Wood twists and bends, which can cause warping and damage to windows and doors. To prevent shrinkage of the house from leading to deformation of window structures and doors, you need to make a frame or casing.

The cap protects the openings from pressure from above and creates the gap necessary for shrinkage. The side parts of the pigtail have poses that create vertical sliding. Most often, the pigtail is made from coniferous wood. It consists of a top, sides and a window sill (threshold).

Important! The casing must be installed before caulking works.

Types of casing (casing)

U-shaped pigtail (in a deck)

Classic pigtail. To perform this, a tenon is cut out at the end of the wall, a vertical part of the casing with a groove is installed on it, along which the frame moves vertically due to shrinkage.

Thanks to this, no pressure is placed on the door and window structure, which guarantees their correct functioning and durability. The casing is treated with an antiseptic, and soft insulation is placed between the tenon and groove.

A wind lock provides protection against blowing under the window sill. The gaps above the top of the pigtail are closed with soft insulating material.

T-shaped socket (in a spike)

The T-shaped frame is made as follows: a groove is cut at the end of the opening, and the side parts of the casing have T-shaped profiles. Bars are glued into the grooves on the risers of the frame, which act as stiffeners; they guarantee the stability of the shape of the casing and uniform shrinkage of the walls.

More on the topic How to insulate windows. Review of insulation materials

When installing a T-type pigtail, strict adherence to technology is required. For example, if you secure a block with nails or self-tapping screws, there is a possibility of freezing or blowing through the window and door opening. An important role in casing is played by antiseptic treatment and insulation of seams with compressible material.

A U- or T-shaped pigtail is selected depending on the house. When visiting the site, the surveyor will tell you the most suitable type of casing. Our craftsmen professionally perform the full range of work on the manufacture and installation of casing in wooden houses.

What is the pigtail for?

What is a door frame? At its core, this is the construction of additional supports that will prevent the walls from moving during gradual shrinkage throughout the entire life of the building.

Over the years, even the highest quality wood begins to dry out, and the pressure on the foundation of the house leads to the fact that its walls and floors can change their original position.

Otherwise known as casing, the frame is a box-shaped structure installed in the door opening. It protects it and the door itself from the impact caused by the movement of logs.

A correctly and timely installed door frame will allow you to:

- Protect the door from skewing and jamming, which can be caused by pressure from the load from the weight of the walls;

- Prevent the destruction of doors - regardless of what material they are made of, wood, plastic or some other;

- Avoid the occurrence of cracks and subsequent drafts.

If you don’t install a door frame in the doorway, you risk not only having problems with the doors, their damage and jamming, but also getting damage to the walls and even their destruction.

This type of work, such as framing door and window openings in a wooden house, is a prerequisite. Without additional strengthening, over time the house may become unsafe, so in this case a lot depends on the quality of the work.

Stages of installing a casing (casing)

1. The opening cut is made at a distance of 80-90 cm from the floor; when determining this distance, the person’s height is taken into account.

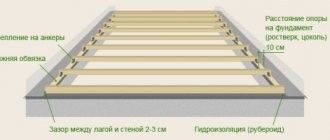

Between the opening and the window or door structure, you need to make a shrinkage gap of 35-60 mm. 2. Preparing the opening. Using a chainsaw, depending on the type of socket, a groove or ridge is cut in the opening.

3. Treatment and insulation. After installing the frame, its surfaces are treated with an antiseptic, and insulation is placed in the gaps. When installing the frame, you cannot use foam, since the window structure must move freely vertically.

4. Installation of wooden elements. At the end, the installation of wooden elements is carried out, namely the window sill, sidewalls and top.

How the casing works

Door or window casing consists of:

- threshold (lower part in the doorway);

- window sill (for a window opening);

- top;

- sidewalls

When constructing the casing, it is important to take into account that the lumber should be slightly smaller than the parameters of the openings. This is especially true for the height, which will decrease as the house shrinks.

It is customary to fasten the elements of the frame using grooves and ridges. Upon completion of installation, all gaps are filled with tow, which will serve as a reliable sealant. As soon as this stage of work is completed, you can begin installing windows, entrance and interior doors.

What affects the price of casing?

1. Wall thickness: wooden houses are built from logs and timber, so the wall thickness can be from 140 to 300 mm. The dimensions of the parts of the frame correspond in width to the walls of the house, or slightly exceed it. You also need to consider the width of the window sill.

2. Size of the opening: the larger the opening, the more material will be required to make the frame and the time to work. The shape of the opening also affects the price of the casing: a standard rectangular design or a complex polygonal one.

3. Quality of a wooden house: if the walls are assembled without connecting elements, the curvature of the walls occurs in the cut out openings. Then you have to additionally straighten the walls, which leads to additional costs.

Houses made of timber are assembled using nails that meet at 300 mm. Because of this, additional money and time are required to sharpen chainsaw chains or purchase new ones.

Source: sotdel.ru/okosyachka-obsada.html

How to make a casing with your own hands

Making a joint with your own hands is a difficult task, but possible.

If you have a timber house, then it is best to make a frame from a T-shaped profile. Both easier and cheaper. No cutter needed. You can get by with a circular saw. To save material, the profile is not cut out, but a spike is glued into its body. But you can also cut monolithic T-shaped sidewalls. The tenon size is 5 x 5 cm. After marking and cutting the opening, the timber is carefully pulled out of it and carefully folded so that it does not interfere. Mark a line for the grooves in the sides of the opening in a timber house using a ruler. They saw through the lines. Excess wood is removed. Align the groove with a chisel.

