Wood treatment with oil has been used for a very long time. The relevance of oil treatment has not disappeared to this day. This is due to the fact that such treatment is one of the reliable and proven methods of protecting wood. Oil treatment perfectly protects wood from various pests and adverse external influences.

Since ancient times, linseed oil treatment has been the most famous and used type of wood protection. Linseed oil really does a great job of strengthening inside the wood, the only downside is that it dries slowly

This is not to say that oil will absolutely protect a wooden structure or give it any special qualities. But other compositions are also unlikely to cope with this

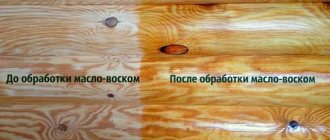

Oil treatment of wood helps to improve the appearance and is a great help after a difficult winter period when the paint requires updating.

What are the popular models?

Product classification is carried out according to basic technical parameters: viscosity, density, type of volatile compounds, amount of dry residue, and the presence of special additives. The following types of oils are considered widespread and in demand:

| Types of coating | Description |

| Degtyarnoe | The main difference from other products is the strongest antiseptic abilities. Refers to natural ingredients. The composition contains turpentine, wood resins and linseed oil. Area of application: processing of piers, yachts, boats and other watercraft. Ideal for impregnating log buildings, gazebos and garden furniture. There is no need for thinner. |

| Tung | It is extremely popular among those who need to protect wooden structures from excessive humidity. Suitable for interior work. Prevents the appearance of rot, mold, mildew, and insects. The scope of application is varied. It opens dishes and furniture, walls and ceilings. The penetration time into the upper layers of logs is minimal. Helps improve structure. To prevent thickening and increased consumption, experts recommend manipulating it at temperatures above 15 degrees Celsius. |

| Linen | The best natural product. Inexpensive and high quality. It has excellent protective characteristics and waterproofing properties. Can be used for interior and exterior work. Popular models are widely used for impregnation of facades, exterior and interior items, and furniture. Penetrates into any hard-to-reach areas, including microcracks. The result is a durable, waterproof film. |

| Vaseline | Belongs to the organic category. The main components are saturated paraffinic carbon compounds. A good choice for covering any wooden products. It is very popular due to its lack of color and odor. Emphasizes the natural beauty of structures. Upon completion of drying, a thin film is formed on the surface, characterized by moisture-repellent qualities. The result is the impossibility of deformation and cracking. |

| Sunflower | Applicable in exceptional cases. The amount of polyunsaturated components is at a minimum level, which does not allow you to fully obtain a decent enveloping effect. Over time, the wood may begin to rot and damaged areas will appear. There is also no polymerization, which prevents it from drying completely. |

| Teak | It is considered a universal and environmentally friendly product. The main components are purified turpentine, linseed oil and tung oil. Used for external and internal work. Often purchased for impregnation of valuable wood species. Breeding is strictly prohibited. You can purchase it at specialized retail outlets or order it online in an online store. |

| Danish | It has nothing to do with Denmark. Special development. A variety of natural resins and components of plant origin are used in production. Allows you to create natural beauty matte finishes. Suitable for use inside and outside. Can be used either independently or as an additional impregnation. Ideally emphasizes the natural beauty of the timber. No shine appears on the surface. |

| Toning | In addition to its protective functions, it helps create a beautiful shade on the surface. Can be used on almost all types of wood. The composition contains natural pigments. The basis is oxidized vegetable fats. Able to prevent damage to the material from fungus and mold, dust and pollution, rotting and getting wet, harmful insects, drying out and fading, and the appearance of microcracks. Can be used for impregnation of: • floors; • stairs; • furniture; • beams; • linings; • external finishing of buildings; • parquets. |

| Mineral | Used in industry for impregnation of deeply cleaned surfaces. It is practically not used in everyday life, except sometimes for outdoor work. To treat external decorative products and facades of non-residential buildings, a mixture of vegetable and mineral oils is used. |

| Colored and white | Area of application: treatment of structures damaged by mold or insects. The white substance is used for tinting if there is a need to lighten surfaces. On store shelves you can find products from domestic and foreign manufacturers. The main purpose is to paint furniture, decorative elements, and walls. Completely safe. The composition contains no toxic elements. Colored models give the logs the desired shade. They can be used to paint lining, sawn boards, planed logs. |

