Tamburat and products based on it

Tamburat became a real hit in 2008 on the European furniture market. In essence, this is a lightweight frameless slab, an analogue of sandwich panels. Among other names for this material you can hear “lightweight honeycomb boards”, “furniture boards”, “frameless boards”, Eurolight. There are also variants of these products - for example, Egger tambourate .

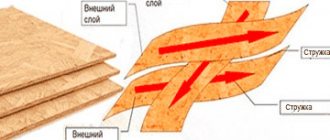

Tamburat is made in the form of a three-layer structure. The outer layers consist of MDF or, for example, chipboard, inside of which there is cellular cardboard. The thickness of the outer layers is usually in the range of 3–8 mm. Tamburat is recognized as an excellent modern substitute for solid wood. With its help, you can reproduce an effect that cannot be achieved with chipboard - modern technologies do not allow the production of such slabs with a thickness of more than 4 cm. At the same time, tambourate makes it possible to create slabs up to 10 cm thick.

So far, this material has not yet received wide distribution in Russia. This is hampered by a number of misconceptions, which, upon closer examination, turn out to be unfounded.

Tamburat – furniture board

Tamburat is a modern construction material that consists of two outer sheets and a filler.

The idea of making slabs with a honeycomb structure arose back in 1943, but implementation began only 20 years later. It took the creators a long time to find the perfect filler. As a result, they stopped on compacted cardboard. The outer layers are made of wood-containing material or plasterboard with surface veneer. And the middle is made of thick cardboard and is placed in the shape of a honeycomb with dimensions from 15 to 25 mm. The vestibule does not have significant dimensions. Companies specializing in the creation of this material provide quite different sheet sizes. Thickness ranges from 30 to 240 mm, length from 2400 to 3000 mm, and width from 600 to 1300 mm.

Misconceptions about tamburate

Misconception 1. Today , making furniture from vestibule is not in demand, since for light slabs, in order to create a visual array, you can use chipboards fastened together.

In fact, the only reason for making a visual array from chipboard is a consequence of the reluctance of most manufacturers to master new technology and new materials, since this will entail additional costs for reorienting the technological process. On the other hand, several chipboard boards cannot be called light in the full sense, and investments in changing technology will pay off by expanding collections and attracting new product buyers.

Misconception 2. When choosing custom-made furniture from vestibule or purchasing it ready-made, the user receives an insufficiently durable product. The main evidence cited is the fact that cardboard is used in the manufacture of the tambourate.

This statement is nothing more than a myth. To confirm this, it is enough to conduct one simple experiment. Roll the cardboard into a tube and try to crumple it vertically. It is unlikely that this will succeed. Meanwhile, any countertop made of tambourate has a shape similar in properties to the shape of such a tube. The presence of tens and hundreds of “pipes” makes the product unusually durable.

Misconception 3. Even the most inexpensive tambourate cabinets cost much more than similar “double” chipboard products.

This statement is quite easy to refute. Turning to numbers and facts, we will see that on average a double array of imported chipboard with a thickness of 25 mm is 40 euros per square meter. At the same time, a Eurolight Egger board with a total thickness of 50 mm is valued on the market at less than 30 euros for the same square meter.

Tamburat or furniture board

Tamburat or furniture board is a composite material with a honeycomb structure. Consists of 2 layers of MDF, chipboard, plywood or other wood-containing board materials. Kraft cardboard, made in the shape of a honeycomb, runs through the center. The cell size varies. From 15 to 25 mm.

Furniture boards or tambourates took a relatively long time to develop. About 20 years, starting in 1943. This is coupled with the fact that it was necessary to find the perfect filler. Meeting all material requirements.

Naturally, there is hardly a person who does not like solid wood furniture. But, unfortunately, not many people can afford this kind of furniture. Oh, so the tamburat is very close in its features to solid wood. But significantly cheaper.

Application of tambourate for furniture production

There are two main methods for producing tambourate furniture.

- • In the first case, light boards are partially used in furniture pieces. This makes it possible to gradually master manufacturing technology, minimally change the production process and expand the range of furniture collections. In particular, lightweight boards are used in those elements that first catch the eye.

- • In the second case, the furniture is made entirely from light boards. Everything in it, even the shelves, is made of vestibule. Naturally, this method will require changing the production process as much as possible, but the results obtained exceed all expectations. This method makes it possible to offer customers fundamentally new collections, which has a positive effect on the competitiveness of the manufacturer.