A groove for the wind bar is cut out in the window sill. First they place the bottom, then the side parts and fasten everything with the top. The casing parts are fixed with a self-jamming lock, inserted into the grooves of the sidewalls, cut in advance. Don’t forget to treat the opening with an antiseptic and insert jute tape for insulation.

DIY pigtail in a wooden house

Modern life, with its busy pace of life, pushes people to look for an alternative place of residence or recreation.

In this regard, a wooden house is a suitable option for a city dweller. A wooden house provides the opportunity to enjoy the naturalness and naturalness of an ecological structure.

Wooden houses, due to their natural characteristics, are environmentally friendly and energy efficient, which is why today the number of adherents of building houses made of wood is growing all over the world.

When building a wooden house, special attention must be paid to the installation of windows and doors, due to their tendency to shrink, which is a characteristic seasonal phenomenon. This phenomenon is due to the fact that wood has such characteristics as drying out and shrinkage.

In this regard, when installing window and door openings, it is important to remember that shrinkage of the building can last up to five years from the date of construction, and, consequently, the openings of windows and doors change.

More on the topic Panoramic windows in a private house

To prevent this deformation, window and door openings are installed in a special flashing, which is otherwise called a casing. A frame in a wooden house allows the natural shrinkage of the house to avoid damaging windows and doors and ensure safe living.

The casing in a wooden house contains 3 components:

- Sidewall;

- Vershnik,

- Window sill board (threshold).

The technology for making a pigtail depends on its type; in order to install a pigeon yourself, you need to carefully study the manufacturing technologies of each type and choose the most suitable one for yourself.

Manufacturing of casing

The casing consists of two sidewalls (side posts), a top - the top board and a window sill or threshold (also called a bottom). It must be said that the lower part is not always present: it is often not made in interior doors. In some cases (when installing PVC windows, for example), they do not make a window sill, but simply a lower embedded board, to which a “standard” window sill is then attached.

Also note that the top does not rest against the top edge of the window or door opening. There remains a gap of 5-7 cm between them - for shrinkage of the log house. This gap is then filled with insulation and covered with platbands and finishing materials.

What does a casing box consist of?

The most questions arise when forming the locks necessary for joining parts of the casing. These elements are especially difficult if a quarter sample is required. It’s difficult to explain in words, let’s provide drawings. Take a look at them and maybe you’ll understand what’s what. But the final understanding will come in the process: when you put the bottom and attach the side posts. They are outlined with a pencil, then gradually cut out. In this process, it is important not to cut off the excess - it won’t be possible to grow it and there will be unsightly gaps.

Drawings of casing/jamb locks

Before installing the casing, the window/door opening is treated with an antiseptic. Then two layers of insulation are laid. The structure is “dressed” on it. The procedure for assembling the casing on the windows is as follows:

- The lower part is installed.

- Place two side panels and check that the locks match accurately. You hit it well on the sides.

- Place the top. Often it “doesn’t fit” - the racks are closer than necessary. Don't take up the saw right away. Take spacers of the length that the opening should be, and with their help bring the window to the required dimensions. First, place it diagonally, then, knocking it out, straighten it out. The sidewalls crush the insulation and occupy the required position. After which the apex falls into place.

The main types of pigtails in a wooden house and their manufacturing technology

The pigtail “in the embedded block”.

This type is a prefabricated structure. A block measuring 50 cm x 50 cm is installed in a cut-out groove prepared in advance. This block will be the main guide for moving the log house vertically. In a wooden house, the frame (casing) is made up of edged boards measuring 50 mm x 150 mm or 50 mm x 200 mm, based on the thickness of the logs.

This technology is highly popular for 2 reasons: 1) due to rapid production and subsequent assembly, 2) due to its relative low cost.

Okosyachka "In Shim Monolith". This technology involves making a casing in a wooden house from a solid rectangular profile beam. Its installation is carried out in a groove in the log house, which is cut in advance. The function of the top (upper horizontal jumper) is performed by an edged board, the thickness of which is 50 millimeters.

The “in the deck” socket is the most common method of casing among the people. Installation involves cutting a groove into a monolithic casing, which is made of rectangular profile timber. The function of the top is performed by an edged board with a thickness of 50 millimeters.

The ridge, which is cut into the end of the log house, serves as a guide for moving the log house. The racks on the sides are also made of timber. At the same time, “blocks” are made, inside of which a groove is cut in the center (50mmx50mm in size); when making them, it is important to take into account the thickness of the logs.

Having laid the thermal insulation in advance, the decks are placed on the ridge, and the racks are attached to the lower supporting crown using pins or wooden dowels. The top is placed on top in a spacer; it is secured with self-tapping screws to the side casing posts.

Pit "in a spike with a ready-made slope." A groove is cut at the end of the opening. A block (50x50 mm) is installed into it through the seal. This block is a guide for the vertical movement of the log house.

More on the topic Standard sizes of plastic windows according to GOST

To make the pigtail, this method uses a glued carriage, which is made from coniferous trees, its thickness is 50 millimeters. Then, on the frame, an “internal quarter” is made from laminated veneer lumber for the installation of window structures. The frame is secured to the opening using self-tapping screws.

In order to facilitate the process of installing a window frame in a wooden house yourself, we present its main stages.

