Doors are an important element of any home. It is necessary to take into account all the design features of both the building and the part being installed. Any installation of doors in a wooden house is accompanied by additional difficulties and has its own subtleties. Before starting installation, you need to know the properties and features of the wood of the constructed house. The article contains useful tips that will be useful at the final stage of construction.

Installing doors in a wooden house is a complex and responsible process Source drevoteh.ru

Features of installing an iron door in a wooden house

Installation of a metal door in a wooden house can be done independently or with the help of specialists. When installing it, you should pay attention to the details and act carefully to eliminate possible errors. When installing a metal door block in a log or timber house, the following characteristics of wood must be taken into account:

- change in the size of the structure during shrinkage. Experts advise installing windows and doors only a year after the construction of the house;

- weakening of fastening. Anchors are used to attach a metal door frame (frame) to a wooden opening. They should not exceed 15 cm, because too much length can lead to splitting of the wood and loosening of the fasteners. Self-tapping screws are installed at a slight angle for greater structural rigidity;

- insufficient strength of wood around door and window openings. In blind walls the wood is strong and durable, but near openings it weakens. Gaps form between the door and the walls, through which dust particles, cold, and pests can enter the house.

Taking these features into account will help avoid deformation of the door leaf and skewing of the opening.

Advantages of metal doors

Metal doors have a number of advantages:

- aesthetic appearance. A wide range of entrance doors will help you choose a model to suit every taste. An iron door will harmoniously fit into the interior of a wooden building. The choice of model depends on your preferences and financial capabilities;

- strength. Metal is much stronger than wood. The steel door block can withstand high loads. It does not deform from impacts, does not change its positive properties due to temperature changes;

- durability. The strength and reliability of the material contributes to the long service life of the product;

- safety. A metal door is difficult to break down. A steel door, strong hinges and multi-level locking mechanisms are the key to the safety of your property. Instead of a regular metal door, you can install a safe door. It is distinguished by high reliability indicators, because it consists of 2 steel sheets with a thickness of at least 1.5 mm and has stiffening ribs. Equipped with two locks of different designs: level and pin;

- moisture resistance. If the door is installed correctly, then water cannot get inside and freeze. The canvas is usually insulated or additional insulation is used;

- fire resistance. A metal door prevents the spread of fire and smoke during a fire.

Design selection

The choice of a door for a wooden house is noticeably different from the choice of the entrance door to an apartment, where the access space protects it from the direct influence of external factors and one function remains, namely protection from unauthorized encroachment.

A door in a private house has direct contact with the external environment, that is, exposure to temperature changes, frost, and precipitation should be taken into account.

The front door should not become a source of cold in winter, that is, it should have thermal insulation of the canvas and heat-insulating sealing gaskets at the joints.

Taking into account the requirements, the door of a log house is usually made of solid wood or steel sheet.

In the latter case, additional thermal insulation lining must be provided. In addition, we should not forget about sound insulation.

There is a nuance to installing doors in a private house: they must be installed so that they open inward, otherwise there is a risk of not leaving the house if there is a snowdrift near the door.

List of tools and consumables

To work you will need:

- nail puller or crowbar. It is necessary for leveling and installing the door frame on the wedges and hanging the leaf;

- metal scrap. It is needed to remove the old door leaf (if there was one) from the hinges and dismantle the hinges. The crowbar should be of medium size. If a metal door is installed during the construction process, then these tools are not needed;

- set of hex keys. They are used to tighten fittings: handles, locking mechanisms;

- building level and wedges. They are used to align the door vertically and horizontally;

- a chisel is necessary for making a groove in the side parts of the opening for casing;

- chainsaw. Needed for cutting a doorway in a wooden house;

- wood screws;

- polyurethane foam. It is used to seal gaps and cracks around the metal door frame.

Technology for cutting window and door openings

Openings for windows and doors can be cut in two different ways:

- The openings are cut after the house has completely settled. Initially, a solid wooden frame is installed, without window or door openings. And only when the house has completed its final shrinkage (usually after 12 months), window and door openings are cut along the intended boundaries. It should be noted that due to the significant amount of waste generated, this method of cutting openings is much more expensive.

- Window and door openings are cut directly during the manufacturing process of the log house. At the same time, in the places of the openings it is necessary to make cuts for the joinery and cut vertical grooves at the ends of the walls. Bars are subsequently inserted into these grooves, the task of which is to perform a guiding function during the subsequent shrinkage of the house. The remaining gap in the upper part of the grooves is insulated. Strict adherence to construction technology guarantees smooth, beautiful and compact openings for windows and doors.

Whatever cutting technology you choose, you should mark the locations of windows and doors in advance so that it does not turn out that dowels and dowels are already installed in place of the windows or doors. Installation of dowels and dowels must be done on those walls where it is planned to cut down more than two windows. Otherwise, such a wall may sag under the weight of the roof.

