Over time, wooden houses experience significant shrinkage due to the fact that the wood dries out.

Wood twists and bends, which can cause warping and damage to windows and doors. To prevent shrinkage of the house from leading to deformation of window structures and doors, you need to make a frame or casing.

The cap protects the openings from pressure from above and creates the gap necessary for shrinkage. The side parts of the pigtail have poses that create vertical sliding. Most often, the pigtail is made from coniferous wood. It consists of a top, sides and a window sill (threshold).

Important! The casing must be installed before caulking works.

Types of casing (casing)

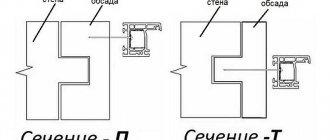

U-shaped pigtail (in a deck)

Classic pigtail. To perform this, a tenon is cut out at the end of the wall, a vertical part of the casing with a groove is installed on it, along which the frame moves vertically due to shrinkage.

Thanks to this, no pressure is placed on the door and window structure, which guarantees their correct functioning and durability. The casing is treated with an antiseptic, and soft insulation is placed between the tenon and groove.

A wind lock provides protection against blowing under the window sill. The gaps above the top of the pigtail are closed with soft insulating material.

T-shaped socket (in a spike)

The T-shaped frame is made as follows: a groove is cut at the end of the opening, and the side parts of the casing have T-shaped profiles. Bars are glued into the grooves on the risers of the frame, which act as stiffeners; they guarantee the stability of the shape of the casing and uniform shrinkage of the walls.

More on the topic How to insulate windows. Review of insulation materials

When installing a T-type pigtail, strict adherence to technology is required. For example, if you secure a block with nails or self-tapping screws, there is a possibility of freezing or blowing through the window and door opening. An important role in casing is played by antiseptic treatment and insulation of seams with compressible material.

A U- or T-shaped pigtail is selected depending on the house. When visiting the site, the surveyor will tell you the most suitable type of casing. Our craftsmen professionally perform the full range of work on the manufacture and installation of casing in wooden houses.

How to make a casing with your own hands

Making clean casing blocks for plastic windows yourself is difficult, but possible. To do this, you will need a planed dry timber or carriage with a thickness of 50 - 100 mm and a width equal to the thickness of the walls in your house. And also jute tape, PVA glue, self-tapping screws, wood sealant, antiseptic impregnation, brush. Construction stapler to secure jute to the wall.

Simple tools you will need are a hammer, a chisel, a construction level, a hacksaw, a pencil or marker, a ruler, and a corner. Power tools include a chain saw or circular saw, an electric planer, and a hand router. The help of one or two friends will not be superfluous.

Before starting work, decide which casing you will do - P or T type. The size of the opening depends on this.

How to cut a casing profile

In a timber house we will make a T-frame, as it is easier to make with our own hands. Here you can do without a router, just use one hand-held circular saw, which you can rent.

Cutting a T casing from solid timber is too wasteful. There will be a lot of waste left. Therefore, we will use the option of gluing a tenon into the sides. On the market, such casing is also called a monolith spike.

The final result of the work.

In a house made of profiled timber 150 x 150 mm, we will need a planed board 150 x 50 mm and a block 50 x 50 mm to make a frame. We mark the drawing as follows: on each part there is a quarter section with a width equal (!) to the thickness of the window profile and a depth of 25 mm, on the sides there is an additional 53x10 mm groove for the tenon.

Important: when marking a groove in the frame for installing a window frame, find out the thickness of the profile of this frame. For example, the Rehau profile comes in thicknesses of 60, 70 and 80 mm, Veka - 58, 70, 82 mm.

For the top we take a beam 150 x 50 mm.

Windowsill. With a wind lock made of 150x90 mm timber and without a wind lock made of 150x50 mm timber.

Longitudinal cuts are made with a circular saw. If the cutting depth is not enough, carefully cut out the remaining wood with a chisel. We also select the groove for the wind lock using a chisel or a router.

And this is what a drawing of the sides of a classic casing deck looks like. The top and window sill are marked in the same way as the T-view.

Dimensional tolerance table

| Quarter Sampling for installation of frames | The width will be equal to the thickness of the window frame. The depth when casing a window opening depends on the height of the blind profile to the glazing bead and to the hinges. If the hinge is close to the casing, then it will not be possible to open the window completely. Usually the frame extends into the quarter by 10-15 mm, another 10 mm is left for the mounting angles. |

| Groove for tenon insertion Side parts of T-casing | - 2-3 mm wider than the block - depth 5-15 mm, depending on the thickness of the casing board. |

| Groove for the wind lock in the bottom board | - 2-3 mm wider than the wind strip - depth 5-15 mm. On a thin window sill, the wind lock is not cut out. |

| Groove in the end of the house wall | The depth is 10 mm deeper than the tenon. The width is 5 mm wider than the spike. |

| Spike at the end of the house wall | The width is 5 mm less than the groove in the pigtail. The height is 5 mm less than the depth of the groove. |

Making the right casing is not easy. Leave it to the professionals. You can buy ready-made casing (custom made to your dimensions) and install it yourself. Send window sizes to whatsapp to calculate the cost - click to start chat We ship casing throughout the Russian Federation by transport companies (we are located in the Moscow region).

Installation of classic P-casing

The technology for installing a pigtail in a timber house is as follows:

- We mark and cut out openings

- We mark a groove at the ends of the cut openings. Let's choose it. Or we form a spike if you chose a P casing.

- We impregnate the openings and the adjacent part of the casing with an antiseptic, for example Veres Base

- We insulate the opening with jute tape

- We install the bottom part, then the sides and finish by installing the top

- Checking the geometry

- We fill the free space above the tops tightly with jute

It seems simple, but as usual, the devil is in the details. I’ll try to show the process of installing casing in a house made of 150x150 mm timber. If it is unclear, ask in the comments.

When marking openings, remember the golden rule “measure twice, cut once.”

Slowly and carefully form a tenon on the side walls of the opening.

Use a building level. The window sill must be strictly horizontal, the sides must be vertical.

When marking openings, proceed from the planned window sizes. Add to these dimensions the thickness of the casing (taking into account the selected quarter) and the gaps for the jute. The sufficient width of the groove for a wall thickness of 150 mm will be 55 mm. I wrote below on the page how to correctly calculate the dimensions of the opening.

