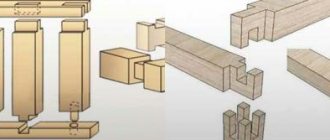

The wood material used for the construction of environmentally friendly buildings has a complex geometric shape with special cuts in the form of ridges and grooves and sawn holes for dowels, which are clearly visible on the flower-shaped cut.

A house made of vertical timber differs from the traditional classic version of wooden buildings in terms of manufacturing, assembly, operational characteristics and the external appearance of the facade, where the material is laid in a vertical rather than horizontal position.

What are the features of such houses, construction rules, feasibility of their construction, assembly technology and other nuances, we suggest you learn from this article.

Description of lumber

The peculiarity of houses made using vertical timber, in contrast to traditional log huts, is that with a special geometric installation arrangement, the wood material acquires additional strength and is well fastened to each other in the side grooves .

The timber itself is manufactured only in the factory using special equipment, and has different length standards - from 2 to 12 (m). But most often, for construction in the central zone of the Russian Federation, products with dimensions of 200 x 200 x 6000 (mm) are used, and in the northern regions - 250 x 250 x 6000 (mm).

The wood material used for vertical construction has a special cross-sectional shape - the sawn edges resemble a flower. On each side of the beam section there is a recess for dowels - specially made long wooden nails with dimensions of 22 x 22 (mm), which help fasten the products together.

A wide variety of tree species are used for vertical beams, it can be:

- oak,

- beech,

- larch,

- pine,

- spruce.

Cedar material is very popular. It is considered the most expensive compared to other breeds, but its aroma will remain in the room for many years, which is considered beneficial for the respiratory system of people at any age, as it releases essential oils.

A vertical beam, made in the form of an W-shaped plank, adheres well to various substances, can be easily processed with tools, and is often used in conjunction with other lumber, the dimensions of which may vary in width and height.

An important feature of the products is that they are used in a not completely dried state . Drying under natural conditions promotes stronger closure of the seams between products in a wall structure made from this type of timber.

Such high closure from the penetration of atmospheric air and wind helps to create a moderate microclimate in the room, in which it will never be too hot or cold. Therefore, many experts compare the compaction of a vertical beam over time with a monolithic one.

At the same time, the timber itself does not shrink, although it is considered somewhat heavy for the foundation , in comparison, for example, with laminated veneer lumber.

Windows and doors in houses made of vertical timber will never move or lose their geometric shape. And finishing work can begin immediately after the beams are installed.

The technology used for vertical lumber makes it possible to make a wall structure of any thickness, while all houses will look very attractive in any chosen style solution.

Disadvantages of such a house

The most important disadvantage is the duration of shrinkage of the constructed frame. This may take several seasons, only after this can the building be covered with a roof. However, shrinkage of timber takes less time than shrinkage of rounded logs. If the owners are in a hurry, you can purchase laminated veneer lumber, but fumes from the glue can affect your health, especially if there is an allergy sufferer living in the house.

When building from timber, it is necessary to impregnate the wood with fire retardants under pressure, then the wood will be protected from the effects of fungi, mold and insects.

Feasibility of construction

It is definitely worthwhile to build houses from vertical timber, since the construction technology of the building allows the use of various design solutions related to the number of storeys and the height of the walls.

According to established standards, it is allowed to build 1, 2 and 3-story houses with different wall configurations from vertical timber. At the same time, year-round construction of houses in any climate zone is permitted.

Companies engaged in the manufacture and installation of timber offer the purchase of both ready-made wall structures, with openings cut into them for windows and doors, and wholesale sales of finished lumber, the installation of which is carried out at the address specified by the customer. The cuts that are on the surface of the beam firmly connect all the structural elements together, like a Lego constructor, which facilitates the assembly process.

The walls of a vertical house

are not subject to deformation, do not shrink or crack , even with a load-bearing load of 3 floors.

