All photos from the article

There is probably no person who would not like the joy in the eyes of a child, and a wooden car for a kindergarten or an ordinary yard will always be the place where you will always find a focused “driver” and “passengers”.

Of course, the ideas for such a car may be very different from each other, but, in any case, there will be a cabin with a rotating steering wheel and additional seats for little “hitchhikers”.

In most cases, such a design can be made by any adult who has a set of (at least amateur) carpentry tools, and we will now tell you more about this, and we also suggest you watch the video in this article on our “automotive” topic.

Lumber machines

Materials

Note. Of course, a DIY wooden car for children should not be too expensive, and even any leftover lumber after repairs is suitable for this. However, we will tell you what is best to use, and everything else is up to you.

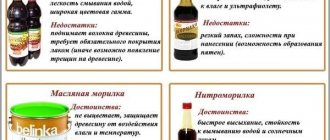

- If you are going to assemble such a structure for a kindergarten, then you should think about the size, since building a large children's car out of wood means giving almost the entire group the opportunity to use it. It is very convenient in such cases to use OSB - oriented strand board, which can be sewn onto a frame made of bars. But we should not forget that such material is classified according to water resistance and density, so there are OSB-1, OSB-2, OSB-3 and OSB-4.

| Marking | Degree of water dispersion | Strength |

| OSB-1 | Very low | Very low |

| OSB-2 | Low | Average |

| OSB-3 | High | High |

| OSB-4 | Very high | Very high |

OSB strength and moisture resistance table

- Of course, you wouldn’t want the structure you built to become unusable in a year - it’s a shame for the craftsmanship, it’s a waste of effort, and it’s inconvenient in front of the kids, therefore, it’s better to choose the appropriate material. In the store you can buy OSB-3, and even if it is not available, you can order it, but OSB-4 is not so easy to find, since it is usually not on sale - either the price is high, or no one is interested .

Having decided to please their child with another toy, most parents confidently head to the store. However, there is an alternative way to solve this issue. It's always nice to make a gift with your own hands. If you have a little patience and healthy curiosity, you can find out if it is made of wood. Moreover, it will be no worse, and perhaps even better, than its store-bought counterparts.

Do-it-yourself children's car: step-by-step description of making a homemade car (95 photos)

Any parent likes to please their child. However, not every family can afford to buy a toy once a week. The way out of the situation is crafts, and the most popular theme for them is cars.

How to make a children's car with your own hands? This will be discussed in this article.

Brief contents of the review:

Where to begin?

You should definitely take into account the fact that the creation process may take some time, so it is better to properly plan your resources in advance. Having figured out the question of how to make a car out of wood, you should pay attention to the tool that you will need. Everything here is extremely simple and clear. The most ordinary ones are perfect. You also have to decide on the size of your creation. The machine may be the size of the original, but in this case a lot of materials and time will be needed.

Electric car

Any child will be delighted just by the thought of this miracle of technology. However, such a car is not cheap in the store. Therefore, the easiest way is to make it yourself. It's quite difficult. But probably.

The procedure is as follows:

- Study the necessary information about the design of children's cars, look at the diagrams presented on the Internet. If possible, take several consultations with an experienced master.

- Based on the information obtained, draw up drawings of a children's car with an electric drive and think over its design.

- Make a list of the materials needed to make a car and go shopping with it. Something can be found in a garage or country shed, something can only be obtained through the World Wide Web.

- Make a frame and screw the wheels onto it.

- Cut out the bottom from plywood.

- Weld the turning mechanism, install the steering column and steering wheel.

- Attach the pulleys to the rear wheels, stretch the cables, hooking them to the engine.

- Place the motor itself behind the seat and securely attach it using clamps and bolts.

- A swing seat is suitable as a seat.

- Install the battery. It's best behind the engine.

- Carefully tie the wires together with clamps.

- Paint the car, screw on the horn and mirror, and install bumper protection. You can start testing.

What to make it from?

