A manual milling machine in the hands of a master has a universal application - with its help you can create both basic household items and masterpieces of artistic processing for decoration. However, to use it correctly, you need a suitable cutting tool. Let's look at what types of cutters there are, how they are designed, what their main purpose is, what criteria they are classified by, and how to choose the right one for a specific type of wood processing.

An example of using a wood cutter on a manual machine Source prosto-instrumenty.ru

Milling cutter for a manual wood router - what is it, device, purpose

A milling cutter is the main tool with which wood is processed. The scope of application, purpose, and result depend on its technical characteristics. Despite the fact that there are many varieties of it in terms of shape and features of the cutting edge, materials and other parameters, they are all united by the general principle of the device and the presence of standard parts:

- The cutting area, also called the head or working part. It can have different geometry, composition and blade design.

- Shank - serves as a support for the previous element. With its help, the tool is clamped in the machine chuck, and torque is also transmitted to the main part.

- Additional component. It is located on the very edge of the instrument - opposite the tail section. This could be a support bearing, locking couplings, screws, washers, calibration bushings and other devices. Their task is to simplify or expand the functionality of the cutter, for example, to arrange the cutting segments in the required sequence or to process the workpiece according to a given pattern.

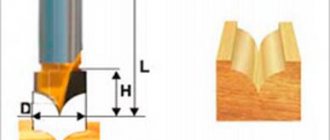

Diagram of an end mill with designation of characteristics Source infradom.ru

Depending on the scope and purpose, modern wood cutters for a manual router allow you to solve the following types of problems:

- Forming edges. It is used when it is necessary to create parts of workpieces that are combined into one structure using a tongue-and-groove connection.

- Creation of cut-outs for installation of fittings.

- Production of decorative forms, cuttings, configurations.

Advice! Certain types of work require your own set of cutting tools. Therefore, before selecting specific types of cutters, it is necessary to determine what the nature, type and volume of wood processing work performed with their help will be.

Slot cutters

If you need to select a groove of any depth and width, then a groove cutter is ideal for this purpose. Its design allows this operation to be performed both on the face (face) of the part and on its edge. A groove cutter is mainly used when joining parts into a tenon. Also, using attachments for a wood router that follow a ruler, you can cut even grooves of any width.

Shaped

They allow you to give the groove certain shapes, similar to curly braces. The tool not only selects grooves inside the workpiece, but also changes the shape of the edge ribs. When making a complex pattern on the surface of a workpiece, a straight cutter (groove) is first passed through it. In the future, this simplifies the alignment of the shaped equipment.

The following pictures show the main types of slotted router bits.

Structural

After processing the workpiece with this equipment, a groove is obtained that looks like a trapezoid (dovetail) or an inverted letter “T”.

This method of connecting parts is considered one of the most reliable, since the tenons are pushed into grooves of the same shape, and they cannot be separated by any other method.

V-shaped fillets

Although the word “fillet” refers to a semicircular notch or groove, V-cutters also fall into this category. The tool allows you to select not only vertical grooves, but also grooves at a certain angle. Also, a fillet cutter is often used for decorative carvings and changing the geometry of edges in furniture production.

Fillet

They have a rounded cutting part. If you look at the groove after it has passed through the section, it will resemble the letter “U”.

The cutter is used for decorative finishing of the edges and ends of wood products, creating complex patterns on the face of the workpiece or various fillet recesses (grooves) on the face of the product and on its edges.

Direct

This is the simplest tool, shaped like a cylinder. The groove obtained in the workpiece has a rectangular cross-section.

The equipment is most often used with plunge routers.

Straight groove (finger) cutters are used if you need to select a rectangular groove with a clean bottom, for example, for inserting door locks and hinges.

Classification of cutters by shank size, type of design and cutting part

Cutting tools for a manual milling machine are classified primarily according to the following three criteria:

- Tail dimensions.

- Type of construction – prefabricated, replaceable blades, monolithic, attachment/set-on.

- Material and method of sharpening the cutting edge.

Let's look at these parameters in more detail.

