Many novice craftsmen want to have a small but functional circular saw in their workshop. You can buy a factory-made machine, but it will be quite expensive. This is the path taken by professional carpenters, who have a direct material dependence of their financial condition on labor productivity. The invested funds quickly pay for themselves and bring direct profits.

DIY stationary circular saw

Amateurs have a good way out of this situation - to make a circular saw themselves using the tools that most craftsmen have. But before starting work, it is recommended to familiarize yourself with existing engineering solutions and operating features of the equipment.

Features of a circular saw

Understanding such nuances is of great importance; it is necessary to pay attention to the operating modes of the structure, master the types of loads and do everything possible to strengthen the most significant components.

Only with such a strategy is it possible to achieve long-lasting and well-coordinated operation of the designed unit.

Additional equipment for the machine

To make it more convenient to work on the machine, a number of additional devices are made. They help the master perform a number of operations. These include:

- guides for longitudinal sawing;

- carriage for transverse movement of workpieces;

- carriage for cutting grooves. Groove joints are used in the manufacture of furniture drawers;

- devices for cutting round parts;

- devices for sawing at an angle. It helps to make legs for furniture.

[author_bq]

Republished by Blog Post Promoter

Characteristics of a circular saw

- Fast speed of movement of the teeth of the product. This ensures cutting quality. However, fairly powerful structures can cause severe damage, so in the process of creating the device it is necessary to focus on safety precautions. All devices that are available on factory samples must be installed. It is wrong to assume that some of them are superfluous, and production options can be improved. The entire list of safety rules is confirmed by statistical data; you should not expose yourself to danger again.

- Reliability of all nodes. We are not talking about the ability to withstand impressive stationary loads, although this is of great importance. A structure can easily take enormous forces of this type, but at the same time create vibration from the action of even relatively insignificant mobile multidirectional loads. This situation does not have a negative impact on safety, but significantly reduces the quality of the cut. Traces of denticles remain on the upper layers of timber, it is difficult to comply with the established linear parameters, etc.

- Fire and electrical safety. Each electrical appliance, motor, starter and other specialized fittings must be installed in strict compliance with the PUE standards. It is necessary to understand that dry sawdust not only ignites well, but also forms an explosive mixture at a sufficiently high concentration in the air. In addition, burning sawdust is difficult to extinguish; they float on the liquid and do not stop burning.

You should not create the most banal option at the expense of safety devices; you must strictly follow the advice of engineers. It’s better to decide what’s more important, a woodworking machine or new difficulties?

What can a wood sawing machine be made from?

For the home workshop use:

- Special shafts with fastening elements for the disk and electric motors of sufficiently high power. Such equipment can work with large-diameter circular saws, which will allow cutting quite thick workpieces.

- Angle grinders (grinders) are produced in different capacities for discs of different sizes. The rotation speed of the shaft with the tool reaches up to 12-15 thousand rpm. Therefore, the quality of the cut is highly clean. Some craftsmen like to use machines based on angle grinders.

- Hand-held circular saws (HRS) are initially equipped with a wood blade and a fairly convenient casing that can remove chips from the sawing zone. Many RDP manufacturers, when developing operating instructions, include diagrams of possible installation of the tool in the countertop. The kit often contains auxiliary fasteners that facilitate such installation.

- A regular electric drill can also help in creating a small circular saw. It can be used to cut small parts from plywood, boards and chipboard.

- If it is necessary to cut large workpieces and even tree trunks, chain saws are used. With their help, you can create more than just a small machine for cutting boards and bars. A small home sawmill is being made; it will allow you to recycle wood from the garden or the nearest forest.

Pros of a homemade circular saw

There are several quite significant technical properties due to which this structure is recommended for use in the following situations.

- A disk with an outer diameter of 350 mm can be placed on the saw, which makes it possible to cut timber with a thickness of 70–85 mm. On a structure, this depth is slightly reduced; boards with a thickness of 60–75 mm can be cut. This is enough for the lion's share of home crafts made from wood - from complex furniture to ordinary toys.

- The motor power is at least two kilowatts, it can withstand impressive loads, and special efficient forced ventilation instantly eliminates heat, which helps systems function for a long period of time with optimal thermal conditions.

- The rotation speed of the unit shaft meets current standards for woodworking cutting equipment. This makes it possible to achieve high-quality cuts and adhere to safety regulations.

- The hand saw can be attached to the tabletop so that, if necessary, it can be quickly dismantled and used in standard mode. At the same time, all the original technical properties are completely preserved.

Do-it-yourself parallel fence for a circular saw

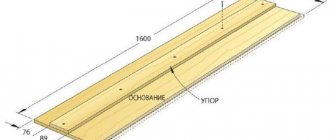

The parallel stop is a mandatory device on a circular table; without it, it is almost impossible to make an even cut. You can make it yourself as follows:

- A U-shaped profile should be made from three strips of laminated chipboard; inserts should be placed and fixed inside, which will add rigidity. The result will be a square section.

- A guide channel is made from two parallel slats, which is bolted to the end of the table in a position perpendicular to the saw blade.

- An inverted T-shaped structure is then made from MDF, which is screwed to the stop and inserted into the channel.

You can make a parallel stop for a circular saw yourself.

Note! The width of the channel should be such that the side of the T-shaped element fits tightly into it.