Interesting: Danish butter is not from Denmark

Wood oil is a very interesting topic for manufacturers and DIYers. There are many recipes, widely known and secret. There are also a kind of folk-historical brands, the essence of which is difficult to explain. For example, teak oil, which is not made from teak, but is mixed from different oils with an indefinite number of additives. The historical homeland and authors of this good complex oil, which ideally should also include a part of tung, are unknown. And even eminent foreign manufacturers do not bother with having at least a minimal additive in the form of tung oil.

Danish oil is even more popular. On the Internet you can find recipes made by leading companies, as well as recipes for making them yourself in your home kitchen. This oil's affiliation with the country of Denmark is very relative: Denmark produced furniture from expensive wood, and post-war Americans really liked this furniture. Either there was not enough furniture for everyone, or it was necessary to bring respectable wardrobes and sideboards into line with the salary - one way or another, interested people from the company Rusting Ltd came up with an oil that turned widely consumed wood into noble wood. Needless to say, it was a very good oil. It gave the desired color and, although it did not form any visible coating, it was stable and durable. Even with effort, it was not easy to get to the essence of the wood. The principle and purpose of this excellent composition has been preserved to this day and has even been developed.

The Danish butter recipes available are full of variety - everyone can bring their best skills under this name. As with teak oil, the presence of a product called tung oil is extremely rare, but in both cases there is linseed oil.

Scope of use

The variety of products is impressive. Which product is best to buy depends on many factors. Products are produced with varying degrees of gloss, and therefore they are divided into the following categories:

- semi-matte;

- matte;

- glossy;

- semi-gloss.

Based on the number of components, wood oils are:

- single-component;

- two-component.

Each composition is designed to perform specific tasks. The product can be used:

- For interior work. It is intended to impregnate tools, decorative elements, children's toys, doorways, balconies, tools, and furniture. Apply to a previously cleaned base. They can be transparent and colored. A roller or sponge is required for application.

- For outdoor work. The list of objects for impregnation is as follows: boats, decking, gazebos, outdoor furniture, garages, building facades, landscape design structures.

Apply oils with a roller

Applying oil with a roller is very popular in Europe and Russia. This method is convenient, simple and does not require special skills. In addition, it allows you to control the thickness of the applied oil layer over the entire area. This method is indispensable when processing large areas.

When working with a roller, it is best to use a telescopic extension for the roller handle or a regular mop handle. This will allow you to always be upright and not get tired.

The optimal roller size is 25 cm. This roller is suitable for both small areas (several tens of square meters) and large areas (hundreds and thousands of meters).

In places where it is impossible to apply oil with a roller (areas near the wall or corners), use a natural bristle brush to apply.

To apply natural oils and oils with wax, we recommend using rollers made of natural materials: velor and mohair. These rollers have proven themselves to be excellent for this task.

The standard pile height for such rollers is 4 mm. However, velor rollers with a pile height of 5 mm, the so-called Premium Velor, have recently appeared. Their pile is denser, and it holds oil better.

Advantages and disadvantages of using oils

Without treatment, wood will not last long. Impregnation involves:

- ease of processing;

- environmental cleanliness;

- reasonable price;

- improving the aesthetics of the appearance of structures;

- the appearance of a beautiful shine;

- speed of restoration work;

- disappearance of scratches;

- extending the service life of products;

- versatility (any processing material is assumed);

- the appearance of a protective film;

- UV protection.

Along with a lot of positive qualities, there are certain disadvantages in using oil compositions, which are worth mentioning:

- there is a need for regular care;

- Grease stains may appear and will require re-processing.

