One of the significant disadvantages of wood is that it quickly loses its attractiveness. Even if the conditions for its storage and use of lumber products are the most favorable, over time the surfaces inevitably change color and “fade,” that is, the wood loses its original appearance.

Many technologies have been developed for restoration and renovation of furniture and structural elements. One of them is veneering (the term veneering is sometimes used), which is quite accessible for DIY implementation.

The need for veneer finishing

Plywood is a type of laminated lumber made from natural wood. But, despite its natural origin, the raw materials for the production of plywood are inexpensive wood species with an inexpressive fiber texture and an insufficiently attractive color.

In order to refine inexpensive material, rare or even valuable species are glued on top. As a result, the price of lumber increases slightly, while the aesthetic design improves significantly.

Finished veneered plywood and products made from it look as if they were made entirely from rare wood. However, along with a more attractive and solid appearance, as a result of veneer finishing, plywood acquires improved technical and operational properties.

Furniture made from inexpensive materials (MDF, chipboard, plywood) can be given a noble appearance by imitating their surfaces to resemble solid wood. To do this, you need to learn how to glue veneer in order to achieve a high-quality result.

How to make and where to use veneered MDF

In the design of classic and modern interiors you cannot do without wood. The high cost of natural wood (especially elite species), and, accordingly, products made from it, forces us to look for ways to reduce the cost of products. This is why veneered MDF is so in demand in the furniture industry today.[contents]

MDF - medium density board is considered an environmentally friendly material, since sawdust from thin gauges, knots, and wood with defects is used for its production. Binders are introduced into production raw materials: paraffin, resins, modified melanin. The homogeneous mixture is pressed under pressure and high temperature aggression into thick sheets.

Interior doors finished with noble or exotic wood, furniture panels and cabinets, wall panels are perhaps the best solutions in interior design.

Purpose of veneer

Veneer is a thin plate of natural wood obtained by peeling, planing or cutting. This material preserves the texture and decor of wood, which allows you to give the renewed surfaces the sophistication of ash, the presentability of oak, the splendor of mahogany, the delicacy of birch, etc.

The main purpose of veneer in a home interior is the cladding of doors and furniture. If necessary, cornices, portals of decorative fireplaces, picture frames and mirrors are finished in wood. If an apartment renovation project involves the use of wooden wall panels, then in this situation, veneer glued to a cheaper material will cost less.

Why veneer furniture?

Two main points can be highlighted.

Firstly, the price

. You can veneer a pine table with your own hands, “turning” it into oak, and the appearance will hardly be inferior to real oak. But the price will be much lower. And if you remember that it does not dry out, does not deform, and is not affected by moisture and temperature, then you should seriously think about whether it is worth spending money on furniture made from valuable wood?

Secondly, wide design

. Do-it-yourself veneering allows you to turn a tattered window sill into a new one, and a boring cabinet into a completely new item in the Art Nouveau style without much expense, just by applying veneering.

Preparatory work

Items on which veneer is to be glued must be wood-based. The doors are removed, decorative elements are removed, and the fittings are unscrewed. The old coating is removed with a heated spatula. All surfaces are carefully checked.

If coniferous materials were used as a base, it is necessary to treat the places where resin leaks appeared. They are cleaned with a knife and wiped with 25% acetone (you can prepare a solution of soda ash for this purpose).

Existing knots to which the veneer does not adhere well are first removed. The remaining small recesses are filled with putty. For large holes, corks from chipboard are cut to shape and placed on glue. If defects in the form of chips, cracks, or gouges are detected on the prepared surface, they are puttied with a special compound for wood. After the putty has dried, sanding is carried out.

First, fine construction sandpaper is used, and then zero-grade sandpaper is taken. The prepared base after sanding should have a velvety, slightly rough surface, ensuring better adhesion of the glue. The last step is degreasing.

The next step is preparing the veneer. It is unpacked and the sheets are laid out on a horizontal plane. This will allow you to study the texture pattern and select individual fragments to obtain a complete image. If you have artistic taste, you can select interesting combinations from different wood species.

