpen, easy to dull).

It is not worth buying a large number of cutters of this quality. Carbide edges are sharpened only with abrasive wheels of sharpening machines or diamond needle files; a regular file will not take them.

Signs of a low-quality or dull cutter - the profile is not completely selected. The tool moves with force, the wood turns black and burns until smoke appears.

A brand's reputation can give an idea of quality. Most brands produce “mass consumer goods” for household use, but the quality is good enough to do the job required.

The cutters of the above brands - Bosch, Enkor, Fit, etc. - have average and sufficient quality for work.

Price is not always an indicator of quality. The fact is that the price depends not only on the expensive or cheap alloys used, the cost of the equipment, but also on the profile of the cutter. A complex profile of a larger size costs more than a simple one.

Good cutters are produced by German manufacturers. Quality guarantee if the product is not manufactured, for example, “in the PRC under control, etc.,” but specifically in Germany. Therefore, when searching in online stores, you should click on country-. The results will only include products manufactured in this country.

German cutters are perfectly balanced, do not create vibrations or beats at high speeds, process wood as cleanly as possible and retain their working qualities for a very long time without sharpening.

Equipment for working with wood cutters

The cutter is the main part of almost any woodworking tool. It can be installed:

- into a regular drill;

- milling machine (milling machine);

- industrial equipment.

Power tools can be used to carry out rough and fine processing of wood at high speed.

Drill

The use of cutters allows home craftsmen to significantly expand the functionality of a conventional drill intended only for drilling. At the same time, the drill turns into a universal tool with which you can process parts made from various types of wood.

Using wood cutters designed to work with a drill, you can produce large-diameter holes without the use of special drill attachments such as ballerina or crown (crown attachment).

To work with a drill, only finger cutters are used, the cutting edges of which have a wide variety of shapes. In addition, fillet, edge (quarter) and cone cutters are often equipped with a support bearing, which limits the depth of cut of the blades into the wood.

Cutting blades can be pointed or backed. Pointed teeth have flat front and back surfaces, and they are sharpened along the back surface.

Moreover, during re-sharpening, the cutting part may change its geometric dimensions. This can be avoided by using a tool with sharpened blades. They only have a flat front surface, along which sharpening is carried out. You can resharpen such cutters many times without fear that the geometry of the cutting edges will change.

Fraser

A hand router is a tool that is designed for processing various lumber and products made from it. It differs from a drill in the presence of an adjustable support platform and the ability to operate at high speeds (up to 30 thousand rpm). Using a router you can with high quality:

- splice different workpieces, connecting them using the “tenon/groove” method (edge work), chamfer the timber;

- embed fittings, locks, hinges;

- form three-dimensional shapes on flat surfaces (decoration);

- cut wooden blanks with complex configurations.

To perform these works, edge, groove, copy and end mills for wood are used.

Groove cutters are used when you need to make recesses of a certain shape, for example, in the shape of the letter T (T-shaped), semicircular or dovetail.

Edge cutters are used to make edges on wood parts. As a rule, they are equipped with a thrust bearing, which prevents excessive immersion of the tool into the body of the part. In addition, it allows you to adjust the depth of departure. If a bearing is not provided, then a parallel stop or template must be used.

For decorative processing of panel parts, horizontal type figurine cutters are used. They are quite heavy and have a large diameter. Considering the great effort required when working with such cutters, they are equipped with a shank with a diameter of 12 mm. They are used on stationary equipment.

Wood end mills for a hand router have cutting edges located at the end of the working surface. In addition, the side edge also takes part in the work, which allows you to move the rotating cutter in the plane of the support platform. The quality of surface treatment is determined by the number of cutting blades. As a rule, end mills have a monolithic design, but there are also composite ones.

A separate group of end products consists of Shaper cutters - cutters (burrs).

They are used at intermediate stages of processing, as well as in cases where it is necessary to finalize the configuration of the part. Their cutting edge consists of large notches (teeth). When working with a cutter, it is important to choose the right mode. This will avoid burning the wood, which is possible at higher speeds. And the original “corn” burr (a cutter with a screw arrangement of teeth) will reduce the load on the shaft of the electric motor of the router.

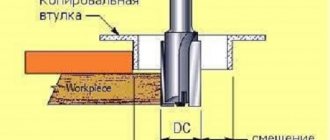

Copy cutters are a rare type of tool for a hand router. They differ not only in the number of cutting edges, but also in the placement of support bearings, which can be located on either side. Some models have two bearings (top and bottom). During operation, the bearing moves along a template, due to which the workpiece being processed takes on the desired shape.

Is it possible to do it yourself?

Despite their apparent simplicity, the production of these products requires advanced, high-precision and high-tech equipment. The cutter should be:

- ideally balanced in weight so that there are no eccentric beats at high speeds;

- the profiles of the knives and their location must repeat each other with high accuracy, up to hundredths of a mm;

- cutting edges (knives) must be made of hard alloys, which can only be profiled and sharpened with an even more durable tool.

For these reasons, it is almost impossible to make a cutter yourself without equipment. The exception is simple straight knives on equipment with replaceable blades. In theory, you can cut the desired size from, for example, planer knives. But even here there are problems with balancing the weight and drilling holes for fastenings in solid metal.

In a home workshop you can sharpen some types of profiles. This is done from the back side of the cutting edge, since it is impossible to do this on a curved profile from the side of the tip, sharpened at an angle.

Sharpening is carried out with a flat diamond file. But it’s more effective on a sharpening machine, a thin or bowl-shaped wheel that fits into the niche of the cutter and reaches the surface to be sharpened.

Severe overheating during sharpening is unacceptable, as this will change the factory characteristics of hardening (heat treatment) of the metal. Sharpening is carried out until a small chamfer appears on the reverse side. Then the chamfer is carefully removed with zero-grit sandpaper, using light movements so as not to dull the tip.

A complete list of what can be done with a hand-held wood router

With the help of a competent approach and home-made devices for securing the router in various positions on a movable carriage, you can do with a manual wood router what expensive machines are capable of. And actually completely replace their functionality.

The main functions of a manual router are as follows:

- Design of ends and edges on workpieces, chamfering using shaped cutters.

- Carving decorative patterns on wood, as well as blanks of various shapes.

- Manufacturing of groove joints of simple and complex shapes (including dovetail).

- Jointing the edge of the board for subsequent gluing (when installing the router on the table).

- Thickening of workpieces of any length and width (when installing the router on the carriage).

- Production of milled furniture facades.

- Drilling holes of different depths and diameters for furniture dowels and grooves, random selection of wood according to the desired template.

All of the above is possible by equipping the tool with special cutters.

How to store

The cutters do not require any special storage conditions. Avoid ingress of water, preferably a dry room to avoid rust. Otherwise, each master stores them in the way that is most convenient.

Complete cutters are sold and stored in boxes. Purchased individually, they can be placed on a board with holes drilled for the shanks. When cutters are needed frequently, they are kept on hand. In other cases, they put it away so as not to interfere.

A hand router is a multi-functional tool with the widest capabilities. First, problems are set that need to be solved. Why is a cutter with a suitable profile selected for their implementation? Beginners should know that a router is not a magic wand that will do everything on its own. This tool needs to be worked. And then all the possibilities that a router with a suitable cutter gives to every master will open up.