The basis of a wooden house is a log house, which is a box assembled from prepared logs or timber. The logs, fastened together in the corners with cut-out “locks,” are laid in horizontal rows, each of which is called a “crown.” In order for the logs to support the weight of the structure, the log production technology must be strictly followed. Ensuring that the contacting elements fit as closely as possible is the main task of builders when assembling a log frame.

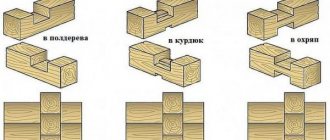

Knowing the basic nuances and features of various types of log joints will help you make the right choice. The technology for cutting a log house from timber and logs differs in the way the corners are arranged, otherwise the rules are the same.

Log joining method

Since ancient times, baths were built only from logs, and therefore the technology of their connection is quite ancient and proven over centuries.

And logs can be joined in two main ways - without a remainder and with a remainder. In the first case, the corners of the bathhouse will turn out to be perfectly even, but the second method looks much more beautiful - when the logs protrude slightly beyond the wall, which, of course, looks much more beautiful. But it also turns out to be more expensive - after all, you will have to use half a meter more logs than in the first method. Although the corners “with a remainder” are much better protected from rain and wind and are much more stable.

So, the logs are combined with the rest in these four options.

"Into the cloud" or "into the bowl"

The “in the bowl” method is the simplest and most ancient. To do this, you need to cut out a round bowl at the top of the log - which is what “oblo” means in the ancient language. A transverse log with the same bowl is placed there. Moreover, this can be done in three more options: in a fat tail, in half a tree, and in the form of an oval comb.

Since ancient times, baths have been built using the “half-wood bowl” method - this is the simplest method. And in order for the laying to be dense, an additional longitudinal groove is cut out in the upper part of the logs - a laying groove. It is also filled with insulation (flax wool more often) and a second log is placed on top. And in order for the wall to be stable, during assembly, each stacked log is connected with a dowel to the bottom one - this is a wooden dowel of rectangular or round cross-section.

Cutting into the fat tail is the most difficult. In addition to the special ridge, an additional protrusion is made at the very bottom of the bowl, which is located along the log and exactly across the bottom of the bowl.

In the third option, the logs are connected to a landslide-shaped ridge - it must exactly repeat the outline of the laying groove, therefore it is cut not from above the log, but from below - such a log house can withstand even strong winds.

“Into the clap”, or “into the Siberian bowl”

This method is similar to bowl cutting, only now it is cut at the bottom of the log. Those. the log seems to roll onto the prepared corner and slams the lower crown, which is why they say - slam.

"To the brink"

Cutting “in the okhryap” differs from the okhlop in that special straight notches are made both at the bottom and on top of the log - exactly a quarter of the diameter. Essentially, this method falls somewhere between regular angles and paw angles.

"Into the paw"

Cutting “in the paw” is, in fact, the same as “in the paw” - only here the logs that protrude beyond the plane of the wall are deprived of the end part. This way the angle itself is obtained without any residue, and in order for the entire structure to be reliable, special sockets and spikes are left at the ends of the logs - cut. True, such a wall will have a lot of ventilation, and therefore during its construction it is necessary to make the horizontal planes of the cut inclined - in two directions at once. This will already be called a “dovetail” - i.e. the spikes between adjacent logs are firmly interlocked with each other - due to inclined planes.

Log house

The technology of log cabins has been developed and tested for centuries, and the features of constructing log cabins directly depend on the area where they were built. Based on the appearance of the finished log house, the types of connections can be divided into two groups: with a remainder - with the ends of the logs protruding at the corners, and without a remainder - with even corners without protrusions of the logs. A bathhouse built using the first method will have much less ventilation and will last longer. But the second method is more economical, because the logs are needed half a meter shorter.

A. In the corners of the house

Connection with remainder

This means that the ends of the blanks at the corners of the building will protrude somewhat beyond its perimeter. The disadvantage is the increased consumption of building materials. But there is also a “plus” of such a connection - it is more durable, moreover, the corner parts of the building (the most problematic areas) are better protected from precipitation.

The most common method is “in the oblo” (“castle” type). It is also sometimes called "chalice", but this only applies to logs.

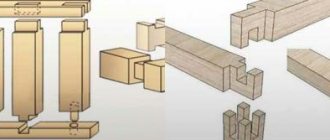

Locks:

- Unilateral. It is already clear that the “drank” is done on only one workpiece.

- Double-sided. Accordingly, approximately ¼ of the material is sampled on each of the beams (joining grooves).

- Quadruple. In this case, “cuts” are made on all faces. This connection is much more complex in execution, but is considered the most reliable. In addition, installation is simplified - all that remains is to assemble the individual parts of the “constructor” together.