Plastic window frame

Plastic windows also require the installation of a frame, but in this case there are some peculiarities. It is necessary to prepare a gap in advance, which should be at least 14 cm wider than the window frame. When calculating the size of the gap, it is necessary to take into account the thickness of the seams and casing boards, as well as the shrinkage coefficient of the wooden house.

Next, a ridge is cut out at the end of the opening, which will act as a base for a carriage with a groove. During the shrinking process, the beams or logs will move along this groove inside it, which will free the window from excess load. For the production of a carriage, a beam with a cross-section of 150-100 mm with a groove in the middle is suitable, the width of which should be 5 cm wider than the window. It is best to cut out the ridge using a chainsaw - this will help achieve the best accuracy.

For the top, you can use a 15040 mm edged board, in which grooves for the ridge are cut on each side. After installing the carriages along the edges of the opening, the top is secured with screws. After assembling the casing, all gaps are caulked and sealed with jute tape.

The main stages of making a pigtail

Cutting the opening

First, it is necessary to clarify the size of the opening and its distance from the floor. As a rule, this distance ranges from 80 to 90 centimeters. When determining this distance, it is necessary to take into account the height of future residents.

Then markings are made using special construction tools (plumb and level). In this case, the dimensions of the opening must be larger than the dimensions of the window structure, due to the fact that there must be shrinkage gaps (compensation) from 40 to 60 millimeters above the casing. Next comes the cutting of the opening.

Preparing the opening

This stage involves making a groove (or ridge), taking into account the technology of the socket.

Production and installation of pigtails

This stage is carried out based on the specifics of the production of various types of pigtails. Because different technologies have different rules and production sequence.

Direct installation of windows

It is important to know that the installation of a socket in a wooden house is installed if the house is not older than ten years. It is possible to install the pigtail with your own hands, but to do this you need to acquire certain knowledge and skills.

How to install windows

Each house has its own characteristics, and even in the same house, windows can behave differently. Professionals recommend strictly adhering to GOST recommendations.

Even windows in the same house can have their own characteristics. Therefore, in your work it is necessary to adhere to the recommendations of GOSTs, namely:

- GOST R 52749-2007 Window installation joints with vapor-permeable self-expanding tapes;

- GOST 30971-2002 Assembly seams of junctions of window blocks to wall openings. General technical conditions;

- GOST 30674-99. Window blocks made of polyvinyl chloride profiles

The window installation algorithm is as follows:

It is necessary to place the window frame in the opening, previously prepared and with a mounted frame, and wedge the structure with corners strictly according to the level. The corners are needed to form a gap for foaming; you can leave 35 mm at the bottom and 20 mm on the other sides.

Then secure the window. Most of those who do it themselves attach a PVC window in a wooden house with self-tapping screws.

The self-tapping screw must not pass through the casing and get into the end of the log, otherwise it will simply be torn out when the opening is deformed!

There is another scheme in which we insert the frame using steel corners: they are screwed to the profile with screws and a drill and attached to the casing quarter with self-tapping screws. The method where such fasteners are used is shown in detail in the video at the end of the article.

The number of attachment points depends on the size of the window: the larger they are, the more attachment points are needed; make from 30 to 70, departing from the corners of the frame by 12-15 cm.

Next, you need to treat all the gaps with an antiseptic and let it dry, and you can start foaming, but there is one more feature: wooden houses shrink, and the polyurethane foam can be destroyed during this process. You need very good professional polyurethane foam - it is quite expensive, and very good, deformation-resistant tape and coating materials are also used to protect assembly seams.

The self-tapping screw must not pass through the casing and get into the end of the log, otherwise it will simply be torn out when the opening is deformed!

The next stage is the assembly of the window block, installation of movable and fixed sashes. Until the polyurethane foam dries, keep the shutters closed so that when it dries, it does not bend the window.

After this, the ebb and window sill are installed, so that the window sill has a slight slope towards the room.

The last stage is the installation of slopes (from the inside) and platbands (from the outside).

The main tasks solved by the pigtail

The formation of a gap between the upper beam and the window opening, which ranges from 5 to 8 centimeters.

Organization of a strong connection of logs located horizontally in the window area. Organizations of structures intended for installation of windows.

Important. The casing in a wooden house does not rigidly tie the structure to the house; it can move freely if the house shrinks.

Installing a frame (casing) in a wooden house is a necessary and important event that should not be neglected. By installing the joint on time, you will save yourself from problems that may arise in the future.

Source: profibrus.ru/okosyachka-svoimi-rukami-v-derevyannom-dome.html

Features of casing for metal doors

Unlike windows and wooden doors, a metal door always has a rigid door frame, which can be used as a load-bearing frame for the casing frame.

If the door frame is made according to a reinforced design, then the top crossbar of the casing can be omitted. However, the benefit of such a solution is questionable, since the upper part of the frame still needs to be decorated in the same way as the side posts.

The second important point that distinguishes the installation of a metal door in a wooden house from a similar process in a stone building is the scheme for fixing the door in the door jamb.

We cannot display this gallery

In a brick or concrete house, anchor bolts or dowels are driven into the wall to the maximum depth. This cannot be done in a wooden house, and the maximum immersion depth of a bolt or self-tapping screw should not exceed the thickness of the casing frame.

It should also be taken into account that large-diameter self-tapping screws installed without preliminary preparation of the holes can split the wooden casing post.

accepts orders for the preparation of wooden houses for the installation of doors of any type. To clarify terms, prices and other terms of cooperation, please contact us by phone or e-mail published in the “Contacts” section.

