The heat loss of sawdust-based insulation is slightly higher than that of modern materials.

However, in terms of the totality of their characteristics, they are not inferior to either mineral wool or polystyrene foam.

Next we will talk about:

- main characteristics of sawdust;

- their advantages and disadvantages compared to other insulating materials;

- methods of their use;

- using sawdust to insulate various parts of the house;

- choosing the most suitable binder for a given situation;

- reviews about insulation with sawdust.

Technical properties of sawdust

The quality of sawdust insulation is on par with other materials. It is characterized by the following technical properties:

- The raw materials contain only organic components that have a porous structure.

- Moderate degree of flammability.

- High level of thermal and sound insulation.

- Environmental safety, since the insulation is completely natural.

- Duration of operation – up to 40 years.

Sawdust is a cheap raw material that is used in buildings for various purposes. You can install it yourself.

Features of the material, advantages and disadvantages

Thermal insulation with sawdust is more often used in private low-rise construction. Raw materials have the following advantages:

- environmental cleanliness;

- low level of thermal conductivity;

- good sound insulation properties;

- low cost;

- ease of installation;

- light weight, so the load on the floor slabs is insignificant.

You can increase the service life of the insulation if you treat it with fire prevention agents, as well as antiseptics. Chips have disadvantages: they absorb moisture and can rot under its influence. Wood waste also has a high level of flammability. If sawdust insulation is laid in violation of technology, it can be damaged by insects and rodents.

Additional components can improve the properties when insulating walls or other parts of a building: copper sulfate, clay, lime, cement.

Preparatory work

Before use, it is recommended to treat sawdust with a wood antiseptic: copper sulfate or boric acid. Sequence of actions during preparation:

- Wood shavings must be dried.

- Then it is evenly moistened with an antiseptic. If necessary, use fire retardants. Thanks to this treatment, the quality of sawdust improves: fire resistance increases, the material becomes less attractive to insects and rodents, and fungus does not form in the structure and on the surface of the insulation.

- The sawdust is dried again.

- Before laying thermal insulation, waterproofing material is laid on the surface.

You can add lime or tobacco to the shavings. The use of a mixture of clay and sawdust makes the material more resistant to moisture. However, even in this case, you need to prepare it first.

Scope of application of sawdust insulation

Before insulating walls with sawdust, the pros and cons of the material are known; you need to know that they are also used to insulate ceilings, roofs, and floors. The technology for carrying out the work may differ slightly.

Walls

More often, wood shavings are used as wall insulation . Sawdust helps reduce building construction costs. First, wood waste is treated with a fire retardant, and chimneys, sockets, and switches are protected with fireproof material. Electrical wires in insulating tubes. The thickness of their walls is 3 mm.

To insulate the walls from the inside of the attic, you must first build a frame into which sawdust will be poured. Slats and wood lathing are fixed to the base. The best material for wall insulation has a coarse fraction. Additional components of the mixture are: water, lime, boric acid, cement. After preparing the solution, it should not crumble. By pouring insulation into the frame on the attic wall, it is compacted to prevent subsidence.

Floor

Sawdust is used as insulation to improve the insulating properties of the floor of a house or attic. The shavings are first prepared: left for about 2 months, mixed with binding components and an antiseptic solution. All insulation components are thoroughly mixed. The thickness of the insulation layer is at least 30 cm. If the attic room will be used only in warm weather or the temperature in winter is not lower than -20 degrees, then this figure is reduced to 15-20 cm.

When insulating the floor, the old covering is removed, and the joists and beams need to be checked for rotten parts or broken fragments. The frame is additionally coated with an antiseptic. The mixture for insulating the attic floor is prepared in small portions. When insulating a house with sawdust, heating pipes and electrical wires are additionally insulated.

The mixture with sawdust is placed on the covering material. After applying the insulation, it should be left for 14 days until fully matured. The attic is regularly ventilated during this period. After 2 weeks, the layer should be checked for voids and filled.

