Tools for wood carving must be carefully selected. Wood carving as a type of decorative and applied art has a long history and has provided humanity with real masterpieces. At home, you can also create works of art, and simply diversify the interior. Although some modern models with electric drive have appeared (for example, a wood carving drill), in general the tool preserves traditions and is intended mainly for painstaking manual labor.

Different types of chisels for wood carving

The main tools of the carver

Wood carving is the processing of wood to give it a special shape or create a relief on it. The following main types of such operations can be distinguished:

- The through type of processing includes sawing and slotting wood carving. The sawing type is carried out with a jigsaw or file. The slotting type consists of punching through wood using a chisel or cutters when using a wood cutting machine. A pattern appears on a wooden product, which is why this type of carving is also called openwork.

An example of a box made with slotted carvings - The flat, creased type involves creating a pattern that is in-depth in relation to the main background. The following varieties of this type are noted: contour carving, staple carving, geometric carving and on a black background. The contour subtype is made in the form of grooves of various shapes using cutters, an angular or semicircular chisel, and a knife. Bracket carving is carried out with the same type of element in the form of a bracket using a semicircular chisel.

- The relief type is typical for carved panels, and the elements in it are raised in relation to the main background. The main tool is chisels of various shapes. Particularly notable is the Kudrinskaya carving, which is distinguished by its unique curls of flower garlands.

An example of making relief wood carving - The sculptural type of carving is distinguished by the creation of three-dimensional forms in the form of wooden sculptures. The entire arsenal of instruments is used in the creation of such works. Recently, a carving pantograph has often been used for this type of creativity.

- House carving is intended for decorating wooden houses and is always popular. In its implementation, almost all types of processing considered are used. The house variety provides for significant areas and large dimensions.

Templates for house carving

In order to do such work, a wood carving tool is used, both the main type and an auxiliary one, or even a carpenter's one.

Finishing of the finished product

The composition using the contour carving technique can be made both on a plain or on a tinted and polished wood surface. In the second case, no further processing of the material is required. If the ornament was carved on light wood, then it is coated with transparent varnish, after sanding the surface with fine sandpaper. Sanding must be done along the wood fibers. It is better to grind turned products and coat them with a transparent varnish in a clamped state while rotating in the machine. Accordingly, the turned product is not cut from a wooden workpiece, but is removed, covered with threads and re-clamped in the machine, after which it is finished, dried and only then cut.

The type of finish is selected depending on the purpose of the wood product. The surface can be varnished to a shine or remain matte by applying diluted varnish to the threads with a hard brush. Before varnishing with transparent compounds, the polished surface of a contour carving can be tinted in different colors by painting only the background or the background with individual, most in-depth lines. The varnish is applied only to a thoroughly dried wood surface.

Beginning woodworkers perform work using the contour carving technique on flat boards. As you gain experience and improve your skills, you can begin to work with more complex products: pieces of furniture, household items and household items. On such elements, contour carving can act either as a separate independent technique or as an additional artistic decoration, performed in conjunction with other carpentry techniques. Contour carving allows you to create subtle and aesthetic ornaments in various styles.

How to use the tool

When performing wood carving, the following work is carried out: drilling, sawing, cutting and gouging. To create a quality product, it is impossible to do without measuring tools.

During the work process, the need arises for auxiliary tools or devices that help fix the workpiece and limit the degree of impact.

The nature of the work determines the choice of the necessary tool. Historically, the best examples were made using hand tools, but the modern trend towards mechanization and automation of labor has not bypassed this area of activity.

Set of various cutters for wood carving

There is a whole range of machines, mini-drills (drills), hand-held milling cutters, jigsaws, grinders, etc. on sale. Certain products can be made in automatic mode using copy-milling devices (pantograph).

History of wood carving

The use of wood has been mentioned since primitive times among different nationalities in almost all corners of the Earth. The origins of wood carving date back to the use of techniques for processing this material and the emergence of wooden architecture. The first find made of wood is an idol discovered on the territory of present-day Yekaterinburg. The approximate date of its creation is attributed to the 8th century BC. It has been established that the body of the idol is covered with geometric wood carvings, and it itself symbolizes the connection between the underground and heavenly worlds.

