Today, this type of construction, such as the construction of frame houses, has become very popular. This is due to simple technology and the ability to do the work yourself.

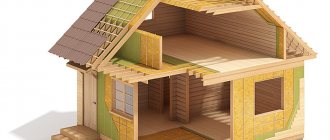

Diagram of a frame house.

A logical question arises: how to build a frame house correctly, where to start, and what to pay special attention to. Many people are concerned about how to secure a frame house. To answer all these questions, let's consider possible options for frame construction.

Installation of vertical posts of a frame house

Before erecting the frame, it is necessary to perform strapping and preliminary calculations. By the time construction begins, the structure must be ready:

- Foundation cured for at least 7 days. The concrete coating becomes durable after at least 27 days, but a foundation poured a week ago will be suitable for the frame. This period is sufficient to ensure a normal strength indicator. In some cases, the grillage is poured with anchors.

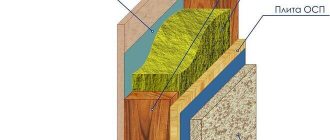

- Wood. If it is not dried, then it needs to be quickly mounted and, upon completion of the construction of the structure, covered with OSB, so the slabs should be prepared in advance.

- Lumber. They are treated with antiseptic impregnation.

- Ruberoid. It is necessary to ensure waterproofing. Experts recommend using a simple variety, without additional topping, which will be economically feasible.

It is difficult to calculate the exact number of fasteners. Most likely, you will have to purchase them additionally: nails and screws tend to break, and defective products come across.

Before purchasing materials, the thickness of the thermal insulation layer is determined. As the thickness of the insulation increases, the size of the frame must also be increased. If wooden posts are attached to a concrete base, additional fixing elements will be required.

Rules to pay attention to

So, the main 10 rules for high-quality house trim:

- Wooden elements must be well dried so as not to warp as they lose moisture.

- The treatment must be carried out with fire-bioprotection either in special factory conditions or in several layers.

- The foundation must be well insulated from the wood, since in places of contact with cement, the wood begins to deteriorate.

- Measure the accuracy of cutting the timber or boards you use in construction.

- Check the geometry after each stage of assembling a frame house.

- Any cracks should be foamed or filled with jute.

- Connections must be made securely, at a distance of at least one and a half meters from each other.

- If you do not understand something, it is better to seek advice from specialists.

- Remember that the top harness is performed at height, so take care of your safety.

- The quality of the piping depends on other elements of the house: the lower one - on the foundation, the upper one - on the evenness of the walls.

Our selection of videos will help you make the binding yourself:

Construction of the frame

The process of constructing a frame can be divided into several stages:

- Creating the bottom trim.

- Installation of the basement floor.

- Installation of racks.

- Making the top trim.

- Construction of the ceiling.

The most labor-intensive and time-consuming procedure is installing racks. The racks are connected to the harness and fixed with temporary jibs so that during further installation they maintain a vertical position.

Some features

Options for attaching vertical frame posts to the bottom frame beam.

Let's take a closer look at some types of steel fasteners. Let's start with the mounting plates.

- Their use is recommended when making butt joints that have tensile loads. This could be the process of installing roof trusses. Such plates are placed on both sides of the part and tightened together with bolts and nails.

- Corners for fastening. Their use is advisable in various kinds of corner joints. For example, when erecting walls, installing racks, manufacturing a rafter system, etc. If you use a corner that has a stiffener rib, the result is a higher degree of resistance to bending. The corners are also placed on both sides, the screed is made using bolts and nails. The use of bolts is recommended only where special strength is required.

- When covering a frame house, you will most likely need holders and supports for the beams. Such fasteners can easily withstand a high degree of tensile load when making corner connections. Fasteners such as holders are used for high-quality fixation of beams and walls or beams and columns. But a support or shoe is used to install a beam on a wall (column) of an already built house, for example, when performing reconstruction work.

- The fastener called “support” is universal. Its design includes two elements: left-handed and right-handed.

- The so-called shoe is intended for columns and racks. It is secured with bolts or the procedure of pouring concrete is carried out during the construction of a foundation or some other foundation.

- In order for the installation of wooden floors to be reliable, it is advisable to use fasteners such as a beam holder. Fixation of this type of connection is carried out in a two-way manner. That is why such fasteners have both left-handed and right-handed elements. Nails are used to secure it.

The universal beam support consists of two parts - again left-sided and right-sided. Can be used on beams of different sections. Bolts and nails are used for fixation. For their production, steel is used, the thickness of which cannot be less than 2.5 cm.

Preparation of vertical racks and selection of boards

Installation of racks is carried out in various ways. The first - the frame is knocked together on the floor, and then lifted and installed, the second involves installing each rack separately. However, the fasteners used are the same.

The main task of the racks is to ensure structural strength. The system must withstand a load of 3-5 tons. Therefore, high-quality material is selected. The maximum stress occurs at the corners. A beam with a cross-section of at least 10×10 cm is prepared for them. The side racks are subject to less load, so a beam with a cross-section of at least 4×10 cm is suitable for attaching and installing the racks to a wooden beam.

You can use timber of a larger cross-section, but this increases the cost of construction. If it is not possible to purchase timber of the required section, you can sew a stand from two boards, for example, 3 cm thick.

Briefly about the main thing

Summing up can be summarized as follows:

- The jib is an important element for creating frame rigidity.

- It is better to use a piece made of high-strength wood. This will slightly reduce the cost of construction and lighten the entire structure.

- During installation, you need to correctly position the part in the frame. It is necessary that the ends of the element are cut into the harness.

- All work should be carried out only with nails.

- The use of temporary jibs is permitted, but only if the structure is subsequently sheathed with OSB boards.

