Oriented strand board (OSB, OSB, OSB - short for the English expression oriented strand board) is a modern structural and finishing material that used for various works.

OSB was conceived as an inexpensive alternative to plywood and chipboard, because the ability to use non-commercial wood to make chips reduces the cost of the finished product.

Next we will tell you:

- what is OSB;

- what types of oriented strand boards are there;

- what regulatory documents regulate the quality and characteristics of OSB boards;

- what sizes do chip OSBs have, and does their price depend on this;

- how much does this material cost?

- advantages and disadvantages compared to other structural and finishing materials;

- What is OSB used for?

What is OSB?

OSB consists of several layers of thin (0.5–1.5 mm) chips of various shapes and sizes, oriented within each layer. The sizes of wood shavings for OSB are 1–20 cm in length and 1–50 mm in width. You can read more about how chips are produced here.

There is no clear orientation in the longitudinal or transverse direction , however, the majority of all large wood chips are oriented in the desired direction with a tolerance of up to 60 degrees (in most cases, the rotation relative to the orientation does not exceed 30 degrees).

Due to the fact that most large chips are oriented in one direction,

the layer acquires increased transverse or longitudinal rigidity and strength .

All layers are connected to each other using a mixture of various natural and synthetic adhesives, and each manufacturer uses its own recipe and keeps it secret.

As a result all layers combined into a single carpet jointly react to any bending or twisting force , which provides high rigidity and strength compared to chipboard.

In this case, oriented strand board is inferior to plywood in these parameters, because in plywood each layer consists of a whole sheet, so its strength and rigidity are much higher. All sheets correspond to the size accepted at the enterprise.

Resins and final product quality

Resins play an important role in the manufacturing process of OSB boards. The quality of the final product depends on how correctly the brand of resin is selected and integrated into the technology.

Various types of resins are used for the outer and inner layers of the board. Their concentration ranges from 11 to 15% of the total mass.

One of the serious problems is the high toxicity of resins. Unfortunately, they emit harmful components into the atmosphere such as formaldehyde, methanol, and phenol.

Regulations

In the Russian Federation, the characteristics of OSB are regulated by GOST 32567-2013 , which you can familiarize yourself with at this link.

The basis of this document was the international standard EN 300:2006 “Oriented Strand Boards (OSB) – Definitions, classification and specifications”. Therefore, slabs that comply with GOST will also comply with the international standard.

The document applies only to the characteristics of the finished product, allowing the manufacturer to independently choose the most suitable technology. We talked about general technological aspects in the article OSB production as a business.

Lumber calculation calculator

You should only buy OSB from manufacturers whose products meet the strictest European standards, even if it costs more. Boards from American and Canadian manufacturers have proven themselves especially well (America is the birthplace of OSB and construction from this material is widespread there) Norbord, Arbeс, Grant, Georgia Pacific, Ainsworth, German Glunz and Austrian Egger and Kronospan.

The products of Russian manufacturers are also gradually reaching a decent level, but studying certificates, the origin of resins and other details is mandatory. OSB of Chinese origin combines low price with the same quality, since it is most often made from low-grade wood and dubious resins, it can only be used for auxiliary work outdoors.

Types of oriented strand sheets

GOST 32567-2013 and the international standard EN 300:2006 divide oriented strand boards (OSB shown in the photo) into strength classes :

- OSB-1 (OSB-1).

- OSB-2 (OSB-2).

- OSB-3 (OSB-3).

- OSB-4 (OSB-4).

In addition, all types of slabs are divided according to the appearance of the front side :

- unpolished;

- polished,

as well as the release of formaldehyde into the air (emission) :

- E0.5.

- E1.

- E2.

Strength and water resistance classes and application features

The OSB-1 class includes a material that is unsuitable for creating load-bearing structures and has minimal moisture resistance. It is used for finishing inside dry rooms and covering various panels. In addition, it is used for making furniture .

Despite the fact that OSB-1 has the lowest fracture strength, even it surpasses in this parameter gypsum plasterboard sheet (GKL) of the same thickness and cement-bonded particle boards, which we talked about here.

In terms of rigidity, OSB-1 is inferior to gypsum plasterboard and fiberglass board, so it is necessary to reduce the distance between the sheathing parts, otherwise the sheathing will be pressed through.

The OSB-2 class includes more rigid and durable slabs that

can act as load-bearing elements .

