In apartment buildings, flights of stairs perform an extremely practical function, helping residents move between floors. Such structures are included in the standard building design, so they look gray and nondescript. Owners of private houses find themselves in a more privileged position.

They can design the staircases at their discretion, making the porch to the house or the ascent to the 2nd floor truly interesting. For this, different building materials are used, and among the variety presented, a log staircase looks quite original. It is noteworthy that you can make such a flight of stairs yourself, without resorting to the services of specialists.

Elements of stairs

The staircase structure consists of supporting elements, steps and railings (see). They are best made from oak, larch or beech.

These wood species have excellent strength and resistance to the vagaries of nature. However, the price of these materials is not always affordable.

More often you have to be content with budget pine or spruce. It is recommended to make outdoor stairs only from coniferous trees, as their increased resin content will help protect the wood from moisture.

Staircase supports are made from debarked or rounded logs.

Here's the second option.

steps

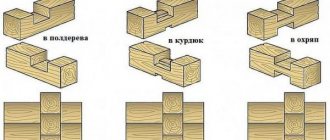

Log steps can be made from debarked or rounded material in the following ways:

cutting the log lengthwise into two halves;

In this option, the role of the tread will be played by a flat surface, and the roundness will act as a riser.

by hollowing out treads in a solid log;

sawing logs into separate blocks;

sawing wood into elements across its length.

Fencing

For log structures, ordinary standard posts, handrails and balusters are also suitable. However, they will look quite simple and ridiculous in combination with the main components of the staircase. It is best to use elements made from tree trunks or branches.

The assembled staircase structure must have the following parameters:

- The angle of inclination of the ladder to the surface on which it is installed: 30-45 degrees.

- Staircase width (minimum): 900-1000 mm (internal structure can be 800 mm wide).

- Step depth: 260-320 mm.

- Height between steps: no more than 200 mm.

- Fence height: from 900 mm.

A staircase with such parameters will be convenient and safe to use.

Types of log structures

The main idea of a log staircase design is semicircular steps. They are made by longitudinally cutting logs that are similar in diameter. When the cutting plane is facing upward, it is perfect for a tread, and the lower hemisphere will serve as a riser. The result is an ideal staircase that meets regulatory requirements.

Judge for yourself: the height of a log riser is half the depth of the tread. If we take a 30 cm log as a basis, then after sawing the height of the step will be exactly 15 cm.

There are many designs of staircases built from logs; when working with this material, the imagination of developers knows no bounds. Conventionally, they can be divided into several groups:

- An ordinary staircase on 2 log strings with the same steps. It is complemented by balusters and railings made of round timber, and can be rotated 90 and 180°. This is one of the most common options.

- The same with steps in the form of blocks (from the end they look like a truncated hemisphere).

- A flight of stairs made of half-logs or blocks mounted into the wall in the form of consoles (1 end of the step is fixed).

- The same, but with a bowstring to support the second end of each tread.

- Spiral cantilever structure, where the end of each step penetrates through a support column made of large diameter logs. The structure is a spiral staircase, only made from solid processed wood.

The spans are particularly original, where treads with ends bent upward are hollowed out in the steps made of half-logs. Bowstrings in such structures can be located both on the sides of the steps and below, depending on the material.

Manufacturing work

Making the components of a spiral staircase is a rather complex step that requires patience and care. You will need skills in working with carpentry tools and machines.

Opening

If the staircase was planned from the very beginning, then, most likely, an opening has already been provided for it. But there are times when the idea of an attic comes during construction or after reconstruction of the roof. It is at this moment that the correct calculation and manufacture of the opening for the screw structure will be required. Depending on the chosen staircase design, the opening for it takes the appropriate shape: rectangular, square, oval or round. The basic rule, which will subsequently help when installing the stairs, is to maintain a gap of 10 cm to the elements of the stairs. This is also done as a reserve if there are railings, so that your hands do not touch the wall.

