Wood is a material in demand in construction: houses and outbuildings are built from timber, floors are made from boards, and walls are finished with them. Band saws are often used for sawing lumber at home. Factory models of equipment are not available to everyone due to their relatively high cost. But you can save money by making your own band saw. Depending on the size and installed cutting blade, it can also be used to work with different metals and their alloys, stone, and synthetic materials, for example, polypropylene.

Setting up band saw equipment

The proper and high-quality operation of a carpentry installation depends directly on the equipment settings.

There is a scheme for setting up the installation. First, install the wheels parallel to each other. Next, install fluoroplastic washers necessary to prevent vertical displacement. For the first time, the launch is performed without guides. At this stage, the smooth start-up and clean operation of the engine are checked, and then a test cut is carried out using a blade, but with minimal loads. To work with increased loads, a block with guide belts is used. This design consists of two halves, which are installed along the line of the cutting blade.

Previously, craftsmen made not only machines, but also cutting blades with their own hands. It is difficult to independently close the belt unit into a ring and requires at least some initial experience in assembling the machine. Sharpening using a template is also carried out manually. You can do all this yourself, saving your money, but the modern market is simply filled with all sorts of devices and parts that improve the quality of material processing or make the equipment multifunctional. The main thing in this matter is to remember about safety precautions, because production models or homemade ones pose a great danger to human health.

Originally posted 2018-07-04 07:38:21.

Preparatory activities

Before starting assembly activities, based on the drawing, you should prepare the necessary materials and tools. This will allow you, first of all, to determine whether you have everything you need for the job (you will need to buy what’s missing), and also not to be distracted by little things during the process.

Required materials and tools

To make a band saw, you will need the following materials and parts:

- boards or sheets of plywood (or chipboard) from which the frame, table, and pulleys will be made;

- sheet steel (for saw);

- channel used to create a support frame, or metal corners, or wooden blocks and slats;

- bearings;

- steel rod - for making pulley axles;

- electric motor;

- self-tapping screws, bolts with nuts and washers;

- polyurethane glue;

- rubber from a bicycle inner tube;

- textolite;

- bushings;

- V-belt;

- varnish or paint.

To work you will need the following tools:

- screwdriver (with drills);

- hammer;

- wrenches (the size of bolts);

- screwdrivers;

- pliers;

- Sander;

- Bulgarian;

- grinder;

- jigsaw

Power tools can be easily replaced with their hand-held counterparts. But in this case, assembly will require more time and labor. When using metal corners or channels instead of wooden blocks, you will also need a welding machine and electrodes. The use of bolted connections creates additional problems with the tight fit of parts.

Recommendations for choosing tape fabric

Making a cutting blade with your own hands is quite difficult. For these purposes, tool steel grades U8 or U10 are needed. The saw must be flexible. Its thickness for relatively soft wood is from 0.2 to 0.4 mm, and for hard wood - from 0.4 to 0.8 mm. The blade length of the assembled version of the machine will be about 1.7 m. You will need to cut the teeth yourself, set them correctly and sharpen them. To solder the tape into a continuous ring (end-to-end), you will need to use a gas torch and solder. The connecting seam must be sanded afterwards.

It is much easier and more convenient to purchase a ready-made cutting blade of good quality in a store, so as not to waste time on its manufacture. The width of the products ranges from 18 to 88 mm. In this case, you need to focus on the material that is to be sawed. Manufacturers offer the following types of saws according to this criterion:

- bimetallic, intended for performing work on metal (stainless steel and relatively strong alloys);

- diamond, with which you can saw marble, quartz, granite and other hard materials;

- carbide, allowing the processing of high-strength alloys;

- made from strips of tool steel used for sawing wood.

The last variety is quite often equipped with machines assembled in domestic conditions. This is due to its affordability and practicality. But if you have to work with hard materials, then it is better to purchase a more durable, wear-resistant and expensive saw to reduce the likelihood of the tape breaking to a minimum.

If you plan to make a figured cut using a band saw, then you need to select the width of the blade taking into account the radius of curvature. Some relationships between these quantities are shown in the following photograph.

Advice! For even longitudinal sawing of lumber, wide cutting blades should be used. They allow you to make a more even cut.

When choosing a saw for wood, you also need to take into account the pitch of its teeth (the distance between their centers). The hardness of the wood that can be sawed depends on this. The following are the most common tooth profiles, their markings and areas of application.