Currently, cutting out window and door openings occurs as follows: they begin cutting down the log house, leaving openings that are somewhat smaller in size than required by the project. Then, in the middle of the opening, one continuous crown is passed through (as when constructing a blank wall). This is done every 3-4 crowns. These logs are cut only after the house has completely settled. It should be noted that window and door openings with this cutting method are usually made several centimeters narrower than necessary, which simplifies the process of final alignment of the openings.

Cutting out the openings is carried out using a chainsaw, while the upper and lower logs are cut only halfway, which simplifies the further implementation of the staking.

Framing is a process of casing openings, which prevents their deformation. Thanks to the socket, the crowns of the timber can move freely during vertical shrinkage, preventing the logs from being squeezed out.

Step-by-step installation instructions

Installation of metal doors in a wooden house is carried out in stages. To install the door correctly, it is important to follow the step-by-step instructions. Installation includes 7 stages. Let's consider each of them separately.

Door installation procedure in case of casing

Marking the doorway

Begin installation by marking the doorway. The width of the opening should be 14 cm greater than the width of the steel door block, because a casing (frame) of two boards will be inserted into it, on the sides of the box with a total thickness of 10 cm. And 2 cm is left on each side for the thickness of the foam.

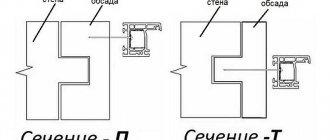

The pigtail is a frame that is connected to each other into a lock using a tongue-and-groove method. The casing is designed in such a way that the parts slide along the side of the opening. They can shift within 7 cm depending on the expansion or contraction of the log house.

The socket is necessary to compensate for the drying out of the wood during shrinkage, and to prevent the openings from skewing when the crowns settle.

Marking is done using a square, a laser level (or plumb line) and a pencil. Measure the width of the opening. Using a laser level, vertical lines are projected. Make marks with a pencil and connect them together with a ruler

Sawing

When cutting, it is important to leave half the thickness of the log or beam at the top and bottom. Remove excess wood. They try to cut the opening straight.

Cutting an opening in a timber frame

Be sure to follow safety precautions; you must wear safety glasses and gloves when working.

After cutting out the opening, grooves are made on the sides of the opening for the casing.

- They make markings. The size of the grooves is 5x5cm;

- The lines of the grooves are marked with a construction ruler.

- They go along the lines with a saw.

- Then the remaining wood is cleaned out of the groove with a chisel.

- The mortgage bars are prepared.

- The opening and bars are treated with an antiseptic.

- Use a stapler to secure jute tape into the grooves and onto the threshold.

- Insert the bars into the grooves.

Sawed groove

Inserted block through jute

Assembled U-shaped frame from a board

Screwed U-shaped frame to a block in a groove with self-tapping screws

Assembly and installation of casing

The next step is to install the casing. The pigtail consists of a bottom, 2 sides and a top. The frame is connected to each other by a tongue and groove. In order to correctly assemble its parts with your own hands, it is important to cut grooves and tenons into them. First, the threshold is laid, then the side parts need to be installed. The installation of the casing is completed by installing the top. It is inserted into the grooves of the sidewalls. There is a shrinkage gap of 5-7 cm between the top and the log. It is covered with tow. Level the casing. The threshold is secured with self-tapping screws. The sidewalls of the pigtails are fixed to the embedded block. It cannot be attached to walls. The threshold can be additionally nailed.

Shrinkage gap at the top 5-7 cm

How to make a doorway in a brick wall

The steps involved in punching an opening in a brick wall are different from cutting a concrete panel. The masonry consists of rows with bandaged seams. The top of the doorway should line up with the joint. You cannot cut bricks lengthwise. Such actions will weaken the tub and cracks will appear along the partition.

After applying the markings, they begin to strengthen the opening in the brick wall by inserting the upper lintel. A row of bricks is selected above the marked line. A lintel longer than the width of the passage is built into the void.

Further actions are aimed at cutting an opening in a brick wall with the selected tool. If the masonry can be disassembled, then it is wiser to pick out the bricks with a pry bar. The seams are drilled with an electric drill. Uneven protrusions at the ends of the doorway are leveled with a grinder.

Additional elements when installing a second door

An important element when installing a door block is the threshold. Without installing the threshold, cold bridges arise, the house has to be additionally insulated, sound insulation properties are reduced, and foreign odors penetrate into the house.

You can install a second door made of wood, it will be warmer and quieter. Most often, a handle with a regular latch is installed on the second door, but it is best to install a locking mechanism, which will create an additional obstacle to entering the house.

Between the doors in the opening, additional elements made of planed boards are also installed around the perimeter of the opening. They are puttied with wood putty and painted.

Casing box

The casing is a rigid structure that takes on the main load from the door system. The casing does not interfere with the shrinkage of the house and at the same time protects the door frame from the impact of the crowns settling down.

How to install casing? At the project preparation stage, when calculating the dimensions of the doorway, it is necessary to add 50-70 mm to the dimensions of the door structure on the sides - this gap will allow the installation of the casing. The upper gap should be 150 mm - this is what will be closed by the settled crowns.