Having selected all the necessary tools, take care of the materials from which your masterpiece will be created. Here you can go different ways. Materials can be easily and simply purchased at a construction or furniture supermarket; you will also not be refused in special workshops. However, you can always use old things you have at hand. For example, in a future project you can easily use old chairs, tabletops, or even ordinary wooden boxes. This approach will help reduce the cost of creating a car.

Making a toy car

Let's start with the use of wood. You can make a very good model out of wood.

For this you will need the following:

Bar; four wheels; varnish; sandpaper; knife; hacksaw; glue.

In this case, the machine consists of three parts, namely the body and two bridges. It is their production that needs to be done. First the body. It is necessary to saw off the timber, its length must correspond to the length of the car body. Then you need to make a body from the blank, cutting and grinding off the excess wood. The most important thing is to take your time. The result should be a body polished to a shine. And also, at the bottom of the car body it is necessary to make cutouts for installing bridges. As for the bridges themselves, they can be made from planks. You can use many different things that look like wheels as wheels.

Then the bridges must be glued to the body and the machine must be varnished. If there is any suitable sticker available, then it needs to be pasted on the machine in the place where it should have a door.

So, let's begin

You already know how to make a VAZ or a Mercedes, or perhaps some other car, out of wood, it doesn’t matter. Any construction begins with the creation of a frame. If you have excellent spatial imagination, cutting out the parts yourself will not pose any problems. However, if such talent is not on your list of advantages, turn to the services of professionals. Order or find the necessary drawings yourself, then take them to a furniture workshop. There shouldn't be any problems when creating the frame. Almost everyone has a good idea of what a car looks like. Be sure to make sure that the car is comfortable for its future owner. The legs should fit freely under the dashboard, and the steering wheel should not hit the knees. Think through all the small details, and then there will be no limit to your delight.

Since you already know very well how to make a car out of wood, it will not be news to you that the parts are well connected using self-tapping screws, and for greater strength they can also be coated with special glue.

DIY four-wheel dump truck

Four-wheel dump trucks are available for sale. Such devices have undeniable advantages. Large load capacity. Mobility. Ease of use of a dump body. It is not surprising that many would like to purchase such a cart. It's just that the price on them bites. The solution is to make an analogue yourself.

The area of my plot is 30 acres. I carried a lot of things on a one-wheel cart. Sand. Crushed stone. Priming. Inconvenient and difficult. The cart balances on one fulcrum. I thought about buying a two-wheeler, but two wheels don’t save me from the stress on my arms and back. A four-wheeled cart with a dump body made of plastic caught my eye. The price for it starts from 6,000 rubles. I thought. I have welding. Cooking table and free time too. I decided to make an analogue with my own hands. Everything worked out.

Compare the IgorVVO trolley with the factory model.

Features of a homemade four-wheeled cart:

The main feature of the trolley is its tilting body.

For tipping, I made a handle the size of two hands. When tipping over, the rear wheels roll toward the front wheels. This makes the process much easier. In fact, the load can be tipped with one hand. There is also a special latch, look at the photo, to prevent the body from spontaneously tipping over when transporting cargo. Particularly loaded trolley components are reinforced with metal corners. I made the “nickels” of the rotation axis from large washers, there are three of them, and everything is thickly lubricated with grease. The cart turns around in one place.

Close-up of the components of a homemade trolley.

Testing a four-wheeled construction trolley.

Decor and furnishings

How to decorate your brand new car is up to you. It depends on the taste and purposes for which the masterpiece was created. If you have some old wheels, you can use them to create a project. You can also make wooden tires, but in this case you will need additional raw materials. Don’t be lazy and make the car as realistic as possible, think over the exhaust system. Install a tape recorder and real seats, and if you wish, you can even attach license plates. All these little things make the car look realistic and improve its appearance.

Now you already know how to make a car out of wood from start to finish. When creating a car, pay attention not only to the exterior, but also to what is inside. Decorate the interior with cute little things that you can’t imagine your car without. Perhaps hang an air freshener or cubes on your windshield. Such a car will be an unforgettable gift for any child, and his joy will have no limits.

You will undoubtedly be pleased with the fact that you can rightfully now consider yourself an auto builder. And the cars made of wood are real, because so much passion and love has been put into them. Every designer will agree that this is worth a lot.