You also need to pay attention to the quality of sharpening of the teeth. The cutting edge must be sharp and smooth

You should also ask your sales consultant about the possibility of re-sharpening it and how many times this can be done. For your own safety, it is recommended to give preference to higher quality canvases.

Selection of tape material

It is extremely difficult to make such a canvas for wood or metal carving at home. For such purposes, tool steel type U8 or U10 is suitable. The log saw should be as flexible as possible. Its thickness for soft wood should be approximately 0.3 mm, and for harder wood - 0.5-0.7 mm. The length of the blade of such a saw will be about 170 centimeters.

It is also necessary to make the teeth yourself, set them correctly and sharpen them. To weld the tape into a solid ring, you need to use solder and a gas torch. The joint seam itself should then be sanded.

It is more convenient to purchase a finished product in a store. Typically, the width of such canvases ranges from 1.8 to 8.8 centimeters. It is better to select a model for such a saw based on what material you plan to cut. Manufacturers usually offer the following categories of saws:

- from hard alloys (they make it possible to process high-strength alloys);

- based on diamonds (their use makes it possible to cut materials such as marble, quartz, granite);

- made from tool-type steel strips (they are used for cutting wood);

- bimetallic (they are necessary for working with metals).

Read also: Crimp a high-pressure hose with your own hands

If the saw is homemade and small, as in the case under consideration, then it is best to buy a product made from tool-type steel strips. This option is affordable and practical. If the work will be carried out with hard materials, then it is better to buy an expensive saw that is highly durable and resistant to wear.

If such a tabletop horizontal mini-saw will be used for shaped cutting, then the width of the blade should be selected taking into account the radius of curvature. Another important criterion is the quality of sharpening of the teeth. The cutting edge should be as smooth and sharp as possible.

Tools and materials

To create the type of saw in question, you will need the following tools and materials:

- a piece of plywood approximately 1.5 centimeters thick;

- timber made of solid wood;

- tapes or attachments that will be used for a screwdriver or grinder;

- a pair of bearings for a drive axle;

- studs, washers, self-tapping screws, nuts, fittings;

- a pair of shafts;

- bolts that will be used to adjust the vertical and horizontal types;

- a pair of brass bushings with internal threads;

- PVA glue;

- upper type axle bearings;

- lamb for tuning screws;

- insulating tape.

Separately, it should be noted that in order to correctly create certain parts of the saw, you must have drawings. To work you will also need the following components:

- pulleys;

- sawing table;

- base;

- cutting blade;

- mechanism responsible for tensioning the tape.

Rip fence

The band saw was already usable, but there was a lack of rip fence. The mechanism for fixing the stop was built on the basis of an eccentric. Due to the rounded front edge of the table, it was necessary to additionally cut out a movable pusher with a semicircular front edge. The support rail was made from larch. On the opposite side of the tire I attached a grip that rests on the edge of the table. It took me almost two months to make the saw. True, I didn’t work on it every day. The project turned out to be very exciting. I am satisfied with the performance of the machine. Now I can’t even imagine how I ever managed without a band saw. I made several boxes as a test for the saw.

DIY band saw

You can find a lot of materials, photos and videos on the Internet about how to make a band saw with your own hands. For example, the Canadian website of Matthias Wandel offers drawings of a machine made almost entirely of wood. But let's focus on something less exotic, which can be done both in a home workshop and in a small wood or metal processing workshop.

Band machine made of wood

Manufacturing of the bed

The initial stage is the manufacture of the frame. For a wood saw, it can be wooden or metal, for metal - only steel. It can be welded from a channel or a corner. For a small workshop or workshop this is not a problem. The dimensions of the bed are selected depending on the expected dimensions of the material being processed. A normally sawing homemade machine can cope with wood up to 350 mm thick and metal several centimeters thick.

The supporting rod is a channel No. 8, which is welded to the frame or bolted. It must be strictly vertical and secured at at least two points along its length to eliminate the risk of deflection. When biting the saw, for example (which sometimes happens) or sawing large material, the loads arise quite large.

At the work site we make a cut for the saw

On the bed there is a horizontal work table with cuts for moving the tape, a ruler, a stop, clamps and other devices for feeding and holding workpieces. The height of the table from the lower stops is 0.7-0.9 meters. The height of the bar above the table is 0.6-0.8 m.