Features of care and restoration

Because open-pore wood is susceptible to dirt accumulation, it requires more intensive maintenance:

- Dry cleaning. The first cleaning with a dry cloth must be performed within the first 10 days after the start of use.

- Wet cleaning is carried out with a slightly damp cloth (wrung out) moistened with special products from the manufacturer of impregnation for surface care.

Important! If you perform regular wet cleaning, the surface will become dull and will require polishing.

- Periodic care. Its essence is to restore shine. Depending on the previous impregnation, wax or an oil-based product is applied, followed by polishing the surface with a pad.

Rules for processing products

Experts recommend taking the impregnation process seriously. It is not enough to buy quality products. To achieve a positive result, it must be applied correctly. There are several ways to oil surfaces. Some resort to rubbing, while others prefer soaking. The second option is acceptable for small structures (dishes, toys, figurines). To get the perfect result and admire it, you need to take the following steps. Let's look at each stage in more detail.

Preliminary stage

At this stage, the surface is prepared for oiling. According to buyers, much attention is paid to leveling the base. Items are sanded well. If there are old layers of varnish or paint, they must be removed. If you have to work with floors, ceilings, walls, you will have to perform the following tasks:

- Removing the surface from the old coating. A spatula or wire brush is suitable for these purposes. If the paint turns out to be of high quality and does not want to peel off, you can resort to using a hair dryer. As soon as bubbles appear, you can pry it off with a spatula and remove it.

- Sanding the base. It is worth using coarse and fine sandpaper. The surface must be brought to a smooth state. There shouldn't be any roughness.

- Removing dust. A soft broom or a regular rag is suitable for manipulation. No contaminants should remain on the surface.

Coating

Actions are carried out using a soft cloth flap (for large areas) or a brush with natural bristles (if the volume is small). The process looks like this:

- The product is thoroughly mixed.

- Pour into a clean container.

- The matter is wetted.

- Application occurs along the fibers.

- The substance is left for 15 – 20 minutes.

- Excess is removed with a rag.

- Wait some time for complete drying.

- Repeat processing.

Soaking

The method is suitable for small items. The substance is poured into a deep container. A wooden product is placed inside the container. The time the structure stays there is not limited. It is advisable to wait until air bubbles begin to emerge from the wooden products.

Afterwards, the item is taken out and placed on a table covered with clean paper sheets. Excess impregnation should drain off. Then take a piece of soft cloth and rub it until it shines. Flaxseed oil in its pure form will dry for up to three weeks. But the depth of impregnation is impressive. Wooden objects receive ideal protection from mold, moisture, rot, and insects. To speed up the drying process, you can add beeswax to the substance.

Preparatory work

To get a beautiful and even coating, you need to go through all the necessary steps and strictly adhere to the application technology. Oil impregnation is absorbed very well into wood, so all the imperfections and defects of the floor will immediately appear under the oil. The surface that is supposed to be impregnated with oil requires more thorough preparation than when varnishing.

Preparing the old floor

Preparation is necessary for both new and old floors, but in the latter case the preparatory work is complicated by the fact that the previous paint coating must be completely removed. This is usually done using a sanding machine, but if you don’t have a sanding machine, you can use improvised means.

- You can use this method: put a sheet of paper on the floor and place a hot iron on it. When exposed to high temperatures, the paint will come off the surface and stick to the paper. The remaining coating is removed with a spatula. You can use special washes, which are available in a wide variety in stores.

- After removing the paint, you need to remove the top layer from the boards using a plane.

- Next, sanding is done with fine-grit sandpaper (150-180).

- All cracks and other defects must be repaired with putty to match the color of the wood.

Preparing the new floor

- Preparatory work for a new floor consists of sanding the surface. This work must be done very carefully, since any defects in the flooring will be visible under the oil.

- Three types of sanding attachments are used for sanding. First, the work is carried out using circles with coarse grain (20), then the base is leveled with a medium-grain nozzle (40). At this stage, you need to putty all the defects, and then perform final polishing with the finest abrasive (150).