I bring to your attention a prefabricated wooden model of a retro car MG TC, from the British company MG Cars specializing in the production of sports cars. The work is difficult, but you shouldn't be afraid of it. The wooden model of a retro car consists of 42 elements. This model will serve as a good interior decoration and will take its rightful place on your shelf.

The most common ideas

As you can see in the photo of children's cars made by hand, the material for them can be any available means: paper, cardboard, plywood, wood, metal, etc. There are no restrictions. The main thing is that the material is safe from an environmental point of view.

What to make a toy car from? It depends on who will do it. If it is a child, then his parents should carefully review the models from the “DIY Cars for Kindergarten” series to suggest a suitable option.

If dad plans to create a vehicle for his child, then it is preferable to focus on more complex designs, for example, making a car for a playground.

Plywood car

In order to assemble such a retro car with your own hands, you will need the following tools and accessories:

Preparation of the workplace

As usual, the first thing you need to do is equip your workplace where you will work. The rules are not complicated: there should be no unnecessary things on the table, all tools should be in their place and at hand. Not everyone has their own desktop, and you’ve probably already thought about creating one. Making a table is not difficult; choosing a place for it in the house is more difficult. A good option is an insulated balcony, where you can start working on your craft at any time. If you have a specially equipped room with a workbench, then you are lucky. You can read about preparing the table in a separate article where I tried to describe in as much detail as possible the entire process of creating it. After you have completed the process of creating a workplace, you can proceed directly to your future crafts.

Plywood selection

Estimated dimensions of a car model made of plywood (10 cm x 26.5 cm x 10 cm). The drawing is based on A3 format, the parts can fit on two sheets of plywood measuring 38x23 cm, the thickness of the plywood should be from 2.5 to 3 mm. Before transferring the drawing to plywood, sand the workpiece with coarse-grain sandpaper and finish with fine-grain sandpaper. It is more convenient to sand with a wooden block wrapped in sandpaper. Sand the prepared plywood along the layers, not across. A well-polished surface should be flat, completely smooth, glossy-matte in the light and silky to the touch. Pay attention to grain placement, knots, dents and other imperfections. Quality and color.

Transferring the design to plywood

You need to translate the drawing accurately and carefully: secure the drawing using buttons or simply hold it with your left hand. Check if the drawing fits the dimensions. Arrange the individual parts so that you can use the plywood sheet as economically as possible. There is no need to rush, because your future craft depends on the drawing. To speed up the translation process, you can use the technique of quickly translating a drawing; for this, I suggest you read the article: You can download the file with a drawing of a car made of plywood at the end of the article.

Profit

The most important question that concerns all novice entrepreneurs is how much profit does making wooden toys with your own hands bring? A small handmade product costs about 150–200 rubles on the market. Its cost is 50-70 rubles. If you make designer toys and sell them at high prices, your income will be much higher. Since the production of wooden toys in Russia is not developed at the highest level, you can easily occupy a free niche in this area and earn good money. Such a business pays for itself in 1-1.5 years. It is not seasonal, but still, such an enterprise brings in the largest revenue during the New Year holidays. On average, producing a New Year's tree toy will cost you about 100 rubles. On the market such a product can be sold for 500 rubles.

To speed up the payback of the project, you can, in parallel with making toys, start producing garden figurines for your dacha with your own hands. This is a profitable and promising business that will bring good additional income.

Cutting out a car with a jigsaw

There are many rules for cutting, but you need to rely on the most common ones. First you should cut out the internal elements and then start cutting out the outline. There is no need to rush when cutting. The main thing is to always keep the jigsaw straight at a 90-degree angle when cutting. Saw out the parts along precisely marked lines. The movements of the jigsaw should always be smooth up and down. Also, do not forget to monitor your posture. Try to avoid bevels and unevenness. If you go off the line while cutting, don't worry. Such bevels and irregularities can later be removed using a flat file or “coarse-grained” sandpaper.