Conclusion

Of all the options, wood chips are the most environmentally friendly material. It has good thermal conductivity and sound insulation properties, which means it can be used along with technologically advanced analogues. If you correctly approach the improvement of the properties of this material, you can achieve increased fire resistance, moisture resistance, and extend the service life.

This becomes possible thanks to treatment with antiseptics and fire retardants. In addition, proper installation will help reduce the intensity of heat outflow from the room when using sawdust: layer by layer with a tamper.

Ceiling

In addition to insulating the attic walls, the same procedure is carried out with the ceiling, since it is through it that up to 20% of the heat is lost. The rough base must be covered with glassine, and all wooden elements must be treated with protective solutions. Sawdust is poured into a solution of cement and water. Next, the mixture is placed on the surface of the floor slabs and compacted. The insulation process is carried out in warm weather so that the layer dries quickly.

For sawdust insulation to be of high quality, the shavings must be dry. It is better to use raw materials after they have been aged for at least 12 months. If you use fresh sawdust, the cement will not set. The chips must have a medium fraction. Raw materials are also checked for the presence of mold.

Roof

If the thickness of the roofing material in the attic is insufficient or the roof insulation is not done correctly, condensation appears on its inner surface, which has a negative effect on parts of the structure. Before insulating the structure, the wooden parts are impregnated with an antiseptic. Joints and cracks need to be foamed.

You need to spread roofing material between the beams, and the sheets are laid overlapping and secured with nails. Communications, chimney surfaces, and electrical wires are additionally insulated. To insulate the roof, you should choose fine insulation for the attic. In most cases, filling with sawdust requires the construction of a frame.

Insulation of walls with sawdust

The insulation technology depends on the material and structural features of the building. It is important to remember that insulating the walls of a frame or wooden house with sawdust is done without using waterproofing so that the walls can breathe. Vapor-permeable membranes help ensure a comfortable internal microclimate.

Preparing for work

At the initial stage, brick and concrete walls are prepared for plastering or shingles are filled to hold the applied layer of insulating mixture. If necessary, arrange formwork. Prepare the necessary mixture or sawdust for backfilling.

Filling internal cavities

The dry backfill method is suitable for filling cavities between a brick or concrete wall and a layer of brick cladding. As the walls are erected, a layer of sawdust mixed with lime is added and compacted without much effort.

Insulation of the frame of a wooden house

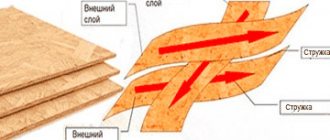

Sawdust mats that match the width of the distance between the frame beams are prepared in advance. The exterior wall frame is covered with clapboard from the room side (you can take moisture-resistant plywood), and from the street side - OSB board or moisture-resistant plywood with lamination. Thermal insulation mats are placed between them. In the insulating “pie,” the inner facing sheet is separated from the insulation with glassine, a vapor barrier is placed on top of the outer one, and guides for constructing a ventilated facade are filled.

Thermal insulation of walls with coating

For this method of insulation, raw mixtures are used, most often sawdust-clay. The solution is poured onto the prepared wall surface or shingles fixed to it. The dried layer is then leveled with cement-sand mortar and the finishing is completed with plaster.

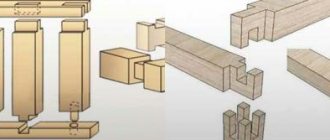

Insulation with ready-made blocks

Before insulating the main walls, a sheathing with a size of bars equal to the thickness of dry blocks/sawdust mats is attached to their surface. The distance between adjacent beams is equal to the width of the mats or blocks. The installed insulation material is fixed with slats nailed to the sheathing. The openings in the internal walls of a frame house are also filled with blocks. In all cases, the remaining gaps are filled with the prepared raw mixture.

