Using wood in its natural form is not always advisable. Insufficient natural strength or susceptibility to external influences can become a serious obstacle. The situation can be changed by processing the material in a suitable way.

One such option is wood stabilization. This exposure technology can be performed both in industrial and home conditions. The result will be an improvement in quality characteristics, as well as a change in the direction of improving external data.

What is wood stabilization

Various techniques are used for mechanical processing of wood - sawing, planing, grinding, carving. In the process of performing these works, the natural order of placement of wood fibers is destroyed.

- Some of them open along the length, the other part is destroyed in the transverse cut.

- As a result, we obtain a part of the required shape.

- But as a bonus, we gain even greater fragility of wood and its vulnerability to various external factors.

- After all, fibers can absorb moisture well, and this can cause fungus or rot.

To prevent rot and rapid breakdown of the product, you can use wood stabilization technology.

As a result of this, the pores in the wood will be completely clogged, which means the product will become durable, will not absorb water, and after stabilization, the wood will acquire a more attractive appearance.

Types of wood protective agents against fungi and insects

Based on the nature of their action, wood protective agents are divided into antiseptics (preventing the spread of microorganisms), flame retardants (preventing fire) and combined action protective agents .

They are divided according to solubility:

- water-soluble - VR,

- soluble in light organic solvents – L,

- soluble in oils and heavy petroleum products (oils) – M.

And on washability:

- easily washed out - LV,

- washable – B,

- difficult to wash – TV,

- non-washable - NV.

Water-based antiseptics are often used to impregnate wood, as they are safer.

Stabilization methods

There are 4 ways to stabilize wood:

- Cold impregnation. This is perhaps the simplest option for stabilizing wooden products. Stabilization is very simple - the workpieces are soaked in a cold composition, usually in an airtight container. The impregnation period for wooden blanks varies from 2 days to 2 weeks. Typically nut, hemp or flaxseed oil is used, but commercial oil-based formulations can also be used.

- Hot impregnation. This method is considered the most effective, since during hot impregnation all pores are filled with the composition. The complexity of the method lies in the fact that three-dimensional wooden parts cannot be stabilized due to the complexity of the technological process.

- Vacuum processing. The method of stabilization under vacuum is difficult to implement, but the result is worth all the costs. To process wood you will need a vacuum chamber. The first step is to pump out the air from the chamber, after which the liquid pumped out from the pores of the wood is removed. After this, a special composition is drawn into the chamber, and then pressure is applied back, as a result, the pores are filled with a stabilizing composition. Finally, work is carried out on the polymerization of the impregnation.

- Processing under pressure. This method is generally similar to the previous one, only now the processing is carried out under high pressure, and the stabilizing composition can be pumped in immediately.

What to protect from

Since wood is an organic material, it is affected by various types of fungi and insects, and is also affected by climatic phenomena and ultraviolet radiation. There is reliable protection against all these damage factors, which cannot be avoided in wooden house construction.

Fungi pose the most serious threat to wood. Infection with fungal spores can occur in the forest during the harvesting process. Under favorable conditions, the spores germinate, forming a mycelium. Such conditions are: temperature from +2 to +45 °C, wood humidity more than 22%, lack of air exchange. The absence of any of these factors leads to the cessation of fungal activity.

Wood protection can be carried out during the production of building materials, at the construction site, during the assembly of the house and after construction, during the operation of the finished building.

There are many ways to treat logs before building a house. But once a house is built, it is very difficult to provide it with reliable protection. Often you have to settle for a not very effective surface impregnation. Today, perhaps, only MABI technology allows deep impregnation of wood in already built structures. Therefore, it is so important to take care of the protection of timber even before construction begins.

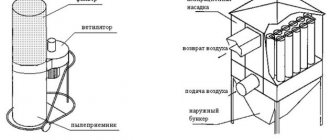

Treatment of wooden structures using deep pressure impregnation (MABI)

Stabilizing compounds

Epoxy resin. In most cases, epoxy is used to stabilize wood products. To improve the fluidity of the composition, the resin is often diluted with ethyl or isopropyl alcohol.

This is the most affordable method, since epoxy resin is sold at any hardware store.

The disadvantages are as follows:

- Stabilizing wood using this method is time-consuming.

- It is better not to stabilize coniferous wood in this way, as there is a possibility of voids forming in the pores.

- Under a vacuum, there is a huge probability of resin boiling, so the processing technology must be followed very strictly.

Liquid glass

After impregnating the wood with this product, a thin protective film is formed on the surface, resistant to various dyes and chemicals. Therefore, liquid glass is constantly used for processing wooden elements that do not require subsequent impregnation with protective agents.

Wood treated with liquid glass is not subject to rotting or destruction from all kinds of biological organisms.

Drying oil

The main components of drying oil are considered to be vegetable oils that have undergone 2-stage processing at high temperatures.

- This heating of oils makes it possible to increase their resistance to high humidity and UV radiation.

- A special solvent is added to the drying oil at the production stage, which further increases the fluidity of the composition.

- Thanks to these solvents, you have the opportunity to use drying oil to produce your own putty and primer solutions, varnishes and all kinds of paints.

If you are processing wood that will be constantly exposed to sunlight and wind, then it is better to give preference to composite or alkyd drying oil.

Composition for vacuum chamber

Only special solutions are suitable for a vacuum chamber, as they have better fluidity, penetrating ability and stabilized behavior under low pressure.

To stabilize wood, it is advisable to buy a vacuum chamber with additional reservoirs (for pumping out moisture, for a stabilizing solution, etc.). Sensors and safety valves will not be superfluous.