Selected and carefully joined sheets are connected at the joints with adhesive tape. The total size of the set should be approximately 10 mm on each side larger than the surface prepared for gluing.

If the material was rolled up, after rolling it out on a horizontal, flat surface, it is necessary to evenly moisten it with a sponge, spread paper on top, which will absorb moisture, and lay a sheet of chipboard (plywood, MDF).

Without the skills to feel how to properly glue veneer, it is advisable to start with surfaces that have small dimensions and are not façade, for example, shelves.

From the video you will learn more:

Surface preparation

- The door leaf is removed from the hinges. If the hinges are old, you will need a pry bar. Self-tapping screws can be easily unscrewed with a screwdriver.

- The door is placed on the floor or on an installed platform, which can be two chairs. The fittings are removed.

- After removing the handles, decor, and hinges, you can begin to clean the base from the old paint layer. It can be removed with a hair dryer, iron or metal spatula.

- If you are going to paste over a new canvas made of coniferous trees, then you need to remove the resin and knots from it with a knife, and then treat the area with acetone.

- The cleaned surface is leveled. Existing protrusions are sanded with sandpaper. Cracks, chips, and pits are filled with a mixture based on wood glue. This way you can restore door leaves made of stacked solid wood, chipboard, and MDF.

- After sanding, the base is primed.

To protect the floor from contamination, it must be covered with oilcloth or a piece of polyethylene.

Bonding methods

Studying information on how to glue veneer, we can distinguish three main methods for carrying out this operation.

Watch the video to find out more:

Cold contact method

Involves the use of contact adhesive, characterized by a short period of exposure and setting. Because of these features, problems may arise when applying the method to large planes, since it will be impossible to correct inaccuracies when applying veneer, which very quickly sticks to the base. Important for high-quality veneer gluing is the compression force applied at the initial moment. The contact method is not recommended for large planes, being considered the most difficult, but it does not require the use of additional devices.

Cold gluing method with pressing

When it is used mainly on small objects, the glued veneer is fixed to the base with a clamp and the time necessary for the glue to fully set is maintained.

Hot gluing method

The layer of glue applied to the planes to be glued must dry for some time. Then the veneer is carefully and precisely applied, which, using a heated lapping hammer or iron, is straightened from the center to the edges along the grain. Due to the high temperature (≈ 150°C), the glue melts and provides reliable, uniform gluing.

Find out more from the video:

When using this method, it is necessary to take into account that the glue is taken with a thick consistency. During grinding, it is recommended to moisten the veneer with warm water, preventing the glue from drying out excessively. If during work, in places where the layer of glue was insufficient, swellings form, then it is necessary to make a small incision in the air bubble with a blade, introduce a little adhesive and rub it in.

When determining the algorithm for gluing veneer at home, to achieve high quality, it is necessary to first glue the side edges. A veneer plate with 10mm allowances is glued onto the façade planes, which are then carefully cut and sanded.

Before gluing veneer from the rarest and most expensive wood species onto a particle board, it is advisable to first glue cotton fabric or cheap veneer to the base as an intermediate layer.

To avoid deformation of the finished cladding due to different shrinkage of the material from which the item being renewed is made and the veneer, it is advisable to glue it across the fibers of the base.

The veneer is sanded along the grain using sandpaper No. 3. After the entire surface is cleaned of dust, the veneer is immediately varnished to avoid its possible peeling due to its ability to absorb moisture. You can use quick-drying transparent furniture nitro varnish.

If you follow the rules for gluing veneer, you can independently update the interior by upgrading furniture and other items with a beautiful finish that imitates the texture of valuable wood species. It will cost less than purchasing new furniture, and the effect will be no less impressive.

Once, at one of the “shabits”, I noticed a huge oak table in the owner’s garage, with massive cabinets, drawers, one of which even had a secret drawer. The table is covered with green cloth, reminiscent of the covering of a billiard table.

According to the hostess, the table was “with history,” and almost Stalin was sitting at it.

His son brought it to her from Abkhazia, after another Soviet sanatorium there was liquidated and everything they could was taken away.

