Everyone knows that wood cannot be left to its own devices - under the influence of external forces it quickly collapses. Impregnation with antiseptics and fire retardants is required. But there is another effective protection, without the use of “chemistry”

Many centuries ago, our ancestors noticed that if you burn a piece of wood a little, it will become stronger. This technique, called Shou Sugi Ban (“cedar languishing”), is believed to have originated in Japan. Although there is quite reliable evidence that wood was processed this way on all continents, including ours. In Rus', pile pillars, joists, floorboards, wall cladding and roofing were protected by firing (smoking).

Today, the ancient method of heat treatment of wood is not only not forgotten, but is becoming more and more popular. The development of technology has made it possible to bring it to perfection. The wood is burned using a gas torch/blowtorch or kept in a kiln, resulting in a new, improved material.

Under the influence of high temperatures, all possible “seeds” of decay die. Wood sugar burns out, making the wood unappetizing to wood-boring beetles and other harmful microorganisms. The melted resin closes the pores of the material, making it less hygroscopic, or, in simple words, no longer “afraid” of water.

As strange as it may sound, charred wood becomes fireproof. It is almost impossible to re-ignite an already burnt board.

But that is not all. During the smoking process, the wood becomes amazingly beautiful. It darkens, becoming dark chocolate or impenetrable black, and acquires a noble silvery sheen that cannot be achieved by any paints.

Of course, such interesting characteristics attracted the attention of craftsmen from various fields. Today, charred wood is used everywhere. It shows itself perfectly both in the decoration of houses (floorboards, cladding of walls, ceilings, facades and roofs) and in landscape design (fences, pergolas, gazebos, greenhouses and even framing beds)

.

Another area of application is the furniture industry

. The exquisite black color with a pearlescent sheen has made Shou Sugi Ban wood a favorite material for designers creating luxury interior items.

Why do they burn wood?

Wood firing is carried out for several reasons, namely:

- During firing, all excess moisture evaporates from the wood.

- The total volume of wood becomes smaller, and the resin channels become clogged with melted resin. Due to this, the strength of the material increases.

- The roasting process destroys all organic compounds, which are a breeding ground for harmful microorganisms and bacteria.

- The wood becomes as resistant to rotting as possible.

- After firing, the wood becomes less susceptible to fire.

- Burnt wood has a more aesthetically attractive appearance, an unusual color with a refined fiber structure.

History of the technology

Residents of Japan were among the first to burn wood to save their homes from fires. They massively burned the forest strips of cypress and cedar adjacent to the villages in order to protect the economy and buildings. After all, burnt, charred wood became perfectly protected not only from further fire, but also from biological destruction.

These new useful properties could not help but impress the artisans, and soon wood burning formed an entire technology that received a poetic name, which translated from Japanese sounds like “cedar languishing.”

Wood burning was widespread outside the Land of the Rising Sun. Craftsmen on many continents have used this method of protecting timber and structures. In Rus', this method was called “smoking.” To do this, they used the flame of a fire, under the influence of which the lumber and structures of future buildings were scorched. Firing is an excellent protection for piles and foundation formwork from groundwater and rot. And elements of the rafter system and roof fired using this technology are more resistant to exposure to sunlight and precipitation.

Types of wood firing

As a rule, wood firing can be done in several types; there are 3 main ones:

- Surface firing is one of the most popular wood firings. This type of firing does not require too much time, special skills, significant materials and tools. In most cases, the burning process is carried out at home using a gas burner or blowtorch. As a rule, the firing depth does not exceed 0.5 cm.

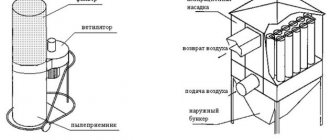

- The full type of firing is carried out under very high temperature conditions, namely at 400 degrees Celsius. To create optimal temperature conditions, a special vacuum oven should be used. It is worth noting that with the full type of firing, the wood loses its total volume by almost 2 times. The firing depth does not exceed 1 cm. As a rule, wood processed by this type of firing is used in the manufacture of furniture and decorative elements.

- Deep firing is a fairly popular and in-demand type of processing for new wood or wood that has already been used. This type of firing processes wood in the form of timber. The firing depth is approximately 0.5 cm to 2 cm. This firing process takes place in a conventional wood-burning oven.

