A horizontal wooden fence is the type of fence that people have been accustomed to using for many years. Natural wood has always been used to build fences. The properties and structure of the material, as well as its long service life, make it possible to use this material for the construction of a capital structure.

At the moment, there are all kinds of options for building materials in order to make a wooden fence, which will be no worse than a European picket fence. The purpose of construction is to protect one’s possessions from prying eyes and unexpected visits. You can install the fence yourself by choosing the appropriate version of the original design.

Pros and cons of a fence made of boards

Like any design, such a fence has a number of advantages:

- Simplicity of work - even a beginner without experience can cope with such material;

- The wood is safe, so the work will not cause harm to the human body;

- Installing the fence, depending on its size, will take about a day;

- Can be used on any type of site, including as a limit to the terrace;

- The area will be ventilated due to holes in the fence, but at the same time it will be protected from uninvited visitors and prying eyes;

The material can be not only fresh, but also old, the main thing is that its quality remains at the highest level.

There are, of course, disadvantages to using wood in construction:

- Such a fence can last a maximum of 10 years. Even if pre-treatment with a special composition was carried out, the service life still remains short. Over time, it begins to deform under the influence of precipitation;

- The new material can be very expensive, especially in those regions where there is no forest of its own, and wood is imported from afar. Alternatively, you can replace it with lumber, which will be cheaper;

- Processing of the material is necessary not only in preparation for installation, but also at intervals of approximately once every 3 years.

Advantages

- Simplicity and ease of installation, suitable for a beginner.

- The material is environmentally friendly and does not cause harm to the health of the owner and family members.

- Examples of possible installation options are so varied that a horizontal fence will be a wonderful decoration and addition to a private building.

- With the right approach, installation will take no more than a day.

- The fence protects the owner from prying eyes, and there are no barriers to the penetration of clean air.

- Installation is possible from different types of wood, the main thing is that the quality is appropriate.

Does this fence suit your site design?

YesNot sure

Types of fences made of boards

A fence made of boards can be different. Each type has its own characteristics, installation method and other parameters.

Most often the following fencing is installed:

- A picket fence is the simplest option; in this case, edged boards are used. It is nailed to the joists, leaving space between the elements. If you don’t do it at all, such a fence will not look very neat;

- Checkerboard type - due to this design, the area remains completely closed, but at the same time the wind calmly passes among the boards. Can be vertical or horizontal. In the first option, each element covers the previous one by one third, the veins are placed horizontally, and the boards are attached to them. In the horizontal, everything goes the other way around. The fastening is vertical, the place for fastening can be made of solid boards;

- The design in the form of a ladder assumes an inclination. The elements are made at an angle, with each new one overlapping the previous one. This option will look very interesting from the outside of the site. Like a chessboard fence, a ladder-shaped fence will appear continuous, while at the same time the area will be freely ventilated;

- You can also build a fence where the elements fit tightly together. For these purposes, it is imperative to choose smooth and straight boards so that there are no gaps left. Sometimes this causes difficulty, and besides, such wood will cost more;

In the form of a wattle fence - planed boards are suitable, it will create an imitation of wicker material. Looks beautiful and original;

In the form of a herringbone - reminiscent of a staircase type, the boards are attached horizontally to the joists.

Support structures

The quality of the fence largely depends on the supporting structures. They are different.

Metal pipes

They are pre-primed and painted. This will protect the material from corrosion and make it more durable. A hole is dug so that the pipe enters about a third of its length.

After this, the soil around it is carefully compacted, the bottom can be filled with crushed stone, and the top is filled with concrete mortar for reliable fixation;

Concrete pillars

They are as durable as metal, and do not need to be painted;

Wooden pillars

Careful preparation is required before installation, because the material is subject to change from external factors.

- The pole, just like a metal one, should go into the ground a third of its length.

- Before this, the bottom, which will be in the ground, must be treated with liquid bitumen for protection.

- Then you need to place the roofing material down, and treat the outer part with products to protect against moisture penetration and mold. The top is also closed.

Photo gallery

In our photo gallery you will find many ways to design wooden fences that will suit different styles of landscape design.

It’s up to you to decide which fence option to choose, whether to make it yourself or order assembly from specialists. The main thing is that the resulting structure becomes a strong protection and decoration of the site.

What boards can be used

There are several wood options that are suitable for construction:

- Unedged material is inexpensive, but its appearance is not so aesthetic. If you need to install an inexpensive and quick fence just to enclose an area, this is an excellent option;

- Edged - suitable for any type of fence, it will be more expensive than the first option;

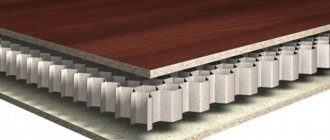

- Lining - the material is prepared for installation, because there are both recesses and protrusions for fixing to each other. The connecting elements are very thin, so careful processing is required;

- Artificially aged material - made in such a way that the structure of the wood is visible. Made from unedged type;

- Terrace - a combination of polymer, wood flour and various modifiers. Looks beautiful and lasts a long time;

- Decorative elements - the ends are carefully processed, the outer surface can be decorated with carvings.

How to install a fence yourself (step-by-step instructions)

The work is carried out in several stages:

- First, you need to prepare all the necessary material so that during the work you will not be distracted by searching for the right element. Before this, you need to make preliminary calculations about how much and what you will need. Unedged material still needs to be cleared of bark at least minimally, this will give it a more aesthetic appearance, and it will also last longer, the bark will not rot. The picket fence is cut to one length, the top must be cut off at an angle, after which the material must be coated with an antiseptic, and only then varnished, if desired;

- Marking the territory - after the material is ready, you need to place pegs around the perimeter, and then stretch a cord between them. The pillars are placed at a distance of 3 meters from each other; with a continuous covering, the distance is reduced to 2 meters. Thanks to this, the fence will not sag and will stand straight;

- Next you need to put up the pillars. Depending on the material, appropriate processing must be carried out, as mentioned earlier. If the pillars are made of concrete, you need to wait until they completely harden before proceeding to the next step. To attach the logs to them, you will first need to install plates;

- Then the veins, or logs, on which the covering will be attached are installed. Edged and unedged boards are suitable for this. For a standard fence up to 2 meters high, you will need 2 wires per span. If it is higher, 3 veins are installed for stability. The same calculations apply to horizontal installation of planks;

- The final stage is fastening the material. The board is attached to the veins in at least two places. For fastening, use self-tapping screws or ordinary galvanized nails. There should be 5 centimeters left from the ground below, otherwise moisture will quickly damage the material.

DIY installation

Construction stages:

- Buy lumber . There can be from 13 to 83 boards in 1 cubic meter. This number depends on the thickness and width of the edged board (the higher the value, the fewer pieces per cube).

- Buy pillars . For wooden fencing, metal strips or beams/logs (section 50x50 or 75x75) are perfect.

- Mark the area using pegs (every 1.5 - 2 meters) and a well-taut rope . The frequency of driving in pegs depends on the type of fence.

- Process the boards (plane, sand, make a profile, etc.).

- Drill holes for the posts . The pegs must be removed and a hole (50-90 cm) must be drilled in their place. Lower the fence post into the hole and cover it with crushed stone, construction waste and earth. For greater strength, concrete is sometimes used. You can level the supports using a plumb line and level.

- The pillars are fastened together with ties (metal or wood). An edged board can be easily attached to such a frame using bolts, nails and self-tapping screws.