Articles

All photos from the article

Birch is a tree that grows widely in our country, so boards made from it are quite common and are used to perform a variety of tasks. In this article we will look at all the main features of the material, talk about its advantages and disadvantages, so that you can understand the issue as best as possible.

In the photo: birch parquet boards are very popular due to their attractive structure

Birch board: pros and cons of wood, use of material

Birch is a tree that grows widely in our country, so boards made from it are quite common and are used to perform a variety of tasks. In this article we will look at all the main features of the material, talk about its advantages and disadvantages, so that you can understand the issue as best as possible.

In the photo: birch parquet boards are very popular due to their attractive structure

Pros and cons of wood

Dry birch boards are used quite widely for various purposes; in order to achieve the best result, you need to know all the main features of this species, let's start with the advantages:

| Hardness | According to this indicator, solid birch boards are second only to the recognized leaders - oak and beech. The material is highly resistant to deformation, and the surface is much less damaged compared to popular pine and other softwoods |

| Attractiveness | The material has a uniform structure and very attractive wood shades. Finished surfaces look beautiful, which is why designers love to use this option when decorating various interiors. |

| Flexibility | While the wood is not yet dried, it can be bent and given a certain shape; after drying, the configuration will be preserved, and you will receive an original decorative product. It is precisely because of this factor that birch is very widely used in the production of furniture elements. |

| Budgeting | For all its attractiveness, the material does not cost much; its price belongs to the budget segment, which allows you to decorate the interior without high costs. |

| Good machinability | The board lends itself very well to a variety of processing, so it is convenient to work with it yourself |

Important! One of the best options is Karelian birch; it has increased strength and has an unusual texture with a pink tint to the wood; its only drawback is that its cost is much higher.

A Karelian birch board looks so unusual that it cannot be confused with anything else

As for the disadvantages, they are also present:

- With very high hardness, the material absorbs moisture very strongly and dries poorly, so it is recommended to use it only indoors. If you use a board outside, then even with periodic processing it will crack after a short period of time;

- The material is also susceptible to rotting, especially if it is used in places with high humidity;

- If drying was done poorly, the elements will crack and become very deformed. It is very important to ensure optimal conditions for preparing the material, so you should purchase it only from manufacturers with a good reputation.

Planed birch boards must be well dried, otherwise they will crack in just a few months

Application of material

Let's consider the purposes for which the option we are considering is used, and we will touch on its use both unchanged and as part of other products.

Array

The use of birch boards is most widespread in the following areas:

- When installing floors, this is a classic option that was used back in the century before last. Moreover, it should be noted that, despite its visual appeal and high strength, birch will cost much less than oak and other valuable species. The surface can have different shades - from almost white to grayish, and if it is periodically treated, it will last a very long time;

- Furniture made from birch is also very popular. When etched, you can achieve a very chic appearance of products that resembles valuable types of wood, while the cost of production will be much lower, because manufacturers use cheap unedged birch boards as raw materials, which are processed in production;

Etching allows you to change a simple birch tree beyond recognition

- This option is also widely used in the production of various souvenirs and useful little things - cutting boards, boxes, shot glasses and much more;

Karelian birch is especially popular in the manufacture of souvenirs.

- Another interesting option is a massive black birch board, this species grows in North America and is distinguished by its original texture with dark veins. It is used both for flooring and for furniture production, although this option is not very common in our country.

This board will attract attention with its unusual appearance.

- When decorating interiors, you can also use such a board, the restrictions apply only to rooms with high humidity, and in living rooms you can use birch without any restrictions, while using different shades of wood impregnations you can give the surface a variety of effects, it is important to choose the best option .

Advice! Sometimes it is difficult to imagine what shade the use of a particular composition will give, so as not to spoil the entire surface, we recommend trying to apply the composition to a separate piece of wood or to a small area of the surface.

In fact, the list of what can be made from birch boards is almost unlimited; they are used very widely, so you can use this material to bring a wide variety of ideas to life.

Use in the production of other materials

Due to the fact that the material has some disadvantages, it is not used in humid conditions, but if you recycle it, you can get more reliable products:

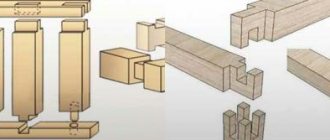

- Parquet and birch parquet boards are classic solutions that are widely popular among developers. Such elements are easy to use; installation instructions consist of leveling the floor and folding the elements through a tongue-and-groove connection;

- As for plywood, birch has no equal; the vast majority of products in this group are made from the material we are considering. Thanks to the processing features, the elements are light and quite durable, while the structure of the wood makes plywood attractive and allows it to be used even as a full-fledged finishing material;

For finishing you can use more reliable laminated birch

- This rock is also used in the manufacture of chipboards; processing makes it possible to make very durable boards that are widely used in a wide variety of fields;

- Furniture board made of birch is very durable and stable; a wide variety of products are made from it and used as a separate material for interior decoration.

Conclusion

Birch is a traditional wood in our country, which has not lost its popularity for several centuries. The main thing is to choose high-quality material and use it where its advantages will be most valuable. The video in this article will help you understand some of the nuances of the topic even better.

Varieties

For the convenience of consumers and product quality control, the modern requirements of GOST 3916.1–96 define four main grades of birch plywood:

- 1st grade: used for making laminated plywood; Defects and errors on the surface are not allowed, the presence of several healthy fused knots with a diameter of up to 8 mm and minor veins is possible;

- 2nd grade: the presence of knots and defects is allowed, which are repaired with veneer in production. Can be coated with finishing materials and paints;

- 3rd grade: knots no larger than 6 mm are allowed in the amount of 10 pieces. per 1 m/sq. sheet surface;

- 4th grade: all manufacturing defects are allowed. Knots can be in unlimited quantities, but with a diameter of no more than 40 mm. It is recommended to use for the manufacture of invisible interior decoration and containers.

Carpentry board – Birch

Birch boards

- Compare

- To bookmarks

- Description:

Unedged birch boards for any needs

Birch is one of the most accessible lumber, as it grows in almost every climate zone. We offer to buy unedged birch boards for further processing specifically for your purposes. The strength of birch wood allows it to be used to make laminate and plywood, skis and veneer, furniture and decorative elements. This material is very pliable for manual processing, adheres well and does not contain resin.

Birch boards for carpentry

Attractive appearance, lightness, strength and low cost make birch an indispensable lumber in the furniture industry. Do you want to purchase commercial birch wood? Buy uncut material, order it to be cut and processed to the required dimensions. As a result, you get high quality edged birch boards. The light tone of the wood allows it to be painted in any shade. Birch absorbs moisture well, and we do not recommend using it for exterior decoration or outdoor buildings without appropriate treatment. If used correctly, it will serve you for many years. Many models of luxury furniture are made from birch.

Birch floorboards: pros and cons, use in the interior

Wood is used in construction finishing works. Birch is often used to make boards. Such wood is characterized by high performance characteristics and a beautiful appearance, and therefore is used in the construction of flooring in residential premises and in the manufacture of products for various purposes.

The wood for the boards must be suitable

Features of birch boards

If the floorboard is made of birch, then they count on the high performance characteristics of this material. Such wood is easy to process by cutting. It is polished, painted in the desired color, and treated with special compounds that retain the shape and color of the laid floor covering.

Birch has positive energy, creating a special atmosphere in the room. This room is comfortable at any time of the year. Birch:

- Environmentally friendly material. Placed in living rooms.

- Affordable price compared to other varieties. As a result, finishing is done at minimal cost.

- Attractive appearance. The special texture allows the flooring to blend harmoniously into the interior.

- Resistant to splits.

- Homogeneous structure, which guarantees the stability of the properties of manufactured products.

- Acceptable for any budget. Purchasing such boards will be cheaper than durable and expensive types of wood.

Birch is limited in use due to its susceptibility to moisture, tendency to deform and rot. For a living space, such wood is an ideal option. It is better to choose a different material for the kitchen or bathroom.

High-quality processing is an important requirement

Advice! To ensure that the birch surface lasts as long as possible, treat the boards with special antiseptic compounds before starting work. An antiseptic will increase the resistance of wood in conditions of high humidity.

Area of use

Birch has been used for flooring for many centuries. Such wood, with its high strength characteristics and visual appeal, costs less than oak. Due to the availability of different varieties, flooring is laid in different shades: from white to grayish. If desired, using paints and varnishes, the color of the coating can be changed.

The quality of the wood makes it possible to use boards in the manufacture of furniture. Etching technology will give the material a texture that imitates valuable wood species. At the same time, the finished product will cost much less than products made from rare types of wood.

Advice! Birch boards are used both to form flooring and to decorate walls. In this case, you can beautifully decorate the interior in a characteristic folk style.

Thus, birch is the wood used for finishing interior living spaces. To form the floor covering, boards that have been dried and treated with an antiseptic are used. This flooring is sure to last a long time. And such wood is used in the manufacture of souvenirs and furniture.

Differences between birch lumber, which explains the demand for them, features of use

Most often, birch lumber is used in the furniture industry; they are also used for interior decoration. Thanks to the attractive appearance of wood and its fairly good strength and at the same time lightness, it is a good building material for furniture sets. At a certain level of steaming, wood bends well.

Birch lumber

Technical parameters of birch

Birch lumber is supplied as edged boards with a natural moisture content. It is made from freshly harvested wood. From April to August, lumber is produced within 2 weeks from the date of harvesting. If stored for too long, it is necessary to treat the wood with antiseptics to prevent fungal damage.

The following are allowed in birch lumber:

- natural defects - knots, eyes, sprouts, mineral inclusions, core, etc.;

- wane – end: depth 5 mm, width 10 mm, length 100 mm, edge – depth 3 mm, length 300 mm, width 10 mm, the wane must be cleared of bark;

- lack of parallelism of edges within 1% of the total length of the board;

- healthy false kernel - no signs of rotting, cracks or minimal signs of fungal infections.

It is not allowed for mold, rot, fungus, or traces of bark beetles to be present on the wood.

Distinctive features of the birch tree

The structure of the array is noticeably strengthened thanks to proper processing and special drying. Wood is characterized by antimicrobial qualities, which make it possible to produce various pieces of furniture.

The smooth texture and its pleasant natural shade allow you not to paint the array, but only to cover it with a layer of protection. Sometimes the wood is whitened to emphasize the originality of the structure. When painted, birch imitates different types of wood.

Karelian birch is often used for the production of luxury furniture. A bed made of such material can last more than 30 years, and a set even longer. The service life of other types of birch wood is approximately 10 – 12 years.

Cost and characteristics of edged boards

Edged boards remain the most common material on the modern construction market. It is easy to process and responds well to finishing. When steamed, wood can bend. Edged boards are characterized by the following qualities:

- great strength;

- light tone, making it easy to give the wood any desired shade;

- resistance to decay and negative environmental influences.

Birch boards require a long drying time during production - at least 10 days, the average period is more than 3 weeks. During this period, a humidity of 12% is achieved. Expensive flooring and premium furniture are made from Karelian birch boards.

The material is recommended for use on the upper part of the heated floor. Even after thorough drying, there is still a risk of shrinkage and deformation due to high humidity in the room.

Application of birch boards

It is best to use lumber in the furniture industry, for the manufacture of various decorative elements, which will subsequently be used indoors.

Birch, like oak, is considered a very hard wood, but at the same time it lends itself well to any processing. Luxury furniture, as a rule, is very often made from birch.

Wood is not recommended for outdoor structures, fencing or any outdoor decorative elements. Wood absorbs moisture well and dries very slowly. This contributes to rapid deterioration of lumber, causing rotting, warping and cracking. In this regard, for exterior decoration, preference should be given to coniferous species, which, compared to birch, are more resistant to moisture and are characterized by resin content.

Birch wood furniture

It is not recommended to build baths, saunas, gazebos, and verandas from such wood. But when using it for interior decoration, the result will be excellent.

The structure of wood and its aesthetic qualities make it possible to recreate interiors that are unique in their beauty and uniqueness, which will delight their owners for many years. Birch is almost as hard as oak, but its price is several times less than solid oak or beech.

Physical properties of wood.

| Scientific classification | Physical properties | ||

| Domain: | Eukaryotes | Average Density: | 630 kg/m³ |

| Kingdom: | Plants | Density limits: | 450–820 kg/m³ |

| Department: | Flowering | Longitudinal shrinkage: | 0,58 % |

| Class: | Dicotyledons | Radial shrinkage: | 5,32 % |

| Order: | Beech-flowered | Tangential shrinkage: | 7,84 % |

| Family: | Birch | Radial swelling: | 0,28 % |

| Genus: | Birch | Tangential swelling: | 0,42 % |

| International scientific name | Bend strength: | 115 N/mm² | |

| Betula L. (1753) | Compressive strength: | 59 N/mm² | |

| Type species | Tensile strength: | 136 N/mm² | |

| Betula alba L. [2], nom. utique rej. = Betula pubescens Ehrh. — Fluffy birch | Thermal conductivity: | 0.143W/km | |

| Fuel properties | |||

| 4.38 kWh/kg | |||

Use of birch bark (birch bark)

The use of birch bark has been known for a very long time. Typically, bark is removed from a fallen tree. The bark will be of good quality in May-June.

Birch bark is dried under pressure and amazing things are made. Masters consider the inner side to be the front side of the bark. Shiny, light-colored More details on the video.

Birch boards

During Rus', the birch was one of the main sacred symbols in paganism and became an integral part of most folk tales. According to ancient belief, this tree, simple and at the same time very beautiful, personified the purity of the Russian soul, protecting against adversity and evil spirits.

Hundreds of years have passed, and birch has not lost its mystery, becoming not only a symbol of Russian culture, but also a practical material that is widely used in the manufacture of magnificent furniture, interior items, construction and handicrafts.

Where is birch wood used?

Let's talk about immediate characteristics. There are no kernels, the texture is smooth, the color of the wood is orange and uniform. The appearance after processing is very attractive, the material is pleasant to the touch and has a slight gloss. It is necessary to pay special attention to the issue of safety of birch products. After drying, it is important to soak them in special oils and varnish them. This will extend the service life and maintain an attractive appearance.

The wood itself is relatively strong and dense, but when exposed to moisture it becomes too flexible and fragile, this is its main drawback. For this reason, you should not use it as a cladding material for walls; it is better to use it as a flooring option. This is an eco-friendly and beautiful choice. You can make plywood by gluing birch sawdust. Subsequently, it can be used to make skis or handles for knives and axes.

Please note that birch, due to its ability to absorb moisture, can be susceptible to rotting; it must be protected with special means, only then can you count on a long service life. The only condition for birch is the absence of obvious signs of disease and moisture, then it is used in production. In other cases, the boards are considered defective.

Properties

In order to increase the strength of birch and its service life, it is necessary to go through several stages of drying and follow wood processing methods. Many people say that it has good energy and can cure a person of illness, but this can be explained by the fact that birch has good antibacterial properties.

The texture of the wood is beautiful and pleasant to the touch; it does not have to be painted, but can only be covered with a layer of transparent varnish. Some fans of the Scandinavian style paint products with white paint, emphasizing the relief of the wood structure and unique appearance.

Karelian birch is widely used for the manufacture of high-quality products. Craftsmen assure that furniture made from Karelian birch can last more than 25 years, and chests of drawers or cabinets even longer. Experts in the manufacture of luxury furniture have conducted research, subjecting birch wood to various tests for strength and durability. They unanimously came to the conclusion that this material can be used to make luxury furniture, and the unique texture and pattern of the wood gives it its own special charm. The cost of such products is lower, and the quality is not inferior to other arrays.

If the wood is processed correctly, it gets rid of its shortcomings and only then can you start making beautiful, expensive furniture. Many are sure that it is impossible to make high-quality furniture from birch, but this is a big misconception. This is confirmed by many factories producing luxury furniture from this noble wood.

Birch boards

Wood obtained from cutting down birch forests has a high density, for this reason it is difficult to saw with a regular household saw. But for all its strength, there is one drawback - moisture permeability. Birch tends to quickly absorb moisture from the environment, and therefore is often susceptible to the development of bacteria and mold. For this reason, it is not recommended to use birch boards outdoors and do not leave them exposed to precipitation.

Despite all the disadvantages mentioned above, birch is very popular in the production of furniture, veneer, plywood, flooring and other materials used in interior decoration. In this environment, it shows all its best qualities - reliability, durability and environmental friendliness.

Frame houses are also built from birch,

but this is a rare and very controversial case. In the article “Birch House” we examined this issue in detail. Nevertheless, we recommend building from coniferous trees; they do not have the disadvantages of birch and are more adapted for private construction. The construction of frame houses is now extremely popular; our website presents projects of frame houses, among which you can choose the most suitable ones or develop an individual project.

Birch

Birch wood has a uniform structure. It contains practically no natural resins. Materials made from this wood have high strength, especially under impact loads. Often used for furniture production.

Birch comes to the market in the form of round timber, lumber, as sliced or peeled veneer, and also in the form of plywood. The material is very easy to process, does not chip, is easy to paint, polish, and bends well when steamed.

Birch wood has the necessary properties that allow it to be widely used in interior finishing work. Birch boards can easily be imitated to resemble most valuable tree species.

Most of the wood produced today goes into the production of veneer and plywood. Despite its pliability, flexibility and elasticity, it is not popular among craftsmen.

Birch boards are a common lumber for work around the house. As a result of the fact that birch wood is quite elastic and soft, it is easy to process, and at the same time it is much harder than poplar or linden.

Solid dry birch board is used only for interior work. It is not suitable as a material for building a house because it is highly vulnerable to fungus and moisture.

Such properties indicate the successful use of birch veneer plywood as a material for interior decoration and furniture production, but it is not recommended for outdoor use, because this wood is susceptible to rotting and warping in conditions of high humidity. Birch plywood is much stronger than other types, easy to process and optimal for further painting or any other type of finishing.

Application areas of birch wood

Birch wood is widely used in carpentry and furniture production and for the manufacture of various household crafts.

Birch plywood is widely used by home craftsmen. Various wall shelves, openwork flower stands, and light furniture are made from it. Plywood is also used for cladding wall panels indoors, to create various partitions, and to change the interior. It should be noted that birch plywood can be successfully used instead of drywall.

Valuable wood species

In this article we will talk about lumber from the main tree species. Let's consider their properties, characteristics, as well as their scope of application.

Ash board

Ash is a deciduous tree of the olive family. Experts value ash timber for its strength and flexibility: thin boards can be used to make bent elements and products. Ash lumber holds up well to impacts, does not cut well, and does not crack, but on the street they rot quite quickly.

Ash wood material, characterized by high physical and mechanical properties, is widely used. The boards have a coarse texture. According to the main characteristics, ash raw materials are similar to oak raw materials, but are distinguished by increased impact strength and resistance to splitting. Ash raw materials can be used to produce veneer, bent and carved furniture parts, and propellers for light aircraft. It is also used to make skis, tennis rackets and other sports equipment. In ancient times, utensils were made from ash because it has no taste.

But you shouldn’t stain or paint ash products, because these procedures change the shade for the worse. For this reason, ash is most often used unpainted, but always thoroughly dried. If drying is carried out according to all the rules, the wood will not be susceptible to cracking. Ash materials are quite expensive; their price can be compared with oak.

The main advantages of ash after heat treatment:

Beech board

Beech wood is a very valuable type of lumber. In solid beech wood you can see a straight-grain structure and a fine, even texture. Lumber may vary in density and hardness. It all depends on where exactly the tree grew. After drying, most of the properties are improved, resulting in beech superior to oak in bending, as well as in rigidity and shear resistance by approximately 20%.

Beech wood has an unusual pattern with narrow, heart-shaped, shiny lines. By polishing, a wonderful pattern is obtained on the manufactured item. Beech materials retain their natural strength for a long time in a dry room, but they rot very quickly if exposed to moisture for a long time. As a result of these properties, beech products often need to be used only in residential buildings.

Beech serves as a raw material for creating furniture and household items. If you steam it, it bends easily, which makes it possible to make Viennese chairs from it. In addition, beech boards are used to create stairs and parquet.

Linden board

Linden lumber is most suitable for use in baths and saunas. They are characterized by low density, which means the risk of getting burned is insignificant. In addition, linden smells very pleasant. Rodents do not like this type of wood; it retains heat well. Even after prolonged use, linden does not darken or turn yellow, and the light natural color is retained. This type is very easy to process, for which it is highly valued by wood carving masters.