Set of cutters for woodworking Source instrumentgid.ru

Tail dimensions

In the characteristics of the tail section, the unit of diameter is of paramount importance. The designation must coincide with a similar parameter of the collet - the place where the cutter is mounted in the machine. As a rule, there are only two standards for this value:

- Millimeter. The most common sizes are 6, 8 and 12 mm.

- Inch. There are two main types - half and quarter inches, denoted - ½ and ¼, respectively.

When comparing two measurement systems, it turns out that products with similar diameters differ only by a small amount in size. Thus, 6 mm and ¼ or 6.35 mm cutters and 12 mm and ½ or 12.7 mm cutters look almost the same - however, the holder of a hand router is not adapted to securely hold any type of tool, like a drill chuck.

Therefore, a 12 mm cutter loaded into a ½-inch collet will not sit securely in the chuck and can easily fly out during processing. Likewise, if you load a ½-inch tool into a 12-mm holder, it may jam so much that you will have to come and repair the machine later.

The packaging indicates the size and other main parameters of the cutters Source goods.ru

The second important characteristic is the length of the shank. However, often when choosing the right tool in terms of shape, design, diameter and other parameters, it turns out that it is impossible to find one suitable for the processing conditions of the required length. In this case, special extension adapters come to the rescue.

It should also be remembered that such “helpers” should be used as a last resort and with caution. Since under loads, speeds and revolutions characteristic of modern machines, such a device will always have the property of a “weak link”.

Important! Metric and imperial cutting attachments are not interchangeable. And their use in this capacity can lead not only to damage to the workpiece or machine, but also risks injury to the operator.

See also: Catalog of companies that specialize in garden furniture and storage systems

Type of construction – prefabricated, replaceable blades, monolithic, attachment/set-on

According to the design features of wood cutters, there are 4 main types:

- Prefabricated. It is made by soldering, using refractory solders, the cutting edge to a monolithic base - the shank and the head. They are distinguished by simplicity and accessibility of production.

Example of a prefabricated cylindrical cutter Source atis-market.com

- With replaceable blades. The cutting edge is a separate element, fixed to the head with screws and which the user can replace or sharpen as necessary. Some products have up to 4 working surfaces - which significantly increases the working life of the tool.

- Monolithic. The cutting part is formed directly on the base itself - by analogy with a drill. The advantage is the minimal risk of blade tearing off. However, for prolonged use it must be periodically sharpened, which over time changes the original geometry, impairs performance and leads to the need for replacement.

- Mounted/set-on. The cutting head is connected to the shank in a movable manner. This allows you to change the distance between elements and their sequence for more varied processing of workpieces.

Recommendation! To gain experience and become familiar with processing techniques, a novice user only needs to purchase prefabricated cutters. For the more experienced and professional, kit tools are the best option.

Milling cutter with replaceable blades Source prostanki.com

Material and method of sharpening the cutting edge

The large number of revolutions and the resulting high temperature in the processing zone force tool developers to use the following 2 types of metal alloys as cutting edge materials for wood cutters for hand routers:

- Tool steel. It is marked - HSS. Designed for processing low-density wood at maximum speeds. Disadvantage: when it gets into a denser environment, the cutting edge instantly becomes dull. Therefore, it is not suitable for cutting chipboard, MDF and other similar materials.

- Carbide brazing. Designated - NM. Used for processing dense wood at medium and low speeds. Can also be used for finishing machining with high cutting edge quality. However, it is often impossible to achieve the ideal degree of smoothness when finishing with an average cutter of this type.

Frame cutters with carbide-tipped blades Source zubr-rus.ru

What is a milling cutter?

The device works due to the movement of the cutter, which affects the material being processed, and it, in turn, moves towards the cutter thanks to a special installation on the table. It is important to install the tool correctly and secure it in order to maintain operating conditions and safety rules (power up to 2000W).

Areas of application: carpentry work with different materials. Wood, acrylic, eurolining, organic glass, polycarbonate, parquet, etc. The machines come in prefabricated models or solid, easily transportable. The machines differ according to the type of processing and the decisive part in them is the cutters, which come in different shapes and types.

