Reviews from owners of houses made of laminated veneer lumber are mixed. Some owners of country houses do not like this material, while others believe that there is nothing better than it in the world.

General information

Short description

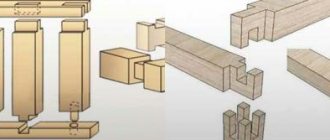

Glued laminated timber is a structural, high-tech wood material. It is made from several layers of wood lamellas (boards, fragments), which are first folded into bags with the required thickness, and then glued under a press. At the end, the material is ground and profiled on a machine. The lumber is intended for the construction of low-rise cottages and other small buildings on a summer cottage.

It is used to create load-bearing walls, floor joists and roof rafters. You can use it to build not only a house, but also a garage, gazebo and even utility yards. It is also used for the manufacture of furniture, stairs, windows, doors and other carpentry products.

When producing laminated veneer lumber for the construction of private houses in Russian factories, the following types of wood are most often used:

Larch.- Pine.

- Cedar.

- Spruce.

The production of timber involves complex, deep processing of raw materials. They use everything - even the trimmings that remain after sawing the wood, and at this stage of sorting, the lamellas that have received defects are rejected or unsuitable areas are simply cut out of them. Thanks to the unique gluing technology, it is possible to use even small fragments.

In the end, the highest quality lamellas come under the press without damage. Before gluing them together in the form of timber, all lumber goes through a preliminary stage, namely drying in a chamber. The resulting product, after being placed in the log house, no longer warps, since it contains little moisture, which means there is simply nothing to evaporate under the sun. Compared to a profiled log house, laminated veneer lumber is a little stronger and smoother during manufacturing. During operation and storage, it does not warp, and after drying in the chamber, its humidity ranges from 8 to 17%.

We also note that, according to reviews from real owners, shrinkage of the walls of a house made of laminated timber is completely excluded. Over the course of a year, they can settle by a maximum of 1%. Compare - a structure made of solid profiled timber or rounded logs with natural humidity will shrink by 11-15% over the same year. The lumber in question has high structural strength due to the fact that the ends are milled before applying glue to it. The surfaces that are glued take on a serrated profile, which guarantees a very strong connection between the boards when bending.

Varieties

Glued laminated timber according to its purpose is divided into:

- Window and door.

- Wall.

- Supporting (bearing).

The second option is used to make the walls of the house. The first is used to make furniture, windows and doors. The third type of timber is used to create load-bearing supports, staircase and roof frames, interfloor beams, etc. The edges of lumber for walls can be either smooth or with spikes to create a strong connection. The remaining types are made rectangular or square in section without cutouts.

Final recommendations

Glued laminated timber is initially classified as a high-quality and durable building material; log houses built according to all the rules last for decades. Maintenance of buildings is minimal, but mandatory, in order to eliminate the risks of shrinkage and rotting:

• every 5-10 years the protective and antiseptic coating of the timber is renewed; • seams and ends are inspected once every six months; • once a year the general shrinkage of the house, the condition of the roof and rooms with high humidity, the operation of ventilation ducts and drains are checked.

Detected areas of rot and similar problems are eliminated without delay. Particular attention is paid to the cellar (if any), bathrooms, toilets, and areas adjacent to foundation and roof structures.

Now you know the answer to the query: laminated veneer lumber, pros and cons.

Details about types of timber

By profile

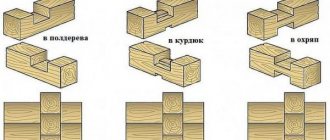

According to the profile of the working side, the most common types of laminated laminated wall timber for the home are Finnish (Scandinavian) and comb. The second option has small rectangular teeth both at the bottom and at the top of the beam. When laying, these spikes help create a reliable connection. But keep in mind that if the material is of poor quality, the teeth on the material may not match each other, and then you will have to spend a lot of time on adjustment.