The groove is always 5 mm larger than the tenon. It won’t dangle, you still need to insulate the opening with 1-2 layers of jute tape.

First, we insulate the lower part and install the window sill, then we insulate the remaining perimeter and install the sides. We close the casing by installing the top.

We coat the locks with wood sealant. No self-tapping screws!

At the final stage, we stuff the protruding jute into the seams. We also tightly plug the space above the top with it.

Let's check the geometry again. Profit!

The result of the work.

Installation video - very detailed

In the video, the house is not entirely made of timber. It is a fire monitor, but also with smooth walls. All stages of casing installation were well filmed. A bonus is the visual installation of plastic windows and doors.

We will install turnkey casing and windows in 1 day! Clean, beautiful and with a lifetime guarantee! There will be no draft from the windows, and there will be no need to finish the slopes either. Send window sizes to WhatsApp to calculate the cost - click to start chat We work in Moscow and neighboring regions. We ship casing throughout Russia.

Video timing:

- marking openings in the wall 0:20 - 1:07

- sawing 1:10 – 2:20

- marking the tenon at the end of the opening - 3:30 - 4:05

- sawing out a tenon - 4:10 - 6:11

- impregnation of the opening with an antiseptic - 6:13 - 6:55

- impregnation of the casing with an antiseptic - 6:56 - 7:06

- installation of casing with insulation of the opening with jute - from 7:08

- how the last part of the casing is mounted - the top - 7:54 - 8:05 and 8:20 - 8:30

- installation of doors and windows - from 8:35

- caulking seams with jute - from 11:06

Installation of T-casing in a timber house

The technology differs only in that a groove is selected at the end of the openings. And the spike is formed on the side of the casing adjacent to the wall.

It’s not difficult to make a groove in a beam or, simply put, a groove. In the drawing I showed the top view of the groove. After marking, you make two vertical cuts, then two more 45-degree cuts. Remove the cut triangles and clean the middle with the tip of the chain. Or a chisel if you are not confident in your abilities.

How and how to cut a groove in a beam - top view of the opening.

To make straight cuts with a chain saw you need experience, a good eye and strong hands. You can also cut the groove with a hand-held circular saw, and where it won’t reach, finish it with a chisel.

Both types of pigtails are equally reliable. P-casing is a classic, time-tested option. T-casing appeared relatively recently; it is used for installation in houses with grooves cut during the construction of walls.

Advice: The cost of installing a frame for 1 opening in a log house from different companies is now in the range of 3,500 - 7,000 rubles. At the same time, you can order the production of casing without a proprietary installation.

Thus, you will receive ready-made casing profiles of the shape and size you need. To leisurely install them in your free time, saving tens of thousands of rubles.

An additional bonus when ordering a ready-made joint is the choice of options, the independent implementation of which is very expensive. For example, you can order casing to widen the openings into the house - this visually enlarges the openings and provides more light. Or order a clean window sill.

How to connect the parts of a pigtail - lock options

The locks connecting the parts of the casing vary in complexity of execution. The correct lock prevents the parts of the box from moving relative to each other. Both during the installation of a window or door, and during the period of shrinkage of the house. It also prevents connections from blowing out.

Options:

- quarter connection. The simplest to implement, often used for self-installation. Requires additional fixation with corners.

- quarter joint with reverse corners. A more rigid option also requires additional fixation. Blown through

- dovetail or box tenon connection

- designer locks from companies that manufacture and install casing.

A quarter is the simplest and most unreliable lock.

On the left is a box plier, on the right is a casing with a designer lock.

The upper and lower locks in the casing are usually different in shape.

Factory cut top lock.

Stages of installing a casing (casing)

1. The opening cut is made at a distance of 80-90 cm from the floor; when determining this distance, the person’s height is taken into account.

Between the opening and the window or door structure, you need to make a shrinkage gap of 35-60 mm. 2. Preparing the opening. Using a chainsaw, depending on the type of socket, a groove or ridge is cut in the opening.

3. Treatment and insulation. After installing the frame, its surfaces are treated with an antiseptic, and insulation is placed in the gaps. When installing the frame, you cannot use foam, since the window structure must move freely vertically.

4. Installation of wooden elements. At the end, the installation of wooden elements is carried out, namely the window sill, sidewalls and top.

What is casing and how does it work

The casing is a frame installed in a log or timber house. It compensates for the expansion and drying of wood. prevents the impact of shrinkage on the opening. Another name for it is pigtail.

It is made from boards 20-25 cm wide. Using a tongue-and-groove connection, the structure slides along the end of the opening. A non-fixed connection helps the parts move depending on the expansion or contraction of the log house by 7cm. The casing compensates for the expansion or shrinkage of the wood.

A log in a wooden house has a humidity of 12% to avoid cracks in it. The casing for windows consists of 4 parts: top, bottom and sides. The top fixes the sidewalls in a static position. A shrinkage gap is formed above the top. Its height is 5-8 cm. It compensates for the processes occurring in the house during shrinkage. Mineral wool or tow is placed in this gap.

Some novice builders foam the shrinkage gap, not knowing that this should not be done.

The foam hardens and becomes rigid, putting pressure on the casing. The casing may become distorted under load. The adhesive properties of foam have an adverse effect on it. They firmly fix the components of the pigtail, preventing its mobility.

What affects the price of casing?

1. Wall thickness: wooden houses are built from logs and timber, so the wall thickness can be from 140 to 300 mm. The dimensions of the parts of the frame correspond in width to the walls of the house, or slightly exceed it. You also need to consider the width of the window sill.

2. Size of the opening: the larger the opening, the more material will be required to make the frame and the time to work. The shape of the opening also affects the price of the casing: a standard rectangular design or a complex polygonal one.

3. Quality of a wooden house: if the walls are assembled without connecting elements, the curvature of the walls occurs in the cut out openings. Then you have to additionally straighten the walls, which leads to additional costs.

Houses made of timber are assembled using nails that meet at 300 mm. Because of this, additional money and time are required to sharpen chainsaw chains or purchase new ones.

Source: sotdel.ru/okosyachka-obsada.html

Violation of technology and its consequences

Failure to comply with casing installation techniques can cause unpleasant consequences for the owner of a wooden house. They are divided into natural and artificial.

Natural ones include:

- The appearance of gaps between the box and the logs;

- Displacement of the walls between the openings of the log house;

- Curvature of the log house and its walls;

- Destruction of a glass unit;

- The need to regularly adjust the settings of the window opening mechanism;

- The same violations occur when opening doors.

