Anyone can build a log house with their own hands. This is facilitated not only by simple technology, but also by the availability of the material. Even our ancestors were engaged in the construction of houses, for the connection of which not a single nail was used. Since that time, the construction method has changed very little. But, in any case, without special skills and abilities in wood processing, it is very difficult to expect that the log house will be made using the “into the bowl” or “in the paw” method according to all the rules.

Preparation for construction

When thinking about cutting down a hut using the “in the bowl” or “in the paw” method, you first need to evaluate this project from the financial side. In practice, the costs are more than significant, although the technology involves the use of simple and accessible tools and eliminates the need to perform additional actions other than wood processing. However, everyone should be prepared for the fact that the process of cutting a log house “into a bowl” or “into a paw” will take a lot of time.

Still, this is not the same as building a frame house. Sometimes the deadlines can drag on even longer if poorly dried timber was purchased for the work. In this case, you will have to wait at least a year for the logs to go through the drying stage according to all the rules.

Foundation

If you are still determined to make a log house “in a bowl” or “in a paw,” then at the initial stage you will have to resolve the issue of the foundation. You have two options - choose a pile foundation or a regular poured one. Experts recommend choosing the first one, since it is more economical, requires less time for construction, and is also simpler in terms of technology.

Naturally, if a person gets down to business and is hearing about the “in-the-cup” or “in-the-paw” technology for the first time, then he will be interested to find out whether this work can really be done with his own hands and how the production of the log-in-the-paw takes place.

If we compare this structure with others, its main features include the presence of a regular shape and the absence of protruding ends of the logs. It is recommended to cut a log house from logs “into a bowl” or “into a paw” from timber of the same thickness.

Material

To cut “into the bowl” or “into the paw”, it is necessary to prepare the material; for this, the ends are marked on it. Elements with a minimum diameter are used first for assembly. During the construction process, you must remember that the log is always thicker on one side. Therefore, during work, the tree can “move apart”. But you can avoid this if you make a spike in the inner corner. To apply precise markings, it is best to use templates. They are made from cardboard, and when the templates are ready, all that remains is to attach them to the ends and cut out a spike along the contour.

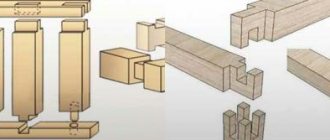

Joining the timber with the remainder

The easiest way to join timber in the corners of a log house is “into the floor of the tree”. A rectangular groove is cut, the dimensions of which depend on the thickness of the timber and are: The depth of the notch is half the thickness of the timber. That’s why it’s called “half a tree”.

Connecting the timber in the corners with the remainder - in half a tree, in a fat tail, in an okhryap

The “tail tail” method is distinguished by the presence of an additional tenon, which provides a stronger and more reliable connection, but requires more carpentry skill. More difficult is connecting the timber into an okhryap. Here you cannot make a mistake when calculating the width of the jumper, but it is much easier to implement than on a log: the geometry here is standard and you can use a template, which significantly speeds up the work, and then an error can only occur when cutting.

Making paws

Beginning builders are recommended to cut a log house according to the simplest scheme - a “straight claw” connection. It differs in that it has only horizontal and vertical lines of the teski. To ensure a more reliable connection of elements, it is recommended to choose cutting with an oblique paw. In this case, the inclined planes will firmly hold the log and help prevent it from twisting.

But regardless of the chosen option, the following rules must be observed during the felling process:

- As part of the preparation, the “block” needs to be cut from all sides.

- When determining the depth of the notches, they are guided by the width of the “block”.

- After the completed operations, the result should be a parallelogram-shaped structure with a square cross-section at the end.

- Markings are applied to the end, the result should be 8 identical horizontal parts.

- Next, the type of paw with which the elements will be connected is selected, and marks are placed on the plane along which they will be connected.

- The pieces of wood that are outside the boundaries of the applied marks must be carefully removed, and then, focusing on the resulting paw, a template must be made.

- The template obtained from cardboard is used when cutting the remaining logs.

Applying markings to the log house

Making grooves is quite simple, but high-quality felling can only be done with proper marking of the ends of the logs and beams. If you use timber, the material should always have the same thickness; the more massive the log, the smaller the number of connecting grooves in the corners will become, thanks to this the building will be much warmer. For a sample of log cutting, you should take a smaller log, and compare others using it.

Considering the diameter of the beam, the dimensions of the paw can be determined using the size table below:

When marking timber, it will be easiest to make a template version than to process each one separately. Most often, templates are made of thick cardboard. Marking is done by simply placing the marks on the ends of the logs. For a high-quality cut of a log house you will need:

- hacksaw;

- axe;

- chisel;

- electric or regular plane;

- roulette;

- level;

- plumb line;

- hammer;

- mallet.

The area facing the future room is processed with a planer. The other side of the beam should be processed only from the ends; the length of the section is processed in compliance with dimensions of approximately 2-2.5 times the diameter of the log. The remaining sides are processed from the ends to 1-1.5 each.

Corner connections

The greatest difficulties for craftsmen who decide to cut a log house from logs arise with the manufacture of a rounded coupling in the timber. However, there is no great need for this, since there are special techniques designed for joining the crowns of logs.

- To connect the walls, a dowel is used, which seems to penetrate these structures. These fasteners are nothing more than wooden vertical nails with a diameter of approximately 30 cm and a length 20% less than the height of the frame.

- Also in construction, specific types and methods of corner joints are used. Special tenons are prepared for them, which can be composite and cut into the material.

- In the process of this work, it is necessary to strictly observe the rule: when connecting elements, which is a necessary operation when building a log or block house, care must be taken to ensure that there is a certain vertical gap. Its purpose is to compensate for the effects of natural shrinkage that accompanies the construction of each wooden object. This gap should be no larger than 0.5 cm. When making longitudinal mounting grooves, the gap size is increased to 1 cm.

Half swallowtail

With this connection, the tenon is sawed down into a cone. The characteristics of the half dovetail connection do not differ from the knot described earlier. But the strength indicator increases. The conical cut securely holds the beams and prevents them from moving apart. This connection is used in the construction of walls with a length greater than the length of the beam.

We suggest you read: What you need to know about a gas sauna stove before buying it

There is no difference in the complexity of manufacturing when joining a half dovetail and a straight tenon. Both methods are performed with or without a template. For an experienced professional, the difference in the labor intensity of making these joints is almost imperceptible.

The half dovetail tenon should not be more than 5cm at its widest point. Otherwise, a crack will appear in the timber with the groove. This happens due to uneven shrinkage. The picture shows this place.

If the half dovetail spike is more than 5 cm

Construction

At this stage, a plane or grinder , with which it is necessary to level one side of the beam. It will subsequently become the inner wall of the house. The other sides are treated a little differently - they are processed at the edges.

In accordance with the accepted technology for assembling a log house, markings are applied to the site chosen for construction, after which the first two logs are placed so that they are located opposite each other. After this, two more pencils are placed on them at right angles.

The resulting square is called the main crown in construction. It must be checked for compliance with the level, and only then proceed to applying markings on both ends of each beam. Particular attention should be paid to the landing socket, the size of which should not exceed half the diameter of the beam. The created depression is used to lay the next log.

The remaining upper part of the paw must be prepared for the next element - it is leveled, which ensures a tight fit of the next element.

Sometimes builders do not have enough skills to ensure that the elements of the log house fit together as tightly as possible. If even with the help of an ax nothing can be done, then a wooden wedge that needs to be driven into the crack will help get out of this difficult situation. However, experts still recommend avoiding such connections.

At this stage of construction of a log house, it is necessary to select the type of connection. This issue needs to be given special attention, since the clutch must be as tight as possible so that the beam does not start to “walk.”

One of the schemes often used in construction is a scheme that involves making a through hole in the paw, into which a stake, called a straight tenon, is subsequently driven. You need to choose it so that its diameter is slightly larger than the hole. This operation is performed according to the chess principle. In other words, each new stake should not fall into the previous one. If there is such a need, you can reinforce the structure using straight spikes that need to be driven in around the perimeter. This measure will help avoid deformation.

A more reliable method can be proposed, however, due to its increased complexity, it is suitable only for experienced builders.

- In accordance with it, at the initial stage you need to apply markings, and there should be a spike on the paw protruding 2-3 cm upward. Here it is important to correctly determine its area, which should correspond to a quarter of the paw.

- Cut out a hole of suitable size for it.

- Within the framework of this technique, the connection of the lags is carried out according to the same scheme that is used in the children's Lego construction set.

- To install the tenon, as a rule, a place is chosen next to the inner corner.

Altitude bonding

When constructing wooden walls and partitions, masonry made from solid timber of natural moisture is reinforced with dowels, staples or “coupling” fastening. The corrugated timber has increased adhesion; reliable adhesion of the crowns is ensured by the tongue-and-groove connection.

The most common construction operation for height bonding is the construction of walls. Dowels with a diameter of 25-30 mm are used as connecting elements; one dowel holds together several crowns. To fix masonry made of corrugated timber, dowels are required 2-3 times less. The dowel connection is reliable and retains its properties throughout the entire period of operation of the structure.

With the help of fastening “on the coupling” they prevent deformation and the formation of cracks when the lumber dries, the screw tie creates an adjustable vertical tension.

Final work

When using this method of making a log house, it is necessary to perform additional finishing inside the room . Having finished laying the logs, they proceed to processing the material, using special compounds to prevent parasites and rot. Along with them, it is recommended to use preparations that increase the fire resistance of wooden elements.

Logs in the paw

Another mandatory operation that is performed in the process of making a log house is insulating the corners. The material can be a board, or you can take any of the modern heat insulators and lay it on the inside. As the wood dries, gaps will begin to appear between the feet. They also need to be dealt with by treating them with a solution or driving wedges into the crevices.

Material selection

For any log houses, it is recommended to use coniferous wood with natural moisture, felled in winter, preferably from the northern regions. Pine is the cheapest, larch and cedar are more expensive, but stronger and more durable. The trunks must be even along the entire length and of the same size.

Removing bark from all sides of logs is done using a special tool called a scraper. You can also remove the bark with an ordinary shovel with a cut off spout and a sharpened bottom edge. It is unacceptable to remove the bark mechanically, using power tools, chainsaw attachments or grinders, since the upper layers of the main wood will be damaged along with the bark. After which the workpieces are stacked with spacers for ventilation and covered with roofing felt. Drying lasts ≥ 6 months.

The timber must be dry, free from visible cracks, mechanical damage, falling knots, rot and mold or mildew.

Common Mistakes

In accordance with the log house manufacturing , assembly is carried out using groove joints. For fastening, only wooden wedges can be used; the use of metal is not permitted by this technology. If you break this rule and use staples or metal nails, this is guaranteed to cause the wood to rot.

the shrinkage of the log house is completed , it is impossible to move on to covering the walls, terraces and ceilings, as well as flooring. Otherwise, it will be necessary to carry out a labor-intensive operation to dismantle the frame in order to correct the groove joints. The fact is that such haste can lead to the appearance of cracks and distortions in them.