How to make a chip extractor with your own hands: drawing , principle of operation

A household vacuum cleaner is quite a convenient and even common tool for cleaning up the house. But if you use such a device to clean the garage, the result can be disastrous, as debris will remain on the floor and the vacuum cleaner will break.

The problem is that household vacuum cleaners are only designed to remove dust and very small debris. In the workshop, waste will consist of fairly large sawdust, wood chips, pebbles and metal/wood shavings.

With

How does the chip pump work?

A flexible hose, preferably corrugated, of small diameter, is connected to the mechanism. The smaller the cross-section of the hose, the higher the speed of the sucked air, which means the quality of cleaning will be better. Along with large chips, small particles several microns in size will be removed from the room.

The air in the device is discharged due to the rotation of an impeller connected to an electric motor.

Selection of material

A hose, preferably with a fabric braid, from an old vacuum cleaner, is suitable for removing air with debris. You will need a plastic sewer pipe D = 50 mm and a length of 150 mm, a plastic corner bend of 45 degrees and a length of 200 mm, a plastic bucket from 10 to 25 liters with a lid, and a second bucket can be purchased in smaller sizes (5 - 10 liters).

You will also need 20 mm thick plywood, screws and sealant.

Cyclone assembly

The design of the chip ejector must include the use of a cyclone filter.

Cyclone assembly:

- Installation of a ring for fixation;

- Side pipe fastening;

- Assembling a figured insert;

- Making a cyclone.

The best cyclone vacuum cleaners according to consumer reviews

When choosing models equipped with a cyclone, you should pay attention not only to the technical characteristics, but also read reviews from real customers, which will help identify the strengths or weaknesses of a particular model. The ranking of the best samples includes household and industrial devices

Household vacuum cleaners with cyclone dust collector

The best models for home use, which do not have a dust collection bag and are equipped with a cyclone, are considered to be products from Dyson, which is the founder of this type of device. One of the best models can be considered the new Dyson Cinetic Big Ball Animal Pro 2. This is a vacuum cleaner that has a number of unique features:

Dyson Cinetic technology, which captures the smallest particles, which is important for people suffering from allergies. At the same time, after cleaning, no additional washing or replacement of filter elements is required; Ball system, which ensures the stability of the vacuum cleaner and increases its maneuverability

Even if accidentally tipped over, the device returns to its correct position; Musclehead brush, which is a turbo head with carbon fiber bristles.

Cinetic technology allows you to achieve constant stability of the vacuum cleaner during operation

The only drawback of the model can be considered its high cost, which is 39,000 rubles. But such a pricing policy is normal for a company that positions its products as products of the highest quality.

Review of Dyson Cinetic Big Ball Animal Pro 2

More details on Otzovik: https://otzovik.com/review_6463819.html

Dyson Cinetic Big Ball Animal Pro 2

Construction vacuum cleaners with cyclone filter

One of the best industrial-type models, according to professionals, is the Ghibli Power WD 80.2 I model. This is a device that is designed for cleaning class M dust over large areas. Its features include the presence of a larger tank (80 l). There are also two turbines inside the device, which together create a power of 22.5 kPa.

Ghibli Power WD 80.2 I – device with 80 liter stainless steel tank

Among the advantages, it should be noted the presence of a reliable stainless steel case, a drainage hole for draining dirt, a long power cord (10 m), three replaceable nozzles, and not the highest noise level for similar models. Among the disadvantages, users highlight the limited actual volume of liquid garbage (56 l) and the optional ability to collect dry garbage. The cost of the device is 34,000 rubles.

Cyclone filters are sold separately, making them easy to replace if necessary.

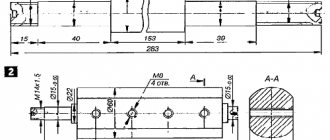

Making a ring and insert

- Cut off the side of a small plastic bucket.

- Having placed the container on the plywood, you need to circle its bottom and determine the center of the resulting circle. To find the center, it is enough to draw 2 perpendiculars to the drawn tangents.

- Another circle is drawn 30 mm larger than the first.

- Using a jigsaw, cut out a ring along the drawn circles.

Ring retainer installation steps

The ring is attached to the cut out side of the plastic container.

- Screw the side using self-tapping screws.

- To prevent the plywood from bursting from the screws, you need to drill holes at the fastening points of a smaller diameter than the thickness of the screws.

- On the lid of a large container, a circle is marked equal to the diameter of the bottom of the container itself.

- Cut out the resulting circle, securing it to the side of a small container with screws.

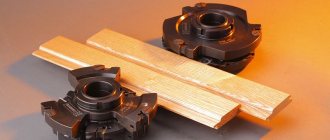

Dust removal system for CNC machine. Part 1 - Selecting a CNC Boot

Attachment - Dust Boots

Dust boots are attached to the spindle or gantry and surround the immediate area around the cutter. They have a curtain of brush or flexible material that prevents dust and debris from flying away and keeps it inside the dust bin. You can connect the dust bag to the dust bin to remove the dust contained inside the dust bin. This prevents the spread of dust and debris and keeps the work surface clean.