Where is tamburate consumed?

Tamburat or furniture board is used for the production of interior doors and furniture. At the same time, furniture is created of any type. This includes kitchen furniture, office furniture, bedroom sets, admin desks, computer desks, and so on. Furniture made from this material looks very fashionable. From the outside it looks like an array. But not as languid as solid wood and significantly cheaper.

Sandwich furniture: features of its production and varieties

The furniture market is constantly evolving, new trends and ideas are emerging, design and functionality are changing. Recently, a return to massiveness has been observed in this area. Once upon a time, the price of furniture depended on the material from which it was made. Now design is also taken into account, that is, compliance with modern trends. Products made from laminated chipboard will surprise few people, but sandwich furniture has distinct features.

Edgebanding and fittings

If the thickness of the outer layers of chipboard is 8 mm, then a regular edge can be used except for melamine; the use of a supporting edge in this case is not necessary. But if the thickness of the outer layers is less than 8 mm, then it must be used. The support edge is a flexible ABS foam strip. Its thickness reaches 3 mm. It is used as a base for decorative edges.

Accessories for the vestibule are:

- standard. Such fittings are used for chipboard. It is used if the thickness of the outer layers is more than 8 mm

- specialized is used if the thickness of the outer layers is less than 8 mm. In addition, it can be used on thicker sheets. In this case, it will provide additional reliability of the product.

Specialized fasteners are designed to compensate for voids in the honeycomb core of the slabs. The most famous manufacturer of accessories for vestibules is the German company Hafele, which produces all the necessary elements for high-quality furniture assembly.

Experts note that Maxifix ties, self-tapping screws with special threads and Aerofix adhesive couplings help ensure a high level of reliability of connections of all types, which in terms of strength will not be worse than the assembly characteristics of blanks made of laminated chipboard or MDF with a thickness of 16-32 mm. The use of such specialized elements makes it possible to equip the body of tambourate products with guides, retractable baskets, pantographs and other additional mechanisms that are designed for standard loads.

Features of sandwich furniture

The technology for producing sandwich panels appeared relatively recently and quickly gained popularity in the construction industry. Gradually, this technology began to be used in the manufacture of furniture, which is explained by the characteristics of the material.

Advantages

At the moment, there is a wide variety of building materials that are suitable for the manufacture of furniture and various interior items. All of them have both advantages and disadvantages.

When drawing up a housing project, it is worth familiarizing yourself with the advantages and features of various materials, which will allow you to make the right choice.

The sandwich design is characterized by the following advantages:

- Ease of processing. Any person can cut a tambourate slab, and no special tools are needed for this.

- Possibility of hidden installation. Explained by the density of the filler. In addition, the fastening elements are easily hidden inside the furniture without spoiling its appearance.

- Ability to combine with other materials. The design assumes classic fasteners. However, if very thin sheets are used, they should be mounted using special recessed fasteners.

- Strength. This characteristic largely depends on the characteristics of the filler. Its design involves many stiffening ribs that can easily withstand increased loads.

- Resistance to bending. Thin products bend easily, while remaining strong and rigid. Due to this, rounded or concave elements are often made from the material.

- Decorative coatings. They are available in a wide variety so that the final product can have a unique look.

- Light weight. Despite the large volume of parts, the products are not heavy. This feature allows the panels to be used to produce impressive structures that will not create difficulties during transportation.

- Availability. The cost is low.

FEATURES OF TAMBURATE PROCESSING

Like any other innovative product, lightweight furniture boards produced by Egger have their own nuances in processing throughout the entire technological process chain for the production of furniture parts.

Let's start with format cutting. The whole subtlety of this operation lies in the relative fragility of the material itself and the low specific strength near the ends, because The strengthening effect of honeycombs in these places is minimal. Accordingly, no difficulties will arise with equipment that does not create pressure on the slab during processing. For example, these are format-cutting machines with a movable carriage. At centers where the material is picked up and fed automatically, it is necessary to monitor the pressure on the plate. Typically this applies to the material feed collets and the pressure bar.