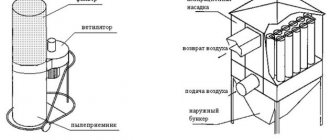

An asynchronous electric motor with start capacitors is installed in the lower part of the frame, connected by a belt drive to a drive pulley of variable diameter. If it is necessary to change the cutting speed, the V-belt is simply transferred to a different diameter. Belt tension is provided by a spring tensioning mechanism.

Band saw drawing

Drive installation

To drive the belt, wooden or metal pulleys of the same diameter (240-260 mm) are used, which are mounted on shafts mounted on bearings. The lower pulley is connected by a shaft to the motor drive. The saw pulley shafts are mounted on a rod. The lower one is stationary, the upper one is in the slot of the fixed tension mechanism. This allows the use of ribbons of different lengths.

The machine is protected from belt beating by a special damper mechanism, which is located under the work table. Drawings of this device can be found on the Internet. Sometimes you can see band saws with two dampers - below and above the working area. This is justified if the machine is designed to work with large workpieces or exceptionally high cutting accuracy is required.

Saw casting shaft

Lubrication system and protection

Lubrication system (adjustable), installed above the work table. The oil flows by gravity to the saw blade in the required quantity, which is determined experimentally for each home-made machine.

All working units where anything rotates or moves must be protected with casings. It is best to make them from waterproof plywood with a thickness of 10 mm. It's inexpensive, and sanded plywood painted with enamel looks very good.

The starting system is a standard button with an emergency shutdown option. It is advisable to make the lower part of the machine in the form of a bedside table with a wide door, or even two. One is used to select falling sawdust, the second is to access the pulleys and adjust the speed of the belt.

We cover the rotating elements with casings

Making a tape machine with your own hands is not difficult for an experienced mechanic. Some of the necessary parts and assemblies can be taken from decommissioned or dismantled machines of your own enterprise or bought on the market or on the Internet, some can be made yourself. In any case, a self-made machine will cost twice as much as a factory machine, with the same level of performance and adjustment accuracy.

How to choose a band saw for wood?

A good woodworking machine is not cheap; purchasing such a tool must be approached responsibly. When thinking about which wood band saw to choose, you need to weigh and correlate the parameters of the tool and your own needs. According to the characteristics, band-type sawmills are divided into several types; you should choose a saw for yourself, taking into account the important characteristics:

- Capacity based on estimated production volumes.

- Characteristics of the working surface.

- Manufacturer of the machine.

Hand band saw for wood

Small-sized tools are not inferior in their properties to professional machines for large-scale production. A mini band saw for wood will serve faithfully a caring craftsman, and will definitely come in handy on the farm; with its help you can easily and simply perform various actions:

- cut down dry branches on trees;

- get rid of old seedlings in the garden;

- prepare firewood for the winter.

Making saw wheels

The saw wheels have a diameter of 400 mm. They just need to be made from plywood or MDF. My wheels came out 29 mm thick. I glued them together from three plywood circles. The most critical area here is the central part of the wheels. The blanks were cut out using a milling machine. In the center of the circle, I drilled a 0 6 mm hole and installed the center of the milling compass into it. Then I used this hole to combine the blanks and gluing them. I cut out the circles with an allowance of 10 mm for finishing. Shafts 0 25 mm (for purchased bearings) were made for me by a turner. They have a limiter on one side and an M12 internal thread on the other. I used plywood to make the flanges. Before drilling holes for the bearing in them, I drilled a 0 6 mm hole in the center and, aligning it with the center of the wheel, drilled four holes for dowels. The position of the flange on the wheel was marked. The flange consists of two parts. The outer part, 15 mm thick, holds the bearing, and the inner part, 10 mm thick, forms the gap between the wheel and the bearing. The diameter of the hole in the wheel should be slightly larger than the diameter of the shaft. The most critical operation is drilling a hole with a diameter of 52 mm for the bearing in the outer part of the flange. Especially for this, I bought a 0 52 mm hole saw and, after checking, ground it along the outer diameter by 0.3 mm. The bearings were then pressed in using a mallet. Before gluing the flanges to the wheel, I cut out the lower wheel shaft holder - a wooden block with a hole for the shaft, which is attached to the bottom of the frame. It is not advisable to drill a hole directly in the frame: there is a high probability that the drill will lead away. It is easier to rotate the holder to the angle required for correction. I drilled four technological holes in the wheels so that clamps could be inserted into them when gluing. Immediately after gluing the wheel, I put it on the shaft. Thanks to the preliminary centering of the flanges and drilled holes for dowels, one of my assembled wheels had virtually no runout, but the second had an uncritical “figure eight” of up to 3 mm. To adjust the wheel diameter and to form the profile, it was necessary to connect the wheel to the engine. At the first stage, I used a temporary pulley made of plywood - I screwed it to the wheel with self-tapping screws. I machined a pulley for the engine using the engine itself, and then connected the engine and the temporary wheel pulley with a belt. Having fixed the wheel, I screwed on a wooden block as a stop and, using turning tools, turned the wheel to 0.400 mm. The diameter of the wheel on the shaft is difficult to control, so I measured the circumference. It is equal to 1,256 mm. The processed edge of the wheel was given a barrel shape. Thanks to this, the belt does not slide off the wheel, but, on the contrary, self-centers on it. The bevel angle should be 5 degrees on each side.