Calculate the cost of painting and insulating your home right now

Select types of work:

Select materials:

Types of casing

The casing is the supporting structure of a wooden structure and requires special attention when choosing.

A window frame or casing on the doors of a wooden house is equally important for strengthening walls and preparing openings. There are several types of pigtails:

The pigtail in the embedded block.

In the 90s, when wooden houses made of timber, chopped and rounded logs began to “grow up like mushrooms after rain” in villages and summer cottages, this type of socket, known as an embedded block, became widespread.

With this installation method, a groove is selected at the ends of the window opening logs, into which a 50x50 mm block is driven through jute.

Next, a 50x150mm, or 50x200mm board is nailed to it or turned on self-tapping screws. The top is also covered with screws or nails with a board of the appropriate size.

This is the cheapest type of casing. It appeared, most likely, out of hopelessness among builders, since in those years there was nowhere to buy the right pigtail, and making it by hand was too expensive and labor-intensive. The socket in the embedded block turns out to be fragile, the connection angles of the structure itself are not airtight, there are still many disadvantages and only one advantage - it is inexpensive.

How much does it cost to install a casing?

The price of a joint is approximately the same in all regions. The main factors influencing its cost:

- Availability of material. (The price is lower from my own material).

- Wall thickness and opening height.

- Type of timber (Building a house from profiled and laminated timber implies the installation of more expensive casing).

- Availability of electricity (the cost of renting a generator is added).

- Is it necessary to finish the casing with platband?

- Remoteness from the city limits. (fare).

- Qualifications of workers (wages for specialists are higher).

Average price for a joint with work:

| Type of pigtail | Box thickness (cm) | |||||||||||||||

| Up to 15 | 15-20 | 20-25 | 25-30 | |||||||||||||

| Price, rub./p.m. | ||||||||||||||||

| installations | material | installations | material | installations | material | installations | material | |||||||||

| height | width | height | width | height | width | height | width | height | width | height | width | height | width | height | width | |

| In the embedded block | 870 | 125 | 300 | 190 | 915 | 125 | 350 | 250 | 950 | 125 | 350 | 250 | 990 | 125 | 350 | 250 |

| In the thorn-monalite, in the deck | 1115 | 125 | 410 | 190 | 1150 | 125 | 500 | 250 | 1190 | 125 | 500 | 250 | 1240 | 125 | 500 | 250 |

Knowing these numbers, it is easy to calculate how much it will cost to install casing using your own material or without installation. Companies offer as an addition a number of installation robots for an additional price:

| Type of installation work | Price, rub./l.m of boxes of various thicknesses (cm) | |||

| Up to 15 | 15-20 | 20-25 | 25-30 | |

| Horizontal cutting in a log house | 190 | 250 | 320 | 370 |

| Platband installation | 130 | 130 | 130 | 130 |

| Installing a window sill up to 30 cm thick | 330 | 330 | 330 | 330 |

| Treatment with antiseptics | 380 | 380 | 380 | 380 |

| Insulating the gap for shrinkage | 140 | 140 | 140 | 140 |

If you decide to entrust the installation of the pigtail to specialists, then it is better to order additional services. Only with them you will receive high-quality casing with a guarantee of 1 to 3 years. And this is enough to completely shrink a timber house.

T-shaped pigtail

The T-shaped jamb, the installation of which is carried out similarly to the casing in the embedded block, has a significant difference that makes it much stronger than the previous method described.

The difference is that the block is glued into the base of the workpiece or is made from a single material. The pigtail itself has a thickness of at least 65 mm. and this is enough to create sufficient rigidity of the structure.

This T-shaped casing can withstand horizontal and vertical loads well and reliably protects the windows and doors of a wooden house from distortions and mechanical damage during shrinkage of the log house.

We most often use a T-shaped frame when replacing a poorly installed embedment bar

Features of casing for an adjacent window opening with a balcony door

Combined opening

If there is a balcony door next to a window, then 2 casings should be installed. The opening where the balcony door is located is larger. And the opening for the window is much smaller. Therefore, the shrinkage of openings can therefore take place according to different scenarios. At the end of the window you can make a casing with a T-profile, and the balcony door with a U-shaped section. They will move relative to each other. The gaps above the top of the window and door will also vary. There is a larger gap above the balcony door than above the window. During the shrinkage process, the gaps will even out.

U-shaped pigtail

U-shaped pigtail is a classic type of pigtail. Someone claims that this is a special development of their company and only they install it this way. Not true. The U-shaped casing appeared a long time ago and it will not be possible to reinvent it again.

The production of the pigtail is carried out from solid wood or laminated veneer lumber with a large cross-section by mechanical processing. The result is a rigid, reliable structure that can withstand high loads in any direction.

Ideal for large plastic and wooden windows as well as for installation of metal entrance doors.

In our company you can buy a U-shaped window frame and install it yourself

Shrinkage and seasonal changes in log dimensions

First of all, let us remind you why the pigtail is needed.

Wood is a good and environmentally friendly building material, but it has one significant drawback - its linear and volumetric dimensions are not stable and depend on the level of humidity.

In turn, the moisture content of wood changes not only over time (due to natural drying), but also depending on climatic conditions.

For a new log house, the total changes in its geometric dimensions can reach 100–150 mm during the initial shrinkage and up to 7–10 mm during the remaining period of operation (due to seasonal humidity fluctuations).

Let us immediately emphasize that humidity changes in size always occur, even after the end of the shrinkage period.