Typical projects may include standard buildings with attics, balconies, terraces, with external and internal finishing made of coniferous wood, as well as those made using combined technology (using different types of wood material in the project).

When assembling timber, there is no disadvantage of all classical log houses - there is no need for additional sealing of the seams with insulation, as well as inter-crown heat insulation. Also, the air gap between the layers of the wall (natural ventilation) is minimal (up to 20 mm).

In wall installation, tongue and groove elements are used . The thickness of the walls is 20-40 (cm), the structure itself has good thermal performance. And the corners are built even, without overcuts.

Despite the fact that it is impossible to build houses from vertical beams with your own hands (mechanical devices and transport are used), a team of builders can assemble a vertical beam in the shortest possible time. At the same time, if the foundation is ready, the time frame for completing all turnkey work can be 3-4 months.

There are different types of vertical beam processing technology (WOOD BRICK, TWIN BEAM,). In the Russian Federation, the NATURI type is very popular , based not only on increasing and improving strength characteristics through special processing, but also preserving the environmentally friendly properties of wood.

The video will tell you about houses made of vertical timber:

Fastening technology: soft method

This method is used using U-shaped staples. The method has both advantages and disadvantages. The main advantage of soft fastening of timber to the wall is the speed of operation, the disadvantage is the unreliability of fastening the frame, the structure can collapse over time.

Among other disadvantages, the fragility of the timber is noted: the frame can be easily damaged by accidentally hitting it. Therefore, it is worth thinking about before you decide to do this work. However, there is still a solution: if the elements are laid to finish the walls from plastic panels, then, as a rule, no deformations are observed. It should be taken into account that the paneling of the panels with a wooden frame is carried out perpendicular to the panels of the element themselves. On the lower part of the wall, timber is laid more often than in the upper area. As a rule, fastening the timber to the wall to a height of up to 1.5 m is located every 0.4 m. Above this mark, the distance becomes larger and can be 0.6-0.7 m.

You can do this work yourself. Installation of the frame does not require any special skills in the field of construction; it is only important to follow the instructions exactly.

Requirements

High-quality wood processing is the key to successful construction. Well-prepared timber is not afraid of changes in atmospheric air, and does not deform when in contact with a humid environment.

The main requirements of vertical lumber include the following important factors:

Processing of products cannot be done manually - only factory processing in industrial conditions using specialized equipment is allowed.- Careful sorting of timber before starting to process products.

- Compliance with strict geometric shapes and specified dimensions for the project.

- Perfectly carried out drying, but not more than 12% of the total humidity indicators.

- Absence of nicks, cracks and knots on the surface.

- Prepared holes for dowels and W-shaped coupling of all wood parts in the wall structure.

- The production of pillars for the corners of the building should be done in such a way that it is convenient to carry out the strapping, on which the timber will then be laid.

For houses with vertical lumber, a strip foundation is most often used. But if the site of the house is located on a swampy area or heaving soils, then it is best to build the house on a slab monolithic foundation. It is necessary to know that after the construction of a monolithic foundation, the foundation itself must shrink within a year.

On any foundation, before screeding the floor with cement-sand mortar or installing wooden floors, double waterproofing (for example, roofing felt sheets) must be laid.

Bracket mounting

When building a house, you can use different beam-to-beam fastenings. The easiest option is considered to be connecting wooden parts with simple staples, joint to joint. A minimum of time is spent, but this method has its drawbacks. Significant gaps will form in the corners of the structure, which will then have to be sealed by caulking the corners.

You will also need to purchase a large number of connecting brackets and corners of various configurations. This is also an extra expense, and the appearance of the wooden blocks deteriorates - not every owner wants to see metal fasteners. So the choice of attaching beams to beams with corners is a matter of taste.