As human society developed, the use of wood in rituals lost its meaning, new techniques for working with wood appeared, and tools were improved. People began to use wood to decorate household items. Since the 16th century, hand-carved wood became a universal craft, and the first workshops appeared. Skilled craftsmen decorate temples, royal palaces, and houses of rich people with skillful, original carvings.

Our ancestors were very closely connected with nature and considered wood to be a conductor between the sun and people, and wooden products were a symbol of health, prosperity and longevity. They also knew the valuable qualities of wood, such as water resistance, thermal insulation, a variety of textures and patterns of wood, ease of processing and preparation. Wood was used in all spheres of life: in the construction of defensive fortifications and houses, in the manufacture of dishes and tools.

What types of knives are used?

One of the primary cutting tools used for artistic wood carving are wood carving knives of various designs and purposes. The following types of knives are distinguished:

- Cutter knife. It is considered the main tool of a carver and is used when carrying out any work. It can have different blade lengths, handles, and even have different shapes. The most important difference is that the cutting angle is 35º. Dimensions and angle of the blade of the cutter knife

- Knife-jamb. It is used in flat-relief and openwork carvings to create long straight lines, form an oval contour and process the sides of recesses. Main dimensions: cutting chamfer angle - 20º, blade bevel angle - 35-60º, blade length - 35-80 mm, blade width - 6-45 mm, handle length - 90-160 mm.

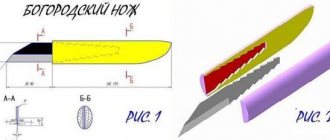

- Bogorodsky knife. Designed for sculptural carving. The length of its blade is in the range of 25-90 mm, and the width is 10-25 mm.

- Auxiliary knives are needed for certain jobs. There are knives that allow you to make curved finishing of a volumetric relief, others are designed for editing slotted threads.

What chisels are needed when working?

Of course, the main handmade tools are wood carving chisels. The most common types of chisels include the following tool:

- Straight type: used as an auxiliary tool.

- Semicircular type: the main type of chisel, which is necessary for any type of work. There are flat, medium and round options.

- Klukarzy. They have a curved working part; there are flat, angular and semicircular varieties.

The process of carving with a crab cutter - Cerasics. They look similar to the semicircular type, but are designed for cutting thin grooves - for this purpose the blade width is 2-3 mm.

- Thicknessers or corner chisels. Used for cutting V-shaped grooves and contour cutting. Such wood carving cutters have an angle between the working cutting knives of 55-75º.

- The graver has a mushroom-shaped handle, and the bend angle is 15º. The tool is designed for making various grooves.

This is what wood carving pens of various sizes look like - Rivets: sharpening of the working edge is made in the form of a sword or leaf, and is used to process the main background in areas where other chisels do not pass.

- Nail is a type of chisel-rivet with sharpening in the form of a nail, used for processing in hard-to-reach places, as well as when making staple carvings.

Work safety

- Durable and stable work table.

- Use of fasteners and clamps.

- Sufficient natural and artificial lighting.

- Use gloves, glasses, and a respirator when working with tools.

- It is forbidden to cut towards yourself.

- It is forbidden to clutter the desktop.

- Clean the workplace only with special brushes.

- The tool must be laid out and secured.

- The power tool must be in good working order and tested.

- If the power tool is connected to a three-phase network, it is necessary to equip it with grounding.

Sawdust and shavings should not come into contact with heating devices and heated surfaces. Heating oil or nitro coatings is allowed only on closed heat sources. The work area must be equipped with a complete first aid kit.

What other tool can you use?

In addition to the main devices discussed, additional tools are used when carrying out work to carry out specific work.

The following additional tool is usually used for wood carving:

- Spoon knives or spoon knives: usually a sharpened ring welded to a steel bar that is inserted into the handle - are used for removing accumulated sawdust in recesses, as well as for grinding the inside walls of large recesses, for example, when cutting utensils.

- Embosses and punches: durable metal rods with a specific pattern on the end. Most common when creating the main background.

When carving wood over large areas, various auxiliary tools are also used:

- For drilling work: gimlets, rotators, hand drills.

- When sawing: hacksaw, hacksaw, jigsaw, two-handed saw.

- Auxiliary equipment: mallet, staple, miter box, clamps, vice, various clamps, hammer.

To carry out measurements and markings, the following tools are used: ruler, square, protractor, leveler, measuring rod, plumb line, leveler, level, calipers, vernier calipers, bore gauge, surface thicknesser, compass, tape measure.