Creating wooden cylindrical products is impossible without a hand tool - a chisel for a lathe. It is from under its blade that the unnecessary amount of material is removed and the workpiece acquires an artistic decoration.

Turning chisels can be bought ready-made, but such kits are very expensive, especially high-quality ones. Cutters for wood processing are easy to make yourself, which will be discussed further.

What types of chisels are there?

For professional processing of a wooden workpiece on a lathe, various working tools are required, including a rich set of chisels. Based on their functional role, they can be divided into groups:

- For rough processing. They have 2 cutting edges located at an angle to each other.

- Meisel for finishing. This cutter is a blade with a flat plane and an angular sharpening on the left or right side. The angle of inclination of the cutting part may be different.

- The semicircular reyer chisel is used for working with non-standard products.

- The cut-off cutter is used to remove fragments of wood when forming a pattern.

- A boring tool for wood turning has a shoulder to help remove excess material released during the pointing process.

- Round chisel for processing round products. Its tip can be smooth or jagged.

- Cutting file for processing the end sections of the workpiece.

- The cutter stop is installed on the tool to adjust the turning depth.

The presented types of incisors are basic; there are many variations in size, modification, and quality. Experienced woodworking craftsmen often come up with their own proprietary devices for turning wood blanks.

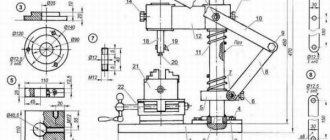

To ensure that tools are manufactured in an orderly and accurate manner, craftsmen recommend creating drawings for the products containing dimensions, shape, slopes and material. This way, you don’t have to constantly think about the required parameters; sharpening wood turning tools can be done simply like clockwork.

Adaptations

Craftsmen have different experiences in creating hand tools, and the sets of tools for production, accordingly, differ from each other. Let's try to imagine an average universal set of blanks:

- Metal - blank. Depending on the intended type of chisel, old files and rasps, scraps of steel pipes, square-section reinforcement, and automobile springs are used.

- A wooden handle is necessary for ease of use of the future cutter. You can buy it ready-made at a hardware store or turn it using a wood lathe.

- Metal processing machine. This can be any setup that works with sanding wheels.

- Overalls. Even when making cutters at home, there is a risk of injury from hot sparks and metal chips. Prepare glasses, gloves, and a robe.

How to choose the right cutter?

When choosing a cutter, you need to take into account a number of recommendations. Determine what type of metal you will be working with, what processing operations you are planning and what degree of load the cutter will experience. Determine what type of metal you will be working with, what processing operations you are planning and what degree of load the cutter will experience.

Determine what type of metal you will be working with, what processing operations you are planning and what degree of load the cutter will experience.

Decide what is most important - the accuracy of the geometry of the product or the level of surface treatment. Depending on this, the cutter is selected in accordance with the classifying characteristics and geometric proportions.

Determine for yourself how important it is to ensure the wear resistance of the device and how long it should remain unchanged.

Algorithm for carrying out the work

The production of any cutting devices is carried out according to a standard algorithm:

- Using drawings and photos, the required shape of the future chisel is cut from the blanks using metalworking machines.

- Primary turning of the product is carried out.

- When the workpiece is processed, the metal needs to be hardened to give the homemade product strength. This way he can process wood of different hardnesses. To do this, the metal tool is heated to maximum temperature and dipped in machine oil until it cools.

Another hardening option is natural cooling at normal ambient temperature. - Final sharpening of cutters for a lathe.

- Wooden handle attachment.

Self-production of cutters

It is worth noting right away that the high cost does not in all cases force a specialist to take radical measures. In most cases, a competent carpenter simply cannot find a device that fully meets his requirements. In fact, this can be solved quite successfully and simply; you just need to find out what materials the cutters are made from and what technology to choose.

Blade

Often, to create a workpiece with your own hands, an ordinary blade for cutting metal or wood is suitable. Using this material you can make a good jamb knife - you just need to cut or break off part of the blade, and then create an edge for cutting.

The saw blade has excellent parameters for creating a future product, since it is made of a carbon metal alloy, which can be easily processed and does not require additional sharpening for a long time, even after processing hard wood.

So, the blade can be made from the following available devices:

- hacksaw blade (for metal or wood);

- saw blade;

- strong sheet metal.

Lever

After making the cutting edge, you can start making the handle. Here you will need a strong block made of hard wood. Particular attention should be paid to the fact that the configuration of the hole in the handle must necessarily correspond to the configuration of the blade tail. Then you need to install the edge directly into the handle, reinforcing the entire structure with a metal ring.

Do it yourself

To understand how hand tools for woodworking are made, let's look at the manufacturing process of several of their main varieties.

Meysel

This is the main tool used for finishing wood workpieces. In skillful hands, this chisel is enough to create any pattern.

A straight-sharpened meisel is ideal for creating rectangular notches in a workpiece . Its width varies from 4 to 40 mm, the standard sharpening angle is from 22 to 450. The required blade slope is determined by the personal preferences of the master over time.

How to make it:

- We take an old file or any other flat rectangular piece. If necessary, align the working end;

- We grind the cutting part, carrying out primary turning. We use an abrasive wheel, making sure that the blade is processed evenly in thickness without differences;

- We harden if the metal is not hard enough;

- We put the handle.

This type of chisel is easy to prepare and can be used to start creating your own collection of hand tools to gain experience and understand the process.

The Meisel with a beveled blade is more versatile than its counterpart:

- It becomes possible to process round products;

- An obtuse angle is suitable for creating roundings;

- The tool is convenient for processing the end of a product.