In general, the use of supports and its proper placement will guarantee that the constructed frame house will serve its residents for many years without reducing its strength parameters.

Installation of corner posts

You can install the corner posts yourself. Installation is carried out in two ways:

- Metal corners. Corners made of hardened steel are suitable for these purposes. It is recommended to choose zinc plated fasteners.

- Wooden dowels. A dowel is a round pin. It is hammered in at the stage of creating the corner of the lower strapping beam, having previously drilled a hole for it. In this case, the dowel should rise above the surface of the harness by at least 8 cm. The frame stand is installed on it. This solution ensures high strength of the connection between the rack and the harness.

The second method requires serious physical effort, but has a number of advantages:

- High reliability compared to threaded fasteners, which weaken after a while because the wood dries out.

- Absence of metal products in the design that are susceptible to corrosion.

Holes equal in diameter to the dowel are made in the surface of the stand. Their depth must be at least 8 mm. After this, the element is connected to the dowel and fixed with braces. Fastening made using homogeneous materials is more ductile and resistant to lateral impact.

Common construction methods

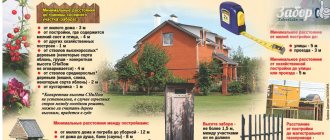

Diagram of corner connections in a frame house.

Everyone has heard at least once about the frame-panel construction method, but it is unlikely that they delved deeply into its essence. This method involves carrying out work using materials delivered to the actual construction site. This list includes beams of various designs, thermal insulation and vapor barrier materials, roofing elements, fasteners, etc.

Usually this option is carried out by professional builders in strict accordance with the project. All parts of the house have special markings, with the help of which builders connect them into a single whole. Sheathing of the finished frame is carried out using OSB boards, followed by work on thermal insulation and wiring of various types of communications. And after all this work is completed, you can begin interior and exterior finishing work. Of course, it cannot be done without installing the roof; in individual cases, the issue of decorating the area adjacent to the house can be resolved.

Scheme of the bottom trim of a frame house.

Another method, frame-panel, consists of assembling finished panels, including frame parts, insulating material, etc., directly at the factory for their production. Ready-made parts and blocks of the future house are delivered to the construction site. These include steps equipped with windows and doors, pediments, roofing elements, floors, etc. The assembly of such a house is carried out very quickly - in a maximum of a week. The building turns out to be beautiful, cozy and, of course, very warm, which is important.

Any type of frame building includes in its design walls (external), partitions, ceilings and roofing. All these important elements are arranged according to the same scheme. The frame is made of wooden beams and is subsequently sheathed on both sides with some kind of sheet material. The void created inside is filled with modern and fairly effective thermal insulation materials.

Both of these technologies are quite common in our time and are considered the most promising in the field of private housing construction.

Attaching the side posts to the bottom frame

Before attaching the side posts to the bottom frame, you should check the geometric dimensions several times: the correct alignment of the diagonals and angles. The beams are secured not only to each other, but also to the foundation. If studs were inserted when creating the grillage, then you can dispense with the anchors. You can pre-drill holes for the studs in the timber. After this, they begin to fix the base beam.

If it was not possible to install the studs, then anchor bolts with a diameter of at least 16 mm will have to be used as fastening. The fastener must be immersed in the foundation by at least 10 cm. If the height of the strapping is 10 cm, then the length of the bolt should be 20 cm. Holes for the anchor are made in hardened concrete. Reliability of fastening is ensured by nuts with wide washers. Thanks to the washer, the contact patch between the wood and the nut increases.

Bolts must be selected with hex nuts for unscrewing with a wrench. Square, round, screwdriver varieties are not suitable in this case. An anchor is not installed in the corners if the beams are connected with dowels or nails. Otherwise, the first anchor bolt is placed in the corner and in the space between adjacent corners at intervals of 1-1.3 m. If necessary, the pitch can be increased. But practice shows that this value should not exceed 2.5 m. At least two bolts are placed on one beam of the lower type.

Upon completion of all work, the master checks the level of the timber, the corners and diagonals of the upper trim. If the need arises, the plane is leveled with an electric planer. After coupling the elements of the lower trim and fixing them to the foundation, vertical posts are mounted.

Fasteners for vertical posts in the ground KS are used when installing gazebos, fences and other structures. This element allows you to eliminate the need for a poured foundation for stakes. The main feature of the product is its unique shape: the top is made in the shape of a parallelepiped, smoothly turning into a sharp end. The lower structural part goes underground. The sharpened stand is mounted in the upper element and secured with screws.

Organization of internal corners

The angle between the outer and inner walls of a building is made in several ways.

Correctly organizing the corner from the inside is no less important than from the outside Source indeco.ru

The first option is the following:

- between 2 beams, one regular beam or three short ones are installed (in the top view the letter “P” is obtained);

- A wall element is attached to the middle beam.

Second option (especially heat-intensive):

- the outer wall at the junction with the internal stand is made up of horizontal bars 50x50, located between the vertical bars, with a pitch of 60 cm;

- A vertical post is installed to the horizontal bars, forming the edge of the inner wall.

The blocks are knocked together only with 90mm nails every 50-60 cm.

As practice shows, not all construction teams offering services to individuals are proficient in the technology for making corners.

Floor beams

Floor beams must be rigid and strong, not bend, and withstand the load well. Their size and number depend on the expected load and are calculated by the engineers of Svoy Dom.

Floor beams are fastened in one of the following ways:

- When arranging non-residential attics, perforated brackets or steel supporting corners are used.

Fastening beams with perforated brackets and steel corners - When constructing the second floor, the beams are secured with a tongue-and-groove cut or half-timbered using a dowel for better connection.

Fastening tongue-and-groove and half-timber beams