Without a trace

This means that the corner edges of adjacent walls are absolutely smooth, without protruding ends of the beams ("joint joint").

From the pictures it is clear that there are many varieties of such fastening of workpieces.

About interventional insulation and insulation materials

Classic sealants for log houses are flax tow and moss. Modern ones are jute, tow and... sphagnum moss. Yes, moss is still used today, it has not gone into hoary antiquity and has not become a relic of the past, used out of poverty. Sphagnum is a natural material with unique properties. They say about him that he heals both the owners and the house. And also that log houses rot before the moss between their crowns.

Sphagnum, or peat moss, is a common plant that grows in swamps. Peat and peat bogs are formed from it. After the moss dries, it becomes light-colored, hence another name - white moss. Another name is medicinal moss, because it was used for dressings.

As a building material, moss is distinguished as an environmentally friendly and durable material. A log house that has been sealed with sphagnum acquires healing properties. Moss has antiseptic and bactericidal properties, and its hygroscopicity and breathability smooth out differences in air humidity.

All insulation based on tow and jute fiber, unlike sphagnum, needs to be impregnated with an antiseptic.

Sphagnum harvesting is carried out in all months except winter. Optimally - in the last month of summer, since the length of the moss is already sufficient, about 20 cm, and at this time it is the cleanest, without fallen leaves. Collecting moss is easy, since it is a surface plant, without a root system.

After collection, the moss is squeezed out to remove excess moisture, cleaned of forest debris and collected in bags. Before laying in the walls, the moss is dried for several days under a canopy.

If moss needs to be prepared for future use, drying is necessary. This is not difficult, the moss is laid out in a thin layer, about 20 cm, in a place protected from the wind, and turned over during the drying process. It takes about a week to dry, and it doesn’t matter whether it’s in the sun or in the shade, the moss dries everywhere. Dry moss can be stored in bags without problems for a long time.

Types of corner joints

Strength. It is known that the timber is fixed under the pressure of its own weight, as well as the pressure of the floors and the weight of the roof. But such connections must be resistant to possible changes in the linear dimensions of the timber, and wood, as is known, is susceptible to deformation that occurs with fluctuations in atmospheric humidity and air temperature.

Tightness. One of the main conditions for why we are building a house is to protect ourselves from the external environment; circulating drafts will bring pleasure to few people. The simplest solution to avoid drafts is to complicate the path for air to pass through the connections, i.e. we must make the connection of parts geometrically more complex.

In modern wooden construction, two types of corner joints are used:

- With the rest. The remainder is the end of a log or beam that protrudes outward from the corner of the frame. The advantage of this type of corner connection is better protection of the seams from blowing;

- Without a trace. The crowns of the log house do not protrude beyond the corners of the house.

Corner joints of logs are performed in almost the same way as joining beams. In this case, the landing nest in the lower log is most often made not flat, but semicircular, resembling a cup. Therefore, this method of joining is called cutting “into the bowl”.

Connecting logs “into a bowl” with the remainder

Joining the beams at the corners of the house is done in two ways:

- Single-sided (wood floor)

- Double-sided (in red)

The one-sided joint of the timber is easy to perform, since it is enough to make only one vertical groove.

One-sided joint of profiled timber “half a tree”

Listing the main methods of joining timber in the corners of a house, it is necessary to say a few words about the double-sided cutting method. It is more complicated than one-sided joining of crowns, since vertical cuts have to be made not only on the top, but also on the bottom side of the beams.

After this, the wood between the cuts is cut out, leaving smooth horizontal landing areas. By laying the beams on top of each other, we get a strong joint with two flat seams.

Connecting the timber “in the okhryap” with the remainder

Reliable joining of logs can also be done using the “in-the-hole” method. However, most often specialists use a “bowl” joint, which is optimally suited for the round shape of the log.

Cutting a corner from logs “in okhryap”

The double-sided “bowl” connection and the semicircular “bowl” require highly qualified carpenters. Here you need to work accurately and carefully. Any mistake with the depth of cut or cutting out a groove can lead to a violation of the geometry and a decrease in the strength of the joint.

Connecting the tail angle with the remainder

Considering the types of connections between logs and beams, we note a very popular method of cutting “in the paw”. It is quite simple to implement and at the same time allows you to obtain a fairly strong and airtight joint.

Connecting logs “in the paw” without leaving any residue

The methods of connecting beams during the construction of a log house are significantly different from the joints of logs. Since ancient Rus', wooden construction has been done from logs; since then, centuries-old experience in connecting corners and joints has been accumulated. But this is the 21st century and ancient techniques are gradually acquiring their modified analogues, so first of all I want to introduce you to the technique of laying beams, and we will disassemble the log later.