The next difficult operation is edge banding. A distinctive feature of the edge banding of the Eurolight board with a thickness of outer layers of 9 mm is the fact that the edge is glued directly to the outer layers. Adhesion at a thickness of 9 mm is sufficient to securely hold the edge. Here special attention should be paid to the thickness of the edge. Considering the fact that the center of the edge falls on the void of the slab, it is possible to use only a thick edge, which, with its rigidity, can prevent subsidence into the slab: for a 38mm thick slab, the minimum edge thickness is 1.5-2mm, for a thickness of 50mm - 2mm, for a thickness of 60mm - 3mm. It is only possible to use an edge with a thinner thickness when using embedded strips or a supporting edge.

For specific fittings mounted at the end of the slab, most often these are door hinges and console shelf holders; it is also necessary to install embedded strips in the slab. The technological chain for installing embeds in tamburat begins with the operation of format cutting. The slab is cut into a detailed row with a certain allowance for overall dimensions. Then the milling operation is carried out. In the outer layers, a quarter is selected whose depth corresponds to the parameters of the embedded parts required in the design. Both wooden blocks and planks cut from chipboard or MDF can be used as direct embedded strips. It all depends on the required geometric parameters. The embeds are prepared in advance, and after milling the quarters, they are mounted into the slab using glue. To speed up the curing process of the glue and prevent the appearance of different thicknesses of the slab, it is advisable to carry out the gluing operation on a press. After complete curing of the glue and technological exposure, the time of which depends on the mode of pressing and glue, the resulting parts are trimmed along the perimeter to the exact size to remove possible unevenness in the installation of the embedded parts.

After which, the remaining necessary operations are carried out as usual: edge banding, drilling, etc. All of the above operations are carried out at Credo using high-tech Homag equipment, which allows us to achieve good results in terms of accuracy and quality of finished products from lightweight furniture boards.

In some cases, the product design requires the use of curved panels. Most often this concerns office furniture. Tamburate can also be processed in the same way. But it is possible to carry out this operation efficiently only at processing centers. The use of hand tools is difficult due to the large thickness of the material.

Types of sandwich panels

Initially, this material was used purely in the construction industry. We are talking about wall and roof sandwich panels. Having seen all the advantages of this solution, builders and designers found application for the material in furniture production. Thanks to it, the mass production of headsets has been facilitated, the final mass of which, compared to classic models, is several times less.

The differences in tambourate come down not only to the thickness of the sheets and dimensions. Several types of slabs are currently produced. They have different characteristics and outer layer coating.

The following types are distinguished:

- Uncoated. Before use, it is necessary to make the cladding from veneer or paper-laminated material.

- Coated. Natural wood veneer, laminated paper or PVC film are used as finishing.

- Standard decorated. These types of boards require factory cladding: varnished paper, veneer or plastic. The only thing you need to consider when choosing is the color of the edge. In the future, the slabs do not require any preparation; they are already ready for use.

Typically, manufactured products are decorated with wood, which allows them to look good in many style solutions.

Depending on the outer coating, the operational characteristics of the vestibule change. The edge is finished in the same way as for solid wood or chipboard. The difference is that it not only performs a decorative function, but also additionally stabilizes the side surface of the material.

How to create a tambourate or furniture board

So, we have already figured out that tambourate is a frame slab with low weight. Creating a furniture board or vestibule is not difficult.

So, to make a tambourate, take two sheets of plywood (MDF, fiberboard, chipboard and others), 3.4 or 8 mm wide. Craft filler with a honeycomb structure is placed between the sheets. The whole system is glued together. A protective edge is glued along the edges. The protective edge is usually made of PVC. Has a thickness of no more than 3mm. An embedded strip made of foamed ABS or plywood is placed under the protective edge. This is done so that the edge holds better.

Tamburat or furniture board. Kinds

There are 3 types of tamburat. Any type of furniture board differs according to the method of its processing. So there is uncoated, coated and standard decorated.

- The standard-decorated tambourate has a finish made of varnished paper, plastic or wood veneer

- Coated tambourate usually has a finish in the form of wood veneer, film or paper-laminated coating

- Uncoated tambourate requires additional processing before implementation. You can cover it with PVC film, paste over it with paper or cover it with veneer

Criterias of choice

Sandwich furniture allows you to create a beautiful and comfortable environment with a small investment. A kitchen set or countertop can visually imitate natural wood, which looks very impressive.