Sometimes you have a dust guard instead of a dust boot. Dust guards are similar in function to dust guards. The difference is that the curtain surrounding the dust boot in enclosures is made of narrow sheets of fabric, plastic or silicone that hang loosely from the edges of the dust boot. When choosing a dust cap for your CNC router, you need to consider the following parameters.

Nozzle size

Size is an important factor to consider when choosing a nozzle. This depends on the size of the tool you are using and the cutting process. When using large diameter tools, more chips and dust are generated; hence, they require a large dust container. Make sure it is large enough to hold all the dust and debris generated during cutting.

Vacuum port size

Dust and debris contained in the dust collector are removed through the vacuum port using the dust collector. Make sure it is large enough to accommodate the required size ductwork. For example, large debris requires a 4-inch diameter channel. If the size of dust and debris is small, you can use the 2.5 inch port.

Brush length.

The length of the brush determines the effectiveness of the vacuum cleaner. So make sure you choose a size that is slightly longer than the length of the tool when it touches the surface. Most dust caps are height adjustable, so set the height so that there is no gap between the brush and the surface. If the length is too long, the compression on the brush will be greater, resulting in more restriction of the spindle's movement on the workpiece.

Brush material.

Brushes for vacuum cleaners can be made of different materials. Some common dust brush materials are nylon, plastic, horsehair, and silicone. Among these materials, nylon is preferred by most CNC router users due to its strength, flexibility and cost. Choose a brush that is stiff enough to keep debris from flying around, but flexible enough to move smoothly across your work surface. If you use a brush with a high stiffness, it may get stuck when you change the direction of movement to the opposite direction.

Assembly

Dust caps are made from a variety of materials, including aluminum, ABS, HDPE, plywood, acrylic, and polycarbonate. They are usually mounted on a Z-axis spindle or on a Z-axis gantry. Make sure the attachment does not add weight to the axis or gantry, as this may affect the accuracy of the machine. I always prefer a lightweight design. Additionally, a transparent material such as polycarbonate or acrylic will allow you to control the cutting process.

Installation

Dust caps typically come in two parts: a mount and a removable dust boot. This design makes it easy to remove and attach when you need to change tools. The mounts can be gantry or Z axis mounted. You should prefer the gantry mount. If the mount is attached to the Z axis, it will add additional stress to the Z axis and will affect the performance of your CNC router.

Installation of the pipe

Before installation, you need to make a hole in the bottom (not in the center) of a small container, and insert a 45-degree elbow into it. The outlet is attached with self-tapping screws and sealant to ensure tightness and strength of the joints.

Cloth dust bag

How to make a filter for a vacuum cleaner with your own hands from the materials you have in your farmstead? A thick bag made of any fabric, ready-made for shoes or specially sewn, will come in handy.

A piece of PCB, suitable in size for the existing vacuum cleaner, is needed to attach the bag to it. To hold some of the debris that gets into the bag, you also need a clamp that will secure the entire filter.

Note!

DIY induction heater - instructions on how to make a simple and powerful heater- Do-it-yourself sound amplifier: selection of materials and tools for making at home + step-by-step instructions for creating and assembling yourself

Do-it-yourself wind generator: step-by-step instructions for making a device at home, choosing materials and type of construction

A hole is made in the PCB to match the diameter of the outlet valve. The hole in the bag is attached to the PCB, and a hole is cut at the opposite end of the fabric section to release the collected particles of larger debris. The fabric should be periodically removed and cleaned of fine dust.

Top outlet mounting

- The entries are drilled in the center of the bottom of the small bucket.

- The plastic pipe is attached to a sheet of plywood with a prepared hole equal to the thickness of the pipe.

- The structure is screwed from below with four screws.

- Fill all formed joints with sealant. In addition to tightness, it gives the assembly additional strength.

The insert is attached to the outer wall of the filter using self-tapping screws.

How does a cyclone chip pump work?

The air purified by the cyclone along with the garbage from the room is thrown outside. The filter involves the use of an electric motor with a power of 3.5 kW.

It sets into rotation the impeller, which can withstand a fairly large load and create the necessary air vacuum. Filtration in such a chip ejector is carried out in several stages.

Large debris, after passing through the filter, is collected in a special bag. The installation housing must be sealed. To reduce noise, the housing can be covered with absorbent material.

It is possible to make such a device yourself.

Design features of home chip vacuum cleaners

Even an amateur without technical education can make a functional chip ejector in a carpentry workshop. The first thing to note in such devices is the presence of a motor operating from an electrical network of 220 volts. It is not advisable to purchase three-phase motors, since many difficulties arise with their connection under normal conditions.

It is better to purchase a fan with a powerful impeller. It provides good spiral turbulence of the intake air with chips.

