Internal partitions are walls that do not perform a load-bearing function and serve only to separate rooms. Partitions in a wooden house are usually made of wood so as not to disturb the overall style of the building. But this is not important, if the interior design solution allows, you can build them from any materials, such as, for example, plasterboard or aerated concrete.

House made of timber with plasterboard partition Source myhome.ru

Requirements for partitions in a private house

All walls in the house are divided into load-bearing, self-supporting, enclosing and partitions. Load-bearing walls must be strong and reliable, since other architectural elements rest on them. Self-supporting ones rest on the foundation and support their own weight. The boundary wall can be load-bearing or self-supporting. It should not only be durable, but also insulated.

Bounding walls of a house made of timber Source patter.ru

Partitions, unlike the above types of walls, rest on the ceilings and do not bear any load. Their strength and reliability indicators are subject to less stringent requirements. However, these designs must have certain characteristics.

- The partitions should be fairly light . The lighter their weight, the less pressure on the foundation and floors, and this is reflected in the economic efficiency of the entire building.

- The partitions must be thin . The thinner the dividing internal walls, the more the living space of the house is saved.

- When calculating partitions, it is necessary to take into account that furniture and household appliances will be hung on them. Therefore they must be strong .

- Partitions act as separating structures, which should provide the premises with a sufficient level of sound insulation .

- Partitions in rooms with high humidity and sudden temperature changes must be constructed from materials that are not subject to the negative effects of these factors. If they are built from wood, then it is necessary to use effective protective impregnations .

- Partitions in the house must have high fire resistance .

- It is very important to consider the need to lay electrical wires in the body of the partition or along it.

Laying electrical wiring in a house made of timber Source criptopia.ru

See also: Catalog of companies that specialize in interior redevelopment.

Overview of the main options

Before making partitions in a wooden house, you need to decide what material will be used. We will look at the most popular and popular solutions.

Solid option

The installation of a partition in a wooden house made of timber is most often carried out in parallel with the construction of the box

As the name suggests, a solid structure is erected, for which a wooden beam with a thickness of 50 mm or more is most often used (the most commonly used material is 100 mm thick).

We'll tell you how to do this type of work yourself:

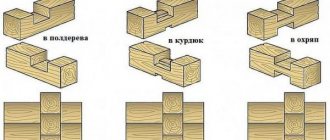

- The elements are fastened together with wooden spikes from 5 to 10 centimeters long; for this, holes are drilled in the material, into which the spike is driven and combined with the second element, and so on.

- The wall is fixed to the floor and ceiling using triangular bars, which act as a limiter. Fastening is best done using self-tapping screws; they hold the system more firmly, and if necessary, they can be unscrewed and disassembled the wall without damaging the wooden parts.

- Since internal partitions in a wooden house are installed independently of the external walls, deformations may occur during the shrinkage of the structure. To avoid this, a deformation groove is made in the load-bearing wall, which will prevent the elements from bending.

The deformation groove allows you to compensate for changes in the size of wooden elements due to changes in temperature and humidity

Frame-panel structures

This option is the most common and in demand, since its price is the most affordable of all possible solutions.

Construction instructions are as follows:

First of all, vertical posts are fixed in increments of 500-600 mm. A beam is attached to the ceiling and floor, to which the remaining elements are attached; you can connect them with self-tapping screws, or you can use perforated corners, this is both simpler and faster.

The frame must be strong and stable

- The installation of partitions in a wooden house continues with the installation of transverse elements; they will give the entire system additional rigidity.

- The entire space is covered with insulation, which will also serve as a sound insulator. The material should be placed tightly - without cracks or voids.

- The surface on both sides is covered with a vapor barrier film and covered with either plywood or plasterboard sheets.

Plasterboard systems

If earlier the question of what to make partitions from in a wooden house was limited to solid and frame-panel options, then these days the option with plasterboard has become very popular.

Before you build a partition in a wooden house, you will need to purchase a partition profile; it differs from the standard one in being thicker and more reliable.

The work is carried out as follows:

- First of all, the wall elements are attached; they determine the location of the future structure, so take all the necessary measurements correctly.

- Next, vertical posts are located at a distance of 50-60 cm. To ensure reliability, horizontal crossbars are added to the structure.

A metal profile frame is erected quite simply and quickly

All internal cavities are filled with mineral wool and covered with vapor barrier material. After this, you can attach plasterboard or gypsum fiber sheets.

What materials are they made of?