For example, due to its low price, OSB-2 of various thicknesses is often used for laying on subfloors.

However, they are also not suitable for use in conditions of high humidity , so they are not used for making external cladding of buildings or SIP panels.

The OSB-3 class includes slabs that differ in their technical characteristics - durable and moisture-resistant elements that are used as structural ones . OSB-3 of various sizes is often used as a subfloor, because they successfully replace floorboards, and their price is noticeably lower.

In terms of strength, particle board OSB-2 and OSB-3 are comparable, so the main difference is the minimal ability to absorb moisture, due to which expansion due to swelling is also minimal.

Moisture-resistant oriented strand boards of class OSB-4 of all sizes are distinguished by the highest price, maximum rigidity and strength, therefore they are used only as structural boards , and in areas with maximum load .

In addition, OSB-4 has a minimal ability to absorb water, thanks to these characteristics they have the most positive reviews and are used in the production of SIP panels, as well as as external cladding of frame houses.

Type of front surface and ends

The first experience of using oriented strand boards of different sizes - moisture-resistant OSB for exterior use and conventional ones for interior decoration - showed their high efficiency and significant superiority over other materials in terms of price/quality ratio.

As a result, there was a demand for higher quality products, with an even and relatively smooth surface.

polished appeared . Sanding preserves the unique surface pattern, but eliminates all major irregularities. In addition, the tolerance for thickness deviation for sanded products is much lower and amounts to 0.3 mm, while for unpolished products a deviation of 0.8 mm is acceptable.

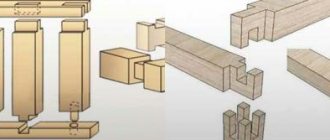

Most slabs have straight ends, but OSB, intended for creating a continuous flooring,

has locks cut out at the ends , which allow the sheets to be laid without gaps.

Such oriented strand boards are called tongue-and- . You can read more about tongue and groove slabs here.

Manufacturers also offer sanded boards, varnished or laminated .

The front side of the former is impregnated with waterproof and wear-resistant varnish, while the latter have a thin wear-resistant film fused to the front side. Typically, such coatings are applied to material intended for finished flooring and external waterproof finishing.

3 formaldehyde emission classes and environmental friendliness

To reduce costs and increase the strength of OSB, manufacturers are forced to use adhesives containing formaldehyde . After hardening and polymerization, such adhesives have fairly high resistance to water and good strength.

The use of adhesives that do not contain formaldehyde either does not provide the required strength or greatly increases the cost of the finished product, depriving it of its main advantage - low price compared to plywood.

Therefore, it was necessary to divide OSB into classes based on formaldehyde emissions. The minimum class E0.5 allows for contents of up to 4 mg/100 grams of OSB. In this case, the content of the toxic drug in the air at any time should not exceed 0.08 mg/m3 .

For class E1, the formaldehyde content should not exceed 8 mg/100 grams, and the maximum permissible content in the air is 0.124 mg/m3 .

For class E2, the formaldehyde content in 100 grams of OSB should not exceed 30 mg, and emissions should not exceed 1.25 mg/m3 .

At the same time, the average daily concentration of formaldehyde in residential premises should not exceed 0.01 mg/m3, as stated in Appendix 2 of SanPiN 2.1.2.1002-00 “Sanitary and epidemiological requirements for residential buildings and premises.”

You can read this document by following the link. Even the conditionally safe class E0.5 releases an amount of this toxic substance that exceeds the standards, so OSB cannot be used for interior decoration of residential premises without ventilation , since it can still be quite harmful to the human body without observing these safety measures.

Dimensions and weight

no single standard, that is, standard OSB sizes , but most manufacturers adhere to the following length and width parameters in mm:

- 1250x2500;

- 1200x2400;

- 590x2440.

There are other sizes of OSB-1, OSB-2, OSB-3 and OSB-4. If, instead of purchasing finished products, you prefer something made to order, then they can make you any size, up to a length of 7 meters.

Sheet thickness ranges from 6 mm to 25 mm in increments of 2 or 3 mm. However, the most popular are slabs with a thickness of 8–16 mm. Also quite often on the Russian market there are OSB thicknesses of 9 mm, 10 mm, 12 mm and 15 mm, their cost usually increases according to the increase in their parameters.

