One of the last stages of building a frame house is finishing its exterior.

For this, various materials are used, both natural and synthetic.

Also, materials differ in cost, complexity of installation and their physical properties.

How to choose the appropriate material for cladding a frame house so that the quality-to-price ratio is, if not ideal, then close to it?

Which finishing can you do yourself, with your own hands, and which is better to entrust to professionals?

Finishing a frame house

Thermal panels for wooden buildings

Thermal panels are becoming increasingly popular, despite their high price.

The reason for this is the opportunity to kill two birds with one stone - to insulate the facade of the house and at the same time bring the walls to an aesthetic appearance.

Panel facades consist of clinker tiles, between which polyurethane insulation is laid.

Thermal panels in the decoration of a wooden house

To install thermal panels, it is necessary to install special fasteners that run parallel to each other.

The thermal panel is already easily installed on them, so a neat appearance of the external finish of the wooden frame is guaranteed.

Disadvantages: price and additional weight. Before installation, make sure your foundation is designed to support the added weight of the panels.

Great for places where the temperature in winter drops by more than minus 25.

However, most often the panels are used for brick or block houses, which do not have a layer of insulation.

DSP

DSP is a cement-bonded particle board, a composite material made from cement, wood shavings and fine stone chips. DSP is durable and resistant to atmospheric and biological factors. This is a fire resistant material. The large format of the slab ensures quick cladding of the house. The disadvantages include the need for additional decorative finishing of the facade.

Cement particle board (CSP) Photos from open sources

Vinyl siding

Traditionally used for country houses or if you want to save money.

At the same time, siding, in addition to a good price, has a number of other advantages:

- does not deteriorate, does not rot, does not decompose

- not susceptible to damage by bugs and rodents

- has a long service life

- easy to install

- it is easy to care for - it is easy to wash and clean from dirt

- not afraid of moisture

Finishing a frame house with vinyl siding

In order for vinyl siding to look neat, it is necessary to level all the walls onto which the beams are then nailed.

By leaving a small space between the wall and the material itself, we create an additional air layer that retains heat in the house.

Steel panels

Some homeowners clad their walls with this metal material, which is coated with powder paint or polymers. To give the building an original look, you can use colored panels. The advantages of this facing material are:

- simple installation;

- high strength;

- low flammability;

- harmlessness;

- does not deteriorate at temperatures from -60 °C to +90 °C.

However, there are also disadvantages:

- strong heating in summer;

- condensation formation;

- impracticality (steel panels are easy to scratch);

- loud noise when it rains.

- If the panels are not treated with an anti-corrosion compound, rust will form on their surface.

Fake diamond

I fell in love with artificial stone because when it is used to cover frame walls, the building looks much more presentable than just a wooden one.

And when compared with natural stone, artificial even wins, since achieving a beautiful shade and structure in it is much easier during production than choosing identical natural stones.

Exterior finishing with artificial stone

Artificial stone will also be lighter, which is much better for the foundation, which is often selected for a frame building in a lightweight version.

And besides, installing it is much easier and cheaper if you decide to entrust this matter to specialists.

Exterior finishing with facade bricks

In ventilated facades of frame houses, heavy wall materials - stone and concrete slabs - are not used. Sometimes they use façade facing bricks and lightweight artificial stone. They are distinguished by their average weight, which allows them to be mounted on a lightweight foundation.

Brick cladding in frame

On a note

Facing the frame with brick increases the weight of its walls by 2 times. However, often the construction of a foundation for a frame structure is carried out with a large margin of safety, which turns out to be sufficient for brick finishing.

Cladding a frame house with brick is rarely used. It requires flexible connection of the external masonry to the house. In addition, such a wall cake does not comply with the rules of insulation, according to which it is recommended to arrange wall materials according to the killing characteristics of thermal insulation. Insulation of a frame house from the inside - less thermally insulating materials (brick, wood), on top of which are materials with better thermal insulation (cotton, polystyrene or other insulation).

Metal siding

Finishing with metal siding to look like a log makes the frame house look very interesting - it looks like a hut from a fairy tale, and the finish is much stronger than wood and lasts much longer.

Metal siding

Metal siding is made from galvanized steel, after which the resulting “logs” are coated with a polymer coating that imitates the structure of wood.

The material does not rust, does not change color in the sun, and tolerates even strong temperature fluctuations.

Due to its qualities, metal siding under logs can be installed even in the winter season, which is fully consistent with the technology of constructing frame houses.

Metal siding is attached to a frame that is pre-installed on the wall of a frame building.

Which side to mount OSB sheets

All sides of OSB sheets do not differ in composition. But there are differences in the surfaces. Often one side is smooth and the other is rough. In this case, when installing slabs on walls on the outside of a building, it is better to mount the sheets with the smooth side out. With this orientation, rainwater will not accumulate in such quantities in the uneven areas of the slab. Water helps accelerate the destruction of the slab. Protecting sheets from water penetration helps increase their durability.

When installing slabs on the roof under the roof, in turn, it is recommended to place OSB sheets with the rough side up so that they are not slippery to walk on during roof installation work.

When installing OSB boards in places protected from moisture, the choice of their orientation does not have a significant impact on subsequent operation.

Wooden lining

Wood lining is considered a traditional material for exterior finishing, especially if the house itself is framed.

Wooden lining looks good, and designers love it for its ability to easily and relatively inexpensively create the image of a Russian house merging with nature.

External lining finishing is quite simple and can be done with your own hands.

Finishing a frame house with clapboard

The only disadvantage is the susceptibility of natural wood to destruction.

Wood easily absorbs moisture, changes its parameters - it can swell or shrink; in addition, it is loved by bark beetles, bacteria that cause rotting, etc.