Even a person with little income can afford to install a comfortable tambourine cabinet in his apartment. In order for the purchased product to fully meet your expectations, you must be careful when choosing.

Experts recommend taking into account the following factors:

- panels should be selected based on the loads placed on them;

- There should be no chips, dented parts, peeling coating or other damage on the surface.

You should also know that the material should not be exposed to moisture for a long time; it does not tolerate large point loads. Sandwich panels are available in different shades. You can select a specific color in the RAL catalog.

By following these simple rules, everyone can afford an inexpensive but attractive furniture set.

Requirements for fittings

You should carefully pay attention to the fittings that will be mounted to the vestibule slabs. This is explained by their thickness - 8 mm. Nowadays various handles, hinges and other components are being manufactured that simply do not fit this parameter.

Simple original chair

- First of all, sandwiches for the walls are created from cardboard from zigzag blanks. In this case, each wall will require 3 zigzag stripes.

- Next, a long piece of cardboard is marked, the interval is 42 millimeters. An incision is made on each side.

Look at the folds of the lines, make sure that the structure will fold as it should.

- Glue the zigzag pieces to the walls. You can make as many layers as you need to give the product strength.

- Then circles are cut out in the walls of the future chair using a special cutter. Next, use pipes from an A2 roll plotter. They are inserted into the holes.

The uniqueness of the EUROLIGHT tambourate.

The boards have all the qualities of a modern wood material:

- Durable and at the same time lightweight material

- Environmentally friendly

- Ideal for wiring communications

- Great design.

Eurolight products are suitable for designers, carpenters and architects. The value of tamburat material can also be assessed by specialists in the design of retail space or specialists in the field of furniture production.

Specialized tambourate fittings

To compensate for the voids in the honeycomb filling of the vestibule slabs, special fittings were invented, which, along with the standard ones, make it possible to produce furniture designs of increased complexity.

Non-standard fittings include:

Designed for slabs with a thickness of 32 to 50 mm, without an internal frame and a front panel thickness of 4 mm;

Scope of application - slabs with a thickness of 32 to 60 mm, with a front panel 4 and 8 mm thick, both with and without an internal frame (with a 4 mm panel, the use of a special Varianta screw is a prerequisite);

Scope of application - slabs with a thickness of 32 to 60 mm, with a front panel 4 and 8 mm thick, both with and without an internal frame (with a 4 mm panel, the use of a special Varianta screw is a prerequisite);

Designed for connecting shelves and side walls made of vestibule with a width of 30 to 38 mm. Pressed into 2 holes with a distance between them of 32 mm;

Designed for slabs with a thickness of 32 mm, with a front panel thickness of 4 mm, without an internal frame. It has a built-in cartridge with polyurethane one-component adhesive and has the following advantages:

- can be installed manually;

- reliably and firmly connects the front panels;

- has excellent strength;

- Fits standard fasteners.

The Aerofix coupling has a wide range of applications:

- shelf supports;

- screeds, including the back wall;

- cabinet rods and rod holders;

- mounting strips and hinges;

- sliding door fittings

- guides;

- furniture legs;

- decorative fittings;

- door handles;

- locking systems;

- furniture casters;

Designed for slabs with a thickness of 50 and 60 mm. Suitable for connections that bear significant load. In this case, the front panel must have a thickness of at least 8 mm. The screed is available in two versions:

- for connecting a tambourate tabletop with an internal frame;

- for connecting tambourate worktops without an internal frame.

In both versions, the screed has a device for adjusting the height;

Thanks to a special key, it became possible to use connecting fittings in the production of vestibule furniture with a front panel 4 mm thick or more.

Benefits of using tambourate.

The low weight of the material helps save on furniture manufacturing time and labor. If compact but massive-looking furniture is required, then, as a rule, several slabs are glued together. Tamburat is produced up to 100mm thick and weighs 50-60% lighter than MDF or chipboard boards of similar thickness. It is more convenient to work with lightweight materials. The tamburat is easy to move from place to place, as well as raise it to a height. Thanks to its structure, which includes a honeycomb filler, the board has excellent bending resistance. At the same time, tamburate is easy to process. Plates with outer layers of 8 mm, as a rule, do not require any special fittings. This combination of high strength and low weight allows for an extraordinary variety of applications, from shelving with large overhangs to seating furniture and benches.