Nowadays, two connection methods are practiced in wooden construction:

- With the remainder (“to the oblo”, “to the bowl”)

- Without a trace (“in the paw”, “in the tooth”).

Cutting logs with corners without residue

As we said earlier, the corners are colder without any residue, but they allow you to significantly save on building materials.

Angle "to the paw"

Among the joints of logs in the corners, the “paw” method is popular. It is easy to implement, and at the same time provides high strength and reliability of the connection. Also, the presence of inclined cuts makes it possible to achieve high tightness. The method has been tested for a long time, even GOST standards have been developed: size tables for each log diameter (see photo).

Table of foot joint sizes for different log diameters

All dimensions are plotted relative to the found middle of the log and a vertical line drawn from it (it is drawn using a plumb line).

Connecting logs without leaving any residue. Angle to paw

The order of work is as follows:

- Find the length of the cut part (called the block). It must be no less than the diameter of the largest log available (in the figure it is marked L). We set this value aside from the edge of the log (let it be 250 mm), draw vertical lines in these places. They will be the boundaries of the idiot.

- Let the diameter of the processed log be 200 mm. From the middle line, 1/2 of the value of A is set aside. D for a 200 mm log is 141 mm. We divide this value in half and put it on both sides of the center. We draw vertical lines.

- We trim (cut with a chain saw). As a result, you should get the same picture as in figure a).

- We take the appropriate dimensions from the table and mark them on the block.

- We trim off the excess (cut it off). The result should be a figure like in Figure b). This is what the angle from the logs into the paw looks like (dovetail due to the fact that the connection is in the form of a trapezoid)

All logs are processed in this way one by one. As you can see, the dimensions depend on the diameters of the logs. In order not to have to worry about drawing every time, they make templates from thin plywood according to the diameters of the logs that are available (they label them). Then, having found the middle and made a block, they apply and trace a suitable template. With this order of work, there is less chance of making mistakes, and chopping bowls takes less time.

Advantages of a log house

Natural wood is the most environmentally friendly material of all possible basic building materials. It is easy and pleasant to breathe in any log house. A natural microclimate, saturated with oxygen, with specific microelements and resins of a particular type of wood will always contribute to the stable health and well-being of residents. Cedar lumber also has an antiseptic and cleansing effect on humans and the environment as a whole. Read more about the properties of cedar in construction.

Fast construction time.

From the moment the material is delivered to the site until the log house is completely erected, it can take only a few days. The construction process by skilled craftsmen does not take much time. With the exception of the construction of large-area log buildings and complex projects. Another thing is its shrinkage, which we will talk about later in the article.

Low thermal conductivity.

A high-quality log house does not need to be additionally insulated with artificial materials. But the wall thickness should not be thinner than 25 cm.

Good sound insulation.

Wooden walls practically do not allow noise to pass through. At a moderate noise level, residents in adjacent rooms will not hear each other. The exception is extreme noise coming from the street, which can be heard in a house made of any material.

Durability.

With normal care and permanent residence, a high-quality log house will last up to a hundred years. In our time, there are quite a lot of examples of such log houses preserved, the strength of which would be the envy of many modern materials.

- Breathing house. The natural and natural gas exchange of a log house always creates an atmosphere saturated with pure oxygen inside the house. At the same time, the log house does not require the installation of additional ventilation. For such a house, natural air flow through windows and doors is sufficient.

- Quite a light house. Compared to heavy stone and brick houses, a wooden frame does not require such a massive and heavy foundation, since it is much lighter. Thus, some savings are possible when constructing the foundation.

- Beautiful appearance. A log house is a structure on which the gaze of any person involuntarily and for a long time lingers. You want to look at it and want to admire it again and again. The log structure, the unique wood pattern of each log and timber makes each log house beautiful in its own way. It is possible to build an ugly stone house, but it is simply impossible to build a log house. Just looking at your own, chopped-up house brings great pleasure.

- Unique and cozy atmosphere. It is impossible not to highlight this ability of a log house as a separate advantage. This kind of atmosphere is created naturally. In such a house, the tree itself seems to endow the residents with its strength and natural inspiration. The beneficial environment of the log house promotes maximum productivity and the creative spirit of its owners.

Connection fastener

With the advent of modern fasteners made of durable alloy and galvanized steel, many construction processes have been simplified, including the installation of reliable connecting units in timber structures. Some of them have been used for a long time and are traditionally popular. Others appeared relatively recently, so they may be unknown to people whose profession and interests are not related to construction.

Traditional fasteners

The simplest and most reliable of them are dowels or dowels made of hard wood. They blend perfectly with the base material without causing it to deform, crack or rot. In combination with adhesives, they allow for durable fastening.