Rules

The basic rules that apply to houses made of vertical timber follow from the technical standards that are used in construction, the main ones being:

- GOST 8242-88 – all about wooden lumber and parts;

- GOST 30974-2002 – corner connections of wooden low-rise buildings;

- GOST 11047-90 – wood products and parts for residential buildings;

- GOST 21779-821 – ensuring compliance with geometry in construction;

- SNIP 2-25-80 - all about wooden structures.

All of the listed regulations refer to other GOSTs, which relate to work from the moment the site is prepared for construction and the execution of earthworks, until the complete completion of construction.

Important rules with which the construction of a house begins also concern the following nuances:

It is necessary to decide on a project and draw it up, taking into account personal wishes, from the engineers of the construction company.

The project indicates the scheme of work and barriers, draws up a step-by-step plan, calculates the amount of required material, and draws up an estimate.Often companies that will build a house offer to complete the project for free. It can also be done in an architectural bureau in your region. The project must take into account the type and level of soil freezing, the location of groundwater, the proximity of communications, and the seismicity limit.

- Then you will need to obtain a building permit from local government authorities. You can contact the MFC (BTI department). Construction companies can also help with the design of the future home and the entry of the construction site into the state register. The main thing is to draw up an agreement providing guarantees for the work performed.

- After this, it is necessary to clear the area of debris and fertile layer, perform precise markings and begin excavation work to form the foundation.

- Once the foundation is completely ready, the installation of the vertical beam can begin.

An important rule that must be followed when constructing a wall structure is the use of high-quality, moderately dry material to ensure sufficient adhesion for the strength of the building. The minimum thickness of the timber used is 180 (mm).

First, boards with holes for the dowels are laid on the foundation, then the dowels themselves are inserted into them, and only then the beams are installed, which are additionally fastened along the horizon line. For horizontal fastening of the ends, dowels made of high-quality wood are also used.

Dovetail

One of the most reliable and strong connections is considered to be the “dovetail” or “warm corner”. A trapezoidal groove is cut into the beam on one side, reminiscent of a swallow’s tail, and a tenon is cut out on the beam on the other side, into which the edge of the first beam will be tightly inserted. It is not easy to assemble such a structure; professional carpenters can handle this work, but the connection is very warm, especially if it is used at the corners of the house.

The fastening turns out to be closed on all sides and the wind does not blow into the cracks, which is why it was given this second name. The work of laying beams using this method is labor-intensive, but the result exceeds all expectations, which is why this type of fastening is considered a leader in the construction of wooden houses.

Step-by-step instruction

After completing all design, permitting and preparatory work, the steps of construction work include the following nuances:

- The selected foundation must be covered with waterproofing in 2 layers. This is required to prevent moisture from entering the wooden structural elements.

- They install the prepared corner posts and make the lower and upper trim. Compliance with geometric lines is controlled using construction devices (plumb line, level, tape measure, cord).

The bottom row of timber is a backing board, which is laid in 2 even rows, in which holes are drilled for dowels.

Here, be sure to check the diameter of the dowels and holes for easier and faster installation.- The top frame made of lumber must be fixed on timber supports, which, according to the design, are made at a certain distance from each other.

- The uprights of the vertical beam must be connected using dowels on all sides. To do this, make 2 fasteners at the top and 2 at the bottom, and the joining points are covered with curly strips.

- The outer cladding of the installed wall structure is arranged as desired. For this purpose, various wood materials are used. An insulating layer is also applied if necessary.

- Then they begin to arrange the interior walls, roof or the next floor (installation of the structure using load-bearing strong floor slabs, structures for the roof, backfilling and filling the distance between the logs, installation of the selected roofing material).

- Lastly, doors and windows are hung, stairs and a blind area for the house are made, with mandatory drainage.

- Internal finishing and installation of communications is the last stage of construction.

During operation, the timber can be treated with antiseptics and special environmentally friendly polymers that increase the durability of the wood. This procedure can be carried out several times.

The beams in the corners must be connected using main tenons. You can use weatherstripping in the corners, but this is not necessary.

