Many professional carpenters make their own oils to save money. However, it is extremely important to follow the recipe, monitor the amount of ingredients and accurately carry out each stage of creating the impregnation. We'll tell you how to make oil for impregnating wood with your own hands and how practical it is in general.

Positive effects of wax oil

This product can highlight the original structure of the wood and provide protection from moisture, discrepancies, fire, fungal diseases or mold. Beeswax does not oxidize, so it stays on the treated surface for a long time. Wax has a strong viscosity, so it melts at high temperatures. This product has water-repellent properties. After applying the composition, the material has a smooth and shiny surface. This increases the wear resistance of the wooden material. Wax oil is usually made at home by adding various types of oil.

Preparation of wax

Method No. 1

This mixture has the advantage that it can be used to treat children's furniture or wooden toys, as well as other items, while the composition does not contain harmful elements. To prepare the composition, prepare 50 grams of beeswax and 150 ml of jojoba oil; when using components in other quantities, their ratio should be 1 to 3. The wax is crushed, this can be done with a grater, then it is melted in a water bath and the oil is added . To prevent the wax from curling, it is constantly stirred until completely cooled. This composition can be stored in a warm, dark place for about two years.

Method number 2

Wax can be made from flax oil, for this the ratio with wax should be 2 to 8. That is, for tablespoons of wax, take 8 oils. When adding more wax, the product has increased viscosity. As in the first case, I grind the wax and melt it in a water bath, then add oil. It must be stirred constantly until it cools completely. This product can be colored using various additives. This composition takes a long time to dry; to speed up this action, it is necessary to add a drier. The wax should be stored in glass containers for about one year.

Method number 3

Beeswax can be mixed with linseed oil in a 1 to 1 ratio. Preparation is carried out in the same way as the previous methods. Sometimes the following recipe is used, two portions of wax, one of oil, and one of turpentine. In this case, the wax is melted in a water bath, then oil is added, stirred, and turpentine is also stirred thoroughly. After hardening, this composition is very dense, but has a pasty appearance and is easy to apply. After treatment, the wood has water-repellent properties.

Do-it-yourself wood waxing composition

The recipe for preparing the composition is simple.

You need turpentine, wax, rosin.

In proportions: 100 g wax, 50 g turpentine, 20-25 g rosin

The wax is melted, turpentine is added, and mixed thoroughly. Next, add rosin and mix thoroughly. Remove from heat and pour into a tin jar.

That's it, the composition is ready. It can be used.

Subscribe to our Yandex.Zen channel

Waxing of wooden elements

To process a wooden product, you first need to prepare a composition, for this you will need oil, wax, a container for kindling, a brush, a cloth for cleaning the brush, and, if necessary, use various additives to obtain different shades.

First, preparatory actions are carried out, the object is cleaned of dust or dirt, and, if necessary, grinding work is carried out. When the composition is prepared, it is applied to the object with a brush in a thin layer and left to soak thoroughly. In this case, the strokes are done very quickly, without stretching the work so that clear transitions do not form. Periodically remove wax clumps from the brush using a prepared cloth. This way the application will be even. After the wax has been absorbed, sanding is performed using a special machine or a cotton cloth, while the surface of the object remains smooth and shiny.

Is polish needed at all?

What is polish used for? The name itself suggests its purpose.

Important! Polish - give a surface a mirror appearance by rubbing.

As a rule, such products are used on varnished furniture, which is the most popular among the entire range of wooden products. Although they are also used to care for unprotected wood - to even out color and texture.

The main advantages of wax oil for wooden objects

The main advantage of the composition is that it is very easy to apply to a wooden object, which makes it possible to get the job done quickly. This product uses only natural ingredients, so the impregnation is considered safe for health and environmentally friendly.

It is also easy to subsequently repair damaged or replaced areas; the mixture is reapplied to these areas. Caring for the item is easy; dirt is removed from the surface using special means, and then wax and oil are applied again. During the preparation of the composition, various additives are used to give the surface different shades. Using oil wax you can create an antique surface that will highlight any interior style. Wax is used to treat floors, wooden objects or surfaces in a bathhouse; this prevents moisture from penetrating into the material and causing its destruction. Preparing the composition yourself allows you to save money on purchasing various wood impregnations.

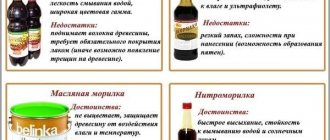

Impregnation of wood with different types of oils

If you know the features of each type of impregnation, it will be easier to make a choice.