In order for the staircase to be located exactly where it is needed, it is necessary to clearly align the lower center point with the upper one. For these purposes, you can use a special laser plummet. It will allow you to accurately transfer the mark of the screw structure from the floor to the ceiling, after which you can drill a through hole, marking the desired circle. There is another option for combining the points of the screw structure. To do this, a hole is drilled from the top floor and a plumb line is lowered on a rope, by the tip of which it will be possible to determine the center of the required circle.

steps

The best material for making steps is hardwood. They have sufficient rigidity to withstand the load of a person’s body weight for a long time. The most commonly used are oak or beech. You should make your choice on a treated board. This will save time and also allow you to see the structure better. The blanks for the stairs must be well dried. If this is not done, then after installation deformation may occur, which will cause damage to the screw structure. The optimal thickness for steps with a span of more than 2 meters is considered to be 6 cm. It can be difficult to find a board that would fit best. Therefore, it is possible to produce glued elements.

To do this, the board is cut into even pieces into small strips and glued under a press. In order for all the steps to be the same, the correct solution would be to prepare a sample. It can be made from cardboard or a piece of thin plywood. The dimensions for the sample must be taken in accordance with the calculations that were carried out for the spiral staircase. When transferring lines from a sample, you should be careful, especially when making curves, as well as the hole into which the central post will be inserted, if there is one. The illustration above shows how best to place the template on the workpiece

Particular attention should be paid to the last step of the stairs. The one that will go to the second floor

Its dimensions should be slightly larger than the other elements of the screw structure. You can use the same pattern for it, but after drawing the lines, you need to slightly increase its dimensions.

Note! After the steps are cut, they are further processed. To do this, elements of a spiral staircase can be passed through a jointing machine, and also passed through a milling cutter

An excellent solution would be to drill holes with a long drill through several elements, which will be rigidly secured to each other with a clamp.

Balusters

In the case where the spiral staircase is located at some distance from the walls, balusters can be made that will perform a decorative function, as well as a protective one for those who use the spiral staircase. Glued laminated timber is also prepared for them. The most commonly used blanks for a spiral staircase are 50x50 mm in size. They are clamped into a wood lathe and a pattern is applied to them according to the drawing. When using fixation only due to the middle post of a spiral staircase, the steps may rotate. To prevent this from happening, the balusters are fixed closer to the edge of the step, and they are lowered in such a way as to fix two steps at once.

Note! Attaching balusters to a spiral staircase can be very diverse. They can be put on prepared pins or glued into the hole provided at the edge.

MARCHING

The most common type. A distinctive feature is easy and quick installation. Such a staircase consists of one or more flights. It has not only steps and handrails, but also a base. This can be like a stringer (in the form of a beam with a comb on top), a bowstring, or a support post.

Many people believe that a flight of stairs is too simple and primitive a structure. However, it is not. After all, the structure is made not only straight, but also rotary, as well as curved in the form of the letter “P” or “G”. In addition, such stairs are convenient for moving people and moving large objects.

Marching stringer stairs are in demand among MariSrub clients. This performance looks solid and majestic. However, such stairs are massive and require a lot of space, so they are not suitable for a small room.

Advantages of a log porch

Making a porch from rounded logs is easier than building a regular platform from timber and boards with steps on stringers or strings: calculations will take less time, and you can do the assembly yourself. In addition, this design has several other advantages:

- Strength and durability. Such a porch does not require additional fastening elements: the base logs and steps are pressed tightly against each other simply due to gravity, so such a structure will not become loose even after many years.

- If assembled correctly, the steps will not begin to creak. If the half-logs are tightly packed into the mounting bowls, friction will not occur. For assembly, it is better to order a rounded log at the enterprise: machine processing will allow you to obtain mounting bowls of an ideal semicircular shape.

- Solid and aesthetic appearance. The structure is massive, it is in perfect harmony with the appearance of the house made of cylinders. In this case, you can use the same finishing option as for the main walls, or, on the contrary, paint them in contrasting colors to attract attention.

A log porch is ideal for houses decorated in the “Russian hut” style. The porch canopy can be decorated with wooden carvings or ornaments. Also, not only turned balusters, but also forged metal parts are often used for decoration.