Assembling a log house on steel dowelsSource remontik.org

Pins are also metal. Their main advantage is their high strength and durability, which is why they are often used to fasten timber crowns vertically.

Nails and staples, which used to be almost the only types of fasteners for wood, are now trying not to be used in the construction of permanent buildings, since the ferrous metal from which they are made is incompatible with wood. It corrodes easily, damaging the wood and gradually deteriorating. For the same reason, it is not recommended to use homemade dowels cut from reinforcing bars.

Modern fasteners

A wide variety of fasteners are made from perforated rolled steel with a thickness of at least 2 mm with an anti-corrosion coating. It is made from:

plates of different lengths and widths with holes for screws and anchors. A large assortment of standard sizes allows you to solve problems such as connecting beams together along a length of 150 by 150, fastening rafters at the ridge part, or strengthening a sagging joint without lower support;

Galvanized connecting plateSource www.sibwindows.ru

- connecting corners from the same source material can be simple or reinforced, with an additional stiffening rib. The range of these products includes both equal-shelf corners and those with different shelf lengths. They are used to strengthen the corner connections of a log house, fasten rafters, floor beams, create a frame for internal partitions, etc.;

- supports are fasteners of complex shapes that allow you to create reliable corner T-shaped joints without making locks. For example, attach floor beams to the walls. Their standard sizes correspond to all standard dimensions of timber sections.

An improved analogue of a perforated plate is a nail or serrated plate. With its help, structural elements located in the same plane are reliably fastened.

Using nail plates, you can assemble trusses and splice timber along the lengthSource cdn.mitekea.com

Threaded rods are also very popular in wooden construction. They tighten the joint by tightening the nuts on both sides of it.

And the most modern fastener, which allows not only to connect the crowns with each other, but also to compensate for the shrinkage of the house and the appearance of cracks between the beams, is the “Strength” spring unit.

Video description

What it is and how this spring unit works is described in the video:

When building a wooden house, the question always arises of how to connect two beams lengthwise or fasten a corner. Each master has his own preferences in this matter: one adheres to methods that have been proven over centuries, the other trusts more modern methods using special fasteners. And this issue needs to be discussed in advance, after independently studying all the possible options and deciding what is your priority: speed and reasonable cost of installation or quality and reliability.

How to connect beads lengthwise

The easiest way is half a tree. Its configuration and shape are similar to those made when connecting a corner. But the disadvantage of this splicing method is that when longitudinal forces arise, which can occur during drying or movement of the soil, such a connection is easily broken. A continuous gap is formed.

Long beam connection

The oblique rim lock has the same disadvantage: it is easy to disengage. If you need reliable joining of timber, use a straight rim lock. As you can see, due to the protrusion, pressed by the crowns located on top and the weight of the roof, it will resist the forces of longitudinal tension (and compression too). It is more difficult to implement, but much more reliable.

3.1. Connecting the corners of the timber with the remainder “into the bowl”

The bars are connected into the bowl using key grooves, which can be of several types:

- One-liners

- Bilateral

- Quadrilateral.

The fastener with a one-sided groove has a shallow cut in the bar in the form of a transverse groove. As a rule, profiled timber is connected in this way.

When fastening with a double-sided groove, cuts are made on both sides, top and bottom, with a depth of 1/4 of the thickness of the beam.

When making a four-sided groove, cuts are made on 4 sides. The presence of transverse grooves significantly simplifies the process of installing crowns - the logs fit tightly against each other, the stability of this method of connecting beams in the corners increases significantly.

Type of connection of profiled timber into a one-sided key groove

General view of a connection in a one-sided locking groove. Connection element.

With this type of connection, a perpendicular groove in the form of a notch is made in each beam on one side - usually the top. The notch must match the width of the beam perpendicular to the cross-section.

Type of connection in a double-sided keyway

General view of a connection in a double-sided locking groove Connection element

The double-sided groove lock technology means cuts on both sides of the beam, i.e. up and down. The depth of the perpendicular cut is approximately 1/4 of the height of the beam. A high-quality connection, but it requires a lot of experience from carpenters in order to prevent cracks or chips when cutting the groove and installing the beam.

Type of connection of profiled timber into a four-sided key groove

General view of connecting a beam into a four-sided locking groove. Element of connecting a beam.

Type of connection of profiled timber into a four-sided key groove (in the “oblo”)

General view of connecting a beam into a four-sided key groove (in the “oblo”) Element of connecting a beam.

When making a four-sided locking groove, a groove is cut out on all sides of the profiled beam. This fastening option will allow you to achieve greater strength of the log house. The cuts on all sides simplify the construction of the log house - the crowns fit like a construction set. Connecting corners in this way greatly increases reliability.

Cup - is the simplest type of corner arrangement.