Without a frame in the window, when the house shrinks, the frame and glass burstsSource makemone.ru

Artificial consequences most often arise due to the installation of substitutes for the frame, which are boards or timber. Recently, this replacement has become popular among unknowing people. Its consequence is that there is no forced expenditure of money on replacing the casing structure. It must be taken into account that only a solid structure can withstand the load that shrinkage puts on window and door openings.

DIY pigtail in a wooden house

Modern life, with its busy pace of life, pushes people to look for an alternative place of residence or recreation.

In this regard, a wooden house is a suitable option for a city dweller. A wooden house provides the opportunity to enjoy the naturalness and naturalness of an ecological structure.

Wooden houses, due to their natural characteristics, are environmentally friendly and energy efficient, which is why today the number of adherents of building houses made of wood is growing all over the world.

When building a wooden house, special attention must be paid to the installation of windows and doors, due to their tendency to shrink, which is a characteristic seasonal phenomenon. This phenomenon is due to the fact that wood has such characteristics as drying out and shrinkage.

In this regard, when installing window and door openings, it is important to remember that shrinkage of the building can last up to five years from the date of construction, and, consequently, the openings of windows and doors change.

More on the topic Panoramic windows in a private house

To prevent this deformation, window and door openings are installed in a special flashing, which is otherwise called a casing. A frame in a wooden house allows the natural shrinkage of the house to avoid damaging windows and doors and ensure safe living.

The casing in a wooden house contains 3 components:

- Sidewall;

- Vershnik,

- Window sill board (threshold).

The technology for making a pigtail depends on its type; in order to install a pigeon yourself, you need to carefully study the manufacturing technologies of each type and choose the most suitable one for yourself.

What is a wooden window casing?

In the modern construction market lately, houses made of logs, panels or timber have often been found. These include bathhouses, country houses, and country houses. Despite the fact that new technologies make it possible to create innovative building materials, environmentally friendly wood remains in demand. In addition, such structures have a beautiful appearance.

A feature of wooden buildings, which is called shrinkage, occurs under the influence of temperature factors. Wood can absorb water and dry out over time. The most vulnerable modules of the house are windows and doors, or rather, their openings. Such building movements can impair their functionality or lead to complete destruction. To avoid this, a special technology for their installation is used, in which a window frame is inserted into the opening . It is a wooden box made in a special way.

The technology for installing windows in wooden houses involves installing a frame

The casing includes: a window sill board, a top and two sidewalls. The boards used for its manufacture are about 25 cm in size. Choose a material that has a moisture content of approximately 10%. You should not take drier wood, as it may have cracks invisible to the eye, as a result of which it will begin to collapse as the building shrinks.

The main types of pigtails in a wooden house and their manufacturing technology

The pigtail “in the embedded block”.

This type is a prefabricated structure. A block measuring 50 cm x 50 cm is installed in a cut-out groove prepared in advance. This block will be the main guide for moving the log house vertically. In a wooden house, the frame (casing) is made up of edged boards measuring 50 mm x 150 mm or 50 mm x 200 mm, based on the thickness of the logs.

This technology is highly popular for 2 reasons: 1) due to rapid production and subsequent assembly, 2) due to its relative low cost.

Okosyachka "In Shim Monolith". This technology involves making a casing in a wooden house from a solid rectangular profile beam. Its installation is carried out in a groove in the log house, which is cut in advance. The function of the top (upper horizontal jumper) is performed by an edged board, the thickness of which is 50 millimeters.

The “in the deck” socket is the most common method of casing among the people. Installation involves cutting a groove into a monolithic casing, which is made of rectangular profile timber. The function of the top is performed by an edged board with a thickness of 50 millimeters.

The ridge, which is cut into the end of the log house, serves as a guide for moving the log house. The racks on the sides are also made of timber. At the same time, “blocks” are made, inside of which a groove is cut in the center (50mmx50mm in size); when making them, it is important to take into account the thickness of the logs.

Having laid the thermal insulation in advance, the decks are placed on the ridge, and the racks are attached to the lower supporting crown using pins or wooden dowels. The top is placed on top in a spacer; it is secured with self-tapping screws to the side casing posts.

Pit "in a spike with a ready-made slope." A groove is cut at the end of the opening. A block (50x50 mm) is installed into it through the seal. This block is a guide for the vertical movement of the log house.

More on the topic Standard sizes of plastic windows according to GOST

To make the pigtail, this method uses a glued carriage, which is made from coniferous trees, its thickness is 50 millimeters. Then, on the frame, an “internal quarter” is made from laminated veneer lumber for the installation of window structures. The frame is secured to the opening using self-tapping screws.

In order to facilitate the process of installing a window frame in a wooden house yourself, we present its main stages.

Manufacturing of casing

The casing is manufactured by specialists in stages.

The first stage is cutting an opening in the log house. First, mark it using a level and plumb line. The distance from the floor to the opening is 80-90 cm. Cut out the opening. They saw the log under the window sill. align the structure first horizontally and then vertically.

Sectional diagram

The second stage is the production of tenons and grooves.

- on the sides of the opening, mark a tenon line using a construction ruler, if it is a P-casing;

- then they pass with a saw along the marking lines on the sides of the opening;

- make markings from the side of the wall;

- cut out excess wood from the log along the intended line;

- at the same distance from the side of the opening, pencil marks are placed on the side of the facade;

- connect them together using a ruler;

- cut off excess;

- the groove is made in the sides of the casing. Mark the location for the groove;

- make several cuts;

- use a chisel to break out and remove excess wood;

- When the groove is ready, it is cleaned with a chisel.

At stage 3, antiseptic and staining is performed. They brush off the dust. An antiseptic destroys pathogenic organisms and prevents their reappearance. Such wood does not rot, and insects do not breed in it.

Stage 4—installation of thermal insulation. To seal and eliminate cold bridges, jute tape is used, which is laid under the casing. It is secured with a construction stapler. A layer of jute is placed under the window sill, then a wind block is attached, and a layer of jute is placed on top again.

Stage 5. Installation of casing. All its parts are prepared. Align the edges of the boards with a miter saw. A one-third cut is made from the end of the board for the groove. The excess is chopped off with an ax. The second side casing is prepared in the same way. Align the groove with a cutter. Place the sidewalls, then the top into the spacer, having previously treated them with sealant. Sealant is necessary in order to avoid leakage and blowing. There is a shrinkage gap between the top and the top log. Place the top until it stops. The gap is insulated with tow.