FAQ

Which wood is better to choose for firing, larch or pine?

As a rule, pine processing is faster and more intensive. However, the texture pattern of larch is more attractive, and the degree of strength allows you to make high-quality and durable furniture.

What distance from the burner nozzle to the product must be maintained?

It depends on the power of the burner and the master’s intentions. It is impossible to give any recommendations without having a specific burner and material in hand. It is necessary to carry out a test treatment on a piece of wood to get a feel for the mode and features of the burner.

Is it possible to do without using burners or open flames?

Such technologies exist, for example, processing wood in hot sand. However, to carry out such a procedure requires detailed knowledge of the technological sequence and experience in working with this type of wood. Therefore, it is easier and more correct to use more accessible methods.

If the oil finish doesn't seem to be enough, can you apply a layer of varnish on top?

It is possible, but this requires compatible material. The usual domestic pentaphthalic varnish PF-218 is suitable. However, we must keep in mind that it is glossy and has an oily sheen.

Is it possible to add coloring compounds to varnish or oil to give the surface a general background shade?

Yes, you can often finish countertops, kitchen furniture, and other products in this way. Such additives can significantly expand the decorative capabilities of burnt wood, which is highly valued by designers.

What kind of wood should it be?

Initially, coniferous trees such as pine or cedar, larch, and spruce were used for firing. These types of wood have a fairly soft structure and are easy to process. After the firing process, such wood produces quite beautiful and original patterns, without stains.

Nowadays several other types of wood are often used, which also lend themselves well to firing. When fired on maple or poplar wood, beautiful elongated lines are formed along all the grains.

Also, to process wood with this process, you can use wood of different qualities; material with knots is allowed. It is worth noting that if there are soft fibers on the surface of the wood, then when fired, small depressions form on the material.

If the wood had a rigid structure, then during firing the wood will become more prominent and after finishing cleaning it will have a fairly expressive texture.

Preparing wood for firing

In order to carry out the firing process, fresh wood should not be prepared too much; it will be enough to cut down large knots or protrusions, and also remove resin (if it is present on the tree).

If the wood is very wet, then it is better to dry it a little so that during the firing process it does not become very deformed or crack.

In the event that old wood can be fired, it should be prepared in a different way:

- It is good to clean the material from paint or varnish residues.

- Sand the wood with sandpaper.

It should be taken into account that if the wood was initially treated with stain, then it can be fired, but if with drying oil, then it cannot be fired.

Lamps

Lighting devices with their heating and natural wood are, at first glance, incompatible things. But, no matter how strange it may sound, carefully burned wood becomes heat-resistant. Anyone who has ever tried to relight a heavily charred log in a stove or on a fire will hardly be surprised.

Wooden shades and holders for chandeliers and sconces, carved legs of bedside lamps and floor lamps can be treated with flame.

Even from a solid beam, without cutting out almost anything, it is not difficult to make a pendant lamp, and if you decorate it with rough metal parts or elegant forged elements, you will get a self-sufficient, memorable piece of furniture.

Stages of firing with a gas burner

Below is a step-by-step action plan for firing wood with a gas torch:

- Turn on the burner and wait until the flame is an even blue color and pass it several times over the surface of the wood being treated.

- The burnt surface should be approximately 0.4 cm deep.

- Using a brush or sander, carefully walk along all the fibers so as not to damage the structure of the wood.

- Carefully remove all accumulated soot from the surface of the material.

- Wipe the burnt wood with a soft cloth or napkin.

If you want to get a more textured surface, then you need to repeat the process again.

Furniture and interior items

0 votes

+

Vote for!

—

Vote against!

Despite the fact that we live in an age of innovative technologies, wooden housing does not lose its relevance, continuing to conquer new horizons. The popularity of wooden buildings is due to the unique properties of wood, namely its environmental safety and high wear resistance. However, due to the peculiarities of its structure, wood needs proper protection, which will extend the service life of the material while maintaining its original characteristics. Currently, for wood processing, it is customary to use chemicals that have antiseptic and antifungal characteristics and prevent damage to lumber by insects, mold and other microorganisms, and also reduce the flammability of wood. Recently, supporters of environmentally friendly materials have begun to pay attention to another method of wood processing - roasting. Despite the fact that it is generally considered innovative, and burnt wood is a novelty in the field of finishing materials, the first mention of the use of this method dates back to the 18th century. It was then that the Japanese first told the world about the unique technology of uniform processing of wood Shou Sugi Ban, which translated into Russian means “languishing cedar.” As you know, everything new is well-forgotten old, and today charred wood is again at the peak of popularity. What are the advantages of burnt wood and how to burn wood at home – we’ll look at it in this article.