- Flaxseed oil is endowed with high water-repellent properties. This allows it to be applied indoors and outdoors. The composition is environmentally friendly. The coating takes a long time to dry, it takes from 14 to 21 days. To speed up the drying process, turpentine is added in a ratio of 70:30 (for outdoor work) or wax (for indoor work). Therefore, the components on the can must be read carefully. It is difficult to work with the material outdoors in winter. It contains linoleic and linolenic acids in large quantities. They do not tolerate frost and the oil thickens and hardens quickly.

- Tar impregnation is endowed with antiseptic qualities. It protects wood from fungus, mold, and microorganisms. It is used to protect the facades of houses made of logs and timber; the bottom of boats is impregnated. In addition, it is a decorative impregnation for furniture in the country and in the garden. One of the components of the composition is pine turpentine. Thanks to it, the penetration into the wood structure is very deep. And tree resin (another component in the composition) holds the impregnation inside the tree. Drying speed – 1 week. Although it depends on weather conditions and the condition of the wooden base. The impregnation retains its technical characteristics at sub-zero temperatures, which makes it possible to work with it in winter.

Important: so that the tar protective material does not lose its beneficial qualities, it is not diluted.

- Universal oil compositions include teak oil. It is used for both interior and exterior work. It consists of linseed oil, tung oil, and purified pine turpentine. Impregnation is applied inside the house to any surface (floor, walls, ceiling), to the facade. She processes the veranda, steps on the street, furniture, and wooden figures in the garden. Impregnation protects wood from the UV rays of the sun and from atmospheric influences. It is used as a protective material for elite species (beech, oak, mahogany), including if a bathhouse or sauna is built from them. These are structures where humidity is high.

- Tung oil emphasizes the beauty of the wood structure. Most often used as wood oil for interior work. It quickly penetrates into the surface layers of the wooden base, thereby creating the wood pattern. Therefore, it is a material for covering antiques, frames, and wooden interior items made from elite species. Compared to other oil compositions, tung dries faster. A water-repellent film is formed. Impregnation is introduced into the paintwork material. To enhance the absorption of the composition, white spirit is introduced into it (proportion 60:40).

- Mineral composition is used exclusively for external work. This is a synthetic product. Despite a number of positive properties (no odor, easy to work with, high drying speed, high level of protective qualities), you can work with it after deep cleaning, since it is the result of oil refining. It is for this same reason that it is not used for finishing inside house construction.

Tip: Sunflower oil is not able to protect the tree or make it look better. It does not polymerize, which means it does not dry completely. The stickiness of the wooden surface will remain forever.

- Toning oils are used to add color. They contain pigments that will melt their color into the wood. The surface can be given any shade. Staining in walnut, teak, rosewood, as well as black and white is in demand. With this composition, the wood is protected from rotting and microorganisms. Products with a high drying speed, resulting in a matte finish.

Rules for applying wax oil to wooden objects

- Before starting work, check the fasteners; all screws should be immersed in the material by approximately 3 millimeters. The caps are sealed with sealant or a special wood putty. When choosing a product, it is necessary to take into account that its color must match the wood.

- If the old surface is covered, then the previous treatment is removed; if there are large distortions or damaged areas, it is necessary to replace individual areas and apply wax to them.

- Before applying wax, sand the surface with sandpaper; it should have different grain sizes. Paper with a fine surface is not used, as dust particles clog the pores of the wooden material, and the work becomes ineffective.

- Then the wooden object is cleaned of dust that was formed during sanding.

- All cracks and fasteners must be covered with a special putty that matches the color of the wood, otherwise treatment can be performed using PVA glue mixed with wood sawdust remaining from polishing. Excess glue is removed immediately with a wet sponge or rag, so the surface acquires a smooth, uniform structure.

- After this, begin to apply the wax with a soft brush; lumps of frozen product are removed with a lint-free cloth.

- Then the item is left until completely dry, after which it is sanded using a cotton cloth or a special machine. As a result, excess wax is removed, and the surface acquires a smooth and shiny appearance.

- The wax coating is renewed about twice a year, while the wood refreshes its appearance. Dust and various contaminants collect on the old coating; they must be removed with a special product, and then wax and oil must be reapplied. After this, polish the surface with a cotton cloth.

Treatment of parquet floors

The floor surface is sanded using different sandpaper. The sanding agent should not have a fine grained surface, otherwise the dust particles will clog the pores of the wood. After this, the floor surface is puttied, that is, all fasteners and significant defects are covered, and then wax and oil are applied. This is done with a soft brush, the work is done very quickly to avoid clear boundaries between strokes.

When the application is complete, polish the wooden object using a special machine or cotton cloth. At the same time, all small scratches and defects become invisible, and the surface acquires gloss and shine. Thus, you can easily restore the old floor covering and it will have a beautiful appearance. When preparing oil wax with your own hands, you must follow the correct technology; after treating the surface with this product, the product takes on an original appearance. Thus, the coating can be given an antique look that suits any interior of the room.