Birch juice

Birch sap can perfectly stabilize any wood. Impregnation is carried out in a vacuum chamber, followed by 3 hours of drying at 70 degrees Celsius.

Polymers

These stabilization impregnations include the following manufacturers:

- Anacrol-90.

- 100therm.

- Buravid.

- Pentacrylic.

The distinctive feature of these compounds lies in the fact that they protect the tree from almost all possible aggressive environmental factors. Also, polymer stabilization mixtures perfectly fill microcracks.

We hope that you found this article interesting and informative, and now you know how you can stabilize wood at home. All the best to you!

Benefits of using a vacuum

Unfortunately, this technology is only available in industrial settings and requires special equipment, and the finished material costs almost twice as much. However, vacuum impregnation of wood provides a number of advantages:

- Reliably protects for many years from rot, mold, and various insects. The board does not rot, even if it is constantly in contact with water or soil. Does not require re-treatment with antiseptics.

- Fire retardant impregnation makes the wood difficult to ignite or even non-flammable, significantly increasing the fire safety of buildings.

- Modern protective agents for vacuum technology, as a rule, are produced on a water-dispersion basis; others are less commonly used. All of them are environmentally friendly, safe for people and animals.

- After impregnation using special equipment, the wood retains its unique texture, but becomes more durable: it does not dry out or crack.

The process of saturation (impregnation) of wood with solutions is carried out on specialized industrial equipment under the influence of a pressure difference in a sealed autoclave chamber and takes, depending on the type and quality of the material, 3.5-6 hours.

The liquid pressure in this apparatus reaches up to 12 kg/cm2, the length of the apparatus is 10-15 m, and the diameter is 1.5-3 m. The equipment has:

- manual or automated control unit;

- Pressure Sensors;

- valves;

- container for antiseptic solution.

The parameters of autoclave processing and the characteristics of the impregnating mixture (fire retardant, antifungal) affect the wood’s resistance to various damage and its strength. Typically, the service life of a board after vacuum impregnation is 60-70 years. During this time, she will not require additional antiseptic or fire retardant treatment. For cosmetic repairs, it is enough to simply paint such material after first cleaning and removing the old layers of decorative coating.

Photo instructions for wood stabilization

Why do you need to treat wood with an antiseptic?

When a tree is cut down, the fibers in its structure begin to die. Such an environment becomes nutritious for fungi - saprophytes. They destroy wood and paint it in different colors: blue, red, yellow, green. In addition to fungal microorganisms, there are other threats:

- insect pests;

- high air humidity;

- precipitation: snow, rain.

Antiseptic treatment is a mandatory stage of working with wood. It protects against all of these negative factors and extends the life of wooden structures or cladding.

How to choose a vacuum pump for your camera

How to choose a vacuum pump for your camera

When doubting the choice of technology, you just need to answer the following questions for yourself:

- Necessary environment? For example, a 70-100 mbar model is suitable for filtration, but for drying or concentrating it is better to choose a 0.6-2 or 7-12 mbar model. The former are suitable for solutions of DMAA or DMF, and the latter for classical products in the form of benzene and alcohol.

- What pumping speed is needed? The more vapors or gas need to be pumped out, the larger the unit itself, so the productivity must be high.

- What substances are used during operation? A conventional pump is easily damaged when corrosive or caustic substances are injected; models made of resistant fluoroplastic are suitable. Classic types are suitable for non-aggressive environments, and ATEX standard models are used when pumping explosive gases.

- Is there a need to monitor indicators? To strictly comply with norms and standards, the user of the equipment must have full control, so the equipment must be able to connect to a PC. In other situations, for simple operations, pumps with on and off are suitable.

- Are built-in capacitors necessary? During drying or distillation, there will be a lot of vapor in the working volume that condenses. To prevent their drops from directly entering the pump, protection in the form of drop eliminators is used. Protection against condensate draining onto the surface of the workplace is provided by a connection between the exhaust and the receiver.

Having figured out how to choose a vacuum pump for a camera, you will be able to choose the right equipment, obtaining the desired power and efficiency.

Why is antiseptic tinting necessary?

Impregnations can be colorless or colored. If you need to give a tint to the wood and emphasize its texture, then select a tint antiseptic. You can also add color to a colorless antiseptic. To do this, do the tinting of wood antiseptic with your own hands - a special tint dye is added to the colorless solution.

Tinting should be done to protect the color of the natural material from fading. In addition, different shades give the building a noble appearance and make the exterior decoration more harmonious. After applying tint solutions, ordinary pine or alder is transformed in appearance: a beautiful shine appears, the texture of the wood is clearly visible.

Advice! If the question arises : how to wash your hands from wood antiseptic, then in this case a special product can help out - hand cleaning paste. It is often sold in car dealerships and is good at cleaning dust, dirt, and fuel residues on your hands.

Antiseptics help extend the life of wooden products. You can buy them, but it’s easier and cheaper to make them yourself. You will need the simplest ingredients and a minimum of time to prepare an effective impregnation, which in properties is not inferior to factory-made analogues.

Properties of the cured material

Proper impregnation at home helps to achieve the following results:

- Wood gains increased strength.

- The fiber density increases. There are fewer voids and cavities in the structure.

- Products become immune to external influences, sudden temperature changes, and increased relative humidity.

- The surface becomes resistant to ultraviolet radiation. It does not fade in direct sunlight, remaining amazingly beautiful.

- Crafts and furniture are insensitive to short-term exposure to flame. Strong heating does not lead to deformation.

- High density prevents oils and all kinds of solvents from penetrating deep into the structure.

Despite this, stabilized wood remains malleable to mechanical processing. It can be sawed, ground, cut, sanded, polished. This expands the possibilities for making decorative products.