Installing a socket requires a serious attitude to work and knowledge of the nuances of wood processing. Highly qualified specialists with extensive experience in construction work know how to make a socket in a wooden house.

The main stages of making a pigtail

Cutting the opening

First, it is necessary to clarify the size of the opening and its distance from the floor. As a rule, this distance ranges from 80 to 90 centimeters. When determining this distance, it is necessary to take into account the height of future residents.

Then markings are made using special construction tools (plumb and level). In this case, the dimensions of the opening must be larger than the dimensions of the window structure, due to the fact that there must be shrinkage gaps (compensation) from 40 to 60 millimeters above the casing. Next comes the cutting of the opening.

Preparing the opening

This stage involves making a groove (or ridge), taking into account the technology of the socket.

Production and installation of pigtails

This stage is carried out based on the specifics of the production of various types of pigtails. Because different technologies have different rules and production sequence.

Direct installation of windows

It is important to know that the installation of a socket in a wooden house is installed if the house is not older than ten years. It is possible to install the pigtail with your own hands, but to do this you need to acquire certain knowledge and skills.

Features of creating and installing boxes for plastic frames

When installing a pigtail in a wooden structure, you need to know some of the features of its installation. The box can have a width of about 26 cm. It is also possible to use a larger width, but this sometimes causes cracks to appear in the casing. It is recommended to make the box using materials whose humidity is 10-12%. The drier the raw material, the more likely cracks will appear.

To install PVC windows, a complicated version of the casing is used

When installing plastic frames, a more complicated version of the casing is suitable. A carriage with grooves is made and the ridge is cut out.

The structure, assembled from timber with grooves for the comb, is called a carriage for the pigtail. The size of the grooves is made so that the frame can easily slide along the guides when the house shrinks.

The price for making casing depends not only on the size of the opening, but also on the raw materials from which the house itself is built (log house, log or timber). To get a quality product, you should order it from trusted builders. To make a casing with your own hands, you need to understand all the nuances of the process and purchase the required tool for the job.

When starting to install windows made of plastic profiles into wooden walls, please note that they cannot be inserted without a frame. It will help create conditions under which the frame will serve you for a long period of time without deforming or requiring repairs.

The main tasks solved by the pigtail

The formation of a gap between the upper beam and the window opening, which ranges from 5 to 8 centimeters.

Organization of a strong connection of logs located horizontally in the window area. Organizations of structures intended for installation of windows.

Important. The casing in a wooden house does not rigidly tie the structure to the house; it can move freely if the house shrinks.

Installing a frame (casing) in a wooden house is a necessary and important event that should not be neglected. By installing the joint on time, you will save yourself from problems that may arise in the future.

Source: profibrus.ru/okosyachka-svoimi-rukami-v-derevyannom-dome.html

How the pigtail works

As can be seen from the photo, the casing is an ordinary window box made of four, sometimes three (sides and top) thick boards, installed inside the opening.

The meaning of this design is that it is independent of the vertical movements of the wall and moves freely in the opening, since it is not attached to the logs (beams) with nails, screws, or other fasteners, but is held in place by grooves in the side posts mounted on the spikes at the ends of the logs.

Even foam is not used to seal the gaps around the window frame - only tow, jute (flax batting) and other soft insulation.

Types of casing

The casing is the supporting structure of a wooden structure and requires special attention when choosing.

A window frame or casing on the doors of a wooden house is equally important for strengthening walls and preparing openings. There are several types of pigtails:

The pigtail in the embedded block.

In the 90s, when wooden houses made of timber, chopped and rounded logs began to “grow up like mushrooms after rain” in villages and summer cottages, this type of socket, known as an embedded block, became widespread.

With this installation method, a groove is selected at the ends of the window opening logs, into which a 50x50 mm block is driven through jute.

Next, a 50x150mm, or 50x200mm board is nailed to it or turned on self-tapping screws. The top is also covered with screws or nails with a board of the appropriate size.

This is the cheapest type of casing. It appeared, most likely, out of hopelessness among builders, since in those years there was nowhere to buy the right pigtail, and making it by hand was too expensive and labor-intensive. The socket in the embedded block turns out to be fragile, the connection angles of the structure itself are not airtight, there are still many disadvantages and only one advantage - it is inexpensive.

Casing: prices, cost

Manufacturing costs can vary greatly: prices and costs depend on many factors; in every wooden building, the part is not just necessary, but simply irreplaceable!

What determine the prices and cost of casing?

It depends on the quality of the wood, the type of casing, the shape of the casing, the presence of decorative elements, the size of the opening, and also on where the part will be installed - in timber, logs or a log house.

The window frame is made of dry material with a humidity of 8-12%. It consists of a top, risers, an adhesive window sill or a window sill board in cases of installing a plastic window sill.

Several types of work:

Solid: all parts are made by processing solid wood while maintaining the correct wood texture.

Adhesive: parts of such casing are made from glued boards. It is glued into a microspike on all four sides. Knots and resin pockets in this case are completely cut out.

Combined is the most common type of casing. The top and risers are made of solid pine. And the window sill is made of glued boards. All of it has a clean appearance and after installation needs to be treated with paint and varnish.

It is important!

Window frames are made to fit each window or door individually. When placing an order, the customer must know which windows and doors will be installed in the future casing. It can be made either with a sample for a window - this option is used in cases where the house will not have exterior and interior decoration, the walls of timber or rounded logs remain untouched

It can be made as a sample for a window - this option is used in cases where the house will not have exterior or interior decoration; the walls of timber or rounded logs remain intact.

And without sampling - this option is used in cases where the house is planned for interior and exterior decoration in the future. This version of the frame can be finished or rough (if it is completely closed during future finishing).

The pigtail can be either a standard shape - a rectangle, or non-standard shapes. Trapezes, polygons, balcony blocks.

Helpful advice!

Non-standard forms have their disadvantages, but there are ways to avoid them. Such information is discussed with the surveyor at the site.

More about the process

After window openings are cut in a wooden house, the structure of the log house no longer has the same rigidity as if the log house were solid. First, let's answer the question, what is a window frame, or, as it is also called, casing (wooden frame).