Various building materials are used to construct internal partitions. The most commonly used materials are brick, porous concrete or plasterboard.

Brick

Brick partitions are characterized by high strength. You can mount any shelves and brackets on them without fear that they will not stay on the wall. In addition, brick walls are a good sound insulator. So that they do not weigh down the building so much, not ordinary solid brick is used, but its porous analogue. But partitions in a house made of timber are quite rarely constructed from ceramics. The fact is that even porous brick is too heavy for a wooden building. In addition, a brick wall requires painstaking leveling of the surface before finishing.

Brick internal partitions Source th.decorexpro.com

Aerated concrete and foam concrete

Cellular concrete blocks are available in various sizes. There are also special products for laying partitions. They have a small thickness and minimal weight. But this also has its drawbacks - when hanging heavy interior elements, you need to use special dowels. Another important nuance is that cellular concrete is hygroscopic, and without additional protection it cannot be used to separate rooms with high humidity.

Drywall

This is the cheapest and easiest to use material. To construct partitions, a metal frame is installed, which is then sheathed on both sides with thick sheets of plasterboard. The difficulty of operating such structures is their low resistance to mechanical stress. You cannot install shelves and equipment on the drywall itself. True, you can attach heavy elements directly to a metal frame.

If the impact is strong enough, the plasterboard wall will crack, requiring replacement of the damaged sheets.

Partition made of plasterboard on a metal frame Source nkkconsult.ru

Gypsolite slabs

Material made of gypsum and silicone with a tongue-and-groove connection system. Practical partitions with a smooth surface are very quickly erected from gypsum slabs. You can’t just hang heavy objects on them either, but in terms of the degree of resistance to mechanical stress, this material is more attractive than ordinary drywall.

See also: Catalog of timber house projects presented at the Low-Rise Country exhibition.

Sequence of installation of a wood-frame partition

Frame making

- The projection lines of the frame partition are marked along the ceiling, floor and load-bearing walls.

- Rigid fastening of the end beam is allowed only to the floor. The horizontal load-bearing element can be immediately installed on a thick damper pad, for example, made of felt; or fix it on steel brackets with a gap, which will subsequently be filled with foam.

- Vertical end beams are installed, securing them with temporary rigid connections to the walls.

- Two post beams are also installed at the location of the future doorway. Their vertical position is controlled by a float level, and temporary fixation is carried out by oblique struts to the floor.

- Install the upper horizontal end element. It is often made up of several parts connected by steel plates. The plates are placed on the upper and lower planes of the beams. It is recommended to calculate the locations of such connections in advance so that they are above the vertical posts.

- After assembling the frame of the frame partition, internal vertical posts are installed with a pitch of 600 mm. It is optimal for laying mineral wool thermal and sound insulation with a standard slab width of 610 mm.

- It is recommended to make horizontal jumpers from short bars inside the formed cells in a checkerboard pattern (taking into account the height of the cladding material, if it is sheet). This will not only make it easier to fix the lintels and sheets, but will also give the frame additional rigidity.

- At the location of the doors, a horizontal element is mounted to the vertical bars, limiting the top of the opening. It is strengthened with an additional short vertical post to the upper horizontal beam.

- Rigid temporary connections with walls are replaced with floating ones. They are made in the same way as for.

Infill and lining

After the cells are filled with mineral wool, the interior wooden partition is sheathed on both sides with a vapor barrier membrane (striped with a stapler)

At the same time, it is important not to confuse the direction of vapor diffusion - it must be provided with an exit in the direction from the insulation, i.e. from inside the partition

The membrane strips are secured with overlaps, and the puncture sites with staples, damage and joints are taped with tape intended for this purpose. If the frame is sheathed with plasterboard, OSB or plywood, then their sheets are fixed with offset joints, which are then puttied. The resulting surfaces can play the role of rough or semi-finish and are subject to further processing in accordance with the selected technology. If lining or blockhouse is used as cladding, then they only need to be coated with paints and varnishes.

Partitions in a house made of timber

The density of the partitions should not exceed the density of the load-bearing walls, otherwise they will be too heavy relative to the total mass of the building. At the same time, the timber from which the walls of log houses are built belongs to lightweight building materials. It is not recommended to build traditional brick and even not very heavy aerated concrete partitions in wooden houses. They can be erected from plasterboard or tongue-and-groove slabs. But the best option is timber or frame partitions. In technical rooms you can install plank (panel) partitions.

