Using a manual milling machine, you can perform a very large number of operations with wood - select a groove and a tongue, a fold on a frame, an edge, make a rounding, embed a lock or a hinge on a door - this is not even half the list. Different types of cutters are used for different operations.

Within the framework of the article, their classification by design, purpose and criteria for selecting cutters will be given depending on the tasks performed and the material being processed, as well as photos of sets of cutters as an illustration.

Wood cutter for a manual router - what is it and what is its purpose

A cutter for a manual electric router is a small-sized cutting tool. Consists of three simple parts:

- shank;

- supporting body;

- cutting knives fixed in the supporting body.

A lot depends on the quality of the cutter. As experienced craftsmen say, it is not so important what kind of router is used, what matters is the quality of the cutter.

However, it is better to work with a high-quality, convenient router. During operation, the cutter rotates at enormous speeds, due to which cleanliness, speed and quality of processing are achieved. The electric motor of the milling cutter, through an overdrive gearbox, gives the cutter a rotation speed from 10,000 to 30,000 rpm. The more revolutions the router can produce, the better.

Purpose of a hand router

As an example, we can consider the milling machine DIOLD MEF - 1.1.

A fairly portable and multifunctional tool, used for processing various lumber. Most experienced carpenters know that a router can also replace a hand jigsaw, plane, or saw. With its help, you can easily install hinges on an entrance or interior door, insert an internal lock, and also make picture frames and make various drawings.

For a more global use of the tool, you need to familiarize yourself with the classification of cutters. Each cutting element has a shank diameter. You should pay special attention to this when purchasing. A hand router has different collet diameters for the shank, which can be either short or long. Some of the most common are 6, 12, 8, which is quite enough for a home workshop. It is necessary to remember that the larger the collet, the larger the cutter can be inserted into it, which will affect the diameter of the workpiece. The router of this model has an 8 mm collet.

As a rule, milling cutters with a collet diameter of 12 mm are quite powerful, and the price is correspondingly more expensive. Before purchasing a power tool, you need to decide for what purpose it is being purchased.

Type of shank diameter

The shank of a cutter is a round metal rod, the same as that of a drill. But unlike a drill press, drill or screwdriver, the cutter shank is clamped not in a 3-jaw chuck, but in a collet clamp (collet).

This clamp is much more compact than the chuck; it is easier to tighten one nut than the jaws on the chuck with a special wrench. This is important given the design of this tool. The disadvantage of this clamp is that you can only use shanks that are suitable in size. This differs from a chuck, in which you can clamp the shank of a drill with a size of, for example, from 1 to 10 mm.

Modern routers use collets to clamp three main shank standards: 6 mm, 8 mm, 10 mm and 12 mm. Many models come with replaceable collets. For example, for 6 and 8 mm shanks.

The cutter rotates at enormous speeds, so it must always be securely tightened when working. If the collet clamp fails, you cannot use the tool, it is dangerous.

The collet is tightened with a special wrench included in the kit or with another spanner (open-end) wrench of similar size. To tighten and unscrew, the shaft is locked either by pressing the lock provided in the design, or with another key, if the shaft has edges for a second key for fixing.

Fixation with a second key is more reliable, since the internal latches sometimes break off. Therefore, on high-quality branded models, key fasteners are often used. This is an advantage, not a disadvantage.

The collet nut is tightened with force until it stops, but without unnecessary zeal, so as not to strip the threads, or the edges of the nut and the key.

Stone cutters

To process artificial stone with a milling cutter (manual), you can use traditional types of cutters designed for wood, but only with carbide blades . There is one nuance here: artificial stone is a composite material containing tiny abrasive particles. Therefore, no matter what carbide material the cutter is made from, it will only be enough to process no more than 10 linear meters of stone workpiece. Further, dull blades will not provide the required cleanliness, for example, of the surfaces being glued, which will affect the quality of the joint.

Therefore, professionals advise using the best cutters from well-known manufacturers such as Festool, Leuco, Titman, Leitz, Dimar. The service life of cutting tools manufactured by these enterprises is 5-10 times higher than that of conventional carbide tools. With “branded” equipment it is already possible to process from 60 to 100 meters of composite.

Cutters for wood and stone are similar in appearance and even have the same names. Some of them are very often used for stone cutting operations. But there are cutters specifically designed for processing composite products.