Transportation savings

You can save on material and transportation costs. Due to the low weight of the slab, vehicle depreciation costs can be reduced. Or accommodate 35% more material.

Environmental safety of the material

The manufacture of tambourate requires 60% less wood than the production of particle boards. Such savings are achieved thanks to the core of the Eurolight board, which is made of cardboard in the form of a honeycomb.

Built-in technology

Gone are the days of exposed wiring. The era of integrating electrical appliances and equipment into furniture has arrived. Thanks to the sandwich-type structure of the boards, all cabling can be done in the middle layer of the board, which is a honeycomb core. Lighting, sockets, chargers, speakers and even iPod docking stations can be built into the core of EUROLIGHT slabs. This opens up many new design options.

High value

The latest trends in interior design require the use of thick materials, thereby emphasizing the modernity of the design and the high quality of the materials. In an increasingly competitive environment, it is important to offer customers undeniable value at a competitive price. Lightweight tambourate has a modern design and is an environmentally friendly material that is easy to process and can be used in various fields.

offers 3 plate options:

- Uncoated slabs. The high-quality surface of the chipboard, from which the outer layers are made, is perfectly covered with laminates or veneer. The range of laminated paper decors includes more than 200 items.

- Ground coated slabs. These boards help to implement any non-standard color schemes, thanks to the varnish coating of the boards with a primer coating. This system allows you to varnish slabs, for example, in the customer’s special corporate colors. You can choose the color according to the RAL, PANTONE or NCS systems. We recommend using waterless polyurethane varnishes DD, PUR or water-based varnishes. Plastic edges with a thickness of 2 mm are suitable as edgebanding material. They are easy to sand and varnish.

- Standard decors. The outer layers are lined with high-quality decorative paper. Apart from applying the edge, no other surface treatment is required.

140070, Moscow region, Lyubertsy, slave. village Tomilino, st. Garshina, 26B

Tamburat: characteristics of honeycomb furniture boards

- Advantages of tamburat

- Slab options

- Application

Tamburat is a construction material consisting of two outer sheets and a filler. The outer layer can be made of wood-containing material or plasterboard with surface veneer. The middle is made of hard cardboard and is placed in the form of a honeycomb with dimensions ranging from 15 to 25 mm. Tamburat does not have specific dimensions. Manufacturers provide different sheet sizes. Thickness - from 30 to 240 mm, length - from 2400 to 3000 mm, and width - from 600 to 1300 mm.

UNIVERSAL

Light furniture board or TAMBURAT is used for the production of almost any furniture. These are kitchen sets and children's furniture, all cabinet furniture, shelving structures of all types and wall shelves, furniture for public spaces and much more. Panels from TAMBURATE can be used for zoning space and erecting interior partitions, including sliding ones. Furniture from TAMBURAT, thanks to a wide range of decors, can be combined with any interior.

Versatility is evident in everything. Both in application and in material processing. Processing TAMBURATE does not require special equipment. Technologies make it possible to produce parts not only of curved, but also curved shapes.

Thanks to the existing fasteners, it is not difficult to equip furniture made of TAMBURATE, like any ordinary one, with guides, retractable baskets, pantographs and other mechanisms. When using TAMBURATE with embedded strips or with outer layers of 8 mm or more, standard fittings for chipboards are used.

Advantages of the material

The idea of boards with a honeycomb structure was proposed back in 1943, but only 20 years later it was implemented in the furniture industry. The next step for manufacturers is to select a filler for this material, and soon a tambourate with a honeycomb of compacted cardboard is created.

Tamburat has just begun to gain popularity . This is connected to the qualities of the material. The advantages of these slabs are their hollow design.

Ease of processing: tamburate is simply cut with any tool; parts of various shapes and difficulties can be made from it.

The possibility of hidden installation, because the cardboard core of the slab allows you to construct hidden wiring and hide fasteners inside the slab. Furniture made from vestibule does not lose its appearance and gains functionality. Hidden wiring is convenient in the production of computer tables or office furniture.

Fastening materials. Accessories for tambourate have the same characteristics and system as similar raw materials. Selecting fastening parts will not cause difficulties. But the thinnest sheets require the use of built-in fittings, which must be ordered from professionals. The uniformity of fasteners allows you to fasten tambourate with other common materials, for example, chipboard or laminated chipboard.