This is not just an entrance to the house, but a full-fledged decorative element that will earn the praise of guests. It is erected from rounded logs very quickly; it is a simple and at the same time very reliable solution.

This is interesting: Making a porch from concrete - a generalized view

Types of wooden porch

There are a huge number of design options, but there are only two architectural options.

- Frame porch made of timber and boards. A frame of the required dimensions is assembled from timber, a staircase and a platform are fixed to it. Railings and a canopy can be used as additional elements. If desired, such a porch can be protected from the wind from the sides. In terms of complexity, construction is a simple option and does not require special training or professional skills.

Frame porch made of timber and boards

- Log porch. A more complex design, but very reliable, durable and beautiful. Allows you to create building facades in a traditional rustic style. A log porch can be used as an entrance to residential buildings, bathhouses, outbuildings, gazebos, etc. For construction, you need to be able to perform carpentry work, handle an ax and a gasoline saw.

Log porch

Porch made of logs

We will tell you step-by-step instructions for creating both types, indicating the features and secrets of construction work. But first, we should consider the general requirements for all elements of the porch.

Positive and negative sides

The strength of log staircases is their unique appearance, and such a staircase will look great not only in a log or log house, but also in cottages built from other materials. There are other advantages:

- an obvious plus is environmental friendliness;

- durability;

- safety during operation;

- wide scope of application; from round timber you can build a large interfloor staircase, a rise for a porch or a slope on a site.

The main negative side of log structures is the high cost, based on the price of high-quality material, the cost of its processing and installation work. Not everyone can build a beautiful log flight inside a house with their own hands; it requires skills and knowledge of techniques for hidden fastening of wooden elements.

The structure made of round timber is quite massive, which is why it requires installation on a reliable foundation. The exception is cantilever options, in which the steps are built into the wall. Wood also requires care and careful handling. For example, walking up such a good staircase in dirty boots is unacceptable; dirt is difficult to remove from wooden surfaces.

Characteristics of the staircase structure

Before you decide to build a log staircase, let's take a look at the pros and cons of this design. Stairs made from logs have a number of distinctive characteristics compared to other manufacturing materials.

Positive qualities of the material:

- Environmentally friendly material;

- Easy to handle during installation;

- Long service life with proper care;

- Warm and cozy material;

- Unforgettable appearance of the staircase structure.

Log steps are reliable and eliminate the possibility of creaking and sagging of the tread when walking on them.

Like any manufacturing material, wood has not only positive qualities, but also negative ones, namely:

- A characteristic change in color, under the influence of moisture, light shades darken over time;

- Logs have a lot of weight and it is necessary to accurately calculate the load on the frame;

- This is a rather labor-intensive method of installation; it will be difficult for one person to install steps made of logs.

Porch materials

It seems that everything is simple - the porch of a wooden house should also be made of wood and the most appropriate thing is to finish the porch with boards. However, not everything is so simple, because it is located on the same level as the base. Then wouldn’t it be better to finish the porch “to match” it? Next, be careful - there must be an appropriate base for different finishing materials.

Quite often the base is lined with natural stone - “cheap and cheerful”. It would be a good idea to continue to maintain the natural style, so finishing the porch with stone would be quite appropriate for the side walls. It is even preferable to lay these walls out of stone - it will be even more reliable and less concrete work will be required.

It’s a completely different matter if you plan to lay tiles on the steps and area near the house. Most likely, not many people will consider it appropriate to create a three-dimensional reinforced concrete structure near a wooden house. You will have to put together a deck on poles, fence it, attach reinforcement and concrete it. In addition, you will need to make metal steps for the porch and cast a screed in them. It turns out that finishing a porch with tiles is a relatively expensive pleasure, but it’s worth it - tiles are many times stronger than wooden flooring.

Requirements of building codes and regulations for structures

Before starting work, it is recommended to make a sketch of the structure, taking into account the following provisions

- Site requirements.