It is worth noting that cutters are sold in sets and individually. The choice between them depends on the goals of the work and the professional skills of the master. The kits may contain parts that may never be useful in the work; on the other hand, such kits are more profitable than the cost.

It is also recommended to purchase kits for beginners in this work, in order to have different options available for practice and training.

Varieties by processing method

In order to choose the right wood cutter for a hand router, you need to have an idea of what types are used for specific types of work with workpieces. According to this characteristic, cutting tools are divided into 5 main types:

- End.

- Grooved.

- Edges.

- Combined.

- Curvy.

Let us analyze in detail the main features and nuances of using each of them.

End

Having a structure similar to a drill, an end mill, however, differs from it in that its working part extends over the entire area of the cutting edge. That is, wood is sampled with the entire head part. There are the following varieties:

- Profile.

- Spherical.

- Conical.

- Spiral.

- End

- Burr cutters (cutters).

Most end mills have a universal purpose. Thus, spiral varieties allow you to drill and select grooves, quarters, and process ends; profile varieties allow you to make grooves of complex geometry, create ornaments, trim, cutters allow you to finish surfaces, engrave, select special shapes of holes and grooves.

Wood end mill set Source fainaidea.com

Grooved

The very name of the groove cutter reveals the nature of its application - the choice of grooves. However, they differ in the following modifications:

- Fillet. A semicircular sample is formed.

- Conical. Creates a V-shaped groove and is also used for carving surfaces.

- Spiral. They have a structure similar to a drill, but with a larger working part.

- T-shaped. They are used to create grooves of the type where one part slides into another.

- Dovetail. Similar to the above modification - with the difference that the cross-section of the base has the shape of a trapezoid.

- Shaped. It has a wide variety of species. It is used both for making grooves and for processing ends.

- Straight or cylindrical. Create a rectangular groove.

- Combined. They are used to form interlocking joints - when assembling linings, panels, and panels.

Slot milling cutter with performance characteristics displayed Source static-sl.insales.ru

Recommendation! When choosing a specific type of wood cutter for a hand router, you need to have an idea of what they are like in terms of workmanship, thermal strength, connection of the cutting area with the tail part and solder material. When processing hardwood, a tool with weak soldering will soon lose its longitudinal stability and quickly fail.

Edge

An edge cutter is used to create an edge that is smooth and perpendicular to the plane of the workpiece. The following types are distinguished:

- Direct. Designed to create an end perpendicular to the upper plane.

- Moulded. Straight, arched, wavy edges are formed. Used for applying complex patterns. There are also double cutters with the ability to adjust the distance between the blades.

Combination cutters

Splicing workpieces is considered most effective if combined equipment is used. These types of cutters consist of both tenon and groove elements: thanks to this design, the equipment produces both profiles in one pass . As a result, the area of the edge intended for gluing increases, which has a positive effect on the strength of the connection.

Framework

Frame cutters are compound tools. All cutting elements are installed on the base, and the master can place them in the desired order. Set cutters have the following components:

- base;

- cutting elements;

- bearing;

- washer;

- fixing nut.

When changing the location of the cutting elements, it is not necessary to remove the shank from the collet of the unit. It is enough just to unscrew the fasteners located at the bottom of the equipment, and all its elements are removed. Thanks to the dismountable design of the equipment, the tool overhang remains the same, and re-adjustment is not required.

Tongue-and-mortise

The kit contains 2 cutters, one for making a groove, and the second for a tenon.

Tongue-and-mortise cutters have a mirror-identical profile of the cutting elements, thanks to which the processed parts are joined as accurately as possible.

The only disadvantage of this equipment is that the grooves and tenons are made with different cutters, which have to be changed and again their offset relative to the base of the unit must be adjusted.

For the manufacture of lining

In their operating principle, cutters for making lining are similar to a tongue-and-groove tool, but the only difference is that when connecting the parts, a V-shaped groove is formed between them to imitate timber. To make the connection, a set of 2 elements is also required.