Laying the mixture into the formwork

The formwork can be installed along the main walls or on both sides of the wall frame posts. The resulting volume is filled with the working mixture, it is thoroughly compacted and left to dry. Then the formwork is removed, moved higher and secured. The entire process is repeated until the top of the wall is reached. In frame buildings, the top of the opening is filled with ready-made blocks.

Dry method of laying sawdust

The installation process is carried out in two layers. For the first, coarse material is used, for the second - fine sawdust. To insulate the floor in the attic from the inside with your own hands, you need to proceed as follows:

- lay film insulation on the joists;

- fill the subfloor from boards;

- lay an additional layer of insulation;

- pour sawdust and compact well (each layer is done separately, and its thickness is 10 cm);

- Dry the material for 3-4 days, after which the shavings are covered with waterproofing.

The last step is to finish the floor. To insulate the walls, sawdust will need to be mixed with a binder. The drying process of the layer takes 2-3 weeks.

Which sawdust to choose

Going into the forest to cut down a tree and use it for sawdust is not the best option. There are many other ways that cause minimal harm to nature and are more intelligent. Sawdust obtained during carpentry is ideal for insulation. This material has good moisture content and is less susceptible to damage by mold, mildew and insects.

Sawdust is available in large quantities at sawmills. They are waste of wood that has not yet dried, so their characteristics are worse than those of the previous ones. But such material can also be used to insulate the floor in a wooden house.

It is best to choose small chips. They will be able to provide the most effective thermal insulation.

Application of auxiliary astringents

In order for the insulation to be of high quality and durable, sawdust must be combined with binding components. They will not only reduce chip consumption, but also improve its technical characteristics.

Lime

If the owner cannot decide which insulation to choose for the attic walls so that it is cheap and effective, you can fill the frame with sawdust and lime. Well-dried shavings are mixed with the second component in a ratio of 10:1. Additionally, an antiseptic is added to the composition (25g per bucket). The solution is placed in a pre-prepared frame or space between the walls and compacted. But you shouldn’t tamp it too hard, as this can worsen the technical characteristics of the material.

The use of sawdust with lime as insulation provides good insulation, and the powder increases the fire resistance of the mixture and its resistance to damage by rodents and insects. This method can be used when arranging the floor if laying a plank structure is planned.

Gypsum

A mixture of sawdust and gypsum retains heat well and is light in weight. But she is afraid of water, so when using the material you need to take care of its waterproofing. To prepare the solution, take 8 parts of shavings and 1 part of gypsum. It should be mixed in small portions so that the entire amount of material can be applied. Liquid is added at the rate of 0.7 liters per 1 kg of gypsum. You can also use components that slow down the hardening of the solution.

Cement

You can insulate the attic base with cement mortar and sawdust. An additional component is lime. To prepare the mixture, the following components are taken:

- 10 buckets of shavings;

- 1 bucket each of lime and cement.

After mixing the components, the solution is irrigated with an antiseptic. It should retain its shape well, but not release water. Only in this condition is the use of sawdust with cement as insulation justified. It is better to make blocks from the resulting solution, which are used to insulate walls, roofs, and floors. It takes 2 weeks for the layer to dry completely.

Clay

To make warm plaster, you can mix sawdust with clay, cement, old newspapers and liquid. The substance is most often used to insulate the internal surfaces of attic walls. It is difficult to prepare such a solution manually, so it is better to use a concrete mixer. It should have a medium degree of thickness. You should not add a large amount of shavings, since after drying the clay shrinks greatly.

Before laying the mixture, the base must be covered with waterproofing. The insulation layer is 10-15 cm. It will take 3-4 days to dry. If cracks have formed on the surface during this time, they can be eliminated using wet clay. The solution is applied to a vertical surface in the same way as plaster. The surface of the base is cleaned of dirt, dust and loose fragments.

PVA glue

An insulated house or attic will save money on heating. In addition to the previously mentioned binding components, PVA glue is used. A construction or universal type of substance is better suited here. Sawdust can be fresh, but must be dry. The mixture must be used within 1.5 hours after preparation.

If lightweight insulation is needed, then a smaller amount of glue should be used, although the ratio can be 1:2 or 1:10. To increase the strength of the insulator, you can add a little cement to its composition. To the question: is it possible to use sawdust with PVA glue to treat walls, the answer is clear - no, since the mixture has a low level of plasticity.

When filling the space between the wall and the facade, the internal surfaces are covered with drying oil or a thin film.

Choice of solution

The selection of components with high astringent properties should first of all be based on an understanding of what characteristics they have.

The most common solutions are:

- Gypsum: The hallmark of cemented mortar is that it sets fairly quickly. It only takes 10 minutes for the resulting mixture to harden, and after a few hours the solution hardens completely. With such a component you don’t have to worry about the formation of voids. When using it to work with external walls, it is highly not recommended to leave the wall open, as moisture will contribute to the destruction and weakening of the protective properties of thermal insulation. Good for working with interior spaces.

- Cement: unlike gypsum, cement has higher strength characteristics. Except that working with it turns out to be more labor-intensive. It takes at least a day for the material to completely harden. Used for insulation of external walls.

- Manure: Unlike other components, manure does not have high strength characteristics. It has a porous structure, due to which high thermal conductivity is achieved. Requires additional use of gypsum coating.

- Clay: Clay has a fairly low cost and a huge disadvantage in the form of poor resistance to moisture. As it dries, the mass of the solution becomes smaller as excess moisture evaporates. We can say that it is as strong as cement.

- Glue: it is good to use in rooms with a lot of moisture. It prevents rotting and corrosion processes.

- Lime: helps compact the insulation itself, which will protect it from any deformation in the future. Effective in the fight against rodents.

Building materials using sawdust

Sawdust is used not only for insulation of walls and other parts of the attic, but also for the production of building materials with good insulating characteristics.

Sawdust concrete

Sawdust concrete contains fine shavings, lime, cement and sand. Its density depends on the ratio of the components. Depending on the technical characteristics, the product is used for the construction and insulation of internal and external walls of dachas, cottages, residential buildings, attics, garages, and outbuildings. Fences or pillars for them are built from sawdust concrete and used to strengthen the foundation.

The material is well processed; various decorative materials can be used for its finishing. If it is manufactured in accordance with technological requirements, then its properties include high fire resistance and resistance to low temperatures. Sawdust concrete provides good sound insulation of attic walls, is easy and quick to install, has a low cost, but slowly gains strength and requires reliable protection from moisture.

Arbolit

Arbolite blocks are made from a mixture of wood chips, cement, and sawdust. The advantage of the product is its high thermal insulation property, strength, and fire resistance of the walls. The block is easy to process. Wood concrete does not crack, even if it is not stored under a canopy, but is subject to slight shrinkage. The product is relatively light and environmentally friendly.

The disadvantage is the inaccuracy of the geometric shape and low resistance to moisture. For finishing wood concrete, only those products that can allow air to pass through are used.

To understand which insulation is best for the attic, you need to decide on its purpose and seasonality of use. Using sawdust, you can well insulate a given room and ensure its impeccable technical characteristics for many years.

Sawdust concrete

This is a durable material whose composition resembles classic concrete, but fine sawdust and lime are added as fillers. The ratio of components may vary. The choice of option is made taking into account the requirements for the strength of the material. For example, to produce high-density sawdust concrete, you will need:

- 200 kg of cement;

- 200 kg of sawdust;

- 500 kg of sand;

- 50 kg of lime.

The number of components can be reduced/increased, but it is important to maintain the proportions. To influence the ability of wood chips to absorb moisture, they need to be soaked in lime milk, then in liquid glass. At the next stage, the sawdust is dried. This is necessary so that the wood chips do not contain moisture at the time of joining the components.