The porch area should be spacious enough

It can be located on separate vertical supports or fixed to the façade wall on one side. There is one recommendation regarding the size - the width should allow at least two people to separate without any problems, in most cases 1.5 meters is enough. In addition, the platform must allow the door to be opened by a person entering from outside.

The bottom edge of the door should be 5 cm above the porch floor

There is one limitation in height - the level of the platform must be three to five centimeters below the level of the bottom plane of the doors. This is explained by the fact that the porch will rise in the winter, if you do not make a gap, the doors may jam. For safety reasons, the entrance doors must be opened outwards, and the difference in height eliminates the negative consequences of heaving of the earth during freezing/unfreezing.

- Requirements for steps.

Width of stair steps

The width of the staircase is at least a meter, the height is approximately 16–18 cm, the length of the steps is 25–32 cm. How to calculate the parameters of the steps? For example, the height of the platform is 120 cm, divide this value by 18 cm and get 120:18 = 6.66. We round to the nearest whole number, in the end we should have 7 steps. The distance between them is 120:7 = 17.14 cm. You can make six steps 17 cm high, and the last or first 17 + (0.14 × 6) = 17.8 cm. This makes it much easier to make porch parts. If you have chosen the length and width of the steps to be 30 cm, then the lower support point of the stairs should be at a distance of 7 × 30 cm = 210 cm from the edge of the platform. That's all the calculations, simple and accessible, there is no need to study complex formulas.

The main indicator when calculating a flight of stairs is its slope (steepness), which depends on the width and height of the stairs

Select only high-quality lumber for making a porch; avoid damage from pests, diseases, rotten knots and through cracks. Only moisture-resistant species: coniferous or hard trees. It is also not recommended to use boards with significant natural developmental defects.

Buy only high-quality lumber

It is advisable to treat the materials several times with antiseptics.

Bioprotective wood treatment

Take all possible measures to prevent water from accumulating on steps and landings. You can make them with a slight slope or leave gaps of 2–3 mm between individual boards.

Wooden porch construction diagram

For the final paint coating, use only high-quality paints. They must be wear-resistant, resistant to moisture and harsh ultraviolet radiation. Another requirement is that when painting surfaces, strictly follow the manufacturers’ recommendations; do not try to simplify the technology by skipping some steps. Remember that there are no wooden structures in the house that are used in such difficult conditions. It is very difficult to restore the original appearance of the paint; you will have to completely remove the old coating. Such work requires a lot of effort and time, and it is rarely possible to completely get rid of traces of old paint.

This is interesting: How to paint a wooden porch on the street - we present it in order

Wood preparation

The logs from which the stairs will be made should be thoroughly dried beforehand, because excess moisture will affect the premature formation of rotting or drying out. Such an error in preparing the material can lead to cracking and rapid loss of strength, as well as rapid loss of its shape.

Sometimes there is an option to use logs from a disassembled log house, but special care will be required here, because during the cutting process old fasteners, such as nails, may come across, which will lead to damage to the saw.

Elements of the staircase structure must be prepared before starting work

To do this, you will not only have to clean the knots, but also pay attention to the following steps:

- processing wood using an antiseptic. This measure will eliminate the possibility of the formation of small pests that will cause the material to become unusable.

- necessary coating of ends with resin. It will also be necessary to treat the surfaces of the logs that will come into contact with the ground to avoid their destruction over time.

The choice of wood depends on the owner's preferences and expected costs. But it is worth noting that the most suitable options would be to use oak, beech or larch

. True, material of such quality may increase the cost of the structure. Among the more economical types of wood, which are also often used to create staircase structures from logs, are soft pine and spruce. It is worth noting that significant budget savings can be achieved if you use steps made of half-logs, in which the cut will act as a tread. The rounded lower part in this case is used as a riser.

Price

It is quite difficult to determine the final cost of such a structure:

- Firstly, the degree of complexity of construction work can only be determined during its actual implementation.

- Secondly, it is quite difficult to indicate the amount of costs for the preparatory processing of a log before its use. Thus, the construction of a staircase structure is a rather serious task, the implementation of which must be approached with all responsibility.