Despite the fact that it was all worn out and the cloth was torn in several places, the table looked great. It was finished with the finest natural veneer, which in narrow places (front and end surfaces of drawers, doors, tabletop trim) was almost completely worn off, but the rest of the veneer finishing of such parts as sidewalls and partitions was almost not damaged.

I bought the table from the owner, and even then I had to learn the technology of veneering, which turned out to be not so complicated - I had to run around the shops longer, choosing veneer that would look like “aged” and would match the “Stalinist” in color. At that time, I couldn’t find the required veneer in stores at all; I had to start searching on the Internet, as a result of which I got a pack of veneer of the required shade, also, by the way, still made in the Soviet Union. By the way, I also bought the cloth on the Internet, ordered it from a man who makes excellent billiard tables with his own hands to order (at first he refused, but then, having learned what kind of table we were talking about, he immediately sent it, and took the money only for the cost price, for which I bow to him).

The table, however, didn’t stay with me for long - it’s not intended for apartments - it’s too big, and my ex-girlfriend demanded that I get rid of it, so I had to sell it.

But the technology of veneer finishing or veneering (veneering) can be useful not for such rare furniture, but simply for any furniture that you make with your own hands - after veneering it looks amazing.

What kind of glue can I use?

To glue veneer, you can use different types of adhesives. Each of them has certain advantages and disadvantages.

PVA

This type of glue is suitable for smooth surfaces. In this case, the method of fixation is used, which involves the use of a heated iron. PVA glue has many advantages. It does not contain harmful components, and therefore is completely harmless to people. The composition is easy to apply and provides reliable fixation of wood.

Carpentry

Wood glue is highly effective. Typically this substance is used to fix large elements.

Polyurethane

This composition provides a high degree of adhesion and allows you to securely fix the veneer. To achieve good results, you must apply the composition correctly.

For wooden surfaces

To fasten complex parts, it is worth using professional solutions that are designed for wood. Titebond is considered a common representative of this category. This one-component adhesive is highly resistant to moisture. The composition provides good adhesion and is resistant to elevated temperatures and solvents.

The product does not contain abrasives and does not cause damage to cutting devices.

Epoxy

Experts say that it is quite acceptable to use epoxy resin to fix veneer. This substance is highly effective and provides good adhesion.

See also

20 best ways to quickly smooth your skin at home

Veneering techniques and technology

Finishing with valuable wood veneers is a quick way to give a product made from ordinary plywood an elegant appearance.

This article will help you veneer a large product, for example, a wall table (read about how to make it yourself in one of the following articles in the “Furniture” section).

Editing veneer sheets

Natural solid wood veneer is so thin that it “remembers” how it was stored. Therefore, before working with it, the veneer leaves need to be straightened - to make them as flat as possible. Most often, the leaves will be curled or warped. This especially applies to veneer made from valuable species.

It is not very difficult to straighten the veneer.

To do this, use a small amount of water - just wet the back side of the veneer

with a damp sponge. The veneer will react almost immediately. But perhaps not as it should (it may curl like bacon in a roll). This is where the principle of flat laying comes into play. Simply place the veneer between sheets of plywood and press down the package with a weight (Fig. 1).

Note. To absorb excess moisture, place a layer of wrapping paper above and below the veneer.

Editing edges

Natural veneer is sold (nowadays you can buy veneer for almost any type of wood for veneering) in sheets of different widths (usually no wider than 300 mm). This means that in order to veneer large surfaces

, for example, the cover of a wall table, the leaves need to be fused. And to do this you need to straighten the edge of each leaf. Do not try to do this with a sharp utility knife along the ruler, as halfway the knife will choose the direction of the veneer grain rather than follow the ruler. Use a planer. Take two 50x150 mm boards and use clamps to clamp the veneer between them (Fig. 2). To get the necessary

Joining veneer sheets

If you use contact adhesive (it sticks almost instantly), it is difficult to get an unnoticeable, even seam. Use the edge pre-gluing method. The thickness of natural veneer is usually 0.8-1.0 mm, which is quite enough for gluing edges with PVA glue (Fig. 3).

Note. Transparent tape makes it easy to check the quality of the seam.