Universal

After passing the tool, 2 planes are obtained, completely compatible with each other, having a groove and a tenon. Both of the latter are located at an angle to each other.

A microtenon cutter is also used to splice parts.

The equipment can be used both for longitudinal splicing of workpieces (in the manufacture of panels) and for end splicing of parts.

For corner jointing of wood, equipment from a series of combined ones is also used, which allows you to prepare joints at an angle of 45 degrees.

It should be noted that the same combination cutter is used to process workpieces that need to be joined. The original design of the equipment makes it possible to achieve maximum quality of joining of parts, and also significantly saves time, since there is no need to change the tool.

Video description

Video instructions for choosing wood cutters for a beginner:

The ends of the workpieces to be joined are given a specific profile using a specific type of cutter. They are then connected by locking into a single, durable structure. The procedure is performed without additional adjustment of the selected surfaces, since the complete tools are perfectly matched to each other.

Curvy

The figuere type cutters are intended for forming panels. Example - baseboards, furniture doors, decorative strips, etc. As a rule, the tool is quite massive, and therefore machines with a power of 1.6 kW or more are used to process workpieces with it. In this case, cutters are divided into three categories:

- Horizontal. Create a panel.

- Double-sided. A panel and tenon are formed.

- Vertical. Used for selecting the profile of skirting boards.

On a note! By itself, even a good hand router and correctly selected cutters for the type of wood processing do not guarantee the planned result. For quality work, you will need a set of suitable stops and templates.

How to choose cutters

When choosing a cutter, we pay attention to:

- Sharpening Level - Swipe across the paper to see how sharp it is.

- You will see the quality of the alloy by its shine.

- The geometry is determined by external inspection - there should be no distance from the knife to the ruler.

- Soldering - must be located along the entire length so that the cutter does not break.

- Hardness of the alloy - this indicator can be confirmed by quality documents for the product.

A novice specialist can choose budget, that is, inexpensive materials and develop practical skills with them, but in the future for professional work you should not save, otherwise it will affect the quality of the work performed.

Briefly about the main thing

The milling cutter is the main cutting tool of a manual milling machine. Among its main parts are:

- Cutting part.

- Shank.

- Additional components.

It is used for various roughing and finishing tasks in woodworking - cutting grooves, trimming, forming interlocking joints, cutting, decorative design, etc. Milling cutters for wood processing are classified primarily according to a number of parameters such as the diameter and length of the tail, the type of design, the material from which the cutting edge is made and the method of sharpening it.

In addition, according to the method of processing the material, they differ into end, edge, groove, combined and figured. Each modification has its own characteristics and nuances of application.

Figurine cutters

A special type of product for the manufacture of panels and similar parts. There are one-sided and two-sided. Deep penetration into the body of the workpiece creates difficulties in work. The cutting edge captures a large mass of wood during processing.

The cutter gets stuck or starts to vibrate. Experienced craftsmen first go through the part with an edge, groove analogue, leaving a small allowance. Finishing is then done with a figurine cutter, which easily copes with the difficult task. Double-sided models of this product can create patterns of various shapes on the front and back sides of the workpiece.

The best milling cutter manufacturers

- Set Fit 6 pieces. Perfectly packaged and suitable for a young master.

- Bit Fit 36692 aybr masters for spot machining. The advantage is that it is a one-piece purchase.

- Set CALIBER 0504 work for wood.

- Total TACSR 1121 great functionality.

- Set STAYER 2992-H12 for soft types of wood.

The best premium cutter sets

These are the most expensive and high-quality cutters, which are made of especially durable metal. They last a long time, so the user can save money in the long run. Not all stores sell these sets due to the fact that the demand for them is relatively small.

Set SKRAB 37090

Many cylindrical nozzles are used here, the diameter of which is from 3 mm. It is possible to work even with metal workpieces. Users note that you can install bits not only in a milling machine, but also in many pneumatic tools. This does not reduce work efficiency. It is important that the rotation speed is high. Can work with various metals.

Set SKRAB 37090

Characteristics:

- hard metal alloys;

- diameter 3-8 mm;

- case.

pros

- good sharpening;

- high wear resistance;

- you can work with metal.