To fix the stop of a homemade circular saw made by yourself, it is convenient to use the original slots. Threaded bolts, nuts and wooden washers are suitable as a locking mechanism; you will need a hole in the bottom plane of the stop. Tightening the bolt helps to securely press the stop to the table top. This design allows you to quickly and easily set the required cut sizes.

What is needed to make a circular saw

Basic inventory:

- Electric jigsaw or hand saw for wood.

- Cutting device with cutting and grinding wheels.

- Drilling device or drill.

- Screwdriver.

- Spanners.

- Knife for working with wiring.

Materials for creating a circular file:

- Wood beams 40*20 mm.

- A sheet of plywood, at least 10 mm thick (width and length are selected according to individual needs and preferences).

- Two-core copper cable, thickness from 0.5 mm square, approximately 1-1.5 m.

- A well-opened key located nearby.

- Electric motor, which can be purchased in an online store.

- Adapter attachment for the power unit for attaching the circular disk (can be purchased online).

- Circular disk.

- Screws, screws, nuts.

- Sandpaper.

- Varnish or stain (shade chosen to suit your taste).

The manufacturing process consists of the following stages:

- Measurements of the landing dimensions of the electric drive motor.

- Preparing the structure drive rocker arm and the fixation post in the workspace.

- Assembling the electrical circuit of the drive structure.

- Assembly of the circular saw system.

- Installation of the unit on the work surface, securing it.

- Carrying out a trial run of the saw.

- Performing final sawing of timber beams and steel pipe trim.

Of the positive features of such a structure, three key ones can be noted: ease of creation, low cost of materials and small dimensions.

Also, do not forget that such a device poses an additional threat, so you need to work with it with extreme caution. In order to prevent injury, do not forget about safety precautions.

Design options

Now you need to get a little familiar with possible design solutions.

| Circular saw type | Brief description of technical features and performance characteristics |

| With asynchronous electric motor | Single-phase motors must be purchased in specialized stores; in addition, you must have a shaft with bearings. This is the most difficult to manufacture and most expensive circular saw. If you accurately calculate all the costs, including the cost of materials for making the table and lost time, then it is more economically feasible to buy a ready-made machine for home use. In addition, it is impossible to completely manufacture a durable metal saw frame with all the adjustment devices at home; you will have to turn to mechanical trowels for turning and milling some parts. Beginners are not recommended to use this version of a circular saw. |

| Such solutions are offered by older carpenters; they still remember washing machines with powerful engines. In those days, no one saved electrical energy; power was always set with a significant margin. Today the situation has changed; low-power, economical motors are installed on washing machines. There is no point in making a machine based on them that can only saw plywood a few millimeters thick. |

| Use an angle grinder for the drive. | An extremely undesirable option for several reasons. ● Firstly, the recommended rotation speed of the circular saw shaft is no more than 2–3 thousand rpm. per minute, and the grinder gives 9-11 thousand rpm. The material used to make the teeth, the sharpening angles, the amount of spread and other very important parameters of circular saws are calculated based on this parameter. It is strictly forbidden to use them at such high speeds. ● Secondly, the power of the grinder is approximately 1 kW, which is very low for a stationary circular saw; it will not be able to saw thick boards. And for cutting only slats, it is not practical to make a life-threatening stationary machine. |

Conclusion. For a non-professional craftsman, the most optimal option for making a stationary circular saw is to use a portable circular saw as a drive.

Photo of a homemade circular saw

Tips for choosing

poses a health risk

Particular attention should be paid to the economic component. When choosing a saw, you should pick it up and try to understand whether it is comfortable enough for you to hold it

Don't think that the same model can suit two people, since each of us has different body structure, skills and habits. Moreover, it doesn’t even play a big role here whether a circular saw from a trusted manufacturer is being considered or not.

You should also take into account the material from which the protective casing is made. It must be highly durable and able to withstand deformation if the tool is dropped.

Test the operation of the regulators located on the body of the model. Set up several different angles. Find out if they are easy enough to unscrew and tighten.

Make sure you have easy access to the carbon brushes if you decide to replace them yourself.

Try to be very careful when studying the settings, since neglecting these points can lead to serious injury in the future.

Tips for caring for power tools

deal with a dangerous tool

It is necessary to work with a circular saw only in protective clothing, gloves and goggles.

Before plugging in the saw, make sure it is turned off.

If you need to turn the saw on or off, it is advisable to do this at idle speed. If this is done under stress, it may shorten the tool life.

Make sure that the load does not exceed the permissible level. To do this, it is recommended to take breaks after every 15-20 minutes of work. This will prevent the engine from overheating.

Before work, make sure that the workpiece is securely fastened. It is unacceptable for it to dangle and sag. Otherwise, this could be fraught with serious consequences for you.

Make sure that there is no moisture near the workplace.

Review and comparison of factory models

| Model | Enkor Corvette-10M | Elitech CP 1221 | Hitachi C10RD | Belmash PC 2000 |

| power, kWt | 1,2 | 1,2 | 1,6 | 2000 |

| Rotation speed, rpm | 4800 | 4800 | 4800 | 3100 |

| Disc diameter, mm | 210 | 210 | 250 | 250 |

| Cutting depth, mm | 48 | 45 | 73 | 70 |

| Weight, kg | 16 | 17,5 | 27,7 | 39,5 |

| Dimensions, mm | 590*460*340 | 455*340*585 | 730*590*370 | 700*670*330 |

| Price, rub | 7188 | 8433 | 14302 | 18156 |

Enkor Corvette-10M

Elitech SR 1221 Hitachi C10RD Belmash PC 2000