The weight of the sheet depends on its thickness and size, because the average density of any type of board is the same and is 600–700 kg/m3. Therefore, the weight of OSB with dimensions 1220x2440 mm is 12.5 kg with a thickness of 6 mm, with a thickness of 9 mm and 12 mm it will be correspondingly greater, and with a thickness of 22 mm it will be 42.5 kg.

Updating the façade of a building with OSB panels

OSB boards, as we already understood, can be used in different ways, depending on a number of factors. They even manage to build full-fledged warm houses from them - here the material acts as a base for expanded polystyrene. The symbiosis of these materials allows you to create special sandwich panels, as in the photo below.

Fast technology for building a house from OSB sandwich

The building is assembled from such sandwiches, like a construction set. A very interesting technology, but today we will not talk about it, but about the use of individual OSB sheets for finishing an existing facade. Let's look at how you can transform your home and what additional benefits you can get from it.

So, let's imagine that in front of us is the facade of an old house that we want to update. OSB is sewn onto the frame, which means that the structure can be additionally insulated, and it would be simply stupid not to take advantage of this opportunity.

Table 1. Installation of OSB panels.

| Steps, photo | Description |

| Step 1 - make the sheathing | The frame for the cladding will consist of several layers - sheathing and counter-lattice. This will allow you to install insulation, provide space for its ventilation, or add a second layer of insulation and make the structure more durable and reliable. The photograph shows the structure of the sheathing with insulation. We see vertical posts made of timber, between which sheets of mineral wool are installed. In this manner we will have to equip the entire facade without gaps. |

| Step 2 - determine how to attach the belts | If the walls of the house are initially smooth, then the task before you is not the most difficult - the racks can be installed directly on the surface without additional leveling. However, this happens extremely rarely, so let’s not hope for the best and describe the alignment technology. The note! Let’s say right away that the base for the sheathing, which is the frame, must be perfectly flat so that there is no internal tension in the panels, so don’t be lazy about leveling the walls if required. |

| Step 3 – basic verticals and horizontals | When determining the parameters of the frame, you must first of all focus on the dimensions of the purchased OSB sheets. We know the standard, so the distance between the posts needs to be 62.5 cm. This will allow the panels to be mounted in any position. 1. So, the first thing you need to do is install the corner posts. We align them exactly vertically using a laser or bubble level. 2. Wooden beams with a cross-section of at least 50*50 mm are used as racks. 3. A nylon thread is stretched between the outer posts above and below. We will need this element to align the remaining racks in one plane. 4. Next, mark the distance between the posts according to the above step. 5. Take the beam and check whether it can be installed everywhere so that the thread does not change its position. If there is not enough space, the outer racks should be moved away from the wall to the required distance. Do this evenly, otherwise you will end up with uneven slopes on the windows and doors. 6. You can move the beam from the base using metal hangers or corners, as in the photo shown. 7. Then the main verticals and horizontals are placed, the position of which is determined by the already stretched thread. We are talking about the elements that form the slopes of door and window openings. After assembling the sheathing, the space between the belts is filled with sheets of mineral wool or foam plastic. One more thing. If you plan to install a counter-lattice, then the step between the belts can be reduced so that the insulation does not need to be trimmed. |

| Step 4 – counter-lattice and insulation with a second layer | Installing the counter-lattice will not be difficult, since we have already leveled the first part of the frame. Your current task is to divide the distance into steps of the required size, screw the beams perpendicular to the previous ones onto wood screws, install insulation, covering the cold bridges of the first layer, if required. Advice! It is very important, if OSB without a profile edge is used, to install jumpers at the locations of the seams, otherwise the skin will be movable and may bend in different directions, which will ruin the finish. |

| Step 5 - installation of waterproofing | Mineral wool is very susceptible to getting wet, so it needs to be covered with a special waterproofing film. It is attached with a stapler to staples. Next, another level of counter-lattice is made. This space will already be used for ventilation of the insulation and for its proper drying. The principle of fastening is exactly the same as before. |

| Step 6 – covering with OSB boards | Next, the frame is covered with OSB panels. They are installed so that the edges fall exactly in the middle of the belts. Fastening is carried out using wood screws of the appropriate length (it is required that the fastener enters the timber at least 2 cm). It will be very good if one sheet covers the entire height of the wall to avoid unnecessary transverse seams. The OSB is attached to all the belts that pass under it. It is best to trim the material at the corners of the building. This must be done with a circular saw with a medium tooth. You only need to cut along the guide so that the edges are smooth and beautiful. |