Core preparation

While the glue on the edges is drying, prepare the core (the material to which the veneer is glued). As a core, you can use maple, birch plywood, MDF, chipboard or dense fiberboard.

When gluing veneer, two rules must be observed: firstly, the veneer fibers must run across the core fibers, and secondly, the size of the veneer sheet must be slightly larger than the size of the core.

Note. If the veneer panel does not need to be mounted in a frame (for example, on the side walls of a cabinet), it is advisable to veneer both sides of the panel to protect the core from warping. The core must be cut to size in advance. The protruding veneer can be trimmed later.

Gluing veneer

When using contact adhesive, you do not need the clamps or clamps that are required when using other adhesives. Contact adhesive is sold in two types - water-based and .

When using water-based glue, there is a possibility that the seams on the veneer may come apart as the glue dries. This is due to the initial swelling of the veneer and its subsequent shrinkage as it dries.

Solvent-based contact adhesive does not have these disadvantages: with it, the veneer does not expand. This glue is easy to apply. Using a brush, apply an even layer to the core and veneer. When the glue has dried (usually it takes 15 minutes), a second layer is applied to the first layer of glue, and both glued surfaces are combined with light pressure. Please note that the veneer must be laid the first time.

To properly align the core and veneer, place sheets of wax paper between them. This way you can slide the veneer into position, then remove the paper from under the veneer and press it into place. For pressing, a heavy rubber roller is used, which is used to roll the veneer, starting from the joint lines to the sides. As a result, all air bubbles from under the veneer come out.

Sawing parts with veneer to size

When the veneer is glued to the core, you can cut the panel to size using a circular saw (Fig. 5). To keep veneer chipping to a minimum, you should use a disc with at least 50 teeth.

Note. If both sides of the panel are veneered, circular sawing is not suitable. Use a router with an edge bit instead, and you can trim both sides without breaking the veneer protruding beyond the core (Fig. 6).

What is veneering and why is it needed?

Natural wood, used to decorate various rooms, transforms and decorates. However, this material has not only advantages, but also disadvantages. It is expensive, rots when exposed to moisture, and over time can dry out, changing its appearance, in particular its shape and size.

Fortunately, production technologies do not stand still. And today, modern materials are used for the manufacture of furniture and for finishing premises, which have high performance properties, but in appearance perfectly imitate natural wood. Such materials include veneered plywood panels, as well as chipboard and MDF.

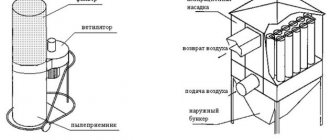

What is veneering? Veneering refers to a decorative finishing method that increases the service life of the product. Veneering is a method of gluing veneer to other materials. Today, when decorative panels or designer furniture are made using this finishing method, 3 types of technology are used: – membrane (vacuum connection, which is used even when processing 3D surfaces); – cold (gluing, which is carried out using special compounds); – hot (pressing of veneer under high temperatures).

In order to produce decorative panels, in particular TRENDY veneered panels, the surface of the material is leveled, in particular treated with wood putties. Then glue is applied and the veneer is attached using the chosen method.

As a result of using veneering technology, it is possible to obtain a material that is practically no different in appearance from natural wood. At the same time, it is strong, reliable and quite durable.

What types of veneer exist today? The veneer used today is divided into three main types: planed, sawn and peeled. 1. Sliced veneer Sliced veneer is made from valuable wood species, in particular mahogany, ash, Karelian birch and walnut. This material is obtained by planing beams through the use of special equipment. It is relevant in the production of almost any furniture, as it has a very beautiful texture. Despite the fact that the thickness of sliced veneer varies from 0.2 to 5 mm, furniture sets and individual interior items made using this veneering technology are decorated.

2. Sawn veneer The thickness of sawn veneer ranges from 1 to 10 mm. This material is made from the wood of certain coniferous species. Its production leaves a large amount of waste. However, the use of sawn veneer when finishing rooms allows you to enjoy the unique structure of natural wood. Thanks to this material, decorative panels are made, as well as designer furniture.