12. When all the parts were ready, I glued the flanges to the wheel. 13. I used the lower shaft mounting block as a holder. 14.I ground the wheel to the required diameter, giving the edge a barrel shape. The bevel in each direction is approximately 5 degrees. 15.After preliminary assembly of the wheel. 16. Guide complete with support bearing blocks. 17. A guide with an upper support bearing is installed, but so far without “crackers”. Rubber tubes are stretched over the wheels (they need to be glued after final assembly). 18. The work table support is equipped with adjustment in one plane. tilt mechanism

Having made both wheels, I installed a standard drive pulley on one of them (read about a similar solution here). Its thickness and shape were adjusted to the belt used, and its diameter was calculated so that the speed of the saw blade was approximately 800 m/min. Now all that remained was to balance the wheels. To do this, I took bearings with an external diameter of 0 22 mm. They were then used as supports for the saw blade. Having fixed the temporary axle horizontally and put bearings on it, I installed the wheel so that it rotates easily, and its heaviest part falls down. Using a Forstner drill, I made small indentations in the lower area of the wheel from the rear side. As a result of such manipulations, I ensured that the wheel stopped rotating in any position. This is where the balancing ends. The wheels were varnished in two layers.

Link on topic: Do-it-yourself belt grinding machine - photo and design

Then I pulled cut inner tubes from 16″ wheels of a children’s bicycle onto the wheels. Rubber protects the wheel surfaces from damage by the canvas, reduces noise and prevents slipping. The balancing, however, had to be repeated.

Drawings for a homemade sawmill

After selecting materials and tools, the design begins. First you need to choose a structure of suitable dimensions, carry out calculations and develop a drawing of the sawmill with your own hands.

The process begins with selecting a site for manufacturing the device. It should be about 4x8 m in size. It is better to choose a closed production facility. Then it will be possible to work in any weather.

When making calculations for the structure, the total number of corners and metal pipes is determined. It is also necessary to calculate the segment between the rails. To do this, add 0.5 cm to the largest diameter of the wood on both sides.

You also need to reserve the distance for transverse installations between the rails. They are attached every meter of the structure. The support for the sawmill is placed at a height of 0.3 m.

Rollers, screws, and bearings are made using a lathe. Before this, you need to make a drawing of these parts.

The cost of the design is calculated individually, based on the availability of certain parts and design.

The manufacture of a homemade sawmill must be approached responsibly. The durability and reliability of working with the machine depends on how well the device is made.

It is recommended to build the structure on a supporting concrete slab. The process of its manufacture is similar to the arrangement of a shallow foundation. To create it, you need sand and gravel up to 20 cm thick. The diameter of the product is 15 mm. In this case, the slab will firmly hold the entire structure.

Self-connection of parts

After a thorough preparatory process, the assembly of the device begins

At the same time, it is important to take your time and carefully check the quality of the connections of the parts.

The assembly of a homemade band saw begins with the manufacture of a table with a cabinet. The mechanism will be located on this table. To assemble it you will need wooden blocks and a furniture panel. The convenient height of the table and the diameter of the pulleys are calculated in advance. The table should be comfortable and accommodate the pulleys and motor.

The table should accommodate the necessary tools and have a place to collect chips. It is advisable to immediately think about a waste tray. Cleaning the saw will be easier and more convenient.

