At a fairly low price, the quality of materials used in frame housing construction is growing every year. It is not surprising that this type of building is becoming increasingly widespread in all regions of Russia. And depending on the climate zone, the same project will have different requirements for heat conservation, therefore, what the thickness of the walls of a frame house should be must be determined in each case separately.

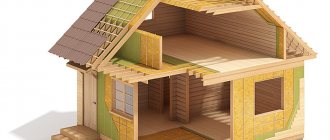

There are several subtypes of frame technology - if the general principle of building houses is the same, then the nuances, including the thickness of the walls, may differ Source ecohome.net

Typical wall design

Of course, the choice of wall thickness depends not only on the climate in the region, but also on the purpose of the structure: whether the house will be for permanent residence, or for temporary residence, as well as on the materials used in the construction of the internal and external parts of the wall, on the type of insulation used, presence of an air gap.

A classic wall consists of the following elements:

- External cladding . It can be from a few millimeters to tens of centimeters thick, depending on the materials used. Most often, cement-bonded particle boards or wood-based OSB boards are used; metal profiles or facing bricks are less often used. If there is no air gap, the outer part can simply consist of plastered insulation.

- Air gap . It is needed in order to prevent moisture from penetrating through the outer skin into the insulation, and it remains dry without losing its heat-insulating properties. Depending on the type of insulating materials used, it can range from 25 to 50 mm.

The order of layers in a frame house is standard Source sargorstroy.ru

- Frame . It may or may not be insulated. The minimum thickness of the load-bearing structure of a wall without insulation is 50 mm and increases depending on the type of insulation used: mineral fiber, ecowool, polystyrene foam, polyurethane spraying. The thickness of the insulation for the walls of a frame house can reach 400mm.

- Internal lining . It usually consists of more environmentally friendly materials than the external one, as it is connected to the living space. Most often they use plasterboard or materials based on natural wood (boards, timber), less often plywood, MDF or OSB. If the supporting structure of the frame is not insulated, then there may be no wall cladding.

From the structural features of the wall it is clear that the most difficult thing is to determine the thickness of the frame insulation.

It is the thickness of the insulation that will determine how warm the house will be Source otdelka-expert.ru

Additional insulation

If an additional layer of thermal insulation is necessary, polystyrene foam is used. It is attached to the OSB board from the outside. First, a vapor barrier film or membrane is placed on the sheathing. It is needed to remove moisture from the first layer of insulation. Then the foam is installed. Usually a thickness of 5 to 10 cm is enough. If necessary, all joints are puttied.

Then the insulation is covered with waterproofing. For this you can use:

- plastic film;

- modern moisture-proof, vapor-permeable membranes;

- OSB-3.

The edges of the insulation should overlap each other by 10 cm, and the joints should be taped with tape or special tape. After this, a reinforcing mesh is glued on top. Plastic or metal corners are used to protect the edges of the insulation. For cladding, apply a layer of plaster, lay decorative tiles or use clapboard.

With the right choice of materials and compliance with all construction technologies, a frame house is not inferior to a block house and even surpasses it in certain parameters.

Insulation thickness

First of all, the thickness of the insulation in a frame house for permanent residence will depend on the geographical location of the future housing, its climatic zone, as well as on the thermal conductivity coefficient of the material.

Using the following formula, you can calculate the thickness of the heat insulator:

δ = R. k ,

where δ is the thickness,

R is the thermal resistance indicator for a specific region, and

k is the thermal conductivity coefficient.

The thermal resistance index R can be calculated independently, based on data from SNiP 23-01-99 Climatology, or can be taken from the following table:

Ready-made data will help determine the approximate thickness, but it is better to entrust the calculations to professionals who know the design features and materials Source sargorstroy.ru

It is equally important to choose the right material that will avoid unnecessary heat loss. Now there is no point in considering insulation materials like sawdust or slag, which were so popular at the dawn of frame house construction. There are a lot of more technologically advanced and practical thermal insulation materials on the market.

See also: Catalog of frame house projects presented at the Low-Rise Country exhibition.

Mineral wool

This type of insulation is made using glass or basalt fiber using the following technology:

- First, the basalt is melted in a furnace at high temperatures until it becomes liquid.