Where is this type of connection used?

The scope of application of units where wooden beams are adjacent to a brick wall is extremely wide. Most often this type of connection is used for the following purposes:

- secure furniture, household appliances or interior elements;

- for installation of wooden partitions;

- to place doors in the opening;

- for internal or external insulation, where the sheathing of bars plays the role of a frame;

- to hang a canopy over the entrance to a house or in another place;

- for the construction of an extension to the building (vestibule or veranda).

When it is necessary to fix interior items on the wall, a wooden beam is applied flat to the surface and fixed with fasteners. So it is able to carry a significant load. The greater the magnitude of this load, the more attachment points to the brickwork must be provided. The same rule applies when installing a partition, only the starting beam is installed vertically.

The door frame is constantly experiencing dynamic loads, so it is secured to the brick with a particularly reliable type of fastening elements: anchors. They are also used when installing various canopies that experience snow and wind loads.

When insulating brick walls externally or internally, a sheathing (frame) is assembled from the bars, which is the basis for installing the cladding: vinyl siding, drywall, plastic panels and other materials. In this situation, the tree experiences minimal mechanical stress, which is why it can be fastened with dowels for quick installation.

To build an extension, a reliable structure is required that can support the roof with all the ensuing consequences.

In this case, the wooden beams act as load-bearing beams and are adjacent to the brickwork at an angle of 90°. There are several ways to successfully rest them on a brick and securely fix them.

Advantages and disadvantages of construction

The important advantages of houses made of vertical timber are:

- construction in the shortest possible time;

- ideal microclimate for living, without drafts, heat and cold;

- no need for additional laying of thermal insulation material - the house will be very warm and cozy;

- environmentally friendly materials used + long-term release of essential oils in the room, which has a therapeutic effect on human health;

- good adhesion to various materials used in installation;

- strength, strength and durability of the structure;

- excellent protection from extraneous noise and sounds;

- the ability to use various design options and construction styles;

- finishing and moving in immediately after the structural construction of the walls;

- distributes the load-bearing load, but without shrinking the structure itself.

Experts identified the following as the disadvantages of the products:

- the high cost of the material due to the complexity of processing;

- the impossibility of reusing all structural elements, since the house is practically impossible to dismantle, which causes difficulties if repairs are needed;

- a large load on the foundation, so it must be technologically ideal;

- DIY assembly is difficult.

Despite the existing shortcomings of a house made of vertical timber, its construction is a fairly expedient solution. It is best to entrust the construction, in compliance with all technological norms and rules, to an experienced team of specialists placed at the disposal of the future owner by the construction company.

Installation methods

In order for the individual structural elements to be firmly connected, it is necessary to use additional installation means. These are nails and bolts, metal and wooden pins, wood grouse and angles, staples and wooden tenons. Each method has its own characteristics. When using metal mounting connections, care must be taken to impregnate the metal so that inevitable corrosion does not later appear on the wood, for example, when attaching timber to timber with bolts.

When installing the first row on the foundation, anchor bolts are used to mount the timber to the T-shaped head. Before laying out the initial level, you need to have wooden parts that are well dried and soaked in antiseptic. The crown layer should be the basis of the entire house so that the frame does not deform.

Possible errors in the process

Various difficulties during work can arise only in the following cases:

Carrying out construction without a developed project, “by eye”.

It is clear that the entire process in this case will be “woven” from errors in technology throughout the entire process, which will lead to complete inexpediency of the work performed and geometric deformation of the building.- Incorrectly selected type of foundation, poorly performed work with it, without taking into account the characteristics of the soil and groundwater in a particular area. In this case, there will be a distortion in the structure, which will be very difficult to eliminate, and the floor in the room will be constantly wet.

- Incorrect installation, piping, compensation cuts, sealing joints, arrangement of floors, etc. Only experienced specialists can accurately perform work with vertical beams.