Content

- Wood burning technology: historical background

- Structural changes in wood under the influence of firing

- Benefits of charred wood

- What is the firing procedure: types of firing

- How to burn wood at home: a step-by-step guide

- How to choose the right type of wood?

- How to prepare material for firing?

- How to burn wood with a blowtorch?

- How to burn wood with a gas torch?

- Burnt wood in the interior

Wood burning technology: historical background

Despite the fact that domestic craftsmen recently paid attention to charred wood, in developed countries it has long been at the peak of popularity. For example, on the island of Naosami (Japan), burnt wood is widely used as a building material, and in the interior decoration of the home, burnt wood products are certainly used, for the manufacture of which the ancient Japanese technique of “simmering cedar” Shou Sugi Ban was used. Processing wood in accordance with this technique allows not only to make the texture of the material more distinct, but also to protect it from insects, rotting, and fire. The history of this method of protecting wood began in the 18th century, when the Japanese, thinking about fire protection of the territory, began to burn stands of Japanese cypress (also called Japanese cedar) growing around Japanese villages. Later they noticed that the burnt cypress wood not only did not lose its original properties, but also acquired additional decorative and performance qualities, becoming resistant to fungus and insects. This was the starting point for the widespread use of burnt wood for cladding facades.

Despite the fact that Japan is considered the birthplace of burnt wood, this method of processing lumber has been known on almost all continents since ancient times, when, along with tarring (impregnation of wood with hot resin), it was used as one of the most effective ways to protect wood from insects and rotting . This is due to the structural characteristics of the tree, which undergo some changes under the influence of open fire. Let's look at them in more detail.

Structural changes in wood under the influence of firing

The structure of wood is such that as the subcortical layers grow, pores form in it, which leads to the gradual death of fibrous cells. The increased porosity of the structure and the gradual displacement of fibers determine one of the most important performance qualities of wood - its high hygroscopicity, that is, the ability to release and absorb water particles depending on the difference between its own humidity and the humidity of the environment.

Another feature of wood is the unevenness of its structure. It is caused by the formation of cellulose polymers, sugars and resins during the life of wood, which are its main organic components and cause the main disadvantages of wood - flammability and the presence of a favorable environment for the proliferation of fungi and bacteria.

However, there are quite effective ways to reduce the exposure of wood to external influences. These include autoclave heating (thermolysis) and creosote boiling of wood, during which lumber is exposed to high temperatures (up to 300-400 degrees), which contribute to the destruction of unstable hemicellulose formations. They are the cause of the formation of highly flammable pyrolysis gases and, as a consequence, fire. It is almost impossible to carry out such treatment at home, however, there are other, more affordable ways to partially block pores and remove most unstable polymer formations. These include wood burning.

Why burn wood and how will this affect its performance? During the firing process, the fiber channels of wood become narrowed, as well as become clogged with resins and combustion products, which helps extend its service life.

In Rus', in order to burn wood, it was often simply thrown into a fire, which became a kind of prototype of the modern firing procedure. Often, only the lower part of the pillars, which were installed in the pits during the construction process, was fired, as well as joists and boards for the floor and roof. This phenomenon in Rus' was called “smoking.”

Benefits of charred wood

- Burnt wood can be made independently at home. To do this, it is not necessary to involve specialists; it is enough to familiarize yourself with the basic principles of firing and prepare the appropriate tools;

- Material prepared in this way acquires a high degree of fire safety, since re-ignition of wood is practically impossible;

- Due to the fact that in the process of burning wood, the destruction of cellulose components, which are a favorable breeding ground for bacteria and fungal microorganisms, occurs, its damage by insects, mold and bacterial microorganisms is practically eliminated;

- Burnt wood is characterized by a high degree of hygroscopicity.

