A wood sawing machine (saw bench) is a rather complex special production equipment that requires strict adherence to safety measures during operation. In the conditions of the Russian Federation, your own sawmill can greatly reduce the cost of wooden construction and/or become a source of stable income. The purpose of this publication is to help the reader understand how to make a sawmill with your own hands, choose a suitable design for yourself and avoid insurmountable difficulties in its manufacture.

The principle of operation of the sawmill

It is necessary to secure the log on the sawmill so that it remains motionless. At this time, the mobile cart is activated and cuts the log. The saw must be in a horizontal position.

To obtain boards of a given size, immediately before cutting, the operator must set the required parameters. The saw blade must be well tensioned so that it acts as a saw.

The most common types of sawmills:

- Chain.

- Disk.

- Tape.

- Angular.

Pros and cons of such devices

The advantage is that with the help of one unit (chainsaw) you can solve many problems - use the chainsaw in the traditional way for cross-cutting and place it on a frame for cutting logs into moldings.

The disadvantages are as follows:

- Poor performance.

- Significant consumption of fuel and oil for cutting 1 cubic meter.

- Thick cut, a large percentage of the wood goes into sawdust.

- Significant, accelerated wear of the chainsaw itself and saw accessories.

As a result, the device can be useful and beneficial when relatively regularly it is necessary to saw small, but not absolutely negligible, volumes of wood. For large volumes, when you need to cut quickly and efficiently, it is better to use traditional sawmills. And vice versa, for sawing only 2-5 logs there is also no point in buying or constructing such a structure.

Disc type of sawmill

Considered the best view. This sawmill is easy to use and does not require much effort when making it yourself. The basis of this design will be a circular saw. It should be installed on an electric motor or on the machine spindle.

Today it is not difficult to find ready-made drawings of such a sawmill on the Internet or in books in order to make it yourself. The simplest type is considered to be “circular”. To do this, you will need a shaft with a circular saw, a table and a motor that will drive the saw.

DIY chain sawmill

The design of this unit is simpler and smaller in size than its belt counterpart. It works on the same principle, differing only in the type of saw. In this case, a special chain stretched over a tire is used to cut logs.

It is much easier to make it; you just need to strictly follow the tips on how to make a homemade chain-type sawmill.

Note!

- Do-it-yourself electric scooter - a master class with step-by-step instructions for doing it yourself. Tips and simple patterns for beginners + the best photo reviews

DIY rocking chair: TOP-120 photos of the best manufacturing options. Master class on creating a rocking chair at home

- Smokehouse from a gas cylinder - the best master class on making a homemade smokehouse with step-by-step photo diagrams for beginners

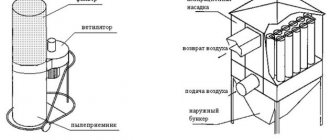

Band sawmill

Has more advantages than disk. This sawmill can work with wood of any species. It doesn’t matter to her whether the wood is highly resinous or deciduous.

- The range of wood produced is also wide - from edged and unedged boards to gun carriages, veneer and more. The sawmill is a high-risk facility and when working on it, you must remember to use protective covers. This will prevent the operator from getting caught under the cutting belt.

- In order to make a band sawmill with your own hands, you need to at least briefly familiarize yourself with the drawings. A simple option involves a basic band sawmill, which has a manual feed of the workpiece. The complex option already implies the presence of sensors and automation. Considered to be a high performance product.

The basis will be a frame that has guides. It is assembled with welded soles in which movable rollers will be placed. The U-shaped frame can be assembled by welding two channels.

On one side of the frame it will be necessary to secure the drive pulley, and on the other end (movable) - another one will be secured. The guides should be mounted in the middle of the frame - this will be a collapsible structure. If the structure needs to be subsequently transported, this will be relevant.

Cost and efficiency of industrial options

Why is there a great desire to create a homemade version of the machine? An example is the Taiga band sawmill, the cost of which, depending on its performance, can vary between 112-165 thousand rubles. Even the simplest version, which does not have great performance, will cost at least 90 thousand rubles. A homemade band sawmill will cost several times less. A self-made machine is suitable for occasional use.

Difficulties in making a machine yourself

The structure of a band sawmill is quite complex. The performance of the band sawmill, service life without breakdowns, and much more depend on the quality of the assembly. You should start making your own machine after considering the following points:

- Installation work is carried out using welding. Therefore, it is practically impossible to carry out work on creating a frame and other elements without a welding machine. To change the shape and size of structural elements you will need a power tool and a milling machine. Of course, the creation of some elements can be entrusted to professionals, but this will significantly increase the cost of the work.

- During operation, a large load is placed on the band sawmill. Therefore, the structure must be stable and durable. To do this, the structure is attached to the base, and the frame and other elements are produced taking into account the possible weight of the processed logs, about 300 kilograms.

- If you are creating a homemade gasoline band sawmill, then you should take into account the need to carry out work on sharpening the saw and routing the working part.

- There are quite a few different designs that allow you to specify the thickness of the resulting product.

- It is necessary to consider the safety of using the equipment. The installed saw and tape can cause significant harm to human health.

It is worth considering that the design of homemade band saws is only suitable for cutting boards of various lengths and widths.

There are quite a large number of options for making homemade band saws, the drawings of which are based on the use of electric and gasoline engines. At the same time, electric versions are very popular due to better performance and ease of use. But not in all cases it is possible to use an electric motor as a driving force, since electricity is not available on all land plots.

Conduct a review of specific machines, the drawings of which have exact dimensions. After all, each production requires a table of different sizes, as well as an electric motor of different power.

Scheme of a homemade band sawmill

Corner or disc sawmill

Since the corner sawmill is multifunctional, it is most often used for large volumes of work. The design is quite easy to make with your own hands. It is much cheaper than purchasing a ready-made structure.

- To assemble this type of sawmill, you must first prepare drawings, and immediately before starting work, make sure that you have all the necessary components and components on hand.

- The first step is to assemble the frame. To do this, you will need metal pipes and guides (rails may be ideal). The joints must be secured by welding.

- The next stage is assembling the carriage. Be especially careful at this stage - the dimensions of the parts indicated in the drawings are important down to the smallest detail.

The engine can be used with high power. The engine is mounted directly on the structure frame. Through special holes, the working elements are attached to the engine. Do not install a chain drive on such a sawmill if you do not want the drive itself to overheat.

Important: Do not neglect safety precautions. Compliance with safety rules when working with a sawmill will eliminate all possible risks during operation.

Making a homemade chainsaw machine

The main structural elements required for assembly are a chainsaw, a pair of channels, metal angles and rails.

First, a frame is assembled, in which holes are drilled for installing ties from metal pipes. During assembly work, it is imperative to ensure the accuracy of dimensions and observance of right angles. To strengthen the frame, it is recommended to weld several stiffeners.

At the next stage, the movable cart is assembled. Its basis is a steel plate, to which corners are welded from below and rollers are mounted. Fasteners for gas-powered tools are installed in the upper part.

At the last stage, a structure with fastenings for logs is installed on the frame.

Which sawmill is better

It's up to you to decide. Only you can determine what kind of design of the future installation you will need. To do this, you need to determine the available area where the sawmill will be located, and also understand the specifics of the work that you plan to carry out on this structure.

If you plan to work with small-sized boards that are used for containers and pallets, pay attention to a sawmill with a simplified design.

- If you need to get boards with clear geometric parameters, put in a little effort and make a stationary installation, with a frame on a concrete foundation.

- In order to make a portable homemade sawmill, you can use a gasoline saw made in the USSR. Models of that time are famous for the special strength of the body, which is made of aluminum alloys.

- The most popular series “Friendship” or “Ural” are equipped with engines with a power of up to 5 hp. This is enough to cut a log up to 6 meters long.

To cut logs into pieces, you can use a gasoline sawmill, which is equipped with a disk or belt mechanism. The disadvantages of such a sawmill include a large amount of sawdust that scatters around. The internal combustion engine has forced ignition.

Recommendation: Install an emergency switch in the operator's area. This will allow you to stop the motor in the event of a dangerous situation with just the press of a button.

Ready-made frames and mobile attachments

The modern market offers many options for frames for such sawmills, from the simplest clamps (attachments) costing about only 3,000 rubles. to frames similar to a band sawmill at a price of about 50,000 rubles. The latter are rather flimsy-looking structures with a high probability of vibration during operation. There's nothing complicated about it. It is quite possible to assemble such a structure on your own if you have available materials.

If you use more powerful rolled metal, the structure itself will be much stronger and more reliable than that offered at a fairly high price.

The simplest attachment for longitudinal sawing.

Alternatively, such an attachment can be used as a ready-made unit when assembling a homemade sawmill. It makes it possible to vertically raise and lower the cutting set relative to the log. All that remains is to organize the movement of the nozzle along the horizontal guides of the homemade frame.

Mobile carriage for longitudinal cutting of logs based on the Husqvarna 142 chainsaw

The author of the video tells how he made a mobile carriage for longitudinal cutting of logs based on a Husqvarna 142 gasoline saw. With this saw and carriage he sawed through a very large volume of material and built an entire house. The video contains everything you need to make the device yourself. We recommend viewing, very useful.

Video about the nozzle from the store

You can see what kind of devices they sell in the store in this video.

Photo of a homemade sawmill

Equipment for work and assembly algorithm

It’s no secret that when building a homemade sawmill you can’t do without good welding equipment. Bolted connections are useless in this case. It is better not to take risks, because after some time such a fastening will lose its former strength, become loose and make the structure dangerous for use. But tightening bolts and monitoring their condition every day is not the best prospect.

As for the equipment assembly algorithm, it remains very simple and understandable. The main difficulties lie in adjusting the size of the components.

First of all, you must install a support platform on which the cart with lumber will move. In addition, you need to attach a frame to the rails where the working tool will be installed. Key requirements include reliability and horizontal alignment. Where and how to attach it is up to you. It is possible to use a specially equipped foundation, for example, a columnar one, or an option with racks that are dug into the ground.

The purpose of the mobile unit (trolley) has already been mentioned several times. To ensure reliable fixation of the log during sawing, the mobile element is equipped with a “clamp” , which securely clamps the wood to the frame and prevents any risk of displacement. The cart should also have wheels that will provide mobility.

As for the saw frame, it should be equipped with a good adjustment mechanism. Otherwise, it will be difficult to ensure the ability to change the position of the cutting units.

There are a number of engineering solutions currently in use, so which one to choose is up to you. There is no point in giving specific examples without first studying existing modifications.