| Step 7 – unstitching | Now the coating needs to be protected and decorated. We start by sealing all the seams. For this, a special elastic putty is used, for example, Holzer Flex Spachtel Elastish. The seams are unstitched 5-7 cm in each direction from the seam, the layer of putty is 3 mm. It will dry within 10 hours. Look for information about similar materials on their packaging. |

| Step 8 - painting | Next, the entire surface of the sheets, together with putty, is covered with a special primer-paint for OSB. This material can be tinted in any color; it will add not only attractiveness, but also qualitatively protect the skin from moisture. The coating lasts 10 years, after which it will need to be re-treated. What paint is suitable for OSB panels? Read in detail in a special article. |

| Step 8 - installation of decorative strips | The seams are covered with decorative panels - this way you can create an imitation of the German style of building a house - half-timbered. The panels are attached with adhesive or with galvanized screws. |

Prices for mineral wool

Minvata

Marking

The general principle of marking OSB produced in Russia and abroad is the same. On one side indicate :

- variety;

- dimensions (length, width, thickness);

- formaldehyde emission class;

- type of front surface;

- manufacturer's name.

If you purchase OSB intended for sale in America and Europe , then you need to be aware of the differences in labeling. The grade may be specified not as is customary in EN 300:2006, but in accordance with CSA O325 , that is:

- W – oriented strand board for cladding internal walls of dry rooms;

- 1F – rough flooring;

- 2F – OSB for finishing flooring;

- 1R – material for roof sheathing without creating support at the edges;

- 2R - the same, but with support at the edges.

In addition, after the letter a two-digit number is indicated, which means the maximum allowable distance between supports in inches, for example, 1F18.

If OSB is suitable for various applications, then all tolerances are listed, for example, 1F18/2R20. Moisture resistance with this marking is also indicated separately :

- Interior is an analogue of OSB-1, with its technical characteristics suitable for use only in dry rooms.

- Esposure Type Binder is a board with medium moisture resistance. Can be used in rooms with slightly increased humidity levels, and after treatment with protective preparations can also be used for exterior decoration.

- Exterior Bond is a material with maximum moisture resistance, suitable for any application, even without additional treatment with hydrophobic agents.

In addition, other inscriptions may appear

- SHEATHING SPAN - the distance between the axes of the joists in inches, if the numbers are indicated as a fraction, then the first value refers to the roof joists, the second to the interfloor joists. If the number 0 is indicated instead of the second value, then the oriented strand board is only suitable for use on the roof and cannot be laid on interfloor floors.

- THIS SIDE DOWN – bottom side mark. On the outside of the OSB with this inscription, small grooves are made to drain water, so improper installation will lead to the fact that during rain, water will not be drained effectively and the slab will begin to swell.

- STRENGTH AXIS THIS DIRECTION - this inscription is always accompanied by an arrow that points in the direction perpendicular to the joists. In other words, OSB with such an inscription must be laid so that the arrow is rotated 90 degrees relative to the joist.

The marking of laminated and varnished boards is not specified in generally accepted documents, so each manufacturer designates this type of material in its own way.

The same applies to wood-oriented boards with locks on the ends.

What types of OSB boards are there depending on the surface finish and type of edge?

Depending on the purpose of the material, OSB may have different surface finishes and sheet edges.

Unsanded

Untreated sheets with a rough surface providing increased adhesion to bitumen coatings. Such panels are an excellent base for bitumen primers and roofing decking, which has ensured their demand for forming a continuous sheathing of roofs of any size.

Sanded

Machined sheets designed for the construction of structures with tight thickness tolerances.

Varnished

Sheets of this type of OSB are coated on one side with liquid or paste varnish. Paintwork is applied using roller installations or paint-filling machines. This technique allows you to obtain a plain transparent or embossed patterned coating. Pre-treatment of the base with primer or putty allows you to reduce varnish consumption, as well as pigment the base in accordance with the decorative purposes being pursued.

Laminated

Lamination refers to the application of paper impregnated with adhesive compositions to the surface of OSB. As a rule, melamine-containing resins are used for these purposes, which, during hot pressing, set with the base and harden to the state of a thermosetting polymer. Excess emulsion is distributed over the surface of the panel by rolling sheets of the press, due to which the outer layer of the sheet acquires the necessary smoothness or relief (embossing).