Anti-overflow cutter

Using this stone cutter, you can create molding edges on kitchen (toilet) sinks and composite countertops. Typically, complete bead formation occurs in 2 passes of the tool.

There is also a modification of the cutter “anti-overflow”, which has a thrust bearing.

Wave cutter

This tool is designed to prepare surfaces before splicing. The cutting part of the equipment has a wavy profile.

Groove for inlay

Using the equipment, a groove is selected, which is subsequently intended for inlaying with composite materials.

Stone repair kit

This set is used to repair damage to the surface of artificial stone products. The set contains 2 elements. One makes the cork, and the second makes a hole for it.

You can also use cutters from CERATIZIT for processing composites.

These are diamond cutters that are distinguished by their wear resistance. They are made by sintering several layers of diamond chips. The multi-layer coating allows you to extend the service life of the tool, since during its operation new layers of abrasive appear to replace worn-out layers.

Main types of structures

Without exaggeration, hundreds of milling cutters of various purposes, profiles and designs are offered on the modern market. By design, there are three main groups of this cutting tool.

Prefabricated

The simplest and most common type. It consists of a shank, a supporting body and cutting knives attached to it. All three parts are made of different alloys. The knives are made of special cutting steel, everything else is made of cheaper metals. They are called prefabricated because different parts are assembled during production. Further, it is impossible to disassemble or assemble the elements of such equipment; everything is tightly secured.

Some profiles are equipped with bearings that can be removed.

Monolithic

This is practically the same equipment as the three-piece prefabricated ones described above. Nothing changes or is rearranged. The difference from the prefabricated version is that the entire cutter is made of the same alloy. In another way, such cutters are called backed ones.

With replaceable cutting edges

Such designs allow you to remove or rearrange individual cutting elements, obtaining the desired cutting profile. As an example, in the image below there is a groove/tenon cutter.

When using two cutting edges, a tenon-shaped cut is obtained. If you unscrew the nut, remove one cutting element and adjust the height of the cutter to the desired size, you can get a groove for this tenon.

The same type includes cutters with double-sided knives. They are not tightly fixed in the case, but are screwed on. When one side becomes dull, the knives are turned over and the other side is used.

An example of such equipment:

Shell cutters with replaceable knives are also used on stationary milling machines. This is a drum for attaching knives, similar to those found on conventional electric planes. But instead of the usual flat ones, figured knives with different profiles can be inserted into it.

Profile rail.

After trimming the slats is completed, you can change the cutters or cutter to another profile. We do not change the dimensions for installing the stop on the milling table. The main thing is to set the height of the cutter so that the depth of immersion of the cutter in the profile coincides, which will help to avoid high or low landing in the connection. Combining the finished tenon with a groove cutter will help you make the adjustment without any difficulties (Fig. 2). After trial cuts, the profile strip is milled (Fig. 3). That's all, a little patience and concentration gives a tight, beautiful connection.

Types of cutter blades

The shape of the profile of the cutting edge (blades) of the cutter determines what kind of sample will be obtained in the end. There are several main types.

Grooved

The purpose corresponds to the name - equipment for making grooves. In turn, there are varieties of groove cutters.

End groove

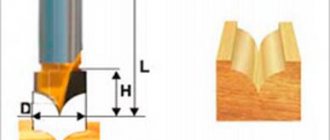

“End” means that the sampling is performed not only by the side, but also by the end part (lower end) or only by the end part. Example in the image below:

Such cutters can be of different diameters. There are options with a bearing located at the top for making a groove (rebate or quarter) on the side of the workpiece.

Slotted structural with side cutting edge

This cutter can be used in different ways. So, as shown above, along a full profile, or to make a simple straight groove on the side of the workpiece to the desired depth, set using a rip fence.

Fillet groove cutters make a groove with a semicircular groove

This is the main cutter for applying decorative patterns and surface wood carvings. With its help, you can apply drawings and patterns both along the intended lines and using a compass or patterns.

We also recommend reading an interesting article about artistic carving with a jigsaw.

Edge

Designed for processing side edges. Their main difference is the presence of a ball bearing at the bottom of the shank. This makes work simple and convenient. The bearing prevents the cutter from going deep inside and damaging the workpiece; it rotates along the surface of the workpiece, making the tool move easily and smoothly.

The edges are processed with a variety of profiles. Therefore, cutters of this type may include slotted, figured (profile), tenon, rebated cutters for selecting quarters and other cutters with bearings.

If necessary, the bearing can be removed and the cutter can be used in another way. For example, for sampling a profile in the middle of a workpiece after a fillet or simple direct sampling, setting the desired depth. In this case, preliminary selection is necessary, since edge cutters with bearings are not end cutters; they do not have knives at the very end, at the bottom end.

Combined

Combined cutters are called cutters for a “complex groove/tenon” connection. The peculiarity of this connection is that the joined edges have the same groove, and not a groove and tenon, as on the lining. You can see what such cutters and connections look like in the following video:

This image also well illustrates the capabilities of such equipment:

If a groove/tenon connection (like a lining or tongue-and-groove floor plank) requires passage with two different profiles (groove and tenon), then a combined cutter makes a compatible connection on both sides.

Curvy

These are large cutters with different complex profiles, a combination of wide semicircles, rounded grooves, etc. The result of their work can be seen on paneled doors (the panel is selected with them) and curly baseboards.

Of course, long-length moldings (the same as skirting boards) are made not with hand milling machines, but with powerful milling machines. But small amounts of work - several doors, 10-30 running meters. skirting boards can also be made using a hand router with a power of at least 1.5 kW. To cut moldings, a hand router is sometimes secured in the table upside down (with the cutter facing up).

An example of a classic figurine cutter specifically for a manual router in the image:

The next image shows a more complex double (double-leaf) figurine cutter.

In one pass, she makes not only a door or furniture panel, but also a tenon for fastening it into the groove of an adjacent part.

Other types

A special type of cutter is Forstner drill. By design these are cutters. But since they perform the function of a drill, that is, they make round holes, they are called both cutters and drills. Their functional difference from classic spiral drills with a conical tip is the following - they form a flat, rather than conical, bottom of a non-through hole. This is often important. For example, when planting round elements of furniture fastenings, hinges, etc.

The image shows a Forstner drill:

Forstner drills are available in a wide range of diameters, from 10 mm to 56 mm, sometimes more, both individually and in sets. The cutting element consists of three main parts:

- Scoring lateral incisors. Due to them, the edges of the holes do not tear, the hole is drilled cleanly.

- The lower incisors are strictly perpendicular to the axis of rotation. Therefore, the bottom of the hole is smooth.

- The third element, centering the peak in the middle, allows you to accurately orient the drill along the mark; when entering the workpiece, it does not jump or move.

Carbide cutters with tungsten carbide or other metals make it possible to use such equipment for drilling chipboard, MDF and other materials with hard adhesive resins, which is important in the manufacture of cabinet furniture from such materials.

A separate type includes cutters for soft metals, plastics and other non-wooden materials. As a rule, knives made of harder alloys are used for such cutters.

Types of cutters

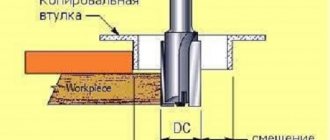

End mills - designed for rolling the edges of products. They are equipped with a bearing as a guide, which allows the cutter to cut to the same depth. End mills also include spiral cutters.

Grooves with a flat end - for cutting a rectangular groove in wood. Without a stop, it is extremely difficult to work with such a cutter, so they are used together with a template.

Fillet – allow you to choose round and V-shaped grooves along the length of the product. By adjusting the position of the cutter, it is possible to select grooves of different depths. A V-shaped cutter allows you to make a groove, the walls of which are located at right angles to each other.

Spike with a reverse cone - designed for dovetail parting. This groove is used for reliable tongue-and-groove connection of parts to each other.

Conical - for rolling the edges of the product, for decorative purposes or due to its design features. Equipped with a bearing as a stop.

Moulder - just like a cone cutter, it is equipped with a stop and is intended for processing the edges of a product, but the resulting edge has a rounded shape, and when the cutter is lowered to the maximum, you can also get a straight line on the edge.

The quarter cutter is designed for selecting rectangular rebates on door and window frames. In some cases, the fold is selected in several passes, depending on the material being processed.

Disc cutters are used to cut a groove, and the working part of the cutter is not only its end, but also its entire peripheral surface. Used for cutting narrow deep grooves, for example, under glass or hardboard.

A combination cutter is used to perform two or more functions in one pass, for example, mortise and tenon.

Although the listed cutters are made with the expectation that they will process wood, in principle they can also work with plywood, plasterboard, oriented strand board, chipboard and some other materials.

Popular manufacturers

Milling cutter manufacturers today can be divided into two groups:

- milling cutter manufacturers who produce accessories for their power tools and compatible tools from other manufacturers;

- manufacturers of cutting equipment who specialize in this and do not produce power tools themselves.

The former produce products of fairly good quality, since they are interested in ensuring that their instrument works successfully. But they are not interested in their equipment working forever so that sales are not one-time. From time to time, such cutters are replaced with new ones.

The most widespread and popular manufacturers are Encore, Bosch, Fit, Corvette and others.

The latter try to maintain a reputation for the quality of their products and produce professional products with a long service life. However, among them there may be “nameless” products of poor quality of unknown origin.

How to choose

The quality and durability of a cutter can only be determined through actual work. It is impossible to do this by inspection or other means before purchasing. If you need to buy a large set of different profiles for a significant amount, you can check the quality without lengthy work in the following way:

- buy one cutter from the selected manufacturer;

- the reverse side of the cutting edge is trial sharpened with an ordinary file with a fine notch;

- if sawdust is removed, the alloy is not strong enough. (Easy to sharpen, easy to dull).

It is not worth buying a large number of cutters of this quality. Carbide edges are sharpened only with abrasive wheels of sharpening machines or diamond needle files; a regular file will not take them.

Signs of a low-quality or dull cutter - the profile is not completely selected. The tool moves with force, the wood turns black and burns until smoke appears.

A brand's reputation can give an idea of quality. Most brands produce “mass consumer goods” for household use, but the quality is good enough to do the job required.

The cutters of the above brands - Bosch, Enkor, Fit, etc. - have average and sufficient quality for work.

Price is not always an indicator of quality. The fact is that the price depends not only on the expensive or cheap alloys used, the cost of the equipment, but also on the profile of the cutter. A complex profile of a larger size costs more than a simple one.

Good cutters are produced by German manufacturers. Quality guarantee if the product is not manufactured, for example, “in the PRC under control, etc.,” but specifically in Germany. Therefore, when searching in online stores, you should click on country-. The results will only include products manufactured in this country.

German cutters are perfectly balanced, do not create vibrations or beats at high speeds, process wood as cleanly as possible and retain their working qualities for a very long time without sharpening.

Is it possible to do it yourself?

Despite their apparent simplicity, the production of these products requires advanced, high-precision and high-tech equipment. The cutter should be:

- ideally balanced in weight so that there are no eccentric beats at high speeds;

- the profiles of the knives and their location must repeat each other with high accuracy, up to hundredths of a mm;

- cutting edges (knives) must be made of hard alloys, which can only be profiled and sharpened with an even more durable tool.

For these reasons, it is almost impossible to make a cutter yourself without equipment. The exception is simple straight knives on equipment with replaceable blades. In theory, you can cut the desired size from, for example, planer knives. But even here there are problems with balancing the weight and drilling holes for fastenings in solid metal.

In a home workshop you can sharpen some types of profiles. This is done from the back side of the cutting edge, since it is impossible to do this on a curved profile from the side of the tip, sharpened at an angle.

Sharpening is carried out with a flat diamond file. But it’s more effective on a sharpening machine, a thin or bowl-shaped wheel that fits into the niche of the cutter and reaches the surface to be sharpened.

Severe overheating during sharpening is unacceptable, as this will change the factory characteristics of hardening (heat treatment) of the metal. Sharpening is carried out until a small chamfer appears on the reverse side. Then the chamfer is carefully removed with zero-grit sandpaper, using light movements so as not to dull the tip.

How to store

The cutters do not require any special storage conditions. Avoid ingress of water, preferably a dry room to avoid rust. Otherwise, each master stores them in the way that is most convenient.

Complete cutters are sold and stored in boxes. Purchased individually, they can be placed on a board with holes drilled for the shanks. When cutters are needed frequently, they are kept on hand. In other cases, they put it away so as not to interfere.

A hand router is a multi-functional tool with the widest capabilities. First, problems are set that need to be solved. Why is a cutter with a suitable profile selected for their implementation? Beginners should know that a router is not a magic wand that will do everything on its own. This tool needs to be worked. And then all the possibilities that a router with a suitable cutter gives to every master will open up.