With Scandinavian-type timber, the combs together when profiling create a “tongue-and-groove” type sound, which has a recess in the middle. This profile makes it possible to lay a layer of insulation into an existing recess, and this will be completely invisible from the outside. As a result, a house made of Scandinavian-type timber will be warmer. In addition, it will have to be sealed less, which will speed up the construction process.

By type of design

Glued laminated timber for the internal structure for assembling the walls of a wooden building can be purchased in the following types:

Uninsulated (cheap).- Insulated (a little more expensive).

- Bent, to create curved railings and arches.

The insulated version has a layer of thermal insulation material. If you use this type of material, you will not have to buy an additional layer of insulation for a wooden house. But keep in mind that the standard option - uninsulated - is much cheaper. If the thickness of the timber makes it possible to do without additional insulation, then it will be more profitable to purchase it.

In terms of price, the bent version will cost 70-100% more than an analogue with the same cross-section, but without curvature. But keep in mind that without such material it will be difficult to create curved shapes in the interior of the house. This material is both a decorative timber and a structural material with a high level of strength. You can use it to make stairs, arches and other interior structures with curves.

Glued laminated timber of a load-bearing type can be up to 30 cm in cross-section. Products for making windows have a width and thickness of approximately 8-9 cm, and for doors approximately 12 cm. Wall laminated timber without a layer of insulation in cross-section has dimensions from 10 to 18 cm, and the thickness of the insulation in the case of purchasing a similar material with a layer of thermal insulation is 27 cm.

Standard or individual project?

At the beginning of any construction, a project is selected. Design allows you to competently plan the space and calculate the cost of work. Construction without a project takes longer and does not guarantee results. At such construction sites, all issues are resolved during the construction of the structure, which is completely ineffective. Before placing an order to create a house project, you need to determine its type. You can choose a standard project or order an individual development with a detailed plan.

- Typical. Standard designs that have most likely already been used in the construction of other buildings. They are completely suitable for work and can be agreed upon by different authorities. Such a project is suitable if the construction budget is limited and the cost of the project is important. You can also choose a standard plan if you don’t have time to wait for a custom plan. If you do not plan to live in the house all year round, then a conventional layout will also suffice. Standard projects have certain disadvantages. For example, they may not be suitable for certain landscapes or specific sizes. Also, the layout of the premises does not always coincide with the wishes of the future owners.

- Individual. By ordering such a layout, you receive guarantees that the architects will take into account any of your requirements. Each step in the development of such a project is discussed with the customer. A specialist creates a functional structure for living all year round. This design method is suitable if nothing in the catalogs with standard projects suits you. Also, an individual plan is relevant for customers who already have a clear idea of their ideal home. It happens that standard buildings (small or non-standard plots of land) cannot be placed on the territory. In this case, individual design will also be required. The disadvantages of this solution include the high price of architects' services. It also takes a lot of time to create such a project.

Features of choice

When choosing laminated veneer lumber for a home, based on reviews from owners, the main attention should be paid to the following aspects:

- The quality of gluing boards and drying the material.

- The absence of bark (wane), uneven cuts and cuts on the lamellas.

- Correct geometry - each plane of the profiled timber must be polished and even, otherwise you may end up with a crooked building.

- Type of construction - the purpose of support and wall products is different.

Please note that the thinner the lamellas are used for gluing, the higher the strength characteristics of the material will be and the more durable the housing will be. This lumber is not afraid of water. Moisture is harmful to wood, but the adhesive layer between the boards of the timber will not collapse. If the material suddenly delaminates, it means that you bought defective material, which was glued together with glue whose shelf life has long expired.

When producing lumber for housing in Russia from laminated veneer lumber, adhesive compositions based on polyurethane or melamine are used. The fact is that such adhesives do not contain phenol, and if there is formaldehyde, it is in minimal quantities. Therefore, you can safely use these types of glue and not worry about the health of your family. The source of phenolic and formaldehyde fumes should be looked for in completely different places. Houses made of timber often use a huge amount of finishing materials. Most likely, they are the ones who will emit harmful substances. Non-woven wallpaper, linoleum, paint and varnish - look for the cause of the pungent odor and deteriorating health in them.