Preparatory stage

A self-made chip ejector will cost several times less than analogues in the store. Some parts for assembly can be found in a workshop or garage, but some of them will still have to be purchased. To quickly produce equipment you need to:

- Draw up a work plan. It is necessary to clearly know what elements will be required during assembly;

- Purchase an electric motor, check its performance and ability to connect to the network in a workshop;

- Select parts that are impossible to make yourself;

- Frame. It can be made of wood, but many use durable plastic tanks with a lid.

When preparing the necessary parts, it will take 2-3 hours to assemble the device.

Filter from plastic buckets

To make a garbage disposal, you will need a cutting tool, a tool for drilling, surface treatment, a heat gun, a pencil, a ruler, and a knife.

The material you can use is laminated chipboard, a plastic thirty-liter tank, a PVC pipe, hot melt adhesive, silicone sealant, bolts, nuts, and screws. You will also need a vacuum cleaner with a hose.

Manufacturing procedure

- A partition is cut from a sheet of laminated chipboard to connect plastic containers.

- Grooves are cut on it for a tight connection with the edge of the bucket.

- A plate is cut to cover the cyclone filter.

- The jumper is attached to the buckets using sealant, then a hole is drilled that connects both vessels.

- The bottom of the container is cut out to create a cone.

- The assembled structure is tightened using clamps and left alone until the sealant dries.

- The recess on the hopper lid is filled with hot melt adhesive.

- Using a drill, you need to make a hole with a diameter of 50 mm. A 120 mm long pipe with sealant is installed into it.

- A PVC corner outlet is inserted into the side hole. It is secured with bolts and nuts.

The cover is put on the mechanism and the vacuum cleaner is connected. The connected hose can be wrapped with electrical tape for better tightness.

Difficulties that you may encounter during work

It is not difficult, as we have seen, to create a cyclone filter with your own hands, or even a homemade vacuum cleaner, if you have the necessary materials.

In some cases, it is recommended to take metal containers for collecting garbage, as they are considered more durable. If you have a vacuum cleaner with enormous power, the plastic bucket can “collapse,” so to speak. It is drawn inward due to the strong flow of intake air. This happens extremely rarely, but it is better to immediately provide for this option. It can be leveled, but the damage to the product will be obvious. So you always need to take into account the quality of the plastic and the power of the device. In the case of a traffic cone, this problem does not arise.

Cyclonic designs of household vacuum cleaners are considered one of the most successful technology options in terms of operating efficiency. The cyclone system is a relatively simple separation mechanism that makes it possible to effectively filter suspended particles present in the air stream.

Based on the theoretical principles of constructing such a system, it is quite possible to create a cyclone for a vacuum cleaner, acting as an additional tool - for example, a construction separator. Interested in the question, but don’t know how to make a simple cyclone yourself? We will help you realize your plans.

The article provides detailed information about the design of the cyclone separator, as well as step-by-step instructions for assembling it and connecting it to a vacuum cleaner. A description of all stages of the work process is accompanied by visual photographs.

Making a cyclone from a traffic cone

A very simple and quick way to make is to use a traffic cone.

- You need to cut off the bottom and top of the cone and, turning it over, place it in any container to accumulate waste.

- Make a round lid approximately equal to the top of the chip by drilling a 40 mm hole in it.

- Secure the corner bend into the opening made in the side wall with glue.

- Glue all connections with a heat gun for tightness and strength. The waste collector is connected to the vacuum cleaner through a corrugated hose.

The chip ejector can be made from a wide variety of available materials with your own hands.

Operating principle

The cyclone, as it may seem at first glance, was created even primitively. This is an ordinary large round container (barrel or bucket). The incoming air flow begins to enter the upper part of the container, and at the same time the air stream is directed horizontally, along the wall. Due to this, the flow begins to twist spirally. The centrifugal force begins to throw all solid particles of debris towards the wall, and they gradually begin to collect at the bottom of the container. Since the air is light, the purified flow gradually begins to calm down in the center of the round container.

The vacuum of the cyclone inside the housing is created by suction of air from the pipe, which is located exactly along the axis of the container. In this part of the cyclone, the air is already cleared of sawdust, dust and shavings, and for this reason can be sucked out using any pump of suitable capacity. Even a household vacuum cleaner is often used as a pump. The design of an industrial cyclone-based chip extractor usually uses a special pump. As a rule, pumps of a centrifugal type are used here, and it looks like a “squirrel wheel” with blades placed across it, instead of the most common spokes.

The wheel should be placed in a housing that is shaped like a snail. A centrifugal wheel driven by an electric motor begins to accelerate the air mass around the ring and strongly throws it out through the exhaust pipe, which is located on the outside of the pump. In addition, a vacuum appears in the center of the centrifugal wheel. The pump design is characterized by excellent performance and unpretentiousness.

Please note that such devices are capable of sucking out even very contaminated air, and this makes them even more valuable in the design of an industrial vacuum cleaner based on cyclone cleaning.