Corner fastening using this method is performed in the following variations:

• half a tree; • in the okhryap; • in the fat tail.

"Half a Tree"

This joining method (the simplest) involves cutting a rectangular groove with a depth of half the thickness of the timber - hence the name.

In order to increase the required packing density, an additional longitudinal groove is formed at the top of the beam, in addition to the bowl. After laying and securing the cross beam, the logs of the next crown are installed. Before laying each tier, the longitudinal groove is sealed with insulation. For structural strength, each new log is attached to the previous one using dowels, which enhances the vertical stability of the surface.

"In the fat tail"

An additional spike ensures a strong and reliable joining of the beams. At the bottom of the bowl, another protrusion is cut out along the block and across the cup bottom. And at the bottom, across the groove, a special recess is formed, onto which the fat tail is placed during installation.

Carpenters with a high level of skill are required to perform a quality connection of this type.

"To the brink"

A connection in which the main task is to correctly calculate the width of the jumper. When working with timber, due to its standard geometry, cutting can be done using a template (as opposed to working with a log). Error-free sawing significantly speeds up work.

Okhryap is an intermediate type of connecting timber in the corners between the classical methods with and without a remainder. The difference between cutting “in okhryap” is that bowls of 1/4 diameter are cut from the bottom and top of the beam.

How and why a longitudinal groove is cut out

All logs of the log house must have longitudinal grooves corresponding to the ridges of the bottom of the logs that will be laid on top. These grooves are needed to preserve heat in the log house, and to prevent the log house from being blown by the wind. According to GOST, longitudinal grooves must have a width no less than 0.5 of the log diameter.

The choice of the width of the longitudinal groove depends on the minimum air temperatures and is assigned:

- At - 40⁰С from 140 mm or more

- At - 30⁰С from 120 mm or more

- At - 20⁰С from 100 mm or more

The triangle groove shape is easy to manufacture, but does not provide a tight and durable joint. It is almost impossible to densely fill a triangular cavity with tow or jute, and during operation condensation accumulates there, insects, mold and mildew grow there. Open wood capillaries take water from the insulation when it soaks. Due to excess moisture, logs have low resistance to rotting. The thermal protection of such a log house is unimportant. Another disadvantage is constructive. The greatest load on the log falls precisely on the top of the groove triangle, in the place where the section is weakened, the groove can crack and open, and cracks will appear along the inter-crown joints.

The only advantage of the “triangular cut” is speed. It is only suitable for log houses that will not be heated, for various warehouses and outbuildings. For a residential log house, such a longitudinal groove is not suitable; it is considered rough and cold.

The better the groove follows the shape of the ridge of the log laid in the bottom row, the more difficult it is to fit, and the warmer and denser it is.

Basic methods of connecting timber during installation

At the connection point, you need to choose a specific method that guarantees optimal strength and tightness of the joint. Corner connections can be made:

- with ends protruding beyond the main dimensions;

- without protrusions;

- butt laying, when the beams do not overlap each other;

- T-shaped connection for walls inside the building.

Figure 2. Construction of a rectangular root tenon.

The technology of the method with a remainder provides better quality corner joints, but requires more material consumption. Each beam produces from 0.4 to 0.6 meters of wasted length. With a height of 15 crowns, the total unused length will be from 20 to 36 m. With a beam length of 4 m, this will amount to from 5 to 9 additional products. You can see the corner connection with protruding parts in Fig. 1a.

The first crown in a building is usually placed in a joint with a key groove with a specific name for the joint - “oblo”. This method is used for any method of laying material, with or without protrusions. The sampling is performed at half the thickness of the product. The articulation of the corners of the house without protrusions can be seen in Fig. 1b. To prevent displacement in the main planes, subsequent crowns must be joined using the “root tenons” type with the installation of dowels. The design of a rectangular main tenon is shown in Fig. 2.

The dowel is a round wooden block 25 cm long and about 30 mm thick. In the beam laid on the cushioning material, you need to drill a hole with a depth exceeding the length of the dowel by 20-40 mm, and hammer the part into it.

Butt jointing corners is the easiest way. The quality of such joints is extremely low; creating a warm corner in this way is unrealistic. The timber is fastened with such joining using metal brackets with spikes, nailed down. Laying timber end-to-end is shown in Fig. 1st century How to fasten a beam with a metal bracket can be seen in Fig. 1e.

Figure 3. Dovetail.

The T-shaped connection of capital and internal partitions has several options:

- joint using a key groove;

- “groove-tenon” joint in the form of a symmetrical trapezoid;

- “groove-tenon” joint in the form of an asymmetrical trapezoid with a right angle;

- use of a rectangular mortise-tenon joint.