Calculations required to build a wooden porch

You can easily calculate and build a wooden porch yourself. You will not need any special knowledge of geometry and construction, just a small amount of free time. Next, we will present the basic calculations and construction nuances that you may need.

Sizes and shape of the site

You can choose the shape and size of the platform that you like and will be comfortable. The main thing is that the width of the structure is no less than 90 cm. If it is smaller, then inconvenience may arise when opening the door outward. Also, if the platform will pass under the window of the house, it should end at least 20 cm beyond the border of the window frame.

The height of the porch platform is determined by the height of the entrance door threshold: we measure from the ground to the upper limit of the threshold and subtract 3-5 cm. This is especially critical if the front door opens outward, since in winter, due to the formation of ice or snow drifts on the platform, problems with by opening it.

A few words about ice: the steps and the platform itself should be made with a slight slope outward, 1-1.5 degrees. When walking, such a slope will not be noticeable, but it will ensure the outflow of rainwater and other water that will reduce the formation of ice on the wooden surface.

We calculate stringers and steps

Counting the height and number of steps. As a rule, risers are made about 18 cm high, so to start calculating we take this figure. We divide the height of the platform by 18, the resulting number is the number of steps. If the output is a fraction, then round it up. For example: 150:18=8.33 pcs. We round 8.33 to 8, count: 150:8 = 18.75 cm. So we got 8 steps with a height of 18.75 cm.

You can calculate the length of the stringers in the following way: a 2 + b 2 √22.65. Here a is the height of the porch platform, b is the distance from the lower support to the front landing beam. The width of the stringer is the height of the riser multiplied by two. The figure is rounded up only. Based on these calculations, you can draw up a project for the porch of a wooden house.

How to make a wooden porch: we take the necessary measurements

Important: if you are designing a porch on two sides, then the stringer calculations are made twice, with the measurements repeated on both sides. The height of the platform may not be the same, and a stringer prepared according to measurements on one side may not be suitable for installation on the other side

street staircase

Designs made from half-logs are widely used by designers when decorating suburban areas, gardens and park ensembles. They blend perfectly with the surrounding natural landscape. In particular, such stairs will be appropriate in areas with sloping areas where buildings made of logs or wooden beams are erected.

Steps made from half-logs are often laid directly on the ground, treated on the bottom with resin, and on the top with moisture-resistant paint and varnish compounds intended for outdoor use. The logs, in this case, can be placed along the steps or across them, and something like a wooden fence is placed on the sides as a fence.

There are quite a lot of design solutions for half-log staircases; you just have to dream or look at the options offered by manufacturers. But in any case, the design will be distinguished by its individuality!

A staircase in a house made of rounded logs is not only a structure for going up or down to another floor of the house, but also an important design element, so any staircase will not work in this case - it is necessary that it fits organically into the interior of the house.

As part of the article, we will look at stairs, which are usually installed in wooden houses made of logs, since in houses with false walls the design can be very diverse, and therefore the choice of stairs too.

But first, let’s look at what kind of stairs there can be in a log house.

- Firstly, these can be flight stairs - stairs that are separate flights, connected by stringers, or separated by a landing.

- Secondly, screw or spiral.

- Thirdly, bolt ladders - they do not have supporting elements (stringers or bowstrings), so they give the impression of being suspended in the air.

To preserve the classic style of a wooden house, it is advisable to make the stairs in it from the same material. Often in houses made of rounded logs you can find a staircase, the role of steps in which is performed by blocks also made of rounded logs, sawn along the diameter. Such stairs are reliable and safe, and blend very organically with the walls of the house. They are often used on the street at the entrance to the house.

There are several suitable options for log stairs:

- with fastening steps-block on a bowstring or stringers made of logs;

- with a through cantilever arrangement of scaffold steps;

- staircase with two strings of logs with flat steps;

- corkscrew cantilevered staircase with flat steps-blocks and a turn of a third or a quarter.

Railings and handrails for such stairs are usually made of wood. Metal can also be used in the design of railings, but some craftsmen consider the use of metal undesirable due to its poor interaction with wood.