Rest

When sawing, we often get tired. Fingers and eyes, which are always tense, often get tired. When working, of course, everyone gets tired. In order to reduce the load, you need to do a couple of exercises. You can view the exercises here. Do the exercises several times during work.

Assembly diagram

Detailed assembly diagram:

Assembling the craft parts in this work is not very difficult, my 6-year-old son assembled a model of a retro car, with my tips and a little help. Such activities develop fine motor skills, imagination, fantasy, and also train patience.

After the parts are assembled into one common craft without any problems, then start gluing them.

To make it more similar, you can add a few strokes in the form of lines using an electric burner. It can be very difficult to burn a pattern beautifully, but here there are not many lines and they are quite simple to make. First you need to draw lines with a pencil, then slowly go along these lines with an electric burner. You can read how to work with an electric burner and add patterns in a separate article.

Main types

Side view:

Back view:

Isometric:

DIY garden wheelbarrow, photo

Many people are interested in the question: why do homemade workers make construction wheelbarrows if they are sold on any construction market and in construction hypermarkets? People are driven by two reasons:

We bought a car at the store. She couldn't even stand digging a well. They carried earth on it. The metal of the frame was deformed. The wheel fell off. We need to buy a new one. In my opinion: homemade ones are stronger and last longer.

About ten years ago I bought a well-made construction wheelbarrow. Its wheels are located approximately in the middle of the body. Most of the cars that are sold now are poorly designed. Their wheel is located closer to the front of the trough. When lifting a loaded wheelbarrow, half the weight falls on the user. And if the front body has a bevel at an angle, then even more.

Therefore, many people prefer to roll up their sleeves and make a garden wheelbarrow “to last forever.”

I had a purchased car. She did not survive serious construction. I decided to make my own. The drawings were made at a military factory. The design is balanced. Low center of gravity, and the main weight of the load goes to the wheel. Therefore, you get much less tired when working. The metal used was second-hand. I took the wheel from a helicopter. It took only 400 rubles to make a construction wheelbarrow. I carry 50-60 kg on it. Nothing breaks. Driving it is a pleasure.

Varnishing crafts

A collectible model of a retro car can be varnished or painted if desired; this is not necessary, but it will add greater individuality to your craft. Try to choose a good and high-quality varnish. Varnish with a special brush, take your time. Try not to leave any visible streaks of bubbles or lint from the brush.

You can download a template for cutting out a model of a Retro car with a jigsaw on our website at the following link:

We begin the work by making the cart. I drill out the wheels with a specially converted feather drill from a walnut plate 3-4 mm thick, leaving a certain distance between the centers equal to the distance between the axles of the wheels of the future car. It is advisable to do this on a drilling machine, because... a crookedly drilled central hole causes the wheel to run out when driving.

But I don’t have a drilling machine, so I have to remove the runout on a lathe, which I made from a UAD-72 engine, placing the smallest chuck on the shaft, which allows me to clamp 5mm workpieces. I ground the shaft into a cone with a file while the engine was running. Everything turned out well (I didn’t even expect it myself), the cartridge rotates without beating. So, I place the wheel on a mandrel (photo 2.) (included in the Dremel drill accessory kit) and, holding it in the chuck, grind it (photo 3.)

photo 2.

photo.3

I remove the runout, grind the profile on the sidewall of the wheel, mark the tread, and grind it. photo 4.

Turning cutters are the simplest, mainly made from needle files (photo 5.) photo 5.

The wheels are ready, I’ll get to work on the platform. In a rectangular blank, I cut out grooves for the wheel axles with a ribbon (you can use a hand jigsaw along a square) (photo 6.). I select the middle with a narrow chisel.

photo 6.

I glue walnut veneer strips over the slots. (photo 7.)

photo 7.

So that the platform does not seem too massive, I remove excess thickness using a band saw (photo 8., 9.)

photo 8.

photo 9.

I drill holes 0.2mm larger than the wheel axles to ensure good rotation. The platform is ready, I'm starting to make the wings. I return to the plates from which I drilled the wheels. They will be the blanks for the wings (photo 10).

photo 10.

I file on the ribbon (photo 11.)

photo 11.