- The resulting liquid is pumped into a centrifuge, where under enormous air pressure it turns into fibers.

- These fibers are then put under a press, which compacts them to the desired parameters.

- Next, the resulting material is rolled into rolls or cut into slabs.

The positive aspects when using mineral wool are its low thermal conductivity, which is even lower than that of wood. With a density of 50 kg/m3, its average value will be around 0.045-0.05 W/m oC (depending on the manufacturer). Based on these data, using the formula δ = R. k you can calculate the thickness of the insulation for any region of Russia:

- 3 x 0.05 = 0.15 (m) - for the Moscow region,

- 4.9 x 0.05 = 0.24 (m) - for Yakutsk,

- 1.8 x 0.05 = 0.09 (m) - for Sochi.

Mineral wool is one of the inexpensive and frequently used insulation materials Source konveyt.ru

If we compare it with the thickness of wooden walls without additional insulation, we get:

3 x 0.11 (thermal conductivity coefficient of spruce) = 0.33 m. This is for the Moscow region.

The only disadvantage of mineral fiber thermal insulation is that when wet, its properties deteriorate significantly. Therefore, during installation you need to ensure compliance with waterproofing standards.

See also: Catalog of companies that specialize in the design and construction of turnkey country frame houses.

Ecowool

A material that has recently appeared on the market is based on cellulose obtained by processing waste paper and other paper waste. Non-combustibility is achieved by adding boron compounds to the insulation. For the same reason, insects and rodents do not grow in ecowool. Today on the market this is truly the most environmentally friendly insulation.

To install this material over large areas, special fiber-spraying equipment is required, colloquially called a “vacuum cleaner.” Thanks to it, you can spray cotton wool granules both onto a structure that is not yet sewn up on one side, or pump the material inside an already mounted wall through holes specially made for this purpose. Fiber can be applied to small areas without the use of special means, like plaster.

To spray ecowool you will need a special machine Source keyinsulation.com

Among the disadvantages, it is necessary to note shrinkage, which occurs after some time, and as a result, the insulating properties are lost. This can be eliminated by pumping additional amounts of insulation into an already installed structure, which is not always convenient.

The thermal conductivity of ecowool is approximately equal to the thermal conductivity of mineral insulation at the same density, so the calculation will be the same.

Polystyrenes

Quite often today, rigid insulation based on polystyrene, produced in the form of molded slabs, is used to insulate frame walls. The most famous of them are polystyrene foam (expanded polystyrene) or extruded polystyrene, the latter including “Polyspen”, “Penoplex”, STYROFOAM. In some of their properties, these materials are superior to many mineral wool insulation materials, as they have a lower thermal conductivity coefficient and higher compressive strength, as well as lower water absorption. Their service life is quite comparable to the life of the building; they do not shrink. Extruded polystyrene foam is characterized by a complete lack of water absorption, but cheap foam plastics can absorb moisture - it penetrates between the granules and, with repeated freezing and thawing, destroys the material.

The most important disadvantage of all polystyrenes is their flammability, combustibility and smoke-generating ability in accordance with GOST 30402, GOST 30244 and SNiP 21-01-97.

Despite a number of positive qualities that give reason for some experts to call polystyrene derivatives almost universal insulation, both polystyrene foam and extruded polystyrene have serious disadvantages that cast doubt on the advisability of using these materials in a number of cases. One of them is related to their fragility: when using polystyrenes, it is difficult to seal the joints of plates due to their rigidity and non-ductility. In addition, this type of insulation is very popular with rodents, who love to chew it and make passages and holes in them.

And frame walls filled with varieties of polystyrene cannot be called environmentally friendly due to the styrene included in this insulation, which, when released into the air, negatively affects the body of people breathing it

In addition, one of the main properties of these insulation materials - very low vapor permeability - means that the walls of the house will not “breathe”; when insulated, a “thermos effect” is created, which is especially important to prevent in your home. The choice of this material as a filler for the walls of a residential building must be approached carefully from the point of view of fire safety.