But this only applies to high-quality materials. Before you make a purchase of laminated veneer lumber, you should ask your consultant for certificates that indicate absolutely all the characteristics of the product. You should buy this type of building material only from manufacturers who use high-quality adhesives. This will be your guarantee that there is no phenol in the lumber, and also that the material is not defective.

Dependence on temperature conditions

The peculiarity of wooden housing is its fairly strong dependence on humidity and temperature conditions. In order for the log house to last as long as possible, several rules will have to be followed during the construction and commissioning of the house.

- Maintain a comfortable temperature of 21-22 degrees.

- Monitor the humidity level. The optimal interval is 45-65%.

- Avoid sudden heating of the structure.

Advantages and disadvantages

The advantages of profiled laminated timber include:

A small percentage of shrinkage of the log house and lumber in general.- The ability to enter the building and begin finishing work immediately after laying the walls.

- Easy to install.

- High speed of creating a cottage from timber.

- Excellent characteristics of strength, thermal insulation and moisture resistance.

- Light weight of finished products made from wooden lamellas that have undergone gluing.

The interesting thing is that assembling a house from laminated veneer lumber can be done without even using special equipment; you only need the help of a friend, and this is a big savings. Although the material for building walls will not be cheap, you will be able to save on the construction crew, and this is already a lot. You will definitely be able to do everything yourself.

But there are also some disadvantages:

- High cost of material.

- Ugly appearance (you will have to spend money on finishing).

- There is no natural circulation of air and steam through walls made of laminated wood.

This building material can only be called environmentally friendly with a stretch. The timber, even in minimal quantities, still contains synthetic glue, but the good news is that it does not cause serious harm to human health.

Problem 4. Gaps between the rims

When using profiled timber with the correct geometry and following installation technology, this problem is not critical. However, it is still inevitable. The reason is the same shrinkage of the log house, which cannot be ruled out. As a result, gaps may form between the crowns, which during the operation of the home turn into cold bridges.

Solution . Repeated caulking allows you to completely eliminate this problem. To accomplish this, either traditional sealing materials or sealant are used. Re-caulking should begin after the period of most intense shrinkage has ended. That is, a year after the construction of the house.

Owner reviews

If you look at the photos, the houses look great. But let's talk about something else - reviews from owners of houses made of laminated veneer lumber differ, as some attribute undeserved disadvantages to the material, while others over-praise it. The main disadvantage, which many agree with, is exceeding the maximum permissible concentration for phenol and formaldehyde, since it is impossible to deny the fact of the presence of fumes from the glue used. But the fact is that the vapors are never phenol-formaldehyde. If there is an unpleasant odor at home, look for its source in the furniture or decoration.

The main mistake of all those who are dissatisfied with houses made of laminated veneer lumber is the complete absence of forced ventilation in the housing. Walls made of this building material are simply not designed to allow air to pass through. In cottages of this kind in the West they always create a forced ventilation system, but in Russia everyone is accustomed to the fact that there is also a natural one, which is what causes the whole problem.

Positive reviews

Anna, 30 years old: “My husband and I have a house made of timber, which we built 5 years ago. We have never regretted that we chose this particular material and not, for example, brick, which turned out to be very affordable. We decided to insulate the outside with polystyrene foam; we also planned to use foam polyethylene, but a friend involved in construction dissuaded us and recommended only polystyrene foam. Fortunately, it’s really warm here in the winter, and the house is pleasantly cool in the summer.”

Sergey, 45 years old: “I built a house from laminated veneer lumber. I covered it with siding on the outside and used aqua panels for the interior. Don’t forget that the material is alive and you can breathe beautifully in it! In winter the house is always warm, children run around in shorts and T-shirts, but in summer it’s not stuffy, we didn’t even buy air conditioning. For me, this material has only one drawback - there is a lot of dust in the house from wood, to which I am allergic, so choose furniture and floors in light shades and do wet cleaning more often.”