- After sanding, the entire floor surface must be thoroughly cleaned of dust using a construction vacuum cleaner. Poor cleaning can also negatively affect the quality of the coating.

All work must be done not manually, but with the help of sanders, and for processing use special pads made of microfiber and felt. The quality of hand grinding is much lower than machine grinding; it is impossible to bring the surface to an ideal state by hand.

Product quality assessment

What should you pay attention to in order to avoid mistakes when choosing a product? There are certain product indicators that need to be taken seriously. Here is a list of the main characteristics:

- Security level. Preference should be given to products that do not contain toxic ingredients. This is especially true for products that will be used indoors and where significant temperature changes are possible.

- Depth of penetration into the structure of the timber. The deeper the impregnation, the better the protective properties.

- Waterproof features. This functionality is given special attention if the facades of buildings or rooms with high humidity levels (baths, saunas, kitchens, bathrooms) are to be impregnated.

- Vapor permeable capabilities. At the end of the drying process, a film should not form on the surface. Otherwise, objects will stop “breathing.”

- Composition components. In the manufacture of the product, both natural and mineral components can be used. Their percentage ratio is very important. The more naturalness, the better the quality of the product.

- No smell. The first sign of the absence or minimal content of hazardous chemical components.

- Transparency. A quality product will not change the structure and appearance of wooden products. This is especially true for valuable breeds. If the composition contains a coloring pigment and the cost of such a product is budget, most likely it is colored azure and not oil.

When is the best time to use brushes?

One of the types of brushes are brushes. What distinguishes a brush from a brush is its width and the possibility of using an extension handle, which can be inserted into a special metal cup attached to one side of the brush.

Brushes can be of different widths: the most common brushes on the market are 200 mm, 300 mm and 500 mm.

Please note that when applying oil with a brush, it may splash in different directions. We recommend that you carefully consider this problem when applying oils in interior spaces, as drops of oil can fall on walls and furniture, leaving stains on their surface. A solution to this problem can be to stick special masking tape with a wide plastic film on the walls and furniture.

Brushes are indispensable when applying oil to terraces, especially if the decking board is corduroy. No other tool does this job better.

How to choose the right one

Experts advise adhering to the following rules:

- Low-density species (linden and alder) prefer to deal with thick, saturated oils. Liquids can penetrate inside and not freeze there.

- For coniferous species, special impregnations are not needed. They have so much resin inside that they do not need additional protection. If absolutely necessary, you can use thick consistencies and use the waxing method.

- A distinctive feature of birch and beech is their high density. The first treatment should be with liquid products. Thick substances are suitable for repeated manipulations.

Before starting work, it is advisable to experiment on a small board.

To improve the functionality of a product, certain components can be added to it. To improve the absorbency of tung impregnation, it is enough to dilute it with white spirit in a ratio of 60% to 40%. To make linseed oil dry faster, add 30% turpentine to it and heat it a little. Sometimes wax is added to the substance. This increases the antistatic characteristics of the product and speeds up the drying process.

The choice of products is so large that you can get lost in its diversity. Improved new products are released annually. Where to buy the product? There are several options. The most acceptable way is to visit a specialized retail outlet, take a closer look at the assortment on display, and understand what it costs. If in doubt, you can consult the seller. He will not only help you choose, but will also calculate the required volume of the purchased product. You can use the services of an online store. The main thing is not to fall for the tricks of unscrupulous suppliers and not to purchase low-quality goods at a high price.

Rating of premium wood oils

Osmo Anti-Rutsch Terrassen-Öl with anti-slip effect

The first place in our rating is occupied by a quality product from the famous German concern Osmo. An excellent option under 5,000 rubles, which will give the surface a matte color and silkiness. It can be used as a finishing coating when treating a terrace or used as an impregnation, applied to the board in two layers. The material is perfectly absorbed and creates a layer that protects the board from moisture. According to users, droplets of water that simply collect on the surface of the treated structure deserve special attention. If there is a slope, the droplets will roll down. This type of substance will protect products from the growth of blue stains, fungus and mold.