UNIQUE

Due to its specific hollow design, TAMBURAT is unique in its simultaneous combination of two qualities - strength and lightness. TAMBURAT expands the possibilities of furniture manufacturing and creates the visual effect of a thick-walled solid mass.

It requires less effort during transportation, carrying and installation compared to solid materials of similar sizes.

The low weight makes it possible to create suspended ceiling structures, and installation of dimensional products becomes possible on various walls, including those with weak load-bearing capacity.

IN TAMBURAT it is possible to carry out hidden wiring and even lay communications in the middle layer - the honeycomb filler. This is convenient when arranging various accessories and equipment in modern furniture. Now it is easy to place sockets, lamps, chargers and even speakers in the panel. TAMBURATE are also made hidden . The shelves look especially impressive.

Fiberboard, LDPS, MDF, tambourate: pros and cons - comparison of sheet materials

Today we will go over the materials from which cabinet furniture is made, consider what they are made of, their strengths and weaknesses, and the main areas of application.

The conversation will focus mainly on sheet materials, from which parts of the required size and shape are subsequently cut.

So, let's start with the most common material in recent years - chipboard (chipboard), or rather, its modification LDSP (laminated), that is, covered with a decorative layer that imitates the texture of wood. It is produced from wood waste by high-temperature pressing with the addition of phenol and formaldehyde binders.

Decorative layers can be represented by laminate (polymer decorative coating), melamine (paper impregnated with melamine resins - laminated chipboard), veneer (natural coating made from thin sheets of wood).

Visually, laminated and laminated chipboard are no different, but the latter has significantly worse performance properties - the melamine coating is less resistant to mechanical damage (even with regular wiping with a dry cloth, the decorative design wears off and is easily scratched), the water resistance of such a coating also leaves much to be desired. Veneered boards have recently been found quite infrequently, which is due to the labor-intensive manufacturing and edging process, and, therefore, the cost.

Article on the topic: How to make furniture for petshops with your own hands

Slabs of the following thicknesses are produced: 8mm, 10mm, 16mm, 18mm, 22mm, 25mm, 28mm, 36mm (but by combining them, by joining, you can achieve other sizes).

Advantages and disadvantages

The strengths, first of all, include the price and availability of this material. It is easy to process, quite durable, and its strength is the same over the entire surface of the sheet. A wide variety of decors, including exotic ones, also attracts attention to it.

But there are also significant disadvantages, such as poor moisture resistance (when in contact with water, the material swells, although moisture-resistant varieties of laminated chipboard are also available), and under prolonged static load (for example, a bookshelf), the material is deformed. In addition, such material evaporates formaldehyde vapor from its surface, which is quite toxic (based on this feature, slabs are divided into emission classes E0.5; E1 and E2 - the latter are practically no longer found). In laminated chipboard, fasteners do not hold well, especially nails and paper clips, which are often used to secure the back wall. During the manufacturing process of parts, additional edge processing is required. And finally, decorative milling cannot be done in laminated chipboard, because... in this case, the thin decorative layer is damaged and an unsightly layer of sawdust is exposed.

Laminated chipboard is used for the manufacture of almost any furniture elements (boxes, facades, countertops, and even back walls).

The second most popular sheet furniture material is fibreboard (or rather DVPO - refined, that is, with decoration). In the production of this material, wood fibers are woven into a kind of carpet during the hot pressing process, due to which unique mechanical properties are achieved. At the same time, on one side the slab is smooth with decor applied to it, while on the other side the wicker structure is preserved.

As a rule, these are thin sheets 3 mm thick, although other thicknesses are also found (up to 5 mm, even with double-sided smoothness - I personally have not seen them).

Advantages and disadvantages

The most important thing about this material is its lightness and elasticity at a cheap price. Moisture resistance also differs for the better (compared to laminated chipboard).

The disadvantages include low strength, inability to use in load-bearing structures, one-sided decor.

Article on the topic: DIY roombox furniture

As a rule, this material is used as a back wall, fixing furniture boxes in the transverse direction, and as a bottom for drawers. In addition, due to its flexibility, it can be used in the manufacture of bent elements (for example, bends in reception posts).

In addition, I use small pieces of fiberboard (3 mm) to open the gap when installing fronts on drawers - it is very convenient to maintain a three-millimeter gap.