Mark, 27 years old: “I’m currently building a house from laminated veneer lumber. Why exactly from this material? Because as soon as the construction is completed, you can immediately move into the house, and for my wife and I this is important - there will be a new addition to the family soon and I wouldn’t want to carry a little one into a rented apartment. I'm also pleased that the material does not crack. The main thing is that you choose a good supplier who will sell only high-quality timber. Good material will not even need to be insulated if its thickness is from 18 to 20 cm, and the laminated timber is durable and will not begin to mold or rot. I’ll try to push it and we’ll move into our own house soon.”

Inna, 32 years old: “I used to live in an apartment, but the children are asthmatics, so it was decided to sell the apartment and move out of town. Fortunately, my income is enough for construction. Since I couldn’t do everything myself, I contacted different companies, even went to the factory to personally control the choice of material. My relatives helped, and the owners of the company showed me all the documents that interested me. Now the house is under construction, but I have no doubt that me and my family will be comfortable in it.”

Maxim, 50 years old: “Strangely enough, laminated veneer lumber is the best material, albeit expensive. He definitely won’t let you down, and you won’t be in for an unpleasant surprise. Another plus is that no finishing is required. Even if you just paint the house, it will already look amazing.”

Negative reviews

Evgeniy: “I don’t know how anyone can consider laminated veneer lumber beautiful, but this is a matter of taste, let’s leave it out. Firstly, it smacks of industry, and secondly, finishing will be required in any case. You’ll still have to caulk everything up, otherwise it will lead.”

Alexander: “Are you really ready to live in a wooden house all year round? It’s okay if you just stay in such a house, but living permanently is hell. My relatives lived in such a house, and they were constantly uncomfortable, so they lined the inside walls with plasterboard.”

Valery: “I’m not satisfied with the price. The cost of the material is just terrible! Do you understand that building a house from the same aerated concrete will be almost 2 times cheaper? Then the point is in buying an expensive material, especially since aerated concrete is considered breathable... Remember that you will have to spend money on finishing, furniture, communications, such a thing can cost you 7-8 million.”

Humidity

Any material of wood origin is very strongly affected by water and steam. On an intuitive level, it is quite difficult to understand exactly what processes are responsible for the destructive impact, however, the obvious need to insulate the tree is beyond doubt. One of the most interesting effects in this regard is the dew point. This is a specific physical phenomenon when, at sub-zero temperatures outside, a layer of space appears in the walls of the house, in which ice turns into water due to the difference. Rotting inevitably occurs, which leads to rapid wear of the wood. To neutralize this process, it is recommended to first completely insulate the walls of the house from moisture from the inside. This requires the painstaking work of a person with experience.

Poorly sealed cracks can also lead to the house being blown through by the wind, which can significantly disturb residents during a snowstorm. Strict adherence to this simple but rather specific technology is important.

Natural properties of wood

Timber is a fairly versatile material; it is considered convenient to work with; most often it is considered as an environmentally friendly option, completely safe for human health. It is worth noting that all of these statements require significant qualifications.

Modern store-bought timber is dried in a not entirely natural way: in a very short period of time it is dehydrated in ovens at high temperatures.

Externally, the material looks almost the same, but the internal properties deteriorate:

- In this process, resin crystallizes in the wood, which negatively affects strength and resistance to decay.

Environmental friendliness is a relative concept, since wood remains completely safe for human health no longer than before the first treatment with impregnations and fire retardants.

Varnishes are also synthetic substances, and such construction is extremely rare without them.

Soundproofing

Today, many construction organizations look at this parameter especially strictly, since it really affects the quality of living. In a completely wooden house, external sounds can behave completely differently, but most often you have to deal with the phenomenon when they are not only not damped, but are also enriched with new overtones and noise. It’s hard to say how bad it is, but for some owners, the creaking of floorboards and the howling of the wind are exactly what can irritate and bother them.