If there are no ready-made ones, then you need to make homemade pulleys. They can be cut from plywood. Then the blanks are sanded and coated with epoxy resin. A hole for the roller bearings is drilled in the center of the pulley. For stability, the bearing itself is fixed in a textolite coupling. After this, the wheels are covered with tape rubber. The diameter of the pulleys can be arbitrary. However, the larger the pulley diameter, the longer the life of the saw.

The blade depends on the size of the pulley. A very good ratio is 1/1000 of the saw blade to the pulley diameter. In other words, if you have a pulley with a diameter of forty centimeters, then a four-millimeter tape will do. When installing the pulley, it is necessary to ensure that the bearing shaft is perpendicular. Even with a slight deviation, the wheel will run out, causing the belt to jump off.

The next step is assembling the support frame. The entire device will be mounted on it. The frame is made from a corner channel and can be C-shaped. This shape holds the tape perfectly. A metal axle is put on the channel. The frame or bed is the most important part of the structure.

Pulleys are mounted on the axle using bushings. After which, they achieve their balance. A damper is used against belt vibration. Attach moving parts to the engine. It must be borne in mind that the average speed of rotation of a band saw is from 700 to 900 revolutions per minute. This parameter must be taken into account when calculating the diameter of the drive pulleys.

It is best to put a protective cover on the engine. It will protect the drive mechanism from fine dust and chips.

To make it easier to feed the material being processed, metal corners are attached. They create a guiding mechanism.

Wooden parts must be planed, painted or varnished. On the one hand, this is aesthetically pleasing and extends the service life of the product, and on the other hand, it protects the hands of the worker from splinters made from untreated wood. Before painting, the wood is cleaned with fine sandpaper and treated with liquids that prevent the wood from rotting.

Setting, checking and sharpening

Before starting work, be sure to check and configure the device. You need to make sure that the tape forms a right angle. The slightest deviation can damage the machine and even cause injury. Using a driven pulley, the belt is tensioned. Achieve maximum tension on the cutting tape.

Sharpening of band blades is simple and affordable. The technology has been tested by many masters. You need a special machine and a little patience. First, the initial sharpening is carried out, that is, the symmetry is restored, the saw teeth are aligned, and small cracks on the edges are removed. Then the saw is cleaned of dust and metal filings and the saw is set, restoring the rear and front angles.

The final step is the final sharpening. It is this that gives the teeth the necessary sharpness and eliminates various distortions.

Necessary equipment

Such a tool is needed if there is a need to work with wood. Although some models of band saws also allow you to work with synthetics, metal, and stone. The high density of the described materials requires the use of devices that contain components made of reinforced steel. A standard analogue will not be suitable due to the fact that when processing metal or any other of the mentioned materials, a disk with teeth very quickly becomes unusable.

If we talk about the equipment that will be needed to make a band saw, then this is:

- welding machine;

- welding machine (it is better if it is semi-automatic);

- Bulgarian;

- sharpening machine;

- electric jigsaw;

- Sander;

- screwdriver

By the way, electric tools can be easily replaced with their manual counterparts. However, it is worth keeping in mind that this will significantly increase the assembly process time and require more labor.

Making a saw stand

I chose the dimensions of the cabinet based on the dimensions of the saw base, and adjusted the height so that the table was at a level of 1,050 mm from the floor - this is just right for me. The cabinet was made from scraps of tongue-and-groove floorboards 35 mm thick. The frame of the cabinet was assembled on dowels. The corners were reinforced from the inside with metal corners. Side inserts are made of laminated chipboard. The back wall is made of MDF. In general, everything is from scraps. The top drawer of the cabinet is used to collect sawdust. The cabinet is mounted on wheels with the ability to fix them.

25. The right wall of the lower wheel casing is beveled at the top to simplify the replacement of saw blades. 26. The rear wall of the lower wheel protection is installed at an angle and directs sawdust into the box. 27. The parallel stop is fixed on the work table. Installation of protection. 28.This is what the protection of moving elements looks like. A saw start button and a backlight switch are installed.

The protective covers and elements of the saw body are also guides for removing sawdust. All working elements of the saw are protected by screens. The material for the casings and screens was 8 mm thick MDF and pine boards.

Related link: How to make a homemade stationary circular with your own hands

Frame

In order to make a band saw with your own hands, you will first have to master the frame construction scheme. To construct it, it is worth choosing fairly hard wood.