Spikes in the form of trapezoids are designed to maintain the connection during loosening of the structure and efforts aimed at pulling apart in different directions. The design of such joints is complex, but also more reliable. Because of its appearance, the connection is called “dovetail”. The structure of such a joint can be seen in Fig. 3. Making a dovetail requires care and patience in fitting the surfaces.

Many craftsmen prefer to fasten walls using rectangular tenons. Often, T-shaped joints are fastened with special brackets, long bolts with large diameter washers or nails. An example of a right-angle tenon connection is shown in Fig. 1 year

Caulk of a log house with moss

After the crown logs are finally adjusted, they begin laying the inter-crown insulation. The moss is laid out across the logs with a layer thickness of 15-20 mm, pressing slightly, but not tamping. Lay out the moss to a width greater than the width of the longitudinal groove of the upper logs, by 100 mm. Moss is placed in the bowl and around the bowl in the same layer, with a protrusion of 50 mm beyond the contour of the bowl.

The traditional and correct technology is laying the log house “on moss”. Or on tow, in case of using tow. But assembling log houses without inter-crown seals, in a hurry, and then driving the seal between the crowns is not a technology. Such log houses do not last long; beetles and company settle in the cavities between the logs, and fungus and mold grow. This is because it is simply impossible to hammer a sealant from the outside into a finished frame; cavities always remain. Sealants used in external seams save the situation for a short time. In a short time, such log houses become cold.

After laying the compactor onto the log, lay the top crown log on top, being careful not to move the moss. The stacked logs are tapped with a wooden “woman”.

After laying the logs, caulk the bowls, tucking the protruding fibers between the log and the bowl. The tool for this operation is called a caulk, and the caulk is tapped with a mallet or hammer.

Dry moss is placed in the crowns, and the frame is moistened with caulk. If moss is dried and then soaked, its strength is much greater than that of fresh moss.

They caulk the log house in two passes. First, immediately after assembly, filling the gaps between the crowns with a sealant as tightly as possible. Caulk until the moss begins to spring under the blows of the mallet on the caulk.

The crowns run along the entire contour, first from the outside and then from the inside. This work is not considered difficult, rather long and monotonous. The crowns are caulked from bottom to top, one at a time. Incorrect caulking can cause the frame to warp.

The second pass is made after the frame shrinks, which takes about a year. The second caulk is made in exactly the same way as the first.

Methods for connecting timber

But construction from timber is a new thing, and, in fact, borrowed its technology from logs. So, let's look at the corner connection of the beam:

"To the region"

This connection is made through key grooves - single-line, double-sided and four-sided. In the first case, a notch is made in each beam in the form of a transverse groove, which is made only on the upper side and the width coincides with the cross section of the beam. It is this technology that is always used to connect profiled timber, which has strictly defined parameters.

In the case of a double-sided locking groove, cuts must be made both from above and from below, and the depth of each should be equal to a quarter of the height of the beam itself. But in the third option, cuts are made on four sides at once - this connection of timber is reminiscent of a children's construction set - it is so simple to do.

In the "paw"

The connection of timber “into a paw” is done in the following three options: end-to-end, on main tenons, on dowels. The simplest is the first option.

Joining the timber into a joint is done using metal plates with staples or nails, and how good the angle is depends on how perfectly smooth the ends of the joined beams were. But still, this is not the best option, and completely unsuitable for a bathhouse.

But dowels are a special liner made from the hardest types of wood that prevent the entire wall from moving. The best dowels are oblique, although they are the most complex.

The most popular option for building a bathhouse today is connecting the beams into a root tenon, when a groove is made in one of the beams and a vertical tenon in the other. This is the most reliable connection.

Only during the installation process you will need to put a flax-jute fabric in the groove for improved thermal insulation of the log house, and after laying each crown you will need to hammer a round wooden dowel into the corner.

In the dovetail

This design is the most reliable. The dovetail beam connection is made using a trapezoidal tenon and making the same groove outline at the end of the joined beam.

These are the most basic types of timber connections. There are others - progress is being made, and builders are always looking for ways to make construction easier, without losing quality. Perhaps in the near future, both the longitudinal connection of the beam and the corner connection will become similar to the assembly of children’s “Lego”.

Requirements for connections between timber and logs

Connecting timber during the construction of a bathhouse

When building a bathhouse, timber (or logs) can be connected to each other in the corners and longitudinally. The corner connection of the timber is used in the construction of the entire structure of main walls, as well as when installing partitions in the bathhouse

.

The longitudinal connection of the beam is used if the length of the material is not enough to erect one wall (for example, the wall of a bathhouse should be 6 meters long, and the beam should be 4 meters long).