The average price for 0.75 l is 4485 rubles.

Osmo Anti-Rutsch Terrassen-Öl with anti-slip effect

Advantages:

- presence of anti-slip effect;

- German quality;

- time-tested brand;

- water-repellent effect;

- minimum consumption;

- different packaging.

Flaws:

- high price.

SAICOS Holz-Spezialol

A product from an equally famous German manufacturer. The substance is used to treat decking boards. Helps create a pleasant tone and a silky surface. It can also be used to refine wooden products, including furniture. The composition will protect structures from excess moisture and ultraviolet rays. Recognized as completely environmentally friendly. No crust is formed during the application process. At the same time, the pores of the wood remain open. The substance penetrates deeply into the material and does not begin to peel off over time. For application you will need a sprayer and a small amount of solvent. The optimal nozzle opening is 1-1.8 mm. Pressure indicator 1.5-2.5 Bar. No tinting required.

You can purchase a 1 liter container for RUB 2,960.

SAICOS Holz-Spezialol

Advantages:

- each type of wood has its own composition, the differences lie in the codes specified by the manufacturer;

- wide range of products;

- the tree breathes;

- dirt-repellent properties;

- economical consumption.

Flaws:

- If the coating is not pre-treated, it will acquire a grayish tint.

Berger OutdoorOil

This product from a German manufacturer is intended for processing structures that are located outdoors. The shelf life is 2 years, which will allow the buyer to wait for a profitable promotion and purchase the product for later use. The minimum container volume is 1 liter, and the maximum is 3 liters. Protects products from moisture and dirt. The maximum consumption per 1 m2 will be 70 ml. The substance is absorbed deeply, leaving only a beautiful shine on the surface. Due to the absence of preservatives, the products are completely safe not only for animals, but also for plants.

The average price per liter is 2,700 rubles.

Berger OutdoorOil

Advantages:

- There are 24 shades in the catalog;

- You can use a brush or applicator for application;

- prevents weathering of wooden surfaces;

- safe composition;

- penetrates deeply into the material;

- Containers of different sizes are available.

Flaws:

- takes a long time to dry;

- applied only by hand.

Biofa 3753

The product from a domestic manufacturer is intended for processing robinium, conifers, larch and bangkirai. The composition is easy to apply and, after drying, promotes the formation of a silky surface. Matte gloss. The maximum effect can be achieved by performing additional polishing after the substance has dried. After time, the coating does not peel off or crack. This was achieved through the inclusion of additives such as paraffin, rosin and other components. Available in containers of 0.125-10 liters. This will allow you not to overpay and purchase containers of the appropriate weight.

The average price per liter is 2485 rubles.

Biofa 3753

Advantages:

- low consumption coefficient;

- safe composition;

- heat resistance;

- ease of application;

- characteristic silky-matte shine of the dried surface;

- wide range of colors.

Flaws:

- annual renewal of the top layer is required;

- darkening of the coating is possible.

Methods of applying impregnation

Before applying impregnation, the wooden surface should be prepared. To do this, remove the old coating (if any), dust and other contaminants. Then the wood is sanded with sandpaper in two passes: the first with sandpaper with P100 grit, the second with P150. After this, the surface is dust-free.

To successfully apply oil impregnation, the wood must be not only clean, but also dry. Its optimal humidity level is no more than 15%.

To apply oil impregnation, you can use a brush, roller or regular cotton cloth. In this case, you can either dip them into a container with liquid or pour it in small portions onto the surface, and then distribute it evenly.

Small items, such as souvenirs, are treated with oil by soaking. They are immersed in liquid and kept there until air bubbles stop escaping from the wood.

There are two main ways to perform such work:

- Cold. The first layer of oil is applied liberally to the prepared area. After 5-7 minutes, its excess is removed using cotton cloth. The absorption process lasts up to 48 hours. Then a second layer of oil is applied. After this, the wood dries within 30-45 minutes. Then excess oil is removed with a cotton cloth. After 12-18 hours, the surface can be polished to give it a pleasant satin shine. To do this, it is most convenient to use a polishing machine with a beige pad.

