The ends are the most vulnerable areas of the logs, since the wood fibers remain completely open and are more exposed to the negative effects of weather factors than other areas. The processes of moistening and rapid evaporation of moisture lead to the formation of cracks at the ends, as a result the logs can crack, which has a very bad effect on the strength of the wooden structure. Treating the ends of rounded log logs with special antiseptic agents will help prevent the development of negative processes. If protective treatment is carried out in a timely manner, the wood dries evenly, which has a positive effect on the appearance of the logs and the log house as a whole.

Why process the ends of logs?

The need to treat the ends becomes obvious if you look at an untreated log that has lain on the street for several years, the ends of which have lost their natural color and darkened, become covered with cracks, and fungus and mold have appeared on them.

This happens because the open ends actively absorb moisture, which then quickly evaporates, and the loose wood structure becomes a refuge for microorganisms and insects.

Moisture evaporates through the end and side surfaces of logs at different rates. Evaporation of moisture through the ends occurs much faster, which leads to the formation of cracks and deformation of the crowns.

Painting the ends of the log house promotes uniform drying of the logs, since the rate of evaporation through the painted surface slows down, and accordingly, the process of cracking stops.

Material selection

We recommend wood that meets the following conditions:

- harvested in winter, when its humidity, due to the slowdown in the movement of juices, is lowest (in warehouses it can be found until the month of May);

- dry in a chamber for at least two weeks before use;

- during natural drying, lasting more than 2 years, it should not be exposed to sunlight, for which a canopy is installed;

- be with a cross-section ≤ 200 mm (less susceptible to cracking).

Glued laminated timber, made from stringently selected and special materials. processing of boards, glued with alternating directions of wood fibers. This significantly increases their ability to resist cracking.

Requirements for protective equipment

The first processing of the ends must be carried out immediately after the construction of the log house.

But since in the first years after construction there is an active process of shrinkage of the log house, it is necessary to treat the ends with a product that does not interfere with the natural shrinkage processes occurring in the wood. An antiseptic for the ends of a log house must have the following characteristics:

- do not interfere with the evaporation of moisture from the logs through the ends along the longitudinal fibers;

- do not suppress the processes of moisture removal through transverse fibers;

- do not interfere with the removal of moisture from the surface.

- protect wood from exposure to ultraviolet radiation;

- prevent rotting processes.

Why is cracking bad?

The first thing that’s bad about cracks is that they noticeably deteriorate the appearance of a wooden house or bathhouse. This is what the owners of such buildings complain about in the first place. Understanding what else is bad about cracks in timber and logs comes later if there is no fight against this defect.

In some sources, however, there is information that a wooden house covered with cracks is beautiful, natural, atmospheric, authentic, and as close to nature as possible. Such information is given to people by companies that harvested the wood at the wrong time, processed it incorrectly, stored it in violation of technology, do not know how to protect the finished lumber from cracking, but are selling it.

In fact, cracks are bad not only because they spoil the appearance of the building. Through them, moisture again enters the unprotected lumber, as well as various microorganisms. And the wood affected by them is already beginning to rot.

In addition, there is another problem associated with cracks in wooden houses. They are called in a fashionable way – bridges of cold. To put it simply, housing turns into a sieve with drafts blowing through it.

How to treat the ends of logs?

The traditional end treatment is lime.

It is still often used for these purposes today. Lime is a natural antiseptic that protects wood from rotting and UV rays. However, the period of action of this product is very short, since the first rain will completely wash away the lime, and the ends will be left without protection. Knowing this, many owners of wooden houses use PVA glue or acrylic varnish to process the ends. But the effectiveness of these products is also questionable, since they form a film on the surface that prevents the evaporation of moisture and interferes with the full air exchange of the wood.

How to paint the ends of rounded logs to ensure their effective protection? Currently, Russian and foreign manufacturers produce a lot of impregnations for processing ends. Among domestic antiseptics, three products are recognized as the best:

- Senezh Tor.

- Neomid Thor Plus.

- Biotor.

Senezh Tor

The product has good penetrating ability.

The antiseptic is absorbed into the wood to a depth of several centimeters, forming a protective layer on the surface that allows air to pass through and repels water. The coating helps remove excess moisture from the wood, prevents the development of putrefactive processes, and reduces the depth and number of end cracks. The antiseptic does not lose its protective properties for several years. The product does not contain solvents and does not emit odor, tolerates frost well and has fire retardant properties. For ease of application and control of treated areas, the antiseptic slightly changes the color of the wood.

Neomid Thor Plus

The product protects the ends from biological damage by microorganisms and insects, prevents the formation of fungus and mold and prevents rotting.

The antiseptic creates an elastic protective film on the ends of the logs that does not allow moisture to pass through, which prevents the accumulation of excess moisture in the wood fibers. At the same time, the coating is vapor permeable, so it does not interfere with the air exchange processes occurring in the wood.

Painting the ends of logs with this product does not in any way affect the aesthetic characteristics of the log house, since the antiseptic preserves the natural color and texture of the wood.

Biotor

It has similar characteristics as the products listed above. Impregnation protects the ends of logs and beams, creating a waterproof transparent coating on the surface that prevents rotting and cracking of the ends, and also reduces existing cracks. The elastic film also helps reduce the linear deformation of wood that occurs during shrinkage.

Compensation cuts

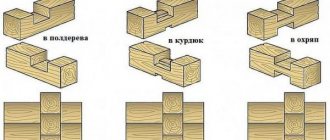

Our ancestors, who had accumulated a wealth of experience, did not make any cuts (except for a longitudinal groove). Modern practice confirms that small cracks (up to 2 mm) appear, and for large cuts it is justified if the following conditions are met:

- location in the middle of the longitudinal groove only on the bottom side, otherwise weakening will occur in two places, which can lead to splitting of logs and beams;

- depth ≤ 1/6 of the thickness of the log or timber;

- logs were dried in stacks for ≥ 1 year.

The cutting device does not affect the formation of side cracks, so this method is not particularly effective.

Processing technology

To provide a wooden house or bathhouse with good and durable protection, it is necessary to adhere to a certain order of work.

Before treating the ends with an antiseptic, it is necessary to perform a number of mandatory operations. The work is performed in the following sequence:

- Trimming of a log house. This operation involves cutting off the protruding parts of the logs. During the construction of a house from otsb, the size of the logs is not regulated. After construction, the length of the logs in the cuts is rarely the same, and the ends, as a rule, are also not perfectly even. The formation of a neat and even vertical plane is done after construction. The protruding ends are cut off with an electric or chainsaw.

- Next, the ends of the frame are polished. Using grinding, the surface is prepared for antiseptic treatment. After sanding, the absorbency of the wood increases, the ends will absorb the antiseptic better and more deeply, which will ultimately increase the period of action of the protective treatment.

At the first stage, rough surface treatment is performed using a grinder with coarse abrasive. Then the ends are sanded with a finer sanding attachment. Processing must be carried out until a layer of undamaged and clean wood appears.

Grinding the ends of a log frame made of rounded logs can only be done in dry weather. You can only process completely dried logs, the humidity of which does not exceed 20%. When sanding wet wood, fluff is formed, which prevents the surface from being smooth and even.

- Protective treatment of ends with antiseptic. The ends are treated with a wide brush at least three times. Impregnation is applied in a generous layer. After the first layer has completely dried (about a day), apply the second, and then after 24 hours the third layer.

- Sealant treatment. This operation is performed after antiseptic treatment to create a durable moisture-repellent coating on the ends that prevents excessive moisture in the wood. For these purposes, it is recommended to use special acrylic sealants.

Wood for building a bathhouse, secrets of its protection and processing

The stages of processing a log house for a bathhouse have their own characteristics. For a bathhouse, it is recommended to use a frame made of coniferous or deciduous wood.

Today, pine is especially popular among customers. Its cost is low, while it deforms little and practically no cracks form on it. The natural release of resin allows you to protect the structure from heat and temperature changes. But due to the resin, internal treatment and additional lining of the premises will be necessary. Experts have compiled several requirements for a log house for a bathhouse, which will help you choose the best option:

- the wood should not emit a lot of resin;

- minimal chance of spontaneous combustion;

- pleasant aroma after heating;

- ability to withstand temperature changes.

End processing after shrinkage

After the initial shrinkage of the log house, approximately 12 months after construction, the ends are painted with a product that creates a durable protective film on the surface. This can be either drying oil or paint containing oil or wax.

Antiseptic treatment is necessary in any case, even if in the future it is planned to finish the ends of the log house with siding, clapboard or other decorative building materials.

will process the ends of the log house at a high professional level. We have been specializing in finishing wooden houses and baths for more than ten years, so we guarantee excellent quality of processing. All work will be completed exactly on time specified in the contract.

To discuss all working conditions in more detail, contact us using the coordinates in the “Contacts” section.

Calculate the cost of painting and insulating your home right now

Select types of work:

Select materials:

Use of protective compounds

The following products are available for sealing cracks:

- acrylic putties are plastic ready-made compounds painted to match the color of various types of wood. They are waterproof, frost-resistant and durable. Dries quickly. Used for sealing small cracks with a depth of ≤ 4 mm;

- acrylic sealants, in their pure form they are laid to a depth of ≤ 5 mm, and for larger ones, a polyethylene rope is placed in the crack, followed by application of sealant;

- an aqueous solution of gypsum and filler (you can use sawdust) and a few drops of shampoo (arbogypsum).

The old-fashioned method is effective - sealing deep cracks with moss. The moss is aged for 30 minutes. in water, wrung out and rolled into a roller. Densely filling the cracks with moss is done with a spatula. After drying, the moss reliably seals all cracks.