Manufacturing is similar to the previous device:

- The blank part is processed to the shape of the future tool;

- The chisel is sharpened at an angle of 70-750, after which the tool must be sharpened.

- We attach the handle. Meisel is ready.

Using a similar algorithm, the remaining angular cutters for a wood lathe are created. Sharpening is carried out only after careful control of the tool dimensions .

Maintaining exact angles when making tools yourself is not necessary. It is enough to adhere to the necessary and convenient proportions and evenness of processing.

Semicircle

The semicircular tip of the chisels allows you to create neat notches when processing a wooden product. To make such a cutter, we mark on the workpiece the outline of the tool along which we cut. After this, we sharpen it in the usual way at an angle of 25...400.

The radius of the chisel affects the size of the recess in the product, therefore for professional production it is advisable to make several cutters with a semicircular tip for different cases.

Groove

After stripping the bark, the wooden trunk is processed with grooved chisels; they are intended for the initial rough finishing of the material and creating a blank for the product.

In addition, grooves are used to cut concave shapes and recesses in frontal turning.

How to make a groove cutter:

- Take a tap to cut a thread of the required diameter.

- We process the metal blank with it at a distance of up to 8-10 cm from the edge, actually cutting off half of the rough product.

- We sharpen the lower convex part of the blade at an angle of 30-400.

Grooved homemade wood turning tools are not easy to make, but it is quite possible to understand the process.

Make or buy

The process of creating tools for working with wood is a fascinating and not always easy task. If you have the right set of tools, an inexperienced person will not have any problems - the process is intuitive, but painstaking.

Of course, you can buy a ready-made set of devices, but how much will it cost... At the same time, the wear of the metal increases over time and even brand new chisels will soon require turning. Own production is a way to get a tool under your own hands. Designer cutters with individual sizes will be adapted to the owner and his needs .

A more detailed description of the chisel making process is presented in the video. The master talks in detail about creating a workpiece, applying sharpening and touches on other important points that are necessary for the successful completion of the work.

Sharpening angles

The following is a list of sharpening angles for all common materials. The first fraction indicates the relief angle during roughing, the second - the relief angle during finishing. The third fraction shows the size of the front angle. The numerator indicates the angles for cutters that sharpen and bore parts, and the denominator indicates the angles for tools that plane workpieces.

- Steel (hardness less than eight hundred Megapascals) – 8/6, 12/8, 15/12.

- Steel (hardness more than eight hundred Megapascals) – 8/6, 12/8, 10/10.

- Steel (hardness more than a thousand Megapascals) – 8/6, 12/10, 10/8.

- Gray cast iron (Brinnel hardness less than two hundred and twenty) – 6/6, 10/10, 12/8.

- Gray cast iron (Brinnell hardness more than two hundred and twenty) – 6/6, 10/10, 8/5.

- Malleable cast iron – 8/8, 10/10, 8/8.

The main plan angle should be 30 - 45 degrees. The width of the chamfer depends on the cross-section of the cutting rods.

What abrasive wheels are used for sharpening turning tools? Sharpening of a tool through the holder and at an angle of 5 degrees is carried out with a wheel made of electrocorundum, having a grain size of forty - fifty, hardness CM1/2. The peripheral speed of the circle is 25 m/s.

Preparatory sharpening is carried out with products made of black silicon carbide, having a grain size of twenty-five to forty, hardness M3-SM1. The final sharpening of the cutting tool is carried out with wheels made of green silicon carbide, having a grain size of sixteen - twenty-five, hardness M3-SM1.

The parameters of grinding wheels for steel and carbide cutters are specified in the table of sharpening modes. There you can also see the circumferential torsion speeds.

Currently, final sharpening is recommended to be done using a diamond wheel. This is especially true for inserts made of hard alloys. The peripheral speed of the circle during preparatory/final sharpening should not exceed twelve to fifteen meters per second.

Classification

Lathes are divided into:

- center ones with mechanized feed. It is possible to perform work on this equipment using hand-held cutting tools (when installing a special tool rest on the frame). An oblong piece of wood is held by a spindle and a movable tailstock. The longitudinal feed of the caliper is mechanized. These machines can be used to work with a copier. When working with short, light workpieces, the tailstock fastening may not be used. When processing the inside of a wooden part, a faceplate serves as a fastener. The moving elements in the operating mode on these lathes are the cutters moving along the piece of wood being processed and the rotating spindle.

- Lathes are used to produce parts on a flat, wide wooden base. Beautiful multi-level carvings, bas-reliefs, high reliefs - this is what can be produced on machines that work with a wide faceplate, on which the workpiece is mounted. Work is carried out only on the front part of the part. The rest of the revision will be done manually.

- round-sticks process wood, giving it a shape with a round cross-section. When working on this equipment, the workpieces do not rotate or move. The only moving parts of the machine are the heads with the cutters. There are also machines in this group for processing long products. Then they will feed the workpieces with rollers under the cutters.

Shaping wood occurs by rotating the material being processed and using a cutting tool.

About blanks

There should be a sufficient number of blanks, at first twice as many. Newbie marriage – 4 out of 10. After two spoiled workpieces in a row, a break of several minutes is necessary.

It is better to immediately exclude workpieces with knots from processing. Before important, urgent work (when making the simplest part), I strongly recommend not to sharpen the tool, because the chance of spoiling the workpiece increases significantly and can reach 80%. If possible, do not use other people’s blanks, glues, or tools. Trim the workpiece if there are end cracks measuring 5-15 cm. Monitor drying and mark longitudinal cracks.

In some species (oak, pear), the cracks converge during drying. For the first turning experiments, use linden, for scraping beech.