- Hot. In this case, the oil is heated in a water bath to approximately 80 °C and then applied to the prepared surface. All further actions are similar to the cold method. The only difference is that the second layer can be applied after 2-3 hours.

For some types of oils, applying the second layer can be done before the first layer dries, using the so-called wet method. An indication of this must be contained in the manufacturer's instructions.

Not all experts consider the hot method to be the best. In their opinion, it speeds up the drying time, but at the same time reduces the depth of oil penetration.

The surface treated with oil must be protected from moisture for 5-7 days. After this, it can be used as usual.

Oil consumption per unit area of a wooden surface depends on the quality of its preparation, as well as on the type and age of the tree.

You can see one of the options for applying oil to a wooden surface by watching the video:

Rating of budget wood oils

Teak Oil BORMA WACHS (Borma)

This product belongs to the teak category. It is used to treat surfaces located both inside and outside the building. Suitable for any coating. Characterized by moisture resistance. Preserves the natural beauty of the breed without changing color. An excellent solution for garden furniture. Perfectly impregnates the material, protecting it from precipitation, insects and fungi.

Average price – 1990 rubles.

Teak Oil BORMA WACHS (Borma)

Advantages:

- lack of oiliness of the finished surface;

- perfectly emphasizes the natural color of the coating;

- protective properties;

- moisture resistance;

- ready-to-use composition;

- used for external and internal work.

Flaws:

- not identified.

Sigma Extra - wood oil with hard wax for stairs and floors

This composition is used to treat floors and stairs located outside as well as indoors. It is used for treating any wooden surfaces that are regularly subjected to significant loads. During the application process, the fibers do not rise. It makes the surface not only aesthetically attractive, but also durable.

Cost for 1 liter – 1420 rubles.

Sigma Extra - wood oil with hard wax for stairs and floors

Advantages:

- excellent aesthetic indicators;

- adds strength;

- does not raise lint during use;

- an excellent solution for structures subject to significant loads;

- Suitable for external and internal work.

Flaws:

- not identified.

Aura Wood Terrace

Our TOP of the best wood oils includes this product, which is used for covering terraces. The composition contains tung and linseed oil, wax, biocide and solvent. Manipulations can be carried out at temperatures from +5°C. In this case, the humidity coefficient should not exceed 80%. Available in containers of 0.9/2.7/9 liters. If necessary, machine coloring is allowed, which will give the composition the required shade. 1 liter is enough to cover 10 m2 of surface. You should not carry out your plans in direct sunlight. Otherwise, the substance may begin to crack.

The average price for 0.9 liters is 1000 rubles.

Aura Wood Terrace

Advantages:

- numerous positive reviews;

- does not darken over time;

- residues are easily washed off with a solvent;

- quality composition;

- certified products;

- different packaging;

- can be used in unheated rooms.

Flaws:

- The substance is colorless (tinting will be required).

Wood oil: what kind of wood will be happy with oil compositions?

In principle, oil compositions can be used to coat any type of wood, however, there are wood species that are simply designed to be coated with oil. This is about:

- Exotic and valuable wood species. An oil coating will perfectly highlight the structure of the wood and its natural relief.

- Soft woods. It is not recommended to varnish soft wood for an obvious reason: soft wood bends under physical stress (we are talking about floors), but a hard varnish coating does not. Therefore, soon, in places of increased loads, cracks may form on the varnish, at first unnoticeable, but subsequently increasingly increasing in size, and the wooden surface will lose its aesthetics.

Rating of inexpensive wood oils from 400 rubles

Tikkurila VALTTI

The first place in our rating is occupied by a product from the famous Finnish concern – Tikkurila. To apply the composition you will need a long brush or roller. Designed for treating terraces. You will need to add solvent before use. The composition contains a complex of vegetable oils. For subsequent absorption, you must wait 45 minutes. Complete drying takes 8 hours if the ambient temperature is above +20°C. If necessary, the substance can be tinted in any shade. Due to auxiliary additives, the product perfectly protects structures from ultraviolet rays, moisture and fungus for two years. Afterwards you will need to restore the layer.