I grind the outer (convex) part of the workpiece on a grinding machine (photo 12.). I'll tell you a little more about it.

photo 12.

I made the machine myself on the basis of an AIM 63A4U2.5 asynchronous motor (250 W, 1350 rpm). First, I simply placed a plywood disk on the motor shaft, to which I glued sandpaper. But... I quickly got tired of the dust and the end of the shaft with the nut sticking out of the disk. Yes, and changing the sandpaper was a problem. I decided to improve the machine. First of all, I bought an aluminum disc disc with Velcro (d=225mm) from a Jet grinding machine at the service center, ordered a bushing from a turner, fitted it, and the machine was almost ready. The dust problem turned out to be not so difficult to solve with a vacuum cleaner. Having firmly secured the engine to a permanent place on the desktop, I cut out a hole in the table top for the disk, screwed a vacuum cleaner attachment from the bottom (photo 14), and made a protective casing from thin plywood on top. The efficiency is simply amazing; dust has no chance of getting past the vacuum cleaner (BOSCH GAS 25). I attached a quick-release support table to the side (photo 13) and the machine received a start in life. Now I buy Velcro grinding wheels from the German company Cora (d=230mm). They are of good quality, wear-resistant and can be replaced quickly and conveniently. At the other end of the shaft I have a wide felt circle with Goya paste attached, for finishing the cutters and pieces of iron from the planes.

photo 13.

photo 14.

I process the inner (concave) part of the workpiece using a homemade attachment for the WorkSharp sharpening machine (photo 15.).

photo 15.

I cut the workpiece lengthwise into two halves using a band saw (photo 16.).

photo 16.

I cycle, grind and glue the resulting wings to the platform (photo 17), put the wheels in place, check for ease of rotation... Well, the cart is ready (photo 18), you can move on.

photo 17.

photo 18.

I cut out chairs for the salon on a ribbon (photo 19.) Well, of course - fitting, processing, polishing using a drill and various attachments. Well, where are we without this “fascinating” and “creative” work? You know it yourself - no way!

photo 19.

Now it’s time for the side walls of the cabin. The following are used: ribbon, chisels, drill, etc. The result is in (photo 20.). I try different types of wood and experiment with color.

photo 20

Fit it to the grinder. machine seat block along the width of the platform, I glue the side panels to it (photo 21.)

photo 21.

I make and glue the cabin ceiling into place (photo 22., 23.) By the way, for gluing I use moisture-resistant TiteBond-II glue. I've been using it for several years now and am very pleased. It goes without saying that each gluing area is thoroughly cleaned of traces of glue and looped.

photo 22.

photo 23.

Now you can glue the rear wall of the cabin and make the front (“windshield”) (photo 24.) I give the rear wall of the cabin the desired shape on a grinding machine. I grind, scrape, process and put it aside for now.

photo 24.

I'm starting to work on the nose of the car. Everything is simple here - I create the form using a template from simple wood - it’s faster and easier (photo 25.)

photo 25.

I glue the hood and sand it into the desired shape. machine, grinding, scraping. (photo 26.)

photo 26.

I glue a radiator to the front of the bow, and a partition with a “windshield” to the back (photo 27).

photo 27.

Before final assembly of the cabin, you need to make a steering wheel and put it in place, because... After assembly, this will not be possible. The wheel manufacturing technology is described above, only the plate is thinner (1.5mm), the feather drill is smaller in diameter (6-7mm) and the axle diameter is (1.5mm). (photo 28.)

photo 28.

Now you can glue both parts of the cabin together, which is what I do (photo 29.).

photo 29.

I level the side pillars in height and prepare the upper strips to close the square of the “windshield” (photo 30.).

photo 30.

I glue it, clean it, admire the result (photo 31) - it already looks like a typewriter.

photo 31.

I am cutting blanks for the roof of the car interior (photo 32.)

photo 32.

Now it's time to start making the headlights. I turn them on a lathe (photo 33.) I need a hard and dense wood, I choose ebony and boxwood.

photo 33.