3. Peeled veneer Peeled veneer is made from alder, oak, some softwoods, etc. Peeling is carried out by cutting a thin layer of wood from a rotating log. It is believed that the quality of this material is somewhat inferior to similar sawn material. Decorative panels are made from peeled veneer. Also, designer furniture is made using this material.

Veneer is also classified according to its texture. Thus, today it is possible to achieve a clear pattern on the veneer surface: various stripes, unique closed lines and cones. At the same time, any TRENDY veneered panels are highly durable, can easily withstand temperature changes, and they can be installed in rooms for various purposes.

How to obtain a material that will not differ in appearance from natural wood, but at the same time will be stronger and more durable?

Of course, remember about veneer technology. TRENDY veneered panels, like designer furniture, have already earned the trust of Russian consumers. They decorate the room and serve for quite a long time. Such furniture and panels are ideal for transforming residential premises and for decorating office spaces. They fill rooms with natural shades and the life-giving energy of natural wood, and also create coziness.

The cost of veneered products is much lower than the price of similar interior items, in the production of which natural wood was used. Therefore, both furniture and decorative panels made using this technology are available to a wide range of Russian consumers.

Source: www.letostyle.ru

Veneer finishing - technology

Veneer can be finished like solid wood. First, the panel is cleaned to remove fingerprints and traces of contact adhesive (read more). Remember that you cannot clean the same place for too long (especially with a sander), otherwise you will quickly wear through the thin veneer!

Finally, cover the veneer with stain and varnish, as is usually done on any product.

The photo shows the techniques and technology of finishing with veneer-veneering. The numbers indicate the stages of finishing:

- Editing sheets

. Place the veneer between sheets of plywood, press down on top with a weight and leave overnight. - Straightening the edges

. To get an invisible seam, you need to straighten the edges of the veneer sheets being joined. Clamp them between the scraps of boards and run the whole bunch through the planer. - Gluing veneer edges

. To join the veneer sheets, apply a thin layer of glue to the edges with a brush. - Connecting parts

. When joining sheets of veneer end-to-end, before the glue hardens, glue them together with adhesive tape. - Sawing to size

. Using a circular saw, cut out the core with glued veneer to size. To keep chipping to a minimum (especially when cutting crosswise), saw with a fine-toothed blade. - Trimming with a cutter

. Trim the veneer protruding beyond the core with an edge mill. Mill counterclockwise.

One of the significant disadvantages of wood is that it quickly loses its attractiveness. Even if the conditions for its storage and use of lumber products are the most favorable, over time the surfaces inevitably change color and “fade,” that is, the wood loses its original appearance.

Many technologies have been developed for restoration and renovation of furniture and structural elements. One of them is veneering (the term veneering is sometimes used), which is quite accessible for DIY implementation.

There is no definition of the term “veneering” in various dictionaries. In essence, it means pasting materials with the thinnest layer of decorative wood-based coating. In principle (if you don’t go into specific details) this is the same lamination technology. The only difference is that, as a rule, products (objects, structural parts) made of wood are subjected to such surface finishing.

Veneer has a certain classification. Differences in production technology, as well as durability and specific use. A detailed description of the groups is unlikely to interest the reader. It is enough to note that if you plan to finish furniture with your own hands, then it is advisable to focus on peeled veneer (a natural product)

and fine line (the so-called reconstructed modification).

They have a lot in common - ease of working with the products (the layer is very thin), a variety of textures (especially fine-line modifications) and an affordable price.

Veneering technology is applied not only to wood, but also to materials (sheet, slab) based on it - chipboard, OSV and a number of others.

Therefore, talking only about furniture restoration is not entirely correct. With the help of veneer, you can give a “second life” to old door jambs and panels, wall panels, countertops - there are plenty of options for using such finishing.

There are several technologies for fixing veneer. There is only one available for DIY implementation - “hot”, which is based on the use of glue. This technology. The other two require special equipment and are not suitable for home use.

What to do if the veneer comes off

Peeled veneer on furniture is smeared with glue and rubbed in with a piece of flannel. It needs to be folded in several layers and a block of dense wood placed inside. Lapping will not harm the varnish coating.