After window openings are cut in a wooden house, the structure of the log house no longer has the same rigidity as if the log house were solid. This is especially true for the window opening itself. During the shrinkage process, the logs can move significantly horizontally, which will also lead to deformation of the windows.

All these unpleasant moments are prevented by the frame (casing, wooden frame), which looks like a wooden box. From all of the above, it is clear that installing a socket in a wooden house is a dire necessity. This is true not only for a log house, but also for a timber house.

The process of installing the pigtail is quite simple. Having the necessary tools and materials at hand, you can install the pigtail yourself.

It is assumed that the window opening has already been cut. Now you need to use a chainsaw to select a spike (ridge) on the sides of the opening. This is done so that the pigtail does not move perpendicular to the axis of the walls.

Then the pigtail is made according to the obtained dimensions. Accordingly, in its side racks you need to select grooves for the ridge.

All elements of the pigtail are attached using dowels. Installation of the frame starts from the bottom beam. A layer of linen or jute is first laid under it.

Then vertical bars are installed, into the grooves of which flax or jute is also placed. And lastly, the upper beam of the frame is installed. The shrinkage gap, which must be left above the jamb, is covered with linen fabric.

It is important!

The window frame is a monolithic structure and is absolutely independent of any movements of the frame. Framed with frames, windows and doors will please the eye and will last you indefinitely.

T-shaped pigtail

The T-shaped jamb, the installation of which is carried out similarly to the casing in the embedded block, has a significant difference that makes it much stronger than the previous method described.

The difference is that the block is glued into the base of the workpiece or is made from a single material. The pigtail itself has a thickness of at least 65 mm. and this is enough to create sufficient rigidity of the structure.

This T-shaped casing can withstand horizontal and vertical loads well and reliably protects the windows and doors of a wooden house from distortions and mechanical damage during shrinkage of the log house.

We most often use a T-shaped frame when replacing a poorly installed embedment bar

Installation of casing of an adjacent window opening with a balcony door

If the house is supposed to have access to a balcony combined with a window, you should take into account some subtleties when installing such a structure.

With this arrangement of the opening, the casing cannot be made common; they should be separated by a T-shaped sidewall. The combined side of the door will have a U-shape, which will allow the overall structure to slide parallel to each other without deforming the opening.

The gap left above the window opening should be smaller, and above the door larger. After final shrinkage, the gaps will become equal.

U-shaped pigtail

U-shaped pigtail is a classic type of pigtail. Someone claims that this is a special development of their company and only they install it this way. Not true. The U-shaped casing appeared a long time ago and it will not be possible to reinvent it again.

The production of the pigtail is carried out from solid wood or laminated veneer lumber with a large cross-section by mechanical processing. The result is a rigid, reliable structure that can withstand high loads in any direction.

Ideal for large plastic and wooden windows as well as for installation of metal entrance doors.

In our company you can buy a U-shaped window frame and install it yourself

Suitable wood species

Photo: box assembly

Only chamber-dried wood with a moisture content of 8 to 10% is suitable for casing. An ordinary board or timber is not suitable - it contains a lot of moisture and will quickly lead.

Suitable breeds:

- pine;

- Karelian pine;

- larch;

- cedar;

- spruce;

- beech or oak.

- KELO cracker.

For a T-shaped casing, a carriage with a thickness of 50 mm or more is used; for a U-shaped casing, a carriage of 90 mm or more is used. The width of the board for the jamb should be equal to the thickness of the wall.

Finishing casing

The finishing casing can be made from solid wood or glued blanks.

Finish okosyachka differs from other types in that it does not require additional decorative finishing. The corner joints of the casing structure are sawn by hand so that the gaps at the junction of the hanger, risers and window sill are minimal, which gives the window opening an impeccable appearance.

The surface of the parts is polished and only needs painting.

It is best to order such a pigtail for a wooden house, in which there will be no interior decoration, where the walls remain as they are.

Purpose of casing in the construction of wooden structures

Such an element is mandatory in the design of the entire house. Its absence leads to the fact that the window opening can completely collapse under the influence of shrinkage of the house. In addition, if the wood dries out significantly, cracks and gaps will appear between the frames and the wall of the building, which will lead to large heat loss and drafts.

It is very important to use a socket if there is a small distance between the windows . A design made according to all the rules will become a decoration for your wooden house.

The window frame protects the window opening from destruction when the house shrinks

Please note that casing for a wooden window is not always suitable for PVC frames. If you decide to replace old wooden windows in a wooden house with plastic frames, you need to pay attention to the frame during dismantling. If it is not suitable for a new plastic window, then it must be dismantled and a new one installed, carefully following the technology.

Properly installed frames made of PVC material will serve you for a long period of time. And if you choose the color of the film covering the plastic structure, which resembles natural wood, this will allow the products to look harmonious, combining with the entire wooden structure.

Rough casing

For a house built from unplaned timber, it is better to order a rough frame made from solid wood. It will reliably strengthen the walls of the house and protect the windows from the negative consequences of the shrinkage process.

Subsequently, the rough frame is covered with internal and external finishing.

You should not pay special attention to the appearance of such a pigtail, but the installation must be carried out according to all the rules.

In log houses, when installing this type of window frame, it is necessary to use a window sill board with a thickness of at least 65 mm.

In houses built from timber, the window sill board may not be used; in this case, the riser frames are cut into the underlying timber.

Suitable formats and sizes

The edging of openings is necessary in houses made of ordinary, planed and profiled timber. Highly recommended for houses made of dry and laminated timber. The main reason for its installation is the phenomenon of shrinkage, that is, a decrease in the volume of wood when drying. When shrinkage occurs, the height of the cut openings decreases, and the timber in the walls can rotate and crack.

If you install windows without casing in a house built from freshly sawn or dried timber, then soon through gaps will appear between the beams on both sides of the window to the street - the timber will hang on the screws that secure the window. There will also be a suspended beam that rests on the frame from above. That is, the entire upper part of the house will rest on the window frame. She won't last long. At first the windows will open poorly, then they will stop altogether. The frame will most likely warp and the glass unit will crack.

To prevent this from happening, casing boxes are installed in the openings. For timber houses, T and P type sockets are suitable. It is easy to distinguish them, look at the end of the pigtail - it will look like the corresponding letter.

P-casing and a quarter.

T-casing made of solid wood with a glued tenon.