Main components of the frame:

- table top;

- support rod;

- pulleys;

- saw blade.

To make a homemade frame more stable and stronger, you must first prepare a drawing according to which the entire structure will be made. It is best to make detailed drawings, but if you have some knowledge, you can get by with a schematic representation of the structure

It is important first of all to calculate the optimal length of the canvas; the remaining dimensions can be adjusted

Therefore, you need to calculate the optimal height with the possibility of installation in a workshop or other place where it will be located. It is also recommended to choose a tabletop height that is convenient for a particular craftsman. The working surface (tabletop) can be made from ordinary plywood.

Hardwood is used for the frame.

The main supporting rod of the structure can be made of durable timber, for example, maple or other wood.

In order to give additional stability to the frame, it is edged with slats. In some cases, you can even use parts from old furniture.

The diameter of the pulleys should be selected in such a way that the design is not too bulky, but at the same time ensures sufficient speed of movement of the blade.

Do-it-yourself band saw at home - how to make a sawmill

First you need to analyze what material will be exposed to the saw, as well as the quality of the tool that will be used in construction. At the very beginning, it is worth checking the sharpness of the saw, its position in the hand and sliding on the material.

DIY band saw

In order to make a band saw at home, you need to highlight all types of band saws:

- metal saw

- wood saw

- mini wood saw

The metal saw is made from alloys of various metals, the most common of which are steel, cast iron, copper and aluminum with tin. In order to select a material, use the following rules:

- The materials must be durable for construction work, and they must also be processed using different methods necessary to create different shapes. (To do this, use gas or electric welding for cutting, bending and other actions).

- The material and the seams connecting it must be strong and resistant to corrosion.

- The use of inexpensive and non-scarce materials is mandatory.

Now we need to consider the metals for creating band saws and its types. Steel tools are usually divided into two categories:

- structural steels used in general construction

- special steels with special properties, such as: acid-resistant properties, heat-resistant properties

There are no universal steels. Steel may be resistant to corrosion, but not resistant to other factors.

Besides:

- Cast iron is used for casting large or small parts. The metal base of a band saw can be cast from cast iron, followed by sharpening the teeth, as well as cutting the teeth.

- Copper and its alloys are used in construction and repair because it has high corrosion resistance.

- Aluminum comes in sheets that are easy to cut into a band saw and sharpen the teeth at the bottom. But the main disadvantage of aluminum sheets is their low strength when cutting hard wood or light metal.

- Tin is used because it is resistant to organic acids. It is more used as a coating for steel or cast iron, against acids.

As the metal variety of band saws is described above, we can draw a small conclusion about its production at home. It is advisable to use more durable metal saws so as not to break when cutting hard materials

Aluminum band saws can be used when cutting glass, but be careful!

To make a band saw with your own hands, you need to purchase a sheet of aluminum (for example), cut it to the required length and weld the teeth at the bottom, with a certain pitch, for example 5 centimeters, and cut at the same distance. This is one way to make a regular bandsaw at home.

Installation of blade guides

The next step is to secure the band saw guides at a 90 degree angle. This will prevent you from ending up with uneven or irregular pieces with crooked ends or defects.

The simplest solution is to screw 3 bearings to the beam: 1 fixes the flat side, and the rest are intended for fastening the tape on the sides.

An important stage in the installation work of a band saw with your own hands is the alignment of the guides in relation to the point of fixation of the support. Otherwise, even small deviations will lead to large defects and deformations.

As an alternative, wooden stops can be used for 2 bearings. You should also secure a number of guides under the table. It is important to fasten them in such a way that they are placed closer to the workpiece, or even better - at a distance of 3-4 cm from the log.

If you want to work with materials of different thicknesses, it is recommended to provide the ability to adjust the height of the guides.

How to make a band saw mechanism with your own hands?

To make a vertical bandsaw machine at home, it is enough to have only a basic understanding of how the assembly process occurs.

- First of all, they make all the necessary sketches of the unit and all its operating components.

- After this, according to the drawings, the mill for the workbench is welded. As a rule, the table dimensions are as follows: 400 by 700 mm.

- A tabletop is installed as a frame covering. Most often it is made from plywood flooring with a penetration depth of 20 mm.

- By welding the transverse profile to the corner, a supporting rod is installed.

- The upper and lower pulleys become the main decking to provide a quality working surface based on sheet rubber.