Sometimes the veneer peels off, completely exposing the base. To correct the defect, after gluing the remaining veneer and grinding it in, the open area of the base is puttied and then tinted with stain. The stain is matched to match the coating. The restoration is completed by applying several layers of varnish.

I veneered the acoustic cabinets from MDF. I glued it with PVA (Slovenian). The first attempt was a complete failure. I applied glue only to the box, but thicker. Then I pressed it down with laminate and loaded it with about 100 kg. The following happened. The veneer began to expand, and partially already stuck. And it turned out into a small shallow wave. I had to rip everything off. There are no photos of the first process.

The second one worked more or less, but I’m not very happy. I applied glue to both surfaces, waited 10 minutes, then smoothed it with an iron and a block. There are videos and photos!

I will try other ways. Maybe contact glue?

Hot veneer technology

Preparing the base

- Removing fittings (if any) and structural parts. For example, a peephole from a door leaf, the rim of a keyhole.

- Dismantling the old layer of finishing on a wooden surface. It’s easy to decide what you’ll need – a spatula, an iron for heating the coating, and so on.

- Elimination of existing base defects. Methods and materials are selected based on their nature and “depth”. Basically, grouting agents, putties and adhesives are sufficient. Upon completion of the work, the base is carefully sanded so that no bulges, dents or folds are formed when the veneer is applied.

Veneer preparation

- Editing sheets. This thin finishing material is sold in rolls. Consequently, when straightened, it will try to return to its original position (memory effect). To restore their correct geometry, just walk along the reverse side with a damp sponge. The veneer will soften somewhat and straighten out. To consolidate the result, the sample should be clamped between two flat surfaces. For example, sheets of plywood, fiberboard slabs and the like, depending on the size of the fragment. To quickly remove moisture from the veneer, it is advisable to cover it with soft cloth or paper. After drying, it will remain in a straightened position.

- Editing edges. When restoring large surfaces, one sheet will not be enough. Veneer is sold with a blade width (with rare exceptions) of 30 cm. Consequently, splicing of fragments cannot be avoided. Edge straightening is nothing more than cutting sheets along a line. At home, 2 pieces of boards with treated ends are quite suitable for this (as an option). A sheet of veneer is placed between them so that only its edge protrudes. All that remains is to clamp the resulting “assembly” with clamps and trim off the excess (irregularities) with a sharp knife. It is advisable to work with a special tool designed specifically for cutting cardboard or thin plywood.

Veneering

Applying glue.

Recommendations for using the selected adhesive are always given by the manufacturer. But those who have already done this work with their own hands advise processing the base in 2 passes. First, the thinnest first layer - a short exposure until it “sets” - then the second. This technology allows you to see all the imperfections and distribute the glue as evenly as possible over the entire area.

Fixing sheets.

Experienced craftsmen recommend placing a sheet of paper (only waxed paper) first. The reason is that the veneer is thin, easily damaged, and it is unlikely that it will be possible to place it on the base immediately as needed. This means that it will inevitably have to be moved. When it reaches the optimal position, it is quite easy to remove the wax sheet without damaging the glue layer.

Processing of joints.

- Before the glue dries completely, in order to ensure the quality of the veneer, it is advisable to secure all joints with adhesive tape. Then it is easy to remove it.

- In some cases, it is advisable to first fasten the veneer strips into a single sheet, and only then lay it on the base. You will have to decide for yourself what to do best. But it’s worth considering (as one of the acceptable options).

- To avoid moisture absorption into the base, it is advisable to veneer not only the front part of the sample, but also the back and ends. This should also be taken into account when determining the course of action.

The final stage

After the adhesive composition has hardened (which implies reliable fixation of the veneer), a number of simple technological operations are performed.

- Inspection of the surface and identification of possible defects in the work.

- Removing excess (if any) glue.

- Sanding joints (edges). Extreme care must be taken here. The veneer is thin, and excessive zeal will lead to bald spots. Everything will have to be redone, since it is difficult to disguise the stains to match the finish, and it will not always work. Of course, the highest quality polishing is ensured by a grinding machine, but not every home has one. If possible, asking friends for some time is the best solution.