Stairs made of logs usually look monumental and heavy. A staircase with steps made of boards and a string made of laminated veneer lumber will be lighter.

If there is little space in the house, you can install a spiral staircase. These stairs are not very convenient for the elderly and children, but they can significantly optimize the interior space of the house. A rounded log can be used as a vertical post for the stairs, and the steps can be made from rounded logs or boards. A metal spiral staircase is also acceptable. Such a staircase can be located not only against the wall, but also in the middle of the room, which gives scope for design solutions.

Bolster staircases are usually used in high-tech or modern style rooms, but in some cases they look natural in houses made of rounded logs. As a handrail for such stairs, ropes attached to the ceiling will look original. The steps can be made of logs or boards.

Choosing a staircase in a house made of rounded logs is not an easy process. What complicates the task is that it is advisable to do this at the design stage of the house, because each type of staircase requires different space. Professional designers and special 3-D design programs can come to the rescue. Only being a specialist with many years of experience in wooden house construction can you design a staircase that is comfortable, beautiful and practical, the embodiment of elegant style and good taste.

Buy and collect

Prices for ready-made factory staircase models are affordable and any average family can afford to purchase a simple design of several flights. And it’s easier to assemble a ready-made version with your own hands. Each model comes with detailed installation instructions and all fasteners.

The price of ready-made models from the most famous manufacturers in various cities of Russia is presented in the table:

| City | Manufacturer | Price for various standard models, rub. | ||

| Simple | Several flights | Screw | ||

| Moscow | LLC "Our Stairs" | From 25 000 | From 45 000 | From 64,000 |

| St. Petersburg | LLC "Verno Ladder" | From 22 000 | From 44 000 | From 60 000 |

| Rostov-on-Don | LLC "Lestnitsa Rostov" | From 20 000 | From 39 000 | From 70 000 |

| Ufa | Factory of stairs "Stolyarych" | From 22 000 | From 37 000 | From 67 000 |

| Kazan | Profi Group LLC | From 25 000 | From 44 000 | From 63,000 |

How diverse timber stairs can be seen in the video:

The price of timber stairs depends on the quality of the material, its size and type. The most expensive models are made from laminated veneer lumber, but they outperform the rest in terms of quality and durability of the structure. An inexpensive option is a birch ladder. But birch wood is short-lived and afraid of moisture, so we do not recommend purchasing this option.

Calculation and design

When starting design, you need to decide on the space that the staircase can occupy. You also need to measure the height between the floors, or between the platform and the level of the entrance to the house.

Basic design parameters

In order for wooden stairs for a log house to be comfortable and safe, when designing them you should be guided by the standard requirements:

- The width of the structure should be such that two people can pass each other on the steps. And in the case of an interfloor staircase, its width should allow furniture and other large objects to be lifted to the upper level.

- It is advisable to make the tilt angle no more than 35 0, especially for long spans.

- The optimal tread width is 25-30 cm. Therefore, the diameter of the log for the steps should be no less, otherwise walking on them will be inconvenient and dangerous.

The instructions also regulate the height of the riser, which should be 15-20 cm. In the case of structures made of logs, risers are usually not made, and the vertical distance between steps depends on the thickness of the log

It can be adjusted by laying the steps close to each other, or by making gaps between them. The optimal height of the railing is 90 cm. When designing interfloor stairs for a wooden house made of timber, it is necessary to pay attention to the size of the opening in the ceiling. It should be such that the vertical distance between the step and the edge of the opening is 20 cm greater than the height of the tallest person in the house.

What you need to know to calculate

The following data will be required for the calculation:

- Size of the staircase in plan;

- Lifting height;

- Step width and riser height.

Example:

Let's say the floor height is 270 cm and the riser height is 15 cm.

- The number of steps is 18, because 270: 15 = 18.

- If the width of the steps is 25 cm, then a single-flight staircase will require a plan distance of 25 x 18 = 450 cm.

For a room or hall in a small house, this is a lot. This means that the staircase needs to be double-flight. And in a very small space it is worth considering a screw design.