Recommended dimensions for walls made of 100 mm timber

| Planed timber with natural humidity | P – casing 90 mm thick. Thin walls tend to shrink a lot; a strong box is needed. |

| Profiled timber with natural humidity | |

| Dry profiled timber | P and T casing with a thickness of 55 mm. |

| Glued laminated timber |

Recommended dimensions for walls 145 – 150 mm

| Planed timber with natural humidity | P- and T-pipe with a thickness of 55 mm. |

| Profiled timber with natural humidity | |

| Dry profiled timber | |

| Glued laminated timber |

Recommended dimensions for walls 200 – 220 mm

| Planed timber with natural humidity | P- and T-pipe with a thickness of 55 mm. |

| Profiled timber with natural humidity | |

| Dry profiled timber | |

| Glued laminated timber |

Important! The dimensions in the tables are correct for standard window openings. If the length or width of the opening exceeds 2 meters, then install casing with a thickness of 90 mm or more.

Find out the price for lining your home!

Send window sizes to WhatsApp - click to start chat We ship casing throughout the Russian Federation, install it on a turnkey basis (with windows and trim) in Moscow and neighboring regions. Casing in an embedded block carries a lot of hidden costs and delayed problems. Therefore, I will not recommend it. Read more in the article “Basics of a warm house - once again about casing in embedded timber.”

Pit from an array

Making a casing from solid wood does not take much time and effort, but preparing the material for such casing is quite difficult.

In the case of a rough casing, where appearance does not play a huge role, the finishing casing, on the contrary, should look flawless. To do this, selected carriages or timber must undergo a soft drying process in order to relieve internal stresses in the wood and, at the same time, the formation of cracks in the workpieces should be minimal.

This work takes a lot of time and not everyone takes it on. If the preparation of the material is not carried out efficiently, then be prepared for warping and cracking of such a frame. Of course it won't fall apart, but the appearance will be ruined.

The pigtail can be made of solid pine, larch or oak.

Types of casing boxes

The casing material is wood, without defects and dry. Finished elements are treated with antiseptics and fire retardants in accordance with fire safety requirements. This will significantly extend the service life of the structure. The casing can be made from several types of lumber. Let's look at the features of each of them.

From the array

Photo: installation of casing in a house made of hewn logs

The solid is taken dry, without signs of damage by fungus or insects. There are four breeds most commonly available for sale:

- pine;

- Karelian pine;

- larch;

- cedar.

If pine is used, it should only be chamber dried. Profile type – U-shaped, with or without the option of choosing a quarter.

Solid wood frames are made in log houses and gun carriages and fit perfectly into the style of the house.

From laminated veneer lumber

A popular finishing option for casing for windows that does not require finishing of slopes. Obtained using the glue-type method. The basis is dry bars. The elements are glued together into a “layer” or into a “microspike”.

Profile shape – T-shaped or U-shaped. Type – straight or with expansion into the opening. It may be with or without a quarter.

Glued laminated timber casing is an excellent option for frame houses with exterior siding.

From the gun carriage

When building country cottages from logs, beams, large baths, the KELO carriage is often used to frame doorways and windows.

The advantage of the material is that there is no need to install platbands. The resulting seam between the wall and the window frame is caulked and then closed with a special decorative rope.

The outer part of the casing is aged by artificial brushing or firing.

The profile shape is U-shaped. Comes with an extension inside the house. Can be ordered with or without a quarter.

Combined casing

In recent years, a combined type of casing has begun to be supplied to our market, the main part of which is made of solid pine. The top of the frames is a glued board, where lumber from oak, beech, larch, and pine can be used. Does not require finishing. It looks beautiful. The price is affordable. The profile shape can be T- or U-shaped.

Glued pigtail

Glued sash is made from lamellas of small cross-section. This material dries well and quickly in drying chambers. There are no internal stresses in such a pigtail. It does not lead, no cracks appear on it.

A laminated timber frame is not made from laminated wall timber. During the production process of blanks for glued casing, a more stringent selection of material is carried out. It is impossible to hide wood defects inside the workpiece, which is why the price of a socket is much higher than the cost of a wall beam.

Particular attention should be paid to the glue used in the manufacture of glued frames. Only glue intended for this work and compliance with all gluing standards can guarantee the quality of the resulting product.

If all production standards are met, the glued frame turns out to be stronger and more reliable than the solid wood. This type of finishing trim is ideal for wooden houses made of profiled timber or chopped logs.

Each type of casing has the same purpose: to strengthen the walls, maintain the functionality of windows and doors, and not interfere with the shrinkage of the log house. Only the cost and appearance are different.

Window frames for wooden houses, the price of which depends on the type, material and complexity of installation, are made according to individual sizes, which are determined by the master during measurement. This takes into account the thickness of the walls, the unevenness of the walls, the size of the shrinkage gap, the height of the lower and upper cut, the thickness of the tenon or groove at the ends of the logs, sometimes the slope of the roof, the alignment of window openings on the first and second floors...

Only a person with extensive experience in the construction and glazing of wooden houses can carry out the correct measurement and installation of the frame.

How to calculate the size of openings if there are window/door sizes

Let's take as an example a 1.4 by 1.2 meter window in a house made of 150x150 profiled timber. We will calculate the width and height of the opening for a P-casing with a thickness of 90 mm. The wooden window sill is the lower part of the frame.

Calculation using the example of a window 1400 x 1200 mm.

Initial data:

- window width 1400 mm, window height 1200 mm

- thickness of side panels - 90 mm, top and window sill - 60 mm

- depth of the selected quarter for the frame - 25 mm

- drank above the tip - 70 mm

Formula:

Opening width = window width + two casing thicknesses - two quarter depths + 5 mm for the gap between the casing and the wall on each side and 10 mm for the gap between the casing and the frame, also on each side.

1400+90+90+30–50 = 1560 mm

The height of the opening = the height of the window + the thickness of the window sill + the thickness of the top + 25 mm for gaps - two quarter depths + the gap above the top.

1200+90+90+25–40+70 = 1435 mm

The principle, I think, is clear. If anything, ask in the comments.

Calculate the cost of installing windows in a turnkey log house. Send window sizes to whatsapp - click to start chat Your benefits:

- Finish casing with lifetime warranty

- Veka or Rehau windows

- Installation in 1 day (up to 7 openings)

- Painting the casing in the color of the windows

- No additional finishing work with windows is required

We work in the Moscow region and neighboring regions. Travel to other regions is possible.