- Application of a protective coating. This is necessary mainly for peeled veneer. It is not difficult to choose a composition, depending on the design of the sample, its purpose and specific use. The range of various oils, varnishes, and stains is impressive.

Having dealt with all the nuances, it becomes clear that do-it-yourself veneering is not a very complicated process. Knowing the technology, anyone can implement it at home. And if you wish, you can bring some of your own “zest” to this work.

Good luck to you, home craftsmen!

There comes a time when wooden furniture or doors lose their original appearance. There is no need to throw away such products. Thanks to new technologies, a variety of finishing materials, and design developments, they can be given a modern look.

One of the finishing materials is veneer. To make it, wood is used, from which a thin layer is cut. At the same time, the material retains the structure of the tree.

You can decorate interior items using veneering technology. Making a new one out of an old product is not too difficult. If desired, repairs can be done by yourself. It is advisable to watch the video before starting work.

Preparation and cutting of material

In construction stores, wood sheets are sold in rolls. Before you start cutting, the roll needs to be rolled out and straightened. Straightening is carried out by wetting with further placement under a press.

The operating principle is as follows:

- rolled out the roll;

- moistened it generously with a damp cloth;

- Lay a layer of plywood or drywall and press down.

When the roll is flattened, they proceed to cutting.

- Measurements are taken from the prepared door leaf.

- The measurements taken are transferred to the wood sheet with a 5 cm gap added on each side. The stock helps to avoid problems with incorrectly taken measurements.

- You can cut the canvas with a plywood knife or a plunge-cut saw. The smoothest cut will be made with power tools. But you cannot work with scissors; they can lead to cracking and damage to the material.

If, on the contrary, you need to make a single structure from several sheets, you can connect them with gummed tape, having previously selected a pattern on the front side. The tape needs to be passed both along the joints and perpendicular to them. The connected structure should extend 7-10 cm beyond the veneered base.

Advantages of the material

Natural veneer has a number of advantages:

- Veneer made from wood is an environmentally friendly material. Its qualities are equal to solid wood.

- Decorative trims with patterns, different colors and textures are available on the market.

- The surface after pasting is smooth, chips, scratches, and mechanical damage are almost impossible.

- Finished products covered with veneer are distinguished by sophistication and nobility.

- Plywood is made from veneer.

It is important to know:

When choosing the right material, read the composition. Today there are similar products made of plastic or eco-veneer (glued together pressed wood waste).

It is not advisable to replace wood veneer with them; they are less environmentally friendly and have a short service life.

History of the creation and use of veneer

Even the ancient Egyptians made veneer by cross-cutting a tree trunk. The widespread use of veneer began when a peeling machine was invented, which made it possible to separate thin plates from wood. An improved peeling method was applied in Germany. This method is still used today.

Both in ancient times and today, veneer is used mainly as a finishing material for cladding doors, furniture and walls. In practice, the use of veneer solves the environmental problem of forest conservation, since it reduces the consumption of wood in furniture production.

On an industrial scale, machines are used not only for the production of veneer, but also for veneering. The most common is a hydraulic press for gluing veneer onto chipboard. The use of such sophisticated equipment is necessary for greater productivity. The compressive forces of the press do not play a significant role in industrial veneering technology, since they can damage the bonded material.

It is possible to veneer surfaces even if there is no special machine. Before you learn how to glue veneer at home, you need to choose the right material. To do this, it is important to know what types of veneer are produced and how they differ from one another.

Preparatory work

To perform high-quality veneering you need to acquire:

- veneer and glue;

- ruler and paper for cutting out the template;

- plywood knife and veneer cutter;

- iron and syringe;

- with a wooden roller or iron.

Restoration should begin with the dismantling of fittings and decorative elements on furniture walls, doors or other products. The old coating, which has served its purpose, is removed with a spatula.

The surface must be carefully leveled, eliminating any defects with glue or putty.

. After complete drying, sand it with sandpaper.

Under each sheet you need to put soft paper (to absorb moisture) and plywood. Place a small press on top. This is clearly visible in the photo. Smooth sheets are cut into strips with a veneer cutter or plywood knife, in accordance with measurements.