Burnt wood photo

What is the firing procedure: types of firing

The appearance and decorative value of burnt wood may vary and directly depend on the firing technique and depth. Depending on the depth of firing, there are three degrees of wood processing:

- Full firing is a type of heat treatment of wood, which makes sense to talk about if we are talking about large-scale work. Complete burning of wood is carried out in vacuum furnaces at temperatures up to 400 degrees. Wood that has undergone a full firing procedure is used extremely rarely, since, despite its initially high strength, it not only decreases in size by almost half, but also loses its performance characteristics. However, this technique has found its application in the manufacture of furniture from burnt wood;

- Deep firing is a technology more often used for previously used lumber. Having subjected the boards and beams to deep firing, you will notice that the entire thickness of the material has warmed up qualitatively, and its surface has acquired a more expressive appearance - the shade of such wood ranges from iridescent graphite to coal-black, making it possible to imitate valuable species. Such a deep black color is almost impossible to achieve by treating wood with other methods, due to which the value of the material has increased significantly in the eyes of modern designers. Deep burning of wood is carried out in open kilns, and the permissible depth of burning of the top layer of material can reach 20 mm;

- Surface firing is the most popular method of heat treatment of wood in home and industrial conditions, the essence of which is to uniformly burn the material using a blowtorch or gas torch, burning the top layer up to 5 mm. Wood that has undergone the firing procedure is sanded, as a result of which it acquires not only its original texture, but also increased strength characteristics.

How to burn wood at home: a step-by-step guide

How to choose the right type of wood?

The first thing you need to decide on before starting work is choosing the right type of wood. The original Japanese wood burning technology Shou Sugi Ban involved the use of only cedar, but over time there was a gradual accumulation of experience in this technique, and views changed somewhat. Today it is believed that any wood is suitable to create the effect of burnt wood, but true connoisseurs of visual delights prefer species with the most pronounced and original texture. These varieties include soft coniferous woods - pine and spruce, characterized by a clearly defined pattern of annual rings.

Burnt beech and hornbeam wood, characterized by its increased density, will look no less original. This causes only the top layer to burn through, due to which the wood acquires original shades of gray and anthracite.

No less popular are valuable types of wood - maple, alder and poplar, which, after undergoing the firing procedure, acquire the famous elongated texture, as well as larch and walnut, on the surface of which fancy small textured patterns are formed. When preparing material for the construction and finishing of a bathhouse or sauna, pay attention to birch - after firing it becomes very porous, due to which it acquires a low heat capacity and does not burn the skin when it comes into contact with it after heating.

How to prepare material for firing?

The material to be fired requires careful preparation. It is important to ensure that its surface is clean, dry and smooth, paying special attention to the absence of moisture on the surface. The wood moisture content should not be higher than 13-15%, since otherwise exposure to high temperatures will lead to the formation of stripes and spots on the surface of the material, which will significantly reduce the quality of the work performed. It is also important that no traces of paints and varnishes (paint or drying oil) are found on the surface of the wood, since after firing they will take the form of spots and appear unevenly on the surface. However, this largely depends on the time of exposure to fire and the depth of development of the material.

Important! The ideal material for firing is freshly processed wood that has not had time to change its color and texture. Otherwise, it will need to be sanded again.

How to burn wood with a blowtorch?

Before you start firing, you need to wait until the nozzle of the blowtorch turns red and the fire acquires a uniform purple hue.

Important! Yellow fire cannot be used to burn wood, since in this case the surface of the material being processed will be covered with soot.

In order for wood burned with a blowtorch to meet all the required standards, during its manufacture the fire must be directed perpendicular to the board and held in such a way that only the end of the torch, where the temperature is highest, comes into contact with the surface of the material. During operation, the fire is moved slowly at a uniform speed, remembering that the latter depends on the temperature of the fire and the degree of dryness of the wood. In addition, it is necessary to monitor the uniformity and contrast of the pattern. To make work easier, it is recommended to place the material being processed on stools, and 4-5 boards can be placed on them at a time, close to each other. The fired boards are nailed to the wall in the same order in which they lay on the stool during firing.

Important! In accordance with fire safety regulations, it is prohibited to burn boards nailed to the wall.