The following requirements apply to the longitudinal and angular connection of the timber:

- The bath box must be sealed from the outside and inside

- The design of the bathhouse must be stable

- Heat loss from the building should be minimal

These are the main requirements for connecting timber and logs to each other. It should also be noted that depending on your woodworking skills, you need to choose the right connection method, because There are strong but complex types of corner fastening material that you may not be able to do.

Connecting timber or logs at an angle and longitudinally

The main technological operation when constructing a log house for a wooden bathhouse is the connection of a log or timber, so anyone who starts independent construction should at least in theory know how to connect a beam or rounded log.

The need for connection arises in 2 cases:

- When cutting a corner

When increasing beams or logs in length, when the dimensions of the standard product are insufficient.

In both cases, various techniques are used, so below we will try to briefly but clearly describe the main methods of connecting timber.

Types of corners in a log house

Corner joints can be “with remainder” or “without remainder”. The difference is in the ends of the timber, which will either extend beyond the frame or not.

Connecting corner beams with the rest is more expensive (material consumption increases). But the heat capacity and protective functions of such an angle are higher. The most used option for fastening timber with the remainder is “in the fat tail”.

Connection without residue

The splicing of timber without any residue is carried out using several types of knots: “into the bowl”, “into the okhop” or “into the okhryap”. The most common option is in a bowl.

Bowls in timber are made on a special bowl cutter or manually using a saw. The specialists have a mobile cup cutter that they can carry out work right on the construction site. The timber is laid one bowl on top of the other. Felt or jute insulation is laid between them.

The connection of the beam “into the clap” is similar to that “into the bowl”, but differs in the location of the drink. The bowl is cut from the top, not the bottom.

If we compare it with the main types, the connection “in the okhryap” is similar to the “in the paw”. Only in this design the end of the beam is removed, thereby forming an angle without a protrusion. The beam is connected to such a corner using dowels and crosscuts. This type of connection does not have high wind resistance, so often a straight cut is replaced with a trapezoidal one.

Any connection must be discussed with specialists, since the choice must be based on the design features. For profiled timber, connections in length are allowed only according to certain parameters, in accordance with GOST 30974-2002 “Connection of corner wooden and log low-rise structures. Dimensions, design and classification."

Any connection breaks the tightness of the walls, so before installation you need to lay a special insulation and treat the joints with antiseptics, since this will be difficult to do in the future, especially with profiled timber.

There are two main types of log frame corners:

- "without a trace"

- "with the remainder."

When starting construction, you should decide what kind of building it will be, what load the foundation and walls will have to bear, and, accordingly, what kind of timber connection in the corners should be chosen in each specific case.

We invite you to familiarize yourself with: Warm floors in the bathhouse - do-it-yourself options

Considering that correctly set corners are the key to the strength and reliability of the entire structure, corresponding requirements are also imposed on them. This:

- Reliability of fastening. The corner of the house, regardless of how it is constructed, should not be made of lumber with cracks and splits. Wood for construction must be taken with a drying level of up to 20%, which ensures its ability to withstand deformation and environmental changes without damaging the structure.

- Air tightness. The absence of cracks that allow drafts to enter the home is the main requirement for wood corner joints.

Connecting corners to build a house made of timber is divided into:

- Angle with remainder.

- Angle without remainder

The corner connections of the house with the remainder are also called “in oblo”. The design of the unit is key, it can be assembled in several types:

- One-sided.

- Two-way.

- Quadrilateral.

Lap knitting is a universal connection of lumber, used when laying walls made of logs and timber. The workpieces are placed at right angles into cut-out grooves; the size of this groove depends on the size of the material used. Such a lock is used in the construction of log houses and ceilings, the construction of bridges, and the construction of canopies. The main methods of cross fastening:

- Half-tree connection;

- Quarter and third wood joint;

- Notch in one row.

The most widespread cross-shaped connection in half a tree is when cutting corners into a bowl; it is used in the construction of utility structures, residential buildings and baths. The structure is reinforced with building brackets, dowels and dowels.

A variation of the cross-shaped connection is the method of fastening the beams together without any residue; in this case, the two sides of the cross-shaped connection have no continuation. This connection is used when laying corners and is called “no residue in the paw.” Cutting a castle without leaving any residue does not require the use of special tools; the construction of a log house using this method is popular among individual developers.

A more complex method of corner mounting is dovetail installation; a dovetail lock is a reliable but complex fastening. Marking and complex cutting of such a connection requires professional skills; the technology is widely used in the construction of low-rise economy class housing.

Main types of log houses for the castle

The appearance of a wooden house depends on how the log house was cut - with or without a remainder. If the frame has corners with perfectly matched ends, then it is folded using the “no residue” method; this type of lock is called “in the paw”. If the logs protrude beyond the wall, the method is “with a remainder” (in Russia it is called “in oblo”), the type of lock is “chalice”.