The facing material is glued to the base of the restored products using the hot veneering method:

- The adhesive composition is applied to the prepared tape, as well as to the required part of the product. To ensure that the veneer is glued, the glue application procedure is repeated again after the first layer has dried. If the glue is applied only once, then it needs to dry slightly for 10 minutes.

- Using an iron heated to 50 degrees, we iron our workpiece, using white paper as a backing. The glue should not boil so as not to lose its properties.

- We press the veneer using a roller to the place to be restored on the product.

- When joining, an overlap of approximately 4 mm should be used. In these places you need to work hard with the iron. If there are any defects left, you will have to trim the veneer and add glue by squeezing it out of the syringe.

- After this, the area is ironed again with a hot iron.

Veneering using clamps

For better gluing of veneer, clamps or clamps are used. In this case, the veneer and base are clamped with chipboard scraps and pieces of linoleum are laid. Andrei Ermolkevich’s YouTube channel .

When gluing, only the base is covered with glue; the veneer is not coated with glue. Veneer is applied to the base, lined with newspaper, and then the structure is tightened with a clamp through 3 bars on top and 3 bars on the bottom. To prevent the structure from warping, the bars must be very accurately aligned with clamps.

If special clamps are used instead of clamps, then the method of pressing the veneer to the base is improved and simplified.

Compression clamp

The clamps are made from 35 x 50 mm bars. They are tightened with M16 studs. This design is more convenient for compression than a clamp.

One of the bars is shaped like a rocker to better press the veneer to the base in the center. If the bars are compressed on one side, then on the other side there will be a gap of 7-8 mm.

Gap between clamp bars

To glue veneer measuring 400 x 400 mm, use 3 clamps.

Pressing the veneer to the base

This design speeds up the veneering process, since there is no need to wait for the glue to dry. It is more convenient than separate bars and clamps.

Video about veneering using clamps:

How to use veneer at home

Working with veneer at home is a more labor-intensive task than gluing a plastic edge or self-adhesive paper tape. But the use of veneer instead of plastic trim increases the service life of laminated chipboard furniture.

Both in industry and in households, the main use of veneer is lining furniture and doors. Veneering can be used if, for example, the set is still in good condition, but has lost its appearance due to scratches. Knowing all the intricacies of technology, how to glue veneer to furniture, you can not only give it an updated look, but also turn your things into exclusive, presentable models, a la a solid wood set.

In addition, if you want to refresh the interior, you can veneer the wall panels. The texture of walls lined with veneer imitates the finishing of timber or clapboard made from natural wood.

If you do not have experience working with veneer, start with small surfaces, for example, the ends of chipboard, shelves, and decorative elements. Once you feel confident in your movements, you can begin veneering furniture or walls.

Veneering at home has its own difficulties:

- Positioning veneer sheets on the product. To make the drawing look beautiful, you need to select sheets with a similar (or vice versa, contrasting) pattern.

- Docking. Veneer sheets, absorbing moisture from the glue, expand, and then, drying, decrease in size. Therefore, after gluing, gaps may form between the sheets. To prevent this from happening, use oblique trimming of the edges, overlapping gluing, or pre-joining the sheets with a special tape.

- “Siskins” or air bubbles between the veneer and the base.

You can completely avoid such flaws as uneven joints and air layers only if you acquire a certain skill in veneering.

Before gluing veneer, you need to select a suitable glue. Its choice largely depends on the veneering methods. However, general rules must be taken into account. So, if the glue is not viscous enough, it can leak onto the front side through the porous surface of the veneer. Therefore, glue that is too liquid will not work.

Many people are interested in how to glue natural veneer obtained from wood species with a high tannin content, and it is no coincidence. In the presence of iron compounds (from which the press is made), tannins stain the veneer, reacting with the glue if its acidity is below 5.5.

To prevent unwanted reactions between glue and metal, use paper or foil spacers, or use glue with a neutral or alkaline reaction.

For veneering, you can use the following types of glue: regular PVA, protein types (hide, bone, casein), special branded glues for wood.