In the finished headlights you need to drill holes for the pins. I do this manually using a drill inserted into a clock screwdriver. First - 1mm, then I drill out to 1.5mm (photo 34.)

Playground

- this is a place that is intended for children, so it must be carefully thought out.

Today I want to introduce you to amazing masters, Alexander Dmitrievich Alexandrov and his son Andrey Alexandrovich Alexandrov. They create amazing and interesting works of wood with their own hands. Looking at the site that he and his son made with their own hands, it is impossible to tear yourself away from the beauty that they created with their own hands. Alexander already developed a passion for carpentry in childhood; his father lovingly instilled this skill in him. Together with his father, he created various wooden toys with his own hands and gave them to his friends. When Alexander grew up, he did not stop doing what he loved, but rather instilled this skill in his sons, who happily help him create interesting ideas for the playground

. On their playground you can see a real plane, helicopter, tank, steam locomotive, cars and much more, all made of wood. But it all started with the fact that Andrei and his sons decided to improve the area around the house. First, birch trees, fir trees, and lilacs were planted, and only then interesting works by the master began to appear. I think that any child who comes to this playground will find himself in a fairy tale. Now I propose to take a walk and look at the author’s wonderful works, which are made from wood with his own hands. But that’s not all, Alexander plans to make a real fountain from natural stone, which will become a decoration for the children’s playground. After all, all caring parents want their children to be satisfied and happy, which is why they need to beautify them and create beautiful playgrounds. After all, playing on the playground develops imagination, strength and, of course, health.

DIY bus for the playground

DIY motorcycle for the playground

Do-it-yourself tractor excavator for the playground

DIY cannon for the playground

I think that children will also like the cannon, and besides, it can be made from simple, affordable things. You can make a cannon out of plastic bottles, and wheels out of old wheels. Imagine and create.

Do-it-yourself helicopter for the playground

Look what a cute helicopter you can make with your own hands for the playground, you need to use your imagination and, of course, have the material to make it. But you don’t have to use or buy a new one; you can make a beautiful helicopter out of old boards.

DIY tank made of wood on the playground

DIY steam locomotive with carriages for the playground

Airplane for children's playground made of wood

We all know that boys already have a love for cars from an early age. Therefore, when the child is still small, his parents buy him various cars, and on the site they make funny sandbox cars, as well as toys in the form of transport. But if you make a real car on the playground, then your child will never want to leave and will always find something to do. Look how beautiful the KAMAZ is made from wood, I think that any boy would like to have exactly the same one.

What magical properties do they have?

The magical properties of the amulet are determined based on the material that served as the basis, as well as the shape and pattern depicted on it. Thus, oak amulets have the following properties:

- healing power;

- energy force;

- endowment with courage and bravery;

- the gift of longevity;

- maintaining physical and spiritual health.

Most often, such amulets were intended for men and boys.

Charms made from birch have the following features:

- cleansing a person’s aura of negativity;

- getting rid of bad thoughts;

- fulfillment of desires;

- healing properties.

We recommend: Amulets for the strong in spirit - Scandinavian amulets. History, meaning, application

Thanks to its light and soft energy, birch products are suitable even for newborn babies and children.

Aspen amulets were most often used to remove the evil eye and damage. Their original purpose is to expel evil spirits and repel evil spells.

Rowan amulets are most often used by women, as they have the following properties:

- give beauty and health;

- an amulet made of berries protects against unkind glances;

- protect the entire family.

Talismans made from willow were considered another women's amulet, as they helped women during childbirth, preserved reproductive health and mental strength. Spruce amulets were more often worn by men; spruce has always been a symbol of confidence, success in business and willpower.

Mascot shape

The power of the amulets also lay in a certain shape or pattern depicted on it. So:

- The circle represents solar energy and brings harmony and prosperity.

- The square is a symbol of the unity of the four elements. Such a symbol will help you make the right decisions and get out of unpleasant situations with dignity.

- Triangle - this form of amulet helps communicate with higher powers.

- Oval - attracts luck and fortune.

The Slavs attached particular importance to the runes depicted on the talisman, which carried their own specific energy.