MDF (Medium Density Fiberboard) is essentially a further evolution of fiberboard. It is also obtained by hot pressing of tiny wood fibers bound in a special way. Lignin, which is released when wood is heated, is used as a binder.

The MDF sheet itself has an unimportant appearance, but after coating (the most common are shrink film and auto enamel) it looks simply great, there are a large number of glossy decors.

Advantages and disadvantages

MDF is an excellent material for furniture production: it is very durable, surpassing in strength not only laminated chipboard, but also many types of wood. Moreover, unlike wood, it is equally strong... The second advantage is moisture resistance - it does not swell in water. Due to the equal density of the entire thickness of the slab, as well as the subsequent decoration of parts (film or enamel), there is the possibility of decorative milling (that is, cutting out volumetric inscriptions of patterns, etc.). And, finally, there is no evaporation of harmful substances that are simply not used in production.

There is essentially only one drawback - the price.

Due to its advantages, this material has found its main application in decorative elements: facades, various patterned overlays, etc., as well as in the production of bathroom furniture.

TECHNOLOGICAL

- sawing,

- applying edge material,

- additive,

- lining with PVC films or laminated plastics,

- veneering with natural or synthetic veneer,

- milling,

- painting.

Optimal for edging would be TAMBURAT with a thickness of outer layers of 8 mm or more, since adhesion at such a thickness will be sufficient to hold the edge on the product. Due to the fact that the center of the edge falls on the void of the slab, only thick edge materials are used, which, due to their rigidity, prevents subsidence into the slab.

There are certain recommendations:

- for a slab with a thickness of 38mm, the minimum edge thickness is 1.5-2mm

- for thickness 50 – 60 mm – 2 or 3 mm

Using an edge of thinner thickness is possible, but only when using embedded strips or a supporting edge.

Implementation

Tamburat has a narrow focus; most often it is used to create furniture. Two methods for introducing this material have been created:

- The first is the introduction of slabs for the creation of large structures. Individually, tambourate is often a substitute for chipboards in open areas of the finished product

- formation of furniture collections that are 100% made from these boards. Such pieces of furniture are easier to create than items made from other wood-containing materials. However, such furniture differs in more unique forms and level of practicality.

Tambour slabs are used in almost all types of furniture. But, for a bathroom this furniture is not the best option.

The thickness of the slab affects the area of its implementation:

- 32mm. Such slabs are used to create interior doors, cabinet doors

- 38mm. Such slabs are ideal for shelving and bedside tables. But the shelves should not be too long, approximately 50 – 100 cm

- 50mm. This material is used to create business class furniture, shelving with long shelves, tabletops, tables for conference rooms, retail and banking equipment. The length of the shelves can be above 1.5 places.

The thickness of the outer layers of lightweight chipboard furniture boards can be 3, 4 or 8 mm. With a thickness of outer layers of 8mm, the processing methods are identical to those for chipboard.

EXCLUSIVE

The latest trends in the design of premises and interiors require the use of thick materials in order to emphasize the modernity of design solutions and the high quality of furniture and materials. When clients require exclusive execution of interior designs, massive-looking but light furniture, impressive work surfaces of tables, racks and shelves with large spans - in such cases TAMBURAT is suitable like nothing else.

Massive furniture in large, spacious rooms looks much more organic than its analogues made from conventional slabs, and the possibility of applying matte, semi-matte or glossy varnish to the front surface makes it possible to produce luxury, premium class furniture.

Tambourate edging

For gluing tambourate parts, PVC edges with a thickness of 1.5-3 mm are mainly used. If Eurolight sheets are covered with 8 mm thick slabs, the edge can be applied using standard technology without any preparatory measures. For all other cases, it is recommended to additionally use a support edge, which is a flexible tape made of foamed ABS, the thickness of which is 3 mm. It serves as a reliable basis for subsequent application of decorative polyvinyl chloride edges to the ends.

Regardless of the thickness of the facing sheets, you should not use melamine edges to finish the ends of tambourate parts. If Eurolight panels have a decorative coating of natural veneer, then strips of similar veneer of the appropriate width are used to cover the ends, and it is advisable to apply the veneer to the supporting edge of ABS. In this case, the lining of the ends of the veneered vestibule is carried out before applying varnish to the front surfaces in order to avoid repeated paintwork.