Making a pigtail

Making a pigtail from solid wood with your own hands is possible!

To do this you will need a number of hand tools and the ability to work with them. It is much more difficult to properly prepare and dry the material for making casing. The same work on the production of pigtails, performed on production equipment, will take much less time and will give a higher quality result. Making glued sockets at home, without special equipment, is impossible.

Buying glued material, such as furniture panels or stair strings, and using it to produce casing is also not a good idea. The adhesive used in the manufacture of such products is not intended for use in areas of constant high loads and aggressive environments (heat and cold).

A glued load-bearing beam is ideal for performing these works, but due to the high cost of such material and the large number of scraps, the price of the blanks is higher than simply buying a ready-made socket from the manufacturer.

Okosyachka: cost and pricing

Manufacturing costs can vary greatly, since the cost of a joint depends on a large number of factors. This is influenced by the quality of the wood, types of casing, its shape, the presence of decorative details, opening parameters, as well as the material into which the installation will take place. Of course, the final cost will be affected by quantitative indicators, how many pieces or meters.

The type of casing will have a big impact on the cost. All types differ from each other in technical features:

- “In a embedded block” is considered the most economical option. Made from edged boards. A groove is cut out on the inner wall into which a block with a square cross-section is placed. Due to quick assembly and attractive cost, this option is popular;

- “Spike” is a more expensive option, but differs from the previous variety in higher quality. This timber is produced with a cross-section shaped like the letter “T”;

- “Into the deck” - has almost the same cost as the previous option. To do this, a tenon is cut into the sides of the opening, onto which a deck shaped like the letter “P” is placed.

Prices for trimming by different companies:

| Company | Installation according to technology | Unit from. | Cost with material (rub.) | Cost including customer's materials (RUB) |

| "Department" | In the embedded block | m.p. | 1560 | 1100 |

| To the deck | m.p. | 2650 | 1200 | |

| In the thorn-monolith | m.p. | 1850 | 1250 | |

| "Nareevo" | In the embedded block | m.p. | 1600 | 1200 |

| To the deck | m.p. | 2700 | 1250 | |

| In the thorn-monolith | m.p. | 1950 | 1350 | |

| "Okosyachka" | In the embedded block | m.p. | 1450 | 1000 |

| To the deck | m.p. | 2550 | 1150 | |

| In the thorn-monolith | m.p. | 1750 | 1100 | |

| "Beaver's House" | In the embedded block | m.p. | 1600 | 1200 |

| To the deck | m.p. | 2700 | 1250 | |

| In the thorn-monolith | m.p. | 1750 | 1100 | |

| "Carpenter-And-House" | In the embedded block | m.p. | 1560 | 1100 |

| To the deck | m.p. | 2650 | 1200 | |

| In the thorn-monolith | m.p. | 1850 | 1250 |

To make a pigtail with your own hands, in addition to applying physical effort, you need to have certain skills. Installation done professionally will help avoid deformation during shrinkage. This is a kind of guarantee of a safe home.

Filing the casing

The frame for plastic windows can be of various shapes: rectangular, triangular, polygonal in the form of a trapezoid with beveled corners, balcony blocks, entrance blocks, octagon and even circle.

In each case there are features of filing the casing corners. It is the correct filing of the corner joints of the casing structure that ensures the rigidity and tightness of window openings.

Filing the corners of the frame is a labor-intensive process that requires accuracy in the dimensions of the tenons and grooves, and an even plane of contact of the risers and window sills. Maybe someone read on the Internet about a unique old Russian method.

This method is not unique, but it is the only correct one. This is done by everyone who knows how to make a joint and who cares about customer reviews. And this is the best advertising.

Doorway casing

Doorway frame

Speaking about the installation of doorway casing, it is worth noting that they are somewhat more complicated due to their large size, but in general the stages of the work are identical:

- First, the opening itself is cut out.

- Then the tenons and grooves are cut out.

- Then the threshold is installed and tightened with self-tapping screws.

- After this, the sealant is laid and the structural elements are installed.

- Next the top is placed.

It is worth adding that when installing a frame on a doorway, you need to take into account the fact that the frame itself also has a certain thickness, which must certainly be taken into account when cutting out interior doorways and installing the frame as a whole.

Making a doorway

It is important to note that when installing door frames, regardless of location, rigid fastening of elements, with the exception of the bottom one, is unacceptable. The possibility of free vertical movement of logs during the process of shrinkage and drying must be ensured. Otherwise, the described work is quite feasible for independent implementation without the involvement of hired specialists

In addition, work done with your own hands always brings pleasure in itself.

Otherwise, the work described is quite feasible to perform independently without the involvement of hired specialists. In addition, work done with your own hands always brings pleasure in itself.

Jigsaw for plastic windows

The casing of window openings in a wooden house for plastic windows and the casing of wooden windows do not have a fundamental difference.

The draft version is absolutely the same. The finishing casing differs in the size of the quarter under the window.

Even for plastic windows, the sample sizes are not the same, since there is now a huge selection of window profiles on the market from different manufacturers.

The quarters in the casing for the installation of plastic or wooden windows are made individually for each profile, so it is important to decide on the choice of window structures before installing the casing.

For the same reason, you won’t be able to buy a ready-made joint in a store; you can only order it.

Our prices

| Job title | Price |

| Cutting out an opening for a single-leaf window | from 1500 rub. |

| Cutting out an opening for a double-hung window | from 2200 rub. |

| Cutting out an opening for a three-leaf window | from 3000 rub. |

| Cutting out a doorway | from 2560 rub. |

| The door frame is rough | from 1150 rub. m.p. |

| The opening frame is rough with tenoning | from 1700 rub. m.p. |

| Opening frame with finishing of the opening inside the house | from 2460 rub. m.p. |

Turnkey okosyachka

Turnkey installation of a frame includes the following stages: manufacturing of the casing, installation, installation of windows, caulking of the outer perimeter of the frame, manufacturing and installation of the casing. Caulking the gaps between the window frame and the wall must be done.

Otherwise, the only thing that works to preserve heat in the house is the shell of the socket, the thickness of which is 5-7 centimeters.

This work is carried out before installing the casing and a couple of years after installing the casing, when the house settles and the sliding of the side logs along the risers of the frame stops, check the seams and repeat in places if necessary.

It is advisable to treat the caulk seam on the outside with yacht varnish to protect it from moisture absorption.

Shrinkage gap

Please note: a large gap is specially left above the jamb, the size of which is designed for the maximum possible amount of shrinkage of the logs (beams). During the first years after the construction of the house, this compensation gap will gradually decrease to a minimum, but the upper log (timber) of the opening, if calculated correctly, will not press down or deform the frame.

Thus, the shrinkage of the house will not in any way affect the size and shape of the window frame, and, accordingly, will not damage the plastic window located inside it.

Where to order a joint?

Ordering a casing from the manufacturer is the best decision that will help you save time and nerves, while you can rest assured of the quality of the casing and the installation work performed.

An experienced measurer will help you decide on the type and cross-section of the frame for your country house; moreover, after the first measurement, the exact dimensions of windows and doors will be known.

By placing an order for frames and windows in one organization, you will receive a guarantee for everything from a single person. You won’t have to waste time on repeated measurements or wait three weeks for the production of colored windows, and in case of problems, the contractors will not shift the blame for the malfunction onto each other.

Waterproofing a window from the outside

Before foaming the gap between the window and the frame, we need to decide what material we will use to waterproof the installation seam on the street side. As you know, the two main enemies of foam are sunlight and water.

If we can simply cover the installation seam with platbands or flashings from the sun's rays, then with waterproofing the situation is more complicated, because it must meet two basic conditions: not let water in and at the same time not prevent moisture vapor from escaping from the inside to the outside.

Well, and, of course, waterproofing must be resistant to prolonged weathering.

All these conditions are met by materials such as PSUL, waterproofing vapor-permeable tape and special sealant “STIZ-A”.

Sealant "STIZ-A" - a one-component, vapor-permeable acrylic sealant of white color for sealing the outer layer - is characterized by good adhesion to the main building materials: plastic, concrete, polymer concrete, foam concrete, plaster, brick and wood, among others.

It is also resistant to UV radiation, precipitation, temperature deformation and can be applied even at temperatures as low as -20 degrees.

More on the topic Sealant STIZ-A

The only disadvantage of this material is that it is difficult to find in small containers, and buying a whole bucket makes sense when you are installing a lot of windows. If you choose “STIZ-A” as external waterproofing, then the procedure will be as follows: first we foam the window, then, after complete drying, we cut off the foam sticking out from the outside and after that, using a spatula, apply sealant to the cut.

Waterproofing vapor-permeable tape (self-adhesive butyl rubber tape consisting of a vapor diffusion membrane with an adhesive layer of sealant on one or both sides) is sold in rolls of different widths.

In our case, a tape with a width of 70 mm is suitable. When using this tape as waterproofing, ensure it is oriented correctly when gluing.

You can determine this by blowing into it from one side and the other (don’t forget to remove the paper first). Since there is a membrane inside the tape, air passage is only possible in one direction. The side from which it is impossible to “blow through” the tape is the outer (street) side.

The sequence of actions (first the tape, then the foam or first the foam, then the tape) does not matter much, but you need to take into account that the foam, expanding when drying, not only stretches the tape with a bubble (it will interfere later when installing platbands), but in general it can tear it away from the window or frame.

Therefore, if you first stick the tape, then screw the platbands or hard strips on top of it immediately, and only then foam it. Or foam it first, wait for the foam to dry, cut off the excess and stick the tape on the same day so as not to expose the foam cut to prolonged weathering.

PSUL is a pre-compressed self-expanding sealing tape (similar to foam rubber), impregnated with a special composition, thanks to which it is waterproofing and vapor-permeable. Supplied compressed, rolled into rollers.

If you choose PSUL tape, then buy one that expands more than 30 mm. The PSUL will have to be glued not to the outer side of the frame profile, but to the end next to the front edge.

This should be done after fixing the frame in the opening, but before foaming. Of course, it is more convenient to cover the frame with PSUL before installation, when it lies on the floor, but then the installation will have to be done at an accelerated pace, because after a few minutes the tape will expand and interfere with work.

The installation seam should be foamed only after the PSUL has completely expanded and closed the installation gap. But here the same problem is quite possible as with the waterproofing tape: the foam expanding as it dries can squeeze the PSUL out. This can be avoided by pressing the PSUL on the street side with platbands or flashings.

Order casing inexpensively

The price of a joint is not small, but there is always a way to save. The casing installation season is spring and autumn. In winter, when it’s cold and no one really wants to build, the manufacturer may offer you a discount.

For this period of the year it is better to leave internal openings and interior doors. It is better to order a window frame in the summer at the height of the holiday season. During this period, not like in winter, but there is a shortage of orders from manufacturers and you can also place an order at a discount

Source: nareevo.ru/pages/okosyachka-dlya-derevyannogo-doma

Why are window frames needed?

The construction of houses has always been improved throughout human history, and a tree house has hundreds of small, but nevertheless suitable parts. What functions do the platbands on the windows of a house serve?

Firstly, this is protection. They close the gap between the window and the skylight to prevent drafts, dust and water, as well as additional thermal insulation . Nowadays, when installing modern window systems, the gaps are filled with foam, which is already a good insulator and seal. The only drawback of this material is rapid destruction under the influence of temperatures and water. In this case, the platband will act as a good protection and finishing of plastic windows outside in a wooden house from the effects of these harmful causes.

The design protects the plastic from the effects of temperature and precipitation

Secondly, the aesthetic function. Only in second place is decorating the gaps between the window and the skylight. Smooth and straight or elaborately carved, they will embellish the home design.

Internal vapor barrier of windows

On the inside, the foam should also not remain open to prevent moisture from entering it from the air in the room.

To install an internal vapor barrier, you can use vapor barrier tape, which has already been discussed in the main section of this site, or use acrylic sealant SAZILAST-11 (“STIZ-B”).

The vapor barrier tape is glued to the end of the frame with a thin adhesive strip before foaming. Immediately after foaming, the protective paper is removed from the wide adhesive strip, and the tape is glued to the pigtail.

Before the foam under the tape hardens, it is advisable to immediately install the window sill and screw the starting profile to the edges of the frame, otherwise later the tape “bloated” with foam will interfere with this.

Sazilast is applied to the hardened foam, or more precisely, to its cut. In this case, it is no longer necessary to rush to install the window sills and the starting profile, as when using tape. Nothing will prevent you from doing this later, when it is convenient.