To prevent size fluctuations from being transmitted to those structural elements of the house, the dimensions of which must remain unchanged, they are installed in special casing boxes, also called “casing” or “casing”.

U-shaped casing for the door

The connection between the casing and the rest of the house structure is always sliding. That is, the logs in the log house shift, but the dimensions of the frame remain constant.

The basis for disputes on the topic “is a door frame necessary in a wooden house?” is the assumption that when using modern methods of wood stabilization (special drying modes, oil impregnation, etc.), seasonal fluctuations in size in a wooden house are negligible and in an old house it is possible to install doors and windows without jambs.

To some extent, these judgments are correct. A wooden house built from profiled or laminated timber, specially dried in a factory and treated with water-repellent agents, will indeed maintain stable dimensions in the first 5-10 years.

But will he retain this ability in 12-15-20 years? It’s unlikely, since we have not yet learned how to completely prevent the appearance of cracks, micropores and age-related deformations in wood.

Impregnations and protective coatings also have a certain “shelf life” and even the instructions for their use state that the coating needs to be renewed (every 3-5 years). But in practice, this requirement is rarely met, especially in cases where the log house is sheathed on the outside with clapboard.

Summarizing the above, let's summarize: installing doors in a wooden house without casing can only be done in temporary buildings, and even then, only under certain conditions, but a house for yourself and your family must be reliable and built with casing installed.

Finishing casing

The finishing casing can be made from solid wood or glued blanks.

Finish okosyachka differs from other types in that it does not require additional decorative finishing. The corner joints of the casing structure are sawn by hand so that the gaps at the junction of the hanger, risers and window sill are minimal, which gives the window opening an impeccable appearance.

The surface of the parts is polished and only needs painting.

It is best to order such a pigtail for a wooden house, in which there will be no interior decoration, where the walls remain as they are.

Manufacturing of casing

For windows

With wooden frame:

- Preparing grooves on the sides of the opening.

- Laying inter-crown insulation material in its lower part, with a block on top. Its task is to prevent displacement of the sidewalls.

- The grooves on the left and right sides of the opening are filled in the same way.

- Installation of the upper casing element.

For PVC windows

Experts do not recommend installing such blocks in wooden houses, but if the decision is made, then you need to know some of the nuances of installing the casing.

- Preparing the opening involves changing its geometry. The gaps between its sides and the block are at least 130 mm. A more accurate value is determined by the following indicators: the moisture content of the wood of the house and its service life (which means the degree of probable shrinkage), the thickness of the crown joints.

- Making a threshold. Cuts are made in it to obtain a comb. It is needed as the base of the carriage in which the groove is installed. This element ensures uniform shrinkage of the house without destroying the structure.

- Making a carriage. A beam of 150 x 100, with a length less than the height of the opening by 50 mm, is sufficient. A groove is cut into it and the surface is ground to ensure “sliding”.

- For the top, take a “magpie” board with a width of 120 - 150 (according to the thickness of the walls of a wooden house). It also contains grooves for connecting to the ridge of the opening.

- Installing the sidewalls is the same as for a wooden window.

- After checking the geometry, all casing elements are fastened with self-tapping screws. It must be taken into account that they should not go into the wood of the wall. Otherwise, it will form a “rigid” coupling with the supporting frame, and the pigtail will not fulfill its function.

- Insulation of the opening.

- Treatment of wood with special preparations.

For doors

*The simplest option

- Preparing the opening. If it is not pre-arranged in the wall, it is marked and a rectangular segment is cut out. At this stage, grooves are prepared for connection to the door frame.

- Processing the jamb. This technology implies that he is a door frame. Accordingly, wood is sampled for the grooves.

- Placing the box in the opening.

- Installation of horizontal struts (lower and upper).

- Sealing the casing with soft insulation. Another option is flax fiber. The work is carried out in such a way as to prevent the frame from being fixed in the opening; she must remain free.

- Removing the spacers.

- Treatment of wood with a fire-retardant preparation.

- Fastening platbands.

Other door lining technologies are difficult to implement

Considering the importance of this element for the home, it is better to entrust the work to a professional

Rough casing

For a house built from unplaned timber, it is better to order a rough frame made from solid wood. It will reliably strengthen the walls of the house and protect the windows from the negative consequences of the shrinkage process.

Subsequently, the rough frame is covered with internal and external finishing.

You should not pay special attention to the appearance of such a pigtail, but the installation must be carried out according to all the rules.

In log houses, when installing this type of window frame, it is necessary to use a window sill board with a thickness of at least 65 mm.

In houses built from timber, the window sill board may not be used; in this case, the riser frames are cut into the underlying timber.

Prices, price

Manufacturing costs can vary greatly: prices and prices depend on a huge number of reasons; in every wooden structure, the part is not just necessary, but simply irreplaceable!

What determines the prices and cost of casing:

- on the properties of the wood species

- casing type

- casing forms

- presence of decorative parts

- opening dimensions

- where the part will be installed - in a timber, log or log house

Well, obviously, the final cost of the order is affected by quantitative characteristics: how many pieces or how many meters.

The window frame is made of dry material with a humidity of 8-12%. It consists of a top, risers, an adhesive window sill or a window sill board in cases where a plastic window sill is installed.

You can find out more about the options for installing windows in wooden houses on this page.

Pit from an array

Making a casing from solid wood does not take much time and effort, but preparing the material for such casing is quite difficult.