Cost for 0.9 l – 930 rubles.

Tikkurila VALTTI oil

Advantages:

- numerous positive reviews;

- tinting possible;

- wood breathes;

- time-tested manufacturer;

- does not allow the wood to “dry out”;

- protection against ultraviolet rays, moisture and fungi.

Flaws:

- takes a long time to dry.

Pinotex WOOD&TERRACE OIL colorless

This composition will protect wooden structures from excessive humidity, significant temperature changes, severe frosts, snowfall, rain and ultraviolet rays. Improves the moisture-repellent properties of products. The substance applies well. Makes the natural pattern more expressive. Can only be used for outdoor work. An excellent option for updating doors, gazebos, garden furniture, platforms, window openings, benches, stairs and terraces.

Cost for 1 liter – 800 rubles.

Pinotex WOOD&TERRACE OIL colorless

Advantages:

- suitable for processing planed wood and sawn wood;

- ease of application;

- inherent water-repellent qualities;

- increasing the atmospheric stability of structures;

- time-tested brand;

- positive reviews online.

Flaws:

- for outdoor use only.

Neomid – terrace oil

Neomid is a time-tested product from a domestic manufacturer. Designed for finishing open wooden stairs, fences, terraces and gazebos. Supplied in 2 liter containers at a price of 740 rubles. You can work with the material at temperatures from +10°C. The dried coating has excellent gas and vapor permeability, while effectively repelling moisture. There is protection against exposure to ultraviolet rays. Wood fibers will not fade, fade, or dry out over time. Prevents the occurrence of fungal infections.

The average price for 1 liter is 370 rubles.

Neomid – terrace oil

Advantages:

- emphasizes the natural grain of wood;

- numerous positive reviews;

- perfectly absorbed even into resinous and hard rocks;

- shelf life – 8 years;

- convenient storage container;

- Effective protection against sun rays, moisture and fungi.

Flaws:

- sold in one weight;

- applied exclusively with a brush.

The advantage of oil impregnation over varnishing

For the uninitiated home craftsman, difficulties begin when choosing the type of finish: what to choose, varnished or oiled parquet boards, which is better? Experts highlight the following significant differences between varnish and oil coating:

- Wood is a porous material that is capable of exchanging moisture with the surrounding atmosphere. It functions as a buffer that absorbs or releases moisture well and smoothes out sudden changes in atmospheric humidity in the room. Impregnation keeps these pores open. The varnish has a pronounced ability to form a beautiful surface film. However, this film completely covers the pores of the wood.

- The varnish film accumulates a static charge and attracts dust. Parquet board oil has antistatic properties.

- When in contact with a varnished surface, it does not seem as warm and natural as an oiled one. It is better to decorate a children's corner in the house using natural materials, among which there must be a parquet board for the floor.

- Oils penetrate deeper into wood than varnish, so the protective properties of oil impregnations are higher.

- With intensive use of the coating, a dense network of scratches will quickly appear on the varnish, which is clearly visible on the surface. On a board impregnated with oil, scratches and abrasions contrast much less.

The varnish film scratches quickly

- The peculiarity of the varnish coating is that it is difficult to restore locally. If a separate area is damaged, you will have to completely remove the entire varnish layer and re-treat the entire floor. Oil coatings can be easily restored in a separate area.

- In general, oiled parquet boards are more durable. Varnish and oil coatings require constant care and periodic restoration, but oil impregnations require updating after application much later than varnish ones.

Important! Ingoda wood is treated with wax alone. It is rarely used as an independent material for floor treatment, since it seals the pores and such a coating is much more difficult to maintain.

One of the disadvantages of oil impregnation is that the wood surface is less resistant to compression.

Oil treated floors require more delicate care and use.

Video: which is better, varnishes or oil impregnations: