Construction of any type involves the use of materials for different purposes. The same applies to the technology of constructing wooden buildings, which consists of several stages. Obviously, there are no special requirements for lumber for rough work - such structures are temporary in nature, which means their properties and appearance are not so important. The same cannot be said, for example, about interior decoration, when every element of the trim must look perfect. In order for the consumer to be able to provide himself with building materials “for all occasions,” the modern market offers three types of boards: edged, half-edged and unedged. If you don’t understand the differences between these products, this blog is just for you. Here are the detailed characteristics, advantages and purpose of each of the above-mentioned lumber - let's look at what they are in order.

Edged, unedged and semi-edged boards – which is better?

Construction of any type involves the use of materials for different purposes. The same applies to the technology of constructing wooden buildings, which consists of several stages. Obviously, there are no special requirements for lumber for rough work - such structures are temporary in nature, which means their properties and appearance are not so important. The same cannot be said, for example, about interior decoration, when every element of the trim must look perfect. In order for the consumer to be able to provide himself with building materials “for all occasions,” the modern market offers three types of boards: edged, half-edged and unedged. If you don’t understand the differences between these products, this blog is just for you. Here are the detailed characteristics, advantages and purpose of each of the above-mentioned lumber - let's look at what they are in order.

Edged board

Edged lumber can be freely used for a variety of purposes. Such a board is obtained by cutting a pre-treated log, in order to avoid wane residues on the edges and ends of the product. Let’s clarify right away - wane refers to areas of bark that can remain on the boards after sawing. Unfinished board edges are considered a defect for edged lumber - only minimal wane is allowed. The corresponding indicators are strictly standardized by GOSTs.

The raw materials for edged boards are various types of wood - from deciduous to coniferous. By the way, it is also worth paying close attention to the type and type of wood - many physical and mechanical properties of the molded product depend on this factor. Experts agree that Siberian larch is universal and effective in all respects. Its wood is durable, wear-resistant, environmentally friendly and impact-resistant. Edged boards made of Siberian larch are recommended for use in rooms with high temperatures and humidity, as well as for outdoor construction and installation work. For such a product, neither precipitation, nor sunlight, nor insects are dangerous. The already high beneficial qualities of such material can be easily enhanced with the help of special impregnations and oils.

The technical indicators and external qualities of the edged board depend on the type of cut, which can be radial, semi-radial and tangential. With radial production technology, a fragment is cut out from the middle of the log, the saw passes through the center. Products of this type are considered to be of the highest quality, as they do not deform when dried or exposed to moisture. In addition, they have a more pleasant and uniform shade. Thanks to the use of semi-radial sawing, it is possible to use raw materials as rationally as possible. The peculiarity is that the cut is made at an angle of 45 degrees relative to the center of the log. The lumber is of a slightly lower grade, but quite suitable for rough work.

The tangential plane is located at a certain distance from the central point of the section, therefore such a cut produces the largest number of edged boards. Their texture is more pronounced. Whether this is an advantage or a disadvantage is up to you to decide, depending on your preferences. But the fact that tangential-type moldings do not have very good practical properties is clearly a minus for the buyer.

Now a little about the typical sizes of edged boards. Typically, the width of lumber ranges from 15 to 250 millimeters. The length varies greatly depending on the models of a particular manufacturer. The thickness of the molded product ranges from 8 to 30-50 millimeters. Only a wooden block is thicker.

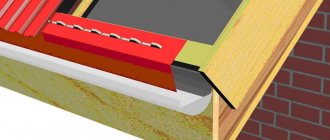

On the basis of edged boards, all types of finishing materials known to us are made from natural wood - lining, imitation timber, block house, straight and oblique planks, terrace and deck boards. The product simply lends itself to special processing on industrial machines in order to form a profile of the desired type in cross-section. The scope of application of edged lumber is not limited to this. Its use is possible literally at all stages of construction - during the construction of formwork, laying subfloors, cladding walls and partitions, and roofing structures. In short, this is a universal product that is indispensable in the construction of private houses.

Cost per cube

I would like to say right away that the difference is quite significant. Of course, a lot depends on what material it is made from. If these are coniferous varieties, then the cost is somewhat cheaper, if these are deciduous “durable” varieties (for example, oak) - more expensive. Also, the price greatly depends on the type of wood, there are 5 in total (according to GOST), you can read about them here.

Unedged option, cost per cube starts from 2000 to 5000 rubles.

Edged version, cost per cube starts from 3,500 to 8,000 rubles.

How to calculate a cubic meter - read this article .

Unedged board

This is a product obtained as a result of longitudinal cutting of a log.

It differs from edged in that the edges are not processed in any way and remain covered with bark. The raw material is wood from the same coniferous and deciduous species. Wane, of course, lowers the class of lumber, but this can also be called an advantage from the point of view of production technology. Less industrial costs – lower price of moldings. There are two types of unedged boards: fence and carpentry. Fence, as a rule, is made from low-quality rocks and has more defects in the form of knots, resins, cracks and stains. Lumber was not originally intended for significant loads, and therefore has a limited scope of use. Unedged fence boards are suitable for installing sheathing and are actively used in landscape design of suburban areas. Joiner's moldings differ from fence moldings because they have a higher class of raw materials. Therefore, it serves as a high-quality basis for interior decoration.

Semi-edged board

This is a cross between edged and unedged moldings. That is, the board has a wane on only one side - the remaining surfaces are treated, clean and smooth. This is the best option for a building material that has sufficient technical characteristics, but is also quite affordable. Siberian larch lumber is especially popular on the market. At a moderate cost, they are considered a good alternative to edged boards.

In our catalog you can order any of the above lumber at a very reasonable price. Contact the manager and place an order with delivery to your city!

Choosing a quality product

Assess the shape of the board. Try to avoid rounded, arched materials - usually this is the most obvious sign of poor quality.

The same can be said about chips and cracks - they must be absent, otherwise the building material will not last for a long time.

Take a closer look at the cross section - if there are signs of warping, it means that the storage conditions were violated. In the future, such material will deteriorate much faster. Next, you can view a photo of an acceptable unedged board to understand how to choose the right building material.

Source

Country and garden houses "Economy" from

Garden timber houses "Economy" are a special offer from our company and are in great demand especially in the spring-summer season. This type of construction is a profitable means of investing small capital for a number of reasons:

- provides an optimal ratio of construction quality and price

- a wide range of possible construction options (prefabricated timber house, among others)

- carried out taking into account soil and climatic characteristics

- has a long warranty service period

Differences between edged and unedged boards

It is probably necessary to recall that unedged boards, in essence, differ from edged boards solely in the degree of processing.

Precisely due to the fact that an unedged board, even of GOST quality, certainly has a thin edge of bark, which is preserved completely or partially along its edges, the cost of an unedged board is significantly less in comparison with similar edged material. Unedged boards, as a rule, are used when performing many “rough” construction works that do not require the use of a material characterized by a beautiful appearance. Therefore, builders who purchase unedged boards, as a rule, use it to construct various temporary structures on the construction site.

Krasnoyarsk is constantly being built up, so unedged boards are also used when constructing the necessary formwork for various concrete structures, when laying floors, creating roof sheathing, making various panels for scaffolding, as well as when carrying out many similar works. Of course, for such work you can use edged boards, but since its cost is much higher, this is economically unjustified.

You complete an order for the purchase of a timber house from our company, draw up an agreement, approve the project we have developed and come at the appointed time to collect the keys to your own home. Believe me, this approach, with its functionality and practicality, will not leave even the most demanding customer indifferent.

Our production

| 25×6000 | 3800 rub. |

| 40×6000 | 3800 rub. |

| 50×6000 | 3800 rub. |

| 650 rub. |

| 9000 rub. | |

| 145×190 | 9000 rub. |

| 195×190 | 11000 rub. |

| Edged board (grade 1) | timber |

All photos from the article

Today, one of the most popular lumber on the market is unedged board, which is due to its low cost, strength, and also the possibility of use in a wide variety of areas of construction. Next, we will get acquainted with this material in detail, and also consider how edged and unedged boards differ, and for what purposes they are used.

Features of the material

Differences from edged boards

The differences between edged and unedged boards lie in the edges - on edged boards they are smooth, while on unedged boards they have an irregular, natural shape. The rough edges are called wane and are often covered with bark.

This difference between edged boards and unedged boards is associated with production technology. The fact is that the first one is obtained by sawing up a wooden beam, while the unedged one is made by sawing up a log. As a result, the edges remain untreated, hence its name.

Accordingly, a board with a wane along its entire length may have unequal width. That, in fact, is all the difference between an edged board and an unedged one.

However, it should be noted that there is one more minor difference between edged and unedged boards - the first can be planed, i.e. have a smooth surface. Moreover, planed lumber is pre-dried. Unedged lumber is not subjected to any mechanical processing before sale.

Advantages

The popularity of the material in question is associated with its following advantages:

- much lower price, since there is less waste in its production, and the manufacturing process is simpler and faster;

- the strength is not inferior to the edged analogue, therefore it can be used in cases where the impeccable appearance of the lumber is not required. True, some designers skillfully use the natural feature of wane, resulting in beautiful and unusual furniture or even finishing material;

- When sawing logs of the same diameter, unedged lumber is always wider than edged lumber.

Note! If necessary, the wane can always be trimmed. The yield of edged boards from unedged boards is on average 80%.

First grade lumber

Wood species

Most often they are made from pine, a little less often from spruce. This is due to the low cost of this type of wood and good performance characteristics. But recently, private construction has begun to develop actively; the market has begun to demand materials with increased resistance to high humidity and temperature changes. These conditions are met by the plant, which has amazing resistance to rotting and can remain in water for decades without deteriorating. can be used for decorating premises or making furniture.

Summer is coming, which means construction season is coming soon. Today I continue to talk about various building materials. The most common type is wood, namely board. You can use it to make “floors”, sheathe walls, or make lathing. However, not all of them are the same, some have more processing, others less. So which ones should you take? Read on...

By “larger” processing I mean “edged” board, by “less” not edged. Don't know what it is? Then read on...

Types of material

Varieties

According to GOST for unedged boards No. 8486-86 and 6564-84, this material exists in several grades:

| Variety | Peculiarities |

| Selective (carpentry) | A special feature is the absence of knots and other defects, so this lumber is used for the manufacture of furniture and other joinery products. |

| First grade | It is a high-quality wood that does not contain rot, wormholes and blue spots. The only thing is that it may contain a small number of knots. |

| Second grade | In addition to knots, it may contain minor cracks that do not affect the strength of the material. Most often used as a structural material. |

| Third grade | In addition to knots and cracks, it contains blue spots, wormholes and some other defects. Therefore, it is used in construction to a limited extent. |

Note! For carpentry and construction, only dry wood is suitable, the moisture level of which does not exceed 18%; the optimal option is 8-12% humidity.

Larch lumber

Application area

When choosing lumber, it is impossible to say which one is better - edged or unedged boards, since they are used for different purposes.

The latter is most often used in the following cases:

- when installing lathing and wall cladding;

- unedged wide board is often used when arranging formwork;

- as a flooring for scaffolding;

- for cladding walls of frame structures;

- as elements of load-bearing structures;

- during the construction of rough floors, etc.

In general, this type of board can be used anywhere where its appearance does not matter. However, as mentioned above, in skillful hands this seemingly completely unpresentable material becomes quite appropriate and presentable.

Kitchen corner made of unedged boards

In particular, furniture made from unedged boards looks interesting. Of course, its use will be appropriate only in certain interior styles. It fits best into rustic design trends, as well as hunting and eco-style.

This material looks no less interesting as a finish. For example, it can be used as siding for a country house. True, in this case, the boards are not mounted on the wall all in a row, but are carefully selected.

The photo shows an example of façade cladding with siding

Therefore, as we see, this lumber can be used even where, it would seem, its use is unacceptable. Here, perhaps, is all the basic information regarding unedged boards, which will help you choose the right lumber.

Bar dimensions

- The dimensions of timber and bars are selected according to GOST 24454-80.

- The main ones that characterize consumer properties are the length and thickness of the edged timber.

- The standard length is 6 m, thickness is in the range of 100 - 250 mm with a width from 50 to 250 mm. The dimensional increment is 25 mm.

- Upon request, timber can be cut from 2 to 9 m in length.

- Permissible deviations in thickness and width: ±2 mm for sizes up to 100 mm and ±3 mm for sizes greater than 100 mm.

- Length deviation: from -20 to + 50 mm.

- The most common sizes of construction timber: 250x250, 200x200, 150x150, 100x100 and 80x80 mm.

- The bars have a thickness and width from 40 to 75 mm.