In the case of a rough casing, where appearance does not play a huge role, the finishing casing, on the contrary, should look flawless. To do this, selected carriages or timber must undergo a soft drying process in order to relieve internal stresses in the wood and, at the same time, the formation of cracks in the workpieces should be minimal.

This work takes a lot of time and not everyone takes it on. If the preparation of the material is not carried out efficiently, then be prepared for warping and cracking of such a frame. Of course it won't fall apart, but the appearance will be ruined.

The pigtail can be made of solid pine, larch or oak.

Features of installing a pigtail in a wooden house

The width of the casing components can be up to 26 cm. In general, it can be larger, but in this case, this may lead to the appearance of cracks along the entire length of the structure. Typically, window frames are made from wood with a moisture content of 10 to 12 percent.

There are two varieties. The usual one, which is notable for the presence of previously machined grooves in the opening logs - for the perfect fit of one side of the casing. This type is used only when installing conventional wooden windows.

It is no longer possible to fasten a plastic profile in a similar way; for plastic windows there is another type of casing. Its essence is this: a ridge is cut out at the ends of the logs, and a carriage with a groove is later put on it. When shrinking, the ridge will fit into the carriage groove without any problems, and the window itself will not be damaged in any way.

Glued pigtail

Glued sash is made from lamellas of small cross-section. This material dries well and quickly in drying chambers. There are no internal stresses in such a pigtail. It does not lead, no cracks appear on it.

A laminated timber frame is not made from laminated wall timber. During the production process of blanks for glued casing, a more stringent selection of material is carried out. It is impossible to hide wood defects inside the workpiece, which is why the price of a socket is much higher than the cost of a wall beam.

Particular attention should be paid to the glue used in the manufacture of glued frames. Only glue intended for this work and compliance with all gluing standards can guarantee the quality of the resulting product.

If all production standards are met, the glued frame turns out to be stronger and more reliable than the solid wood. This type of finishing trim is ideal for wooden houses made of profiled timber or chopped logs.

Each type of casing has the same purpose: to strengthen the walls, maintain the functionality of windows and doors, and not interfere with the shrinkage of the log house. Only the cost and appearance are different.

Window frames for wooden houses, the price of which depends on the type, material and complexity of installation, are made according to individual sizes, which are determined by the master during measurement. This takes into account the thickness of the walls, the unevenness of the walls, the size of the shrinkage gap, the height of the lower and upper cut, the thickness of the tenon or groove at the ends of the logs, sometimes the slope of the roof, the alignment of window openings on the first and second floors...

Only a person with extensive experience in the construction and glazing of wooden houses can carry out the correct measurement and installation of the frame.

How the casing is installed

In general, the process technology is as follows:

- an opening is cut in the wall

- a tenon is formed on the sides of the opening or a groove is selected

- the opening is insulated with jute tape

- a wind block is laid at the bottom of the opening and a window sill is mounted

- risers are installed

- the top is mounted

- the free space above the top is sealed with soft insulation

Now let’s look at the important nuances point by point:

- Before cutting the opening, make sure once again that its dimensions are correct. Especially if you have already ordered windows/doors. After cutting, check the verticals and horizontals

- the finished opening is impregnated with an antiseptic

- jute tape is an excellent wind barrier. It also additionally promotes the sliding of logs/beams inside the casing.

- if you install a P-casing, a spike will form in the wall. Its width should be 1 cm less than the groove in the casing. If you have a T-casing, then choose a groove in the wall; the width of the groove is 1 cm wider than the width of the tenon in the casing. This centimeter is needed for laying 2 layers of jute tape.

- use a staple gun to secure the jute in the opening

- 1 layer of jute is laid at the bottom of the opening, then a wind block is installed, then another 1 layer of jute.

- casing parts are connected to each other in a self-jamming lock, and can additionally be fixed with sealant

For clarity, we have prepared a video that shows in detail all the stages of installing the pigtail:

It is better to entrust the installation of the casing to professionals. But if you are confident in your abilities, then you can do everything yourself. For handy owners, we have prepared a special offer - a ready-made casing for self-installation (in your size, with cut corners).

Differences in the installation of door and window casing

The door casing may be missing the lower part - the threshold. In this case, the bottom of the risers is bolted to the lower crown/beam.

The lower part is always present in the window casing. But its appearance may differ. The following options are possible:

- in the rough casing the lower part is not visible. The window sill is usually plastic, matching the color of the frame.

- in the finishing/Euro casing, the lower part acts as a window sill. In this case, the casing can move inside the room and to the sides of the opening, forming so-called ears.

The video shows the entire process of installing a door casing in a timber house (T-type, with the formation of a tenon in the wall):

The technology for installing casing in a timber or log house is the same.

Manufacturing of casing

High-quality casing should be made of dry wood (forced drying in drying chambers, output humidity 8-10%). Boards and timber from the construction market are not suitable for these purposes, precisely because of the high humidity.

Pine wood is most often used, as it is the most common and inexpensive. Spruce is also used. Exclusive options are also possible - cedar, larch, Karelian pine, KELO crackers.

The basis for the solid casing is a carriage with a thickness of 50 mm or more. For P-casing, a carriage of 90 mm is used. The width of the casing board is equal to the thickness of the wall.

The adhesive casing can be with or without knots. In the first case, the prepared bars are glued together on their sides - this method is called sheet gluing. Knot-free casing is assembled from short bars, which are glued together at their ends - into a microspike (looks like a comb).