Expanded polystyrene boards are classified as combustible materials (flammability groups G1-G4). However, low-flammable materials also pose some danger from an environmental point of view. To reduce their flammability, hexabromocyclododecane (HBCDD), which is a persistent toxic substance, is added to the composition. The only reassurance is that this toxicant most likely does not evaporate and does not dissolve in water. However, the European Chemicals Agency puts it at the top of the list among the most dangerous substances, which means there is still reason to think about it.

What is especially unpleasant is that all polystroles, without exception, when burned, emit to one degree or another suffocating smoke, which includes toxic substances - carbon monoxide, benzene and others. The material class for flammability (G1-G4), smoke formation (D1-D4), flammability (B1-B4) and toxicity of combustion products (T1-T4) is indicated in the fire safety certificate, which is issued on the basis of a test report on the material. For comparison: mineral BASALT wool is a non-combustible material - NG group.

In conclusion, I would like to add that, of course, there are tasks for which the use of polystyrene has practically no alternative, for example, insulation of foundations in the ground, but when insulating the outer part of any building, primacy remains with basalt insulation

It is important in each specific case to choose a material that will solve a specific problem.

What to choose is up to you.

Video description

About the types and features of materials for wall insulation in the video:

Expanded polystyrene

Foam plastic is familiar to everyone from childhood. It has been used in construction technologies for a very long time, but has not yet lost its relevance due to its low thermal conductivity and low weight.

The production technology of expanded polystyrene is quite simple:

- Polystyrene is brought to the melting point and saturated with vapors and gases under pressure. As a result, small balls filled with air are formed.

- The balls are then reheated and pressed into sheets of various shapes.

- To improve the characteristics, the foam is processed with an extruder - again brought to a viscous state, and then molded (extruded through a special hole). This is how extruded polystyrene foam is obtained.

Expanded polystyrene sheets are inserted and fastened between the partitions of the frame Source obrawa.ru

Among the disadvantages of this insulation, one can note its flammability, although if we talk about extruded material, this indicator will be within acceptable limits.

The density of the foam varies from 20 to 160 kg/m3 with a thermal conductivity coefficient of 0.03-0.05 W/m °C.

Thus, it can be calculated that the minimum thickness of this insulation for the Moscow region should be no less than 150 mm (3 x 0.05).

Requirements for thermal insulation material

The frames of houses built using “Canadian” technology are assembled from OSB boards or wood. To prevent the insulation from causing damage to structures, it must have sufficient vapor permeability - at least 0.32 Mg.

Fiber heat insulators – mineral wool materials – absolutely meet this requirement. Popular synthetic insulation materials, such as polystyrene foam and polymer-based analogues, cannot be used in wooden structures for two reasons:

- Firstly, due to the lack of elasticity, the heat insulator will not be able to adapt to temporary deformations of the wood (shrinkage, increase in volume). The result is the formation of cracks and cold bridges.

- Secondly, polystyrene foam and its analogues do not allow wood to “breathe”. This leads to moisture accumulation, mold and rotting of structural elements.

When choosing how to insulate a frame house, in addition to vapor permeability, you should also take into account the additional properties of the heat insulator. The following indicators are welcome:

- fire safety;

- environmental friendliness;

- low thermal conductivity;

- resistance to shrinkage;

- minimal water absorption.

Example of calculating wall thickness

The thickness of the insulation of a frame house for permanent residence using the example of the Moscow region (this calculation was given above) was 150 mm when using mineral wool with a density of 50 kg/m3. Since most manufacturers produce this insulation in thicknesses of 50 and 100 mm, you will have to put insulation in either three layers of 50 mm thickness, or two layers of 100 and 50 mm. This will not change the thermal conductivity coefficient.

OSB with a thickness of 12 mm with an air gap of 50 mm and plaster of 5 mm was chosen as the external cladding.

The interior is lined with 13 mm plasterboard.

Total: 150 + 12 + 50 + 5 + 13 = 230 (mm).

Now, based on these data, you can now calculate the foundation, but you need to understand that this is just a mathematical calculation and it does not take into account problems that may arise during installation of the structure.

Online foundation calculator

To find out the approximate cost of various types of foundations, use the following calculator:

To make sure that there is no draft anywhere in the house, the structure is checked with a thermal imager Source sargorstroy.ru