The OSB edge can be straight or curved

Panels with smooth edges are used in rough construction and container production.

Plates with ends shaped like a tongue-and-groove connection are in demand for cladding large surface areas. Such materials provide effective thermal insulation and a hermetically sealed connection at the junction of adjacent sheets.

Price

The price of the slabs depends on :

- strength, water resistance and formaldehyde emission classes;

- dimensions (length, width, thickness);

- sanding, varnishing, laminating or locking the ends;

- manufacturer.

| Brand | Dimensions (thickness, width, length in mm) | Manufacturer | Cost, rubles per sheet |

| OSB-1 E1 Unsanded | 6x1250x2500 | Egger (Romania) | 500 |

| OSB-1 E1 Unsanded | 12x1250x2500 | Egger (Romania) | 650 |

| OSB-2 E1 Unsanded | 9x2440x1220 | Kalevala (Russia) | 530 |

| OSB-3 E1 Varnished | 18x1250x2500 | Glunz (Germany) | 2150 |

| OSB-3 E1 Grooved Unsanded | 12x1250x2500 | Bolderaja (Latvia) | 900 |

| OSB-3 Laminated E1 | 18x1220x2440 | Baumak (Russia) | 1500 |

| OSB-3 E1 Sanded | 12x1220x2440 | Kalevala (Russia) | 700 |

| OSB-3 E1 Unsanded | 22x1220x2440 | Kronspan (Russia) | 1350 |

| OSB-3 E1 Unsanded | 12x1250x2500 | Egger (Austria) | 1180 |

| OSB-3 E1 Unsanded | 22x1220x2440 | Egger (Germany) | 1350 |

| OSB-4 E1 Unsanded | 12x1250x2500 | Kronspan (Belarus) | 820 |

The most popular strength class is OSB-3 and emission class E1 - it is quite difficult to find OSB particle boards of other emission classes, so most often they are made to order , so the price is discussed individually.

It is also worth noting that with the same length and width parameters, but with different OSB thicknesses - for example, 9mm, 12mm, 15 or 18mm, the price for them will also be different.

Video description

This video explains which typical house designs can be built using SIP panels:

- Reusable formwork.

OSB can be used as a material for removable formwork for foundation work. For such applications, either laminated or sanded boards are used.

Reusable formwork Source onlyprofi.rf

- Packaging.

Low price and safety factor made this sheet material an excellent solution for packaging large cargo.

The walls of the drawers are made of OSB Source tcrllc.com

- Furniture.

Using OSB for furniture production is a non-standard solution. However, such furniture looks original and can become a decoration for a designer interior.

An example of organic use in the interior Source helblingfotografie.ch

Technical characteristics and comparison with other finishing materials

Here are the main competitors of oriented strand boards:

- plywood (No. 1);

- Chipboard (No. 2) (link to chipboard);

- Fiberboard (No. 3);

- GKL (No. 4);

- glass-magnesite sheet (No. 5);

- smooth slate (No. 6);

- DSP (No. 7).

The numbers assigned to them are indicated in brackets, in the order in which we included them in the table, where you can compare the main parameters and technical characteristics, that is:

- density;

- the possibility of use as a structural element, that is, subflooring, roofing, etc.;

- thermal conductivity;

- vapor permeability;

- flammability (ability to sustain combustion);

- toxicity under normal conditions/in case of fire.

| Options | Materials | |||||||

| OSB | 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| Density kg/m3 | 500–600 | 500–900 | 600–700 | 500–700 | 500–900 | 800–1300 | 900–1500 | 350–1500 |

| Possibility of use as a structural element, that is, subflooring, roofing, etc. | Yes | Yes | Yes | No | No | Yes | No | Yes for slabs with a density over 1100 kg/m3 |

| Thermal conductivity | 0,14 | 0,14 | 0,15 | 0,16 | 0,15 | 0,21 | 0,28 | 0,07 |

| Vapor permeability | 0,004 | 0,02 | 0,08 | 0,1 | 0,1 | 0,2 | 0,1 | 0,4 |

| Flammability high, medium, low (B, C, H) | IN | IN | IN | IN | WITH | N | N | N |

| Toxicity under normal conditions/in case of fire, high, medium, low (V, C, H) | I/O | I/O | S/W | N/S | N/N | N/N | V/N | N/N |

The density of the finishing material affects the weight of the sheet and can make it difficult to climb to the upper floors and install. Therefore, the low density of OSB is a serious advantage, which is further enhanced if we take into account the possibility of using oriented strand boards as a structural material.