Calculate windows with casing

How to calculate the size of the casing/opening

Let's say that you want to install a plastic window measuring 1 meter in width and 1.2 meters in height in a log house with a wall thickness of 150 mm. At the same time, only technical openings have been cut in your house. Let's do the math.

First, you need to decide on the type and thickness of the casing. For the selected conditions, casing with a T-shaped profile, glued “in-situ”, 55 mm thick, is ideal. The window sill will be plastic, which means the lower part of the casing can be taken with a smaller thickness - 45 mm.

If the frame is installed without a quarter (on a plane), then the width of the cut opening should be 15 cm greater than the width of the frame (1.5 cm for foam, 0.5 for jute, 55 for the riser). The final width of the opening is 115 cm.

With a quarter, the width of the opening will be +12 cm, the total - 112 cm.

Calculate the height so that there is 9-12 cm of free space above the top. If you think that 10 cm is a lot, look at the photo report “Test drive of the casing: a year later.”

What happens if you leave the openings WITHOUT casing?

This is possible, but windows/doors installed in this way will not function normally for long. Why, wherefore and how - read in a separate article - Windows without casing = wasted money.

Making a pigtail

Making a pigtail from solid wood with your own hands is possible!

To do this you will need a number of hand tools and the ability to work with them. It is much more difficult to properly prepare and dry the material for making casing. The same work on the production of pigtails, performed on production equipment, will take much less time and will give a higher quality result. Making glued sockets at home, without special equipment, is impossible.

Buying glued material, such as furniture panels or stair strings, and using it to produce casing is also not a good idea. The adhesive used in the manufacture of such products is not intended for use in areas of constant high loads and aggressive environments (heat and cold).

A glued load-bearing beam is ideal for performing these works, but due to the high cost of such material and the large number of scraps, the price of the blanks is higher than simply buying a ready-made socket from the manufacturer.

What kind of joint is there?

Preliminary casing

Cheap option for high quality casing. The best choice for houses where upcoming finishing of skylights is planned.

- Cost per 1 m.p. — from 160 rubles

- Material: solid pine

Casing for a window 1.2x1.2 m - 1,480 rubles excluding installation (for product size 45x150 mm, type T and P)

Finishing casing

A cheap casing option that does not require finishing of slopes.

- Cost per 1 m.p. — from 270 rubles

- Material: solid pine.

Casing for a window 1.2x1.2 m - 2,758 rubles excluding installation (for product size 90x150 mm, type P)

Eurosurface

A cheap casing option that does not require finishing of slopes.

- Cost per 1 m.p. — from 461 rubles

- Material: adhesive made from solid lamellas (pine).

Casing for a window 1.2x1.2 m - 4,155 rubles excluding installation (for product size 90x150 mm, type P)

Power casing

Casing with a width of 90 mm or more, made using the “in-situ” glue method. We recommend it for installation in arched openings, balcony blocks, panoramic windows, huge swing doors, gates.

- Cost per 1 m.p. — from 905 rubles with a size of 90x150 (90 casing thickness, 150 wall thickness)

- Material: glued pine wood.

A power casing for a 1.2x1.2 m window will cost you 5,200 rubles excluding installation.

Combined casing

A new development from our company. The base of the product is made of solid pine, and the top layer is made of a composite adhesive board, which can be made of pine, oak, beech, and valuable wood species.

- Combined casing successfully combines attractive cost and aesthetic appearance.

- The cost is calculated individually.

Filing the casing

The frame for plastic windows can be of various shapes: rectangular, triangular, polygonal in the form of a trapezoid with beveled corners, balcony blocks, entrance blocks, octagon and even circle.

In each case there are features of filing the casing corners. It is the correct filing of the corner joints of the casing structure that ensures the rigidity and tightness of window openings.

Filing the corners of the frame is a labor-intensive process that requires accuracy in the dimensions of the tenons and grooves, and an even plane of contact of the risers and window sills. Maybe someone read on the Internet about a unique old Russian method.

This method is not unique, but it is the only correct one. This is done by everyone who knows how to make a joint and who cares about customer reviews. And this is the best advertising.

Some common features of casing for windows and doors

Method of attaching the door leaf to the casing

The increased popularity of wooden houses has led to the fact that construction teams who do not have practical experience in this area of architecture began to undertake their construction.

The consequence of this were three main mistakes made when installing casing elements for window openings and doors:

- Rigid connection of the frame and logs using self-tapping screws or nails. This absolutely cannot be allowed, since such a connection fundamentally contradicts the basic working principle of the casing frame (the casing must allow vertical displacement of the frame).

- Using polyurethane foam to seal the casing-frame joint. Due to the high strength and good adhesion of polyurethane foam, such a connection is equivalent to a fastening one and will ultimately lead to deformation of the windows.

- The use of additional brackets connecting the door block in the casing with the log house. That is, first, according to all the rules, they install the frame and the door, and then, to create additional rigidity, they connect the casing frame and the frame with brackets.

In general, when designing a wooden house, you should always take into account that the casing is an important strength element of the entire structure of the house, and its manufacture and installation are carried out without nails and screws.

We also recommend that you take into account that any end-to-end connection of wooden elements without a seal (that is, plane to plane) when making casing is unacceptable. Due to drying of wood, such compounds become the main conductors of cold within a year or two.

Jigsaw for plastic windows

The casing of window openings in a wooden house for plastic windows and the casing of wooden windows do not have a fundamental difference.

The draft version is absolutely the same. The finishing casing differs in the size of the quarter under the window.