- Insufficiently treated timbers with antiseptic. They can cause the appearance of fungi on the surface of the timber.

- Non-compliance with the declared technology by the manufacturer. Installation difficulties may arise during the construction process. Here it is recommended to check the available product documentation from the manufacturer, warranty and quality certificates.

If people make offers about the low cost of timber or offer exorbitantly inflated prices for lumber, it’s worth thinking about it, since cheap or very expensive products may not be of the best quality. You can check their compliance using the Russian product nomenclature.

Use of wood grouse

A capercaillie is a metal rod with an external thread. The head is a square or hexagon. After screwing into wooden beams, wood grouse form an internal thread there. They are taken in cases where significant pressure is applied to the products fastened in this way. Such connections can withstand enormous loads much stronger than any screw.

When installing such products, a hole is drilled that is smaller than the diameter of the wood grouse, up to approximately 70%. The length of the hole should be a little longer so that the rod does not break under pressure, especially when it comes to hard wood. Screw them with a wrench into the wood itself or into a dowel. The fastening of timber to timber with wood grouse is very strong and reliable.

Expenses

Construction costs in the Russian Federation largely depend on the region. So, for example, in Moscow Region and St. Petersburg, they are always more expensive , which can be seen by studying the official websites of construction companies that indicate services in the form of formal price lists.

On average, a one-story spacious house for a family of 4 people costs from 2 million rubles. This includes complete turnkey construction, from the moment the project is formalized and permits are obtained.

Large houses with a total area of 190 m2 are equal to 3 million, and 245 m2 officially reach 3-3,600,000 rubles. Some websites separately describe the services for installing vertical beams, with consumables provided starting from 59,000 rubles per 1 m2. Dry timber standard 100 x 100 x 6000 (mm), presented in the form of 4 pieces per 1 m3, costs from 10,500 rubles/m3.

Installation of vertical parts

The vertical posts of the building frame are installed in several different ways:

1. Staples (as shown in the photo).

2. Strapping using a notch (full or half timber).

3. Metal corners.

4. Corner posts (miters).

Attaching the beam to the beam vertically must be perpendicular and stable so that the frame of the house has a strong foundation.

A full notch connects the parts by cutting half the thickness of the bottom beam. Its width corresponds to the thickness of the vertical post. If the connection is half, then make a cut on horizontal and vertical beams.

Less effort is expended when installing vertical posts using metal corners. There is no need to make many cuts and measure their accuracy. But you will have to spend a certain amount on purchasing corners.

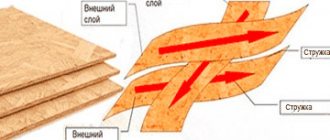

Timber splicing

The need for longitudinal connection of parts appears when the size of the room exceeds 6 meters. The binding is performed using different methods of cutting joints. They do it one by one, first on one side of the row, and in the next row they connect the beams on the other side. This alternates constantly. By tying it in a checkerboard pattern, the stability and strength of the wall will be better, and the appearance will be more aesthetically pleasing.

Whatever shape the joint is used, it must be perfectly smooth, soaked in antiseptic and slightly dried. When joining parts, do not forget about flax fiber insulation. Severely overdried parts can subsequently form cracks.

When building from profiled timber, the best connections would be an oblique lock, as in the photo, and a tenon tie. If you do the work diligently, the house will turn out not only reliable, but also very attractive in appearance.

- Features and methods of fastening

- How to attach timber to the foundation? Attaching to a slab foundation

- Attaching timber to strip foundation

- Attaching timber to a pile-type foundation

- How to carry out work on tying the foundation of a construction site with timber?

- What is the process of tying foundation piles with timber?

If you are planning to build a log house, one of the main issues that you will face at the very beginning of construction is how to attach the timber to the foundation of the future building. After studying the materials presented below, you will be able to get an answer to your question and competently complete the subsequent work.

It is very important to correctly connect the foundation and the first row of timber.