With a low density, OSB has high strength , so it can be used to make:

- rough and finished floors in residential premises;

- roof decking;

- steps on stairs;

- removable formwork;

- SIP panels;

- various fences.

In terms of thermal conductivity, OSB is comparable to plywood and superior to most finishing materials, second only to DSP and fiberboard. However, in such an important parameter as vapor permeability, it is inferior to most competitors.

Because of this, in houses lined with OSB, it is necessary to take special measures to remove moisture and protect against condensation. For more information about the effect of vapor permeability on the humidity in the house and the condition of the walls, read the article (Application of OSB).

Oriented strand boards

belong to the class of combustible and fire hazardous materials.

Manufacturers are trying to reduce the level of flammability using pyrophobic preparations, but even such boards are superior to plywood and wood in this parameter.

In addition, high strength of finished boards can only using adhesives based on formaldehyde , which is a strong poison, and therefore OSB is not environmentally friendly.

Therefore, covering the internal space with OSB sheets, although inexpensive, leads to exceeding the maximum permissible concentration of this substance, which negatively affects well-being and health.

However, all the significant disadvantages of this material can be neutralized by proper use. After all, even in E2 class slabs, the rate of formaldehyde release is so low that any ventilation or periodically opened window can easily cope with it.

But you still need to know - during a fire, OSB emits not only carbon dioxide and carbon dioxide, but also many toxic substances that pose a threat, causing harm to health.

Installing fire safety systems, including smoke detectors, is useful in any home. After all, during a fire, the main danger is not toxic substances, but smoke, which makes it difficult to leave the room.

In addition, many pieces of furniture and household appliances release toxic substances in large quantities during a fire. Therefore, in case of a small fire, OSB sheathing does not pose a threat if the fire safety systems work properly and extinguish the fire. If the systems do not work and the fire gains strength, then there will be enough smoke and toxic substances even in houses without such cladding.

Heat transfer resistance

The heat transfer resistance of building materials is an indicator of their ability to retain heat and keep out cold. Heat transfer resistance is especially important for residential buildings. For OSB, this indicator is directly dependent on the thickness and density of the slab.

| Plate thickness, mm | Heat transfer resistance, (m2.®C/W). |

| 9,5 | 0,08 |

| 11,0 | 0,09 |

| 12,5 | 0,11 |

| 15,5 | 0,13 |

| 18,5 | 0,16 |

Conclusion

OSB boards are a good and modern structural and finishing material that has both advantages and disadvantages. However, all the disadvantages are compensated by the correct use of boards, and the advantages make OSB more attractive than other materials.

After reading the article, you learned:

- what is OSP, and how to decipher this abbreviation;

- about the characteristics and properties of OSB boards;

- what is the difference, for example, between OSB-2 and OSB-3 and other types of oriented strand boards;

- about the price of chip OSB;

- about the features of their use and other parameters.

How to protect OSB

FORUMHOUSE member Forsazh discovered that the street side of his house was “very bad” after living in it for 4.5 years. It turned out that there was complete destruction of the OSB.

Fast and the FuriousForumHouse Member

I read from SIP builders how wonderful SIP panels are. And they don’t burn in fire, and they don’t drown in water, and a pound weight hangs on one self-tapping screw. Only the fungus calmly eats it and makes fun of me.

The fact that the fungus “quietly eats” the panels is a natural phenomenon, experts say. OSB is 90% wood and has the same weaknesses.

Artem Soloviev

People are mistaken that OSB is impregnated with resins that prevent rotting. These resins are needed only to glue the chips together. Formaldehyde resins do NOT have antiseptic properties.

The color of the material that has already changed should be alarming. Our experts say that the gray color of OSB boards indicates that such boards are already contaminated with mold.

For quite a long time, it was believed that only the frame should be covered with bioprotection, and OSB boards and other structural elements do not need this. This is wrong - OSB boards were not covered with bioprotection simply because until recently there was no composition that would have good adhesion to OSB boards.

The house has been treated with a specialized fire-retardant compound

Artem Soloviev

In a frame house, everything is interconnected. The frame holds up the house, and OSB makes the frame stronger. Even the counter-lattice on which OSB boards are attached must be treated with a bioprotective compound. There are products to protect each structural element.