Important! If you want lumber with a contrasting pattern, consider softwood.

After you have fixed the boards to the wall, they must be covered with drying oil or nitro varnish. You can also use urea-formaldehyde varnishes.

Remember that prolonged exposure to direct sunlight reduces the contrast of wood burnt with a blowtorch, and therefore it is not recommended for use for external cladding of house walls located on the sunny side. On average, the contrast of wood under such conditions will decrease after two months.

How to burn wood with a gas torch?

The gas burner is used only for surface firing of lumber. This is due to the fact that deeper aging of wood in fire, as a rule, is not uniform, which contributes to the uneven thickness and width of the product.

When burning wood with a gas burner, only the edge of the torch, which has a light blue tint, comes into contact with its surface. The movements in this case are similar in intensity, speed and scope to those during painting. The depth of firing during the processing of the material can be easily controlled by the degree of change in its color.

After the part has been fired, its surface is wetted using a hand sprayer. The time interval between firing and sprinkling should be the same for each section of wood, and therefore it is important to process each part consistently. After the wood has cooled, it is necessary to clean off the soot and carbon deposits formed during the firing process. To do this, use brass brushes, which will carefully remove soot without damaging the surface of the material. In the process of mechanical processing, it is possible to additionally artificially age the wood or so-called brushing.

Important! Color solutions for furniture and finishing materials made of burnt wood are distinguished by their diversity and are realized through the use of acrylic paint. If you prefer softwood, in particular pine, focus on ivory acrylic paint, which is applied along the grain.

After mechanical processing of the material, you can begin installation of products. The structure of burnt wood does not require additional protection, but, as practice shows, protective measures do take place, and they are carried out mainly to preserve the original operational and decorative characteristics of the material, such as color, contrast and overall appearance. Thus, it is recommended to coat lining made of burnt wood for interior decoration with linseed or hemp oil, which is applied in several layers. Facade wood and other materials for exterior finishing are coated with two layers of colorless nitrocellulose varnish with the addition of synthetic wax, which are applied using a spray gun or brush.

Important! To protect facade wood, it is necessary to use synthetic wax, in no case replacing it with natural wax, since the latter, due to its performance characteristics, will not lose its stickiness after processing. Before using technical varnish, it must be dissolved in turpentine heated to 40-45 degrees.

Burnt wood in the interior

The introduction of burnt wood into widespread production has made it possible to solve pressing issues in the design of interiors and exteriors. If the interior design involves the use of burnt wood for the manufacture of doors, interior partitions and floors, then the exterior line offers materials for the construction of pergolas, balconies, terraces and canopies. A furniture set made of burnt wood, including a table made of burnt wood and a set of chairs, together with finishing materials made of thermal wood, allows you to create a unique harmony in the area being designed.

Today, charred wood continues to be one of the fashionable trends not only in construction, but also in the furniture industry.

Modern designers have learned to use furniture made of charred wood in almost all stylistic directions with a striking aesthetic effect, and today it will become an organic complement to various design concepts, from classic to ultra-modern eclecticism.

How to burn wood video

How to treat burnt wood

In principle, after firing the wood becomes stronger and more durable, but if desired, it can be further treated with additional means.

- As a rule, oil is used for this, which gives the material a more decorative appearance and improves the operational functions of the wood.

- After the surface is saturated with oil, the material should be opened with a thin layer of transparent nitrocellulose varnish or varnish with artificial wax.

- If burnt wood is to be used as a façade material, it should be coated with synthetic wax with the addition of turpentine.

The most popular oils for impregnating burnt wood are: linseed, hemp or tung oil. You can also use synthetic oils in order to get the most noble look and achieve an imitation of valuable wood. The oil should be applied with a brush or spray gun.

Use of burnt wood

Burnt wood is quite popular in finishing both internal and external surfaces. Windows and doors, gazebos and terraces, benches with tables, chairs are made from wood of this type, and some technical buildings and fences are built.

Very often, burnt wood is used as flooring and wall decoration.

In the interior, burnt wood is most often presented in the following items:

- Caskets;

- Panel;

- Photo collage;

- Dressers;

- Bedside tables and cabinets;

- Chairs, stools, tables;

- Shelves and stands.