Minuses

- high price;

- During operation it is necessary to periodically apply lubricant.

Set SKRAB 37090

Kit Hammer 222-005, No. 2

These are consumables made of hard alloy that do their job perfectly. The cutters can withstand elevated temperatures, rarely break and hold an edge for a long time. There is protection against burn-through of the workpiece, which is an important advantage.

Kit Hammer 222-005, No. 2

Characteristics:

- cutters made of hard alloys;

- diameter 8 mm;

- 12 pcs.;

- case included.

pros

- convenient and stylish case;

- wide functionality;

- adequate cost;

- The bearings rotate without play or jamming.

Minuses

- not identified.

Kit Hammer 222-005, No. 2

Video - Fiolent 1100 milling cutter and HAMMER cutter set

Set BOSCH 12 NM SET 8MM-ХВ

This is the best set you can find on the market today. It is considered quite expensive, but high-quality materials are used in production, which allows the cutters to be used for a long time. Comes with a convenient plastic case, thanks to which you can keep your sharpening. Can be used to work with lining, plexiglass, wood and a number of other materials.

Set BOSCH 12 NM SET 8MM-ХВ

Characteristics:

- 12 pcs included;

- diameter 8 mm;

- hard metal alloy.

pros

- convenient and practical case;

- universal use;

- excellent sharpening;

- long service life.

Minuses

- high price.

Set BOSCH 12 NM SET 8MM-ХВ

Video - Review of the BOSCH 12 NM cutter set SET 8MM-ХВ

Important! If you plan to buy premium products, then you need to have enough experience to get the maximum effect. Otherwise, improper use can cause the cutter to break or become dull.

Edge cutters

They are a cutting tool for working with edges and creating the desired shape. The following types of such parts can be distinguished.

Direct

Simple and common, these cutters produce flat, straight, perpendicular type edges. The version with a bearing makes it possible to work with round shapes.

Mouldings

The goal of this type is complex patterns. Consist of two cutting parts. Suitable for straight machining, smooth bends and rounding.

When choosing this type of cutter, it is recommended to take those that are equipped with the ability to adjust the distance between the cutting elements.

Folded

Suitable when you need to make rectangular grooves on curved or straight parts. They make it possible to obtain the result of the desired shape through a double pass.

Conical

A special type used by furniture manufacturers. Used for processing parts before joining. By changing the angle of inclination of the cutting part, decorative chamfers are achieved for connecting products of polygonal and round shapes.

Fillet

Used when you need to make a rounded groove. Equipped with two bearings that protect the tool from distortion. The result is similar to that obtained with groove fillet cutters, but edge cutters are sometimes more convenient.

Curly

Characterized by heavy weight. Used on large professional machines. They speed up the process by working over the entire area of the product. You can combine different elements.

Half-rod

Used to create semicircular protrusions on edges. Transform rectangular blanks into rods. You can make chamfers and edges of complex shapes and hinged joints. To do this, you will have to, along with a half-rod cutter, process the part with a fillet or molding tool.

Using a milling tool to remove a quarter

To cut a quarter groove (rebate) on the edge of a wooden product, a rebated edge cutter is used. As a rule, when it is necessary to perform a sufficiently large volume of such work, manual milling cutters equipped with an edge rebate cutter are used in conjunction with a special device that is easy to make by hand. The need for it is explained by the fact that creating quarter grooves is a rather labor-intensive operation, so for its accurate and high-quality implementation it is better to use additional equipment.

The depth of the rebate made by the cutter can be changed by installing a bearing of a different diameter

You should know that a rebated edge cutter changes its working diameter when sharpened, which, of course, affects the accuracy of the processing performed. That is why it is very important that the rebated edge cutter that you are going to purchase is of high quality and does not require frequent sharpening.

The seam edge cutter must be equipped with a guide bearing, which will ensure its accurate and uniform movement along the edge of workpieces of considerable length. On sale you can find entire sets of wood rebate cutters for a hand router, which include bearings of different diameters.