Even for plastic windows, the sample sizes are not the same, since there is now a huge selection of window profiles on the market from different manufacturers.

The quarters in the casing for the installation of plastic or wooden windows are made individually for each profile, so it is important to decide on the choice of window structures before installing the casing.

For the same reason, you won’t be able to buy a ready-made joint in a store; you can only order it.

Do you need a frame for arched vaults?

Of course, it is necessary, and this is the most complex and most expensive version of the casing frame. Such doors are often installed in bathhouses and wooden houses, stylized as antique.

The casing for them is made according to the same principles as for rectangular openings: with the possibility of displacement in the vertical direction and with a gap to compensate for shrinkage between the top and the frame.

The design of the vertical posts and the bottom crossbar in it is the same as in a conventional pigtail, but the top is made of several sections that simultaneously perform a strength and decorative role.

Turnkey okosyachka

Turnkey installation of a frame includes the following stages: manufacturing of the casing, installation, installation of windows, caulking of the outer perimeter of the frame, manufacturing and installation of the casing. Caulking the gaps between the window frame and the wall must be done.

Otherwise, the only thing that works to preserve heat in the house is the shell of the socket, the thickness of which is 5-7 centimeters.

This work is carried out before installing the casing and a couple of years after installing the casing, when the house settles and the sliding of the side logs along the risers of the frame stops, check the seams and repeat in places if necessary.

It is advisable to treat the caulk seam on the outside with yacht varnish to protect it from moisture absorption.

Types of jobs

Solid: all parts are made by processing solid wood while maintaining the correct wood texture.

Adhesive: parts of such casing are made from glue-type boards. It is glued into a microspike on all four sides. Knots and resin pockets in this case are cut out one hundred percent.

Combined is the most common type of casing. The top and risers are made from solid pine. And the window sill is made of glued boards. All of it has a clean appearance and after installation needs to be treated with paint and varnish.

The window frame is made to measure for each window or door individually. When placing an order, the customer must know which windows and doors will be installed in the future casing. It can be made as with a selection for a window - this option is used in cases where the house will not have external and internal finishing, the walls of the timber or rounded logs remain intact.

The pigtail can be either a standard shape - a rectangle, or unusual shapes. Trapezes, polygons, balcony blocks. Unusual forms have their downsides, but there are ways to avoid them. Such information is discussed with the surveyor at the site.

Where to order a joint?

Ordering a casing from the manufacturer is the best decision that will help you save time and nerves, while you can rest assured of the quality of the casing and the installation work performed.

An experienced measurer will help you decide on the type and cross-section of the frame for your country house; moreover, after the first measurement, the exact dimensions of windows and doors will be known.

By placing an order for frames and windows in one organization, you will receive a guarantee for everything from a single person. You won’t have to waste time on repeated measurements or wait three weeks for the production of colored windows, and in case of problems, the contractors will not shift the blame for the malfunction onto each other.

What is a pigtail or casing for?

Over time, timber houses experience significant shrinkage due to the fact that the wood dries out. Wood twists and bends, which can cause warping and damage to windows and doors. To prevent shrinkage of the house from leading to deformation of window structures and doors, it is necessary to make a frame or casing.

The socket protects the gaps from pressure from above and creates a gap necessary for shrinkage. The side parts of the pigtail have poses that create vertical sliding. In most cases, the sap is made from coniferous wood. It consists of a top, sides and a window sill (threshold).

Installing a plastic window in the casing | a pigtail in a wooden house or log house

Movie 2 of the series “ Installing windows”

in

a wooden house

“

Installation

(installation) of a plastic

window

in the casing in ...

Making an opening, casing, frame in a timber house

1st movie in the series “How to install windows

in

a tree house

."

Glazing a timber house

is a task...

Order casing inexpensively

The price of a joint is not small, but there is always a way to save. The casing installation season is spring and autumn. In winter, when it’s cold and no one really wants to build, the manufacturer may offer you a discount.

For this period of the year it is better to leave internal openings and interior doors. It is better to order a window frame in the summer at the height of the holiday season. During this period, not like in winter, but there is a shortage of orders from manufacturers and you can also place an order at a discount

Source: nareevo.ru/pages/okosyachka-dlya-derevyannogo-doma

How to check a metal-plastic window

When you receive the window, you need to check it. There is a chance that you will have to do this, even if the installation is carried out by specialists. Don't neglect this step.

6 points to pay attention to when checking:

- Opening and window dimensions. The gaps between the posts and the frame should not exceed 20 mm on each side. If the window size is 1900 mm, then the opening with installed casing should not be larger than 1940 mm. Thus, the thickness of the casing is usually 50 mm, the maximum difference between the sizes of the window and the opening is 140 mm.

- The kit must include a stand profile - sweet clover. It allows you to install a sill on the outside and a window sill on the inside. The thickness of the clover is about 30 mm, and it must be taken into account when calculating the window.

- If you ordered windows with mosquito nets, there must be fasteners for them.

- Handles are often lost because windows are shipped without them - check their availability immediately.

- Little things: decorative elements, drainage holes.

- Glass linings. You will find out about their presence by disassembling the window into its frame and glass unit.

The following items are not included with the window by default - they must either be specified in the order or purchased separately:

- Pins are small wooden cylinders that are used as fasteners. The length of the dowel should only reach the middle of the pigtail. If you screw it into the wall, the window will deform within a year or two.

- Window sill and low tide.

- Wedges for leveling the frame. Specialists must have a set of these tools.