The casing is a “sliding” structure. On the sides of the opening, a ridge is cut out, onto which carriages with a groove of appropriate sizes are placed. A transverse strip is attached to the carriages at the top. As a result, a frame is installed in the opening that will not change its geometry when the log house shrinks. It cannot be rigidly attached to walls. Please note: the frame must be positioned strictly vertically.

How to install a door correctly if the house is old

When you decide to install a new metal door in your wooden house, in which you have been living for several years, an important stage in its installation is dismantling the old structure and arranging the opening.

- In the case of collapsible hinges, screws are removed from them and it is easily removed from the box. If the hinges are not removable, then the sash can only be removed by prying it from below with a crowbar.

- To disassemble the door frame, use a grinder to cut off the fasteners or cut the vertical posts of the frame. Then they are pryed with a crowbar and pulled out of the opening.

- The opening is cleared of debris and old insulation, and cracks and cracks are sealed.

- If the new hole is larger than the opening, then it needs to be widened using a saw.

- The procedure for further installation of a metal door block in an old house is the same as in a new one, only you can do without the casing.

May be useful: Step-by-step instructions for decorating a wooden house with siding

The door can be installed as in the video below, only use self-tapping screws instead of anchors:

How to strengthen a lintel over an opening

Before starting the construction of the opening, it is necessary to install a lintel.

A part of the wall will rest on it, which will remain above the future opening, which will remain from:

- Floor resting on the wall.

- Walls of the upper floor.

- Roof structures.

The safety of the wall structure and the entire house depends on the rigidity of the lintel. When developing lintel drawings, it is necessary, in addition to previously obtained information, to take into account several more factors, which should be:

- The dimensions of the opening relative to the entire wall area.

- The distance between the opening and adjacent walls.

- Dimensions from the ceiling to the upper border of the opening.

- Type and placement of floor slabs.

There are several ways to strengthen the lintel.

Most popular:

From two channels.

When making an opening in the wall, you can build a prefabricated reinforced concrete lintel, which will consist of two profile corner sections. For this:

- a niche is cleared in places where the corners will rest on both sides;

- a thick layer of cement mortar no lower than grade M100 is applied;

- a reinforced concrete beam is laid;

- after the mortar has set, the voids between the wall and the beam are filled with cement mortar, the grade of which is at least M50.

- after the solution has hardened, the opening can be knocked out;

- wrap it with mesh, as in the photo, and plaster it (see).

How to make an opening in a load-bearing wall

It's easier to make a hole in a brick wall.

Wherein:

- It is enough to remove one row of brickwork

- All remaining rows can be removed without much difficulty.

Reinforced concrete is more difficult to dismantle.

You will need:

- Bulgarian.

- Hammer.

Instructions for cutting the opening:

- The grinder disk is immersed into the wall to its full depth.

- Vertical slits are made in increments of approximately 60 centimeters.

- Horizontal lines are then cut with the same step.

- The resulting cubes are knocked out with a puncher.

- The following layers are removed in the same way.

- If the thickness of the load-bearing wall is standard, such notches are made on both sides. In this case, the internal residue is removed in one cut.

This method is used for internal load-bearing walls located in panel houses. In external load-bearing walls, cutting will need to be done several times on each side.

Final design of the opening

The final completion of the reinforcement of the metal structure is as follows:

- They are connected by welding with transverse channel plates on both sides of the wall. Plates are used with a thickness of at least 4 millimeters and a width of more than 5 centimeters, which depends on the instructions in the developed project and technical specifications.

- The elements are distributed in increments of 30-40 centimeters along the entire perimeter of the completed opening.

- At the same time, the channel is welded in previously inaccessible places until the opening has been cut.

- The inside of the opening is plastered and a reinforcing metal mesh is installed, which will be welded onto the channel.

Errors allowed

With a correctly mounted door frame and a hung door, when it is opened at 90 degrees, the door should not close on its own or open even wider.

When installing a metal door yourself, the following errors are possible:

- the opening was cut out of level

The place where the box is supported must be cut level

- The door frame is not level. To level it, you should use a building level. A door unit mounted in this way will be difficult to close and open, and difficulties will arise in the operation of the locking mechanisms;

- use of low-quality loops. If the hinges are not designed for the weight of the structure, then they will not be able to withstand the load from a heavy metal sheet and the service life of the door block and fittings will be reduced;

- the seat has not been previously cleaned;

- Weak fastening of the door frame can also lead to its distortion and failure. Fasteners (screws) must be used universal (yellow or white) of large diameter (4.5 mm or more) with a wide thread pitch;

- incorrect measurement, lack of technological gap cause the door to creak when opening and closing;

- the absence of casing leads to deformation of the door block during shrinkage of the wooden house.

We hope our article will help you avoid mistakes when installing iron doors in a wooden house yourself.

What will you need?

Preparing the iron entrance door for installation

The type of door you need depends on correct measurements of the opening - this is one of the most important operations, so you cannot make mistakes in this matter. Difficulties in obtaining accurate dimensions may arise if you still have an old door: the door frame makes it difficult to find out the specific parameters of the new door.