AVAILABLE

Of the many modern materials used in various design and construction solutions, TAMBURAT as a furniture board is gaining popularity.

This is also facilitated by its low cost. For example, the cost of a full-size frameless slab with a thickness of 38 mm (2800 x 2070 mm), decorated on both sides with a laminated Egger slab in Wenge Aruba color, will be only 5,565 rubles. TAMBURAT accessible by the ways it is used in furniture. All furniture parts can be made from it. Or you can use it partially. For example, only in those elements that are the first to catch your eye, while for other parts use material of a smaller thickness. The external parts of the case create a massive effect, and the internal parts have absolutely no effect on the appearance.

It is possible to supply both whole full-size slabs and parts of sheets. Then the price of the material needed to make the order may pleasantly surprise you. The following additional formats are available (price is based on Wenge Aruba board):

Areal company, Sverdlovsk region, Asbest. Manufacturer of veneer panels and doors

Tamburat (light furniture boards) are lightweight furniture boards.

The production of tambourate is carried out according to the “sandwich” type, where the upper and lower front panels (outer layers) are MDF of various thicknesses, and the middle layer is cellular cardboard (corrugated paper, honeycomb filling), reminiscent in its structure of a honeycomb. Tamburat slab is used for the manufacture of parts of great height or length. It retains its original straight shape well thanks to its rigid frame: tambourate is much lighter than chipboard, so it is not subject to deformation under its own weight. Furniture made from tambourate turns out to be massive in appearance and light at the same time. The thickness of the vestibule is from 32 to 80 mm. Despite its low weight, tambourate has very high strength and thus makes a real revolution in the field of furniture design and interior decoration. Thanks to the board structure, which consists of a dimensionally stable honeycomb core and 3, 4 or 8 mm outer layers, you can use any type of board processing and edge covering.

Article on the topic: DIY furniture from old tires

Advantages of veneered vestibule. The visual effect of thick-walled natural solid wood, a wide range of colors, lightness, strength, durability and compatibility with any fittings, innovative solutions in design and construction. Tamburat, unlike solid wood, does not have the ability to change geometry and clearly retains its shape during use. Application of tambourate.

Tamburat is used in the manufacture of furniture, combined with laminated chipboards and other veneered boards such as veneered wall panels and veneered MDF. In this case, tambourate is used on visible, eye-catching details. For example, when making a sliding wardrobe from vestibule, only the side panels, floor and ceiling are made, as can be seen in some illustrations. It is also possible to make furniture entirely from vestibule. This method is more difficult in terms of execution, but the result is fashionable, stylish, modern, beautiful furniture. Tamburat of various thicknesses in a variety of furniture products: • 32mm. This is a façade board, most often used in interior doors, cabinet doors, etc. • 38mm. Shelves, bedside tables, etc. are made from such slabs. In this case, shelving with a short shelf length. Long shelves made of vestibule with a thickness of 38 mm do not look wide. For frameless slabs with a thickness of 38 mm, the optimal shelf length is 50 – 100 cm. • 50mm. Such boards are used to produce executive-class furniture, shelving with long shelves made of tambourate, table tops, tables for conference rooms, trade and banking equipment, reception desks, coffee tables, etc. With a thickness of 50 mm, the optimal shelf length is from 1.5 m or more. Tamburat edging. When the thickness of the outer layers of veneered MDF is 8 mm, you can use a regular edge (any one except melamine), the use of a supporting edge is not necessary, and if the thickness of the outer layers is less than 8 mm, then its use becomes necessary. The support edge is a flexible 3mm ABS foam strip. It is used as a “base” for decorative edges. Accessories for vestibule. Accessories for vestibules, as well as edging, are divided into standard and specialized. Standard fittings are common fittings that are used for MDF. Its use is only possible for vestibule with a thickness of outer layers of 8 mm. Specialized fittings for vestibules are primarily used when the thickness of the outer layers is less than 8 mm, but they can also be used with vestibules with external layers of 8 mm to ensure additional reliability of the product.

Article on the topic: How to make furniture in Minecraft

If you have any questions or would like to purchase veneered tambourate, please contact us. We are always glad to see you!

Delivery to Yekaterinburg is FREE!

We have a special offer for designers! Find out by phone: +7 903-086-44-92