- Using a special resin, a bushing made of duralumin alloy is installed, inside of which an opening for the bearing is first machined.

- A motor is placed inside the table surface, which is the drive for the operation of the machine. The drive pulley is attached to the engine.

- To reduce the vibration of the installation, install a damper made with your own hands from textolite material.

- If the machine overheats, it is necessary to let it “drink” from time to time.

Republished by Blog Post Promoter

Band saw machine: device and assembly

Band-type wood carpentry machines consist of a work table, which serves as the basis for other elements, and the elements themselves. The design provides for constant circular movement of the blade, supported by two pulleys.

A full-fledged unit with a frame and tabletop is made if there is a separate large room for installation: the equipment has impressive dimensions. In other cases, a tabletop manual mini-installation is made, which will not be able to unravel whole logs.

It is recommended to draw up drawings in special programs.

bed

The machine frame is a load-bearing element that must support the weight of the entire structure. It is better to make it from a metal profile, but wood will also work. Plywood and chipboard are usually not used; boards 20 mm thick are used. The frame is glued according to the rule of intersection of the fibers of each next layer relative to the previous one . Self-tapping screws are used to strengthen the frame. The structure must be rigid and at the same time elastic in order to act as a damper, dampening jerks of the cutting blade.

Pulley block

The upper pulley block does not hold the blade in tension when moving vertically. Hardwood is required to make the frame. On the inside of the frame there is a wooden insert to which the wheel shaft is mounted. The tilt of the axis is adjusted using a threaded rod and nuts mounted in the wood.

The vertical stroke is carried out along guides fixed in the upper part of the frame and is ensured by a screw mechanism. For reinforcement, the adjusting nuts are supplemented with washers or welded. When recessing the shaft, a flange is provided, due to which it will be fixed from the rear side.

Pulleys

Wheels about 30 mm thick are glued together in several layers of plywood circles, after which a hole for the bearing is formed in them. To make the sawmill stable, the bearing is fixed in the coupling . A washer is put on the shaft on the inside, and a flange is secured on the outside. So that the tape can self-center, the wheels are given a barrel shape and the treated surface is covered with a bicycle inner tube.

When installing the bearing, it is necessary to ensure that the shaft is perpendicular, otherwise the wheel will hit the plane during operation. As a result, the cutting blade may slip out of its seat. A drive pulley is attached to the lower wheel.

Tabletop

The tabletop is located on a pedestal base, inside of which a motor with a trigger mechanism is placed. The table is usually made of a sheet of thick plywood; the working side is covered with textolite . To make it more convenient to cut at a given angle, the tabletop is made rotating. A parallel stop is also provided; for this purpose, roller guides or a profile with clamps are used.

Tips for use

- Tension the saw blade correctly. Exceeding the permissible force reduces the service life of the tool. For control, you can use special devices. The saw should not be in operation for more than two hours, after which it must be dismantled and suspended for a day to relieve residual stress.

- Be sure to use belt lubricant. In warm weather, you can use water with the addition of detergents such as “Gala”, “Fairy”, etc., and in winter - a mixture of kerosene or diesel fuel with motor oil in a 5:1 ratio or lubricant for chainsaw chains.

- After finishing work, be sure to release the tension on the saw. This will prevent fatigue phenomena from forming on its surface and will extend its service life.

- Work only with properly sharpened and set tools. If you have no experience in this area, you can use the services of specialized offices. As a rule, their representatives service more than one sawmill in your area.

- Do not work with freshly cut timber. Let it dry for at least one month. In addition, before work, clean the logs from dirt and sand, and even better, remove the bark.

Final finishing, inspection and adjustment

A wooden saw can be used immediately after assembly, but experts recommend first equipping it with a casing that will cover the upper pulley.

Such manipulations will not only add aesthetic appeal to the structure, but will also increase the degree of safety: even if the belt slides off the pulley, it will stop in the casing. As an additional accessory, a container for chips should be provided that can be easily accessed.

It is recommended to remove the belt drive from under the work table, protecting it from sawdust. The power unit is protected by a casing that is insulated from dust and other debris.

The final stage of processing wood with varnish or paint has a positive effect on the service life of the tool, and also prevents injury from contact with chips and slivers of untreated material. Before use, all surfaces are additionally sanded and impregnated with antiseptics - they prevent rotting and the development of mold.