How to correctly calculate the dimensions of a spiral staircase in a private house to the second floor

Let's look at how the design of a spiral staircase with standard dimensions is calculated. Let's say the rotation angle of the spiral staircase is 360°, the diameter is 2000 mm, and the height is 3000 mm.

First, it is necessary to determine the circumference along the center line of movement. Calculating the dimensions of a spiral staircase with your own hands should be done using the formula: L = 2mR, where r = 2R: 3. It should be remembered that the center line of movement is two-thirds away from the radius of the staircase. After the transformation, the formula looks like this: L = 4wR: 3. Substituting the results, we get: 4 x 3.14 x 1000: 3 = 4187 mm.

Secondly, you need to determine the step height of the steps. With a floor height of 3000 mm, this size in the design of a spiral staircase to the second floor can be equal to 150 or 200 mm, i.e. the number of rises will be 20 or 15.

The width of the fifteenth step can be equal to the width of 2-4 main steps. But it should be taken into account that when climbing to the first step, the total height is reduced by the height of the step, i.e. by 200 mm, which corresponds to 15 lifts. At the same time, in spiral staircases with a 360° rotation, there is a platform above your head. Therefore, with a floor height of 3000 mm, it is necessary to build a platform 4 steps wide. This means that in the fourth stage the overall height will be reduced by 800mm, but will still maintain a safety clearance of over 2000mm overhead.

When correctly calculating a spiral staircase to the second floor, it is important to determine the width of the tread along the center line of movement. The following formulas apply here: 2h + b = 600-650 mm and h + b = 460 mm

By transforming the formulas (b = 600-650 mm - 2h and b - 460 mm - K) and substituting the value of the step height (200 mm) into them, you can calculate the width of the tread, which, based on the first formula, will be 200-240 mm, and according to the second - 240 mm.

Now we need to check whether these values correspond to those that actually exist. When dividing the sweep length of 4187 mm by 14 steps, we get 299 mm. This step is too broad. If you specify treads with a similar parameter in the project, then there will be a need to increase the step width. To check, you should make calculations using the first formula. We get: 2 x 200 + 299 = 699 mm instead of the average 620 mm. This means increasing the number of climbs from 15 to 17, which includes 16 steps and one landing.

After calculations, it will become clear that the width of the tread will be 262 mm (4187 mm: 16 steps), and the height of the rises will be 177 mm (3000 mm: 17 steps), and the first rise must be reduced by 9 mm to fit into the total height of the floor (168 mm+ 16×177 mm = 3000 mm). With such dimensions of the steps of the spiral staircase, it becomes possible to design an upper platform 5 steps wide, since they will be 1000 mm, which, with a total height of 3000 mm, will create the required margin of 2000 mm.

In general, the selection of the number of steps is carried out as follows: it is necessary to divide the total height of the floor into a certain number of rises and compare the resulting height and width of the steps with whether they are suitable for the width of the average human step. If a residue is formed during the calculations, then the height of the first step should be increased or, conversely, reduced. The possible difference will be less than 10 mm, which will be practically unnoticeable. This assumption is justified by the fact that the height of the floor cannot be changed; it can only be adjusted by laying the floor covering, so that when divided by the height of the rises, a whole number is obtained.

It is equally important, when calculating the dimensions of the spiral staircase to the second floor, to determine the width of the step in its narrow part with your own hands. The winder steps of the spiral staircase are supported by a central post in the form of a casing pipe with a diameter of 50 mm, on which the steps are strung

In order for the stand to become more rigid and the steps to be securely fixed, sleeves with washers must be inserted between them. In this case, the pipe diameter will increase. In addition, a hole with a diameter of 50 mm should be drilled in the narrow part of each step. For greater strength of the step, it needs to be expanded, making the surface around the hole larger by the same amount (by 50 mm). It becomes clear that the width of the narrow part of the step is 150 mm.

Thus, it is possible to determine all the parameters of the tread, the width of which in the narrow part is 150 mm, along the line of movement - 262 mm, and in the wide part - 393 mm.