Partition in a house made of timber Source domoholic.ru

Partitions made of timber

Timber partitions allow you to maintain the harmony of the interior of the log house. They are built from material with a small thickness. But the height of the timber for the partitions should be the same as the material for the external walls. This is necessary in order to facilitate the process of constructing partitions and increase the aesthetics of the interior of the premises.

The main advantages of timber structures:

- rigidity;

- strength;

- good sound insulation.

However, it is worth noting that all the advantageous characteristics of timber walls are reduced due to the presence of openings in them. An important advantage of timber partitions is their appearance, in which there is no need for additional decoration with finishing materials.

Partition made of timber Source derevyannyy.com

Such partitions are erected in the same way as the outer walls of a log house. The basis of the internal dividing walls are floor beams. During the construction process, it is necessary to remember that the timber in the finished log house shrinks. This applies to both the material for the building frame and the wood for the interior walls. It is more convenient to erect partitions simultaneously with load-bearing walls. But if you are not sure that the timber for the walls and for the partitions has the same shrinkage coefficient, it is better to install the partitions after the house has completely shrinked.

The amount of timber and the type of connection between the partition and the wall is determined by the designer or builders. To protect the wood as much as possible from moisture, the bottom row of the partition is laid from moisture-resistant aspen or larch. In addition, the bottom row is insulated from a vapor-permeable film.

Finished timber partitions are sanded and coated with protective compounds along with the main walls. You can safely mount heavy shelves and fastening systems for household appliances on timber partitions.

Sanding timber partitions Source remontik.org

Start of installation

To mount a frame made of timber, you will need a saw (both petrol and electric will do), a hacksaw for wood, a chisel and an axe, a drill with wood drill bits, and, of course, a pencil, a marker, a tape measure and a level.

A hammer will also come in handy. A simple way to connect a new wall with an old one is to cut out a groove into which the beam will be inserted. And a tenon is cut out on it to fit into the groove.

If a tenon is necessary, make it with a height of 3-5 cm. Accordingly, the groove is cut out to a similar depth.

Before installing the beam, flax fiber is laid in the groove. An alternative is to use tow. As soon as the first block is laid, fix it to the floor using self-tapping screws.

The next stage involves installing a new beam, on which a tenon is also made and placed in grooves on top of the old beam. In this way, the partition is mounted to the ceiling.

The lower beam is first lined with jute tape.

It is imperative to attach the base with self-tapping screws to the main wall, otherwise the mounted structure will be unstable.

If there is an opening in the partition, then additional stiffeners are made. They are attached to the upper structural elements using iron corners.

Video description

Arrangement of a frame partition in a log house made of timber or logs:

Plank partitions

A type of wooden non-load-bearing interior wall. A plank partition differs from a timber partition in thickness, sound insulation and strength, as well as price. Typically, plank partitions are installed in utility and technical rooms, where it is not necessary to maintain an ideal design.

This option has the principle of a frame partition. Boards installed vertically or horizontally, depending on the characteristics of the room, are used as a frame. Frame boards are covered with planed boards.

Frame for a partition made of boards Source wotsite.ru

Frame-panel view

It is considered the most economical and easiest to implement:

- The frame is made of timber with a section of 50×100mm;

- Beams are attached in increments of 50-60cm;

The connecting element here is the harness. It also gives strength and stability to the partition.

The frame is insulated with mineral wool or polystyrene foam 50-100mm thick. It is recommended to seal both sides using a vapor barrier material. It will protect the partition from moisture.

To give a perfectly flat surface, the partition can be sheathed with sheets of plywood.

The soundproofing properties that the partition receives as a result are much better than in any other form.

Preparatory stage

Drywall is a finishing material characterized by durability. It is this fact that makes us think about carrying out preventive treatment of all surfaces that will be hidden behind gypsum board sheets. The owner of the building can only find out that fungus has appeared on the surface of the main walls or mold has grown at the moment when the structure, erected several years ago, begins to crumble and collapse.

Natural wood is a fire hazard. Therefore, all surfaces should be thoroughly treated with antifungal agents. The gaps between the beams must be caulked with tow, impregnated with compounds that ensure the structure’s ability to resist fire. Silicone or foam can be used as an additional treatment.

Foaming cracks

All components of the structure are pre-cut or sawn into separate pieces, the length of which is determined after accurate measurements are taken. This applies not only to the contour. Longitudinal (rack-mount) guides and jumpers are prepared in advance.