To protect the finishing, new modern impregnations have been developed, which not only extend the life of the material, but also significantly increase the service life of frame housing.

At the same time, impregnations also improve housing safety indicators, making the lining self-extinguishing and not supporting fire. This is very important for wooden frame construction.

Quartblog Digest

What can you save on during renovations - Tricks from designers: where can you trim your renovation budget a little without losing quality? How to save on repairs? We'll tell you in our article!

Non-standard ideas for decorating the ceiling - How to decorate the ceiling if you want something original? The quartblog will tell and show 6 interesting and non-standard ideas and 29 photo examples.

Repair: know, consider, control. Part 2. Air conditioning, ventilation and heating - Designer Valeria Belousova continues to share with us her secrets that allow us to avoid all the pitfalls during renovation. Today we will dwell in detail on air conditioning, heating, electrical and other communications.

Repair: know, consider, control. Part 4. Electrical – We continue to teach you all the secrets of professional repairs. To conclude the topic of rough finishing, designer Valeria Belousova told us about the intricacies of correct electrical wiring.

Repair: know, consider, control. Part 3. Plumbing - Today designer Valeria Belousova told us in detail about plumbing and even showed us a photo tutorial on installing a box under a bathroom in one of her projects.

finishing, frame

Plastering walls

Plaster finishing looks simple, but very neat, especially if it was done according to all the rules. The most important thing is not to miss a single stage in the finishing.

Plastering on a frame house

In Russia they don’t really like to plaster frame walls. The fact is that OSB-3, which is used to form the wall, can move, change size, the house can shrink and then cracks occur.

If the plaster is of poor quality, it will peel off literally after one season, lag behind the walls and look extremely unesthetically pleasing.

However, in America they have long ago solved this problem by improving the technology for applying plaster to frame walls.

The structure of the improved plaster layer, which is needed for a frame building:

- A galvanized steel plaster mesh is laid on top of the waterproofing and drainage film.

- The mesh is fixed in a horizontal direction, overlapping.

- Fastening is carried out using roofing nails, half-inch construction staples, or special mushrooms and ordinary wood screws.

- First layer of fiber reinforced plaster. Drying time - 48 hours.

- The second layer is distributed over a finer plastic plaster mesh. Drying time - 7 days.

- The third layer is decorative finishing plaster.

Do not forget: the minimum total thickness of the plaster layer must be at least 2.2 cm.

If you want to plaster in one layer, use a plaster mixture of Portland cement, white cement (lime) and sand.

If you want to make it more durable, add fiber fiber to the composition, which will reduce the likelihood of cracks.

After drying, you can apply the final layer of decorative plaster of the selected color.

Block house - imitation timber

Another wooden material for finishing the outside of a house based on a frame.

Externally, when laid, it resembles timber, thanks to which a frame cottage can be made into a complete imitation of a timber hut.

Block house in house decoration

The block house can be used both inside and outside the house, while impregnations make the material fire-resistant and inedible for bark beetles and pests.

In addition, the block house does not crack over time, and is much stronger than rounded logs.

However, with age, the appearance, of course, changes, because, in truth, this is the most ordinary lining, only changing its shape.

There are block houses of different sizes on sale, the thinner one is suitable for interior decoration, and the wider one is suitable for exterior decoration.

Types of overhangs

There are two types of overhangs in roof construction: cornice and pediment. The first is located at the bottom of the roof and plays an important role in providing ventilation. The overhang on the facade is located at an angle and is the end of the slope. It is usually formed from lathing. This option is used for light coverage:

- metal tiles;

- soft roof;

- euroroofing felt.

Note! The fragile structure will not withstand a large overhang, so it is made up to 50 cm. The protruding sheathing is hemmed at the bottom, and the end is covered with a metal profile

The protruding sheathing is hemmed at the bottom, and the end is covered with a metal profile.

Another design can be used when the gable overhang is made with a rafter beam. The extension of the outer rafter pair determines its depth. Supporting elements such as a mauerlat, ridge beam, and intermediate posts are also placed outside the pediment. The reliable design does not limit the length of the overhang and is suitable for any roofing covering, such as ceramic tiles and slate. For a roof with low weight, the rafter leg is replaced with a cornice board; with the help of crossbars it is connected to the rafter system and the eaves overhang.

Finishing brick

A frame house can be finished on the outside with special facing bricks. However, before finishing, you need to make sure that the foundation and walls will hold up.

Despite the fact that the facing brick is hollow inside, the weight of the entire building after finishing will increase significantly.

Brick finishing scheme for frame

Brick not only looks good, but also protects a wooden house from external environmental influences, extending the life of the frame.

The downside is the cost, since finishing the outside with brick is the most expensive cladding method.

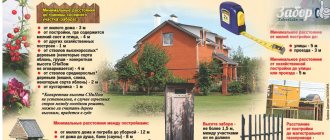

Requirements for facade material

The facade is the calling card of any building. However, in addition to the decorative function, the cladding performs a number of other tasks: increasing the energy efficiency of the house and extending the service life of structural elements.

It is the facing material that takes on the negative impact of external factors : temperature changes, high humidity, UV rays, mechanical shocks and others. When choosing a finishing method, you should evaluate not only the aesthetic aspect, but also the technical characteristics.

General requirements for cladding:

- Weather resistant. The material must retain its original properties and shape during temperature fluctuations, wetness and icing.

- High strength – ability to withstand mechanical damage. Hail, gusts of wind and tree branches should not cause damage to the cladding.

Additional arguments in favor of the selected material will be: affordable cost, light weight, simple installation technology, ease of maintenance and care.