Based on the obtained dimensions, you can make a step, but usually they do it much simpler by connecting the markings in the narrow and wide parts. Thanks to this, the tread becomes wider, although after installation it does not exceed the calculated width, because the steps are winder.

The following is a step-by-step instruction on how to build a spiral staircase in your home with your own hands.

Staircase made of logs on the street

Staircase made of logs on the street

This method of constructing a staircase structure will fit perfectly into the design of a suburban area, garden or park ensemble. Using logs as the main structural element will allow you to create a staircase that blends perfectly with the surrounding nature and landscape. If there is a slope on the site, as well as the construction of main buildings made of logs or wooden beams, the use of such a decorative element will be most justified.

Steps of this design can be laid on the ground using resin to treat its lower parts. A moisture-resistant paint coating intended for outdoor use is applied to the upper part of the elements. The arrangement of logs is allowed transversely or along the steps. A decorative wooden fence is perfect for decorating a fence.

Beautiful and exclusive chopped spiral staircases for cottages and houses

today they often decorate a huge proportion of suburban housing. They allow you to create original and unique interior solutions, decorated in both classic and country style. Moreover, we can talk about a small country house with an attic, or a huge country house with several floors. Because a staircase in a log country house made of wood will always help solve the problem of beautifully and competently arranging a living room or corridor, while emphasizing the high quality of materials and their safety for human life and health.

Distinctive features

Despite the variety of building materials that the modern market offers, wood remains the most popular option for the construction of private houses and decoration.

The popularity of the material is explained simply. Wood naturally has an original texture and in most cases does not require finishing. Several layers of varnish - and the surface acquires a bright and aesthetic appearance. In addition, only wood can create an atmosphere of comfort and harmony, making the house truly alive.

If we talk about specifics, the advantages of using solid wood in private construction look like this:

- absence of chemically active substances - absolute environmental friendliness and health benefits: resin from coniferous trees is often used in aromatherapy to treat colds;

- ease of processing - no technically complex and expensive equipment is required: wood can be sawed, planed and chopped, any visual defects can be easily removed from the surface;

- durability - many tree species are not inferior in strength to brick, and after treatment with special compounds they become neutral to a humid environment and do not attract pests;

- reliability - contrary to popular belief, it is very difficult to destroy a tree. The fibrous structure is resistant to mechanical damage and intense dynamic loads.

Despite its apparent simplicity, wood is a very variable material and even in the budget segment of the market there are more than 10 different solid textures.

How to build a log staircase

Let's consider, as an example, how to make a simple one-flight staircase with your own hands on two stringers (strings):

| Image | Description of the stage |

| Making a drawing on graph paper | Having made all the calculations, we transfer them to graph paper, drawing a drawing of the future staircase to scale with dimensions indicated. |

| |

| We saw the logs along and lengthwise for the steps. | |

| We clean all manufactured elements of the future staircase from bark, remove knots, grind chips and burrs. | |

| We install the stringers in place and fix them. If the house is new, then rigid fastening to the ceiling cannot be made in the upper part until the structure shrinks. | |

| We try on the steps, setting them according to the level. | |

| The steps are attached to long anchors with washers. We pre-drill a through hole in the stringer with a diameter of 8 mm, and then countersink it to a depth of 5-6 cm with a 28 mm feather drill. Before fastening, lubricate the bowl with wood glue or sealant. | |

| After installing the steps, the holes in the stringers are sealed with wood putty or closed with plugs. | |

| At the final stage, support posts, railings and balusters are installed. |

When making wooden stairs, the log must first be dried, and after cutting into elements, it must be treated with protective compounds against rotting and burning.

If the staircase is external, then the ends need to be coated especially carefully and several times. The best thing is to tar it. And those areas that will come into contact with the ground should be protected with several layers of roofing material.

After installation is completed, the structure is sanded again, after which it can be coated with decorative paints and varnishes. By deciding to make such a staircase yourself, you will save a lot, since the price of such structures and their installation by specialists is very high.