The main tool for cutting log houses is an ax (carpenter's or adze). When working with an ax, the rings of wood that open during the cutting process become jammed, which to some extent protects it from external factors.

When using a chainsaw, the side cut of logs in a log house becomes smooth, the pores of the wood open and become accessible to atmospheric phenomena, which leads to rapid rotting. A log house will last longer if it is sheathed.

Both types of locks – the “bowl” and the “claw” – have different options.

Log house “in a bowl” (with remainder)

A simple “bowl” is carved into the lower crown of the log house. The design of such a bowl is a longitudinal groove with a semicircular cross-section.

Simple bowl

“Bowl in ridge” is a “bowl” lock with a ridge cut out at the bottom, which is designed to ensure the strength of the corner connection and seal the frame.

Bowl in comb

The fat tail lock has a tenon cut into the log of the lower crown, which is inserted into a groove made in the upper log. This type of lock is difficult to cut, but is the most reliable.

Castle in the fat tail

The Siberian bowl (“in the okhlop”) is cut down in the log located on top, and, as it were, “slams” the lower one - hence the name “in the okhlop.”

Siberian bowl (“to the clap”)

The “bowl” lock has several varieties, which are based on the same elements as in the “bowl”: the comb and the fat tail. Depending on the options for their use, locks are called “lock with a comb”, “lock with a tail (spike)” and “lock with a comb and tail (spike)”.

A lock "in the okhryap" is used, as a rule, in the construction of buildings for utility purposes, since the connection density is insufficient for a residential building. This is a complex castle, cut in two logs (upper and lower), which is why it is called double. The lock has only two varieties: a simple “ohryap” and “ohryap with a fat tail (thorn)”.

The castle is "in a state of disrepair"

Loghouse locks “in the clutch” (without remainder)

Log houses without residue are those buildings whose ends of the logs are at the level of the walls. In this case, logs or beams are connected with locks of the “paw” type. These connections are not very strong and do not have good thermal insulation. For comfortable living at any time of the year, such a log house should be clad on the outside.

Connection to the paw: 1-straight paw with a cut; 2-oblique paw (dovetail); 3-oblique paw with undercut

The “foot” can be straight, oblique (“dovetail”) and oblique with a notch (groove).

Other types of log house locks

The main types of log houses and castles were described above. In addition to them, there are a large number of other methods of building wooden houses, which have different origins and features.

Hook cutting

Hook cutting is a structurally quite complex method of angular connection of logs, characterized by increased strength. This type of fastening has two varieties.

Hook connection

In the first case, the bowl is cut down to ½ the thickness of the log. At the ends of the logs, a kind of hook is obtained with which the logs are connected. This connection guarantees absolute windproofness of the corner.

Hook connection: 1-walls inside are round; 2- the walls inside are smooth.

A distinctive feature of the second option is that, due to the logs hewn on one side, the walls inside the building are smooth. Thanks to this, the usable area of the room is significantly increased.

Finnish log house

Finnish bowl (Finnish groove)

House cutting using Finnish technology is similar to the Russian “bowl”. The difference is in the radius of the inter-crown groove (it should be less than the radius of the bowl) and its configuration. The Finnish groove has two “tenons” at the bottom, and grooves are made at the top. As a result, the crowns fit tightly to each other, and the blowing of the walls is reduced. The intercrown seal is completely located in the groove, and not outside it, and is not affected by moisture, which leads to damage to the wood.

Swedish castle

Swedish cutting

Swedish cutting is fundamentally different from all others, first of all, in appearance - aesthetic and very creative. Hexagon - this is the shape of the ends of the logs. The bowl, accordingly, is not round, but in the shape of a trapezoid. Cutting a Swedish log house is very labor-intensive, so it is done when there is a need for beautiful, unusual angles.

Norwegian castle

Norwegian log cutting is a technology widely used in Scandinavian countries - Finland, Sweden, Norway. Therefore, the names “Norwegian” and “Scandinavian” log cutting are identical.

Carriage

Lafet (half-beam) is a building material from which a Norwegian log house is made. The carriage is a thick pine trunk hewn on both sides. The corner connection “Norwegian castle” or “house from a gun carriage” is one of the most reliable technologies for constructing wooden houses.

A distinctive feature of the Scandinavian castle is its wedge-shaped section. A wedge-shaped tenon cut into the top log is “settled” into a groove made in the bottom log when assembling the frame. From the outside, the design is similar to a saddle.

Norwegian castle

A wooden house in the Scandinavian style looks monumental and neat. Thick logs reduce the number of crowns, therefore, the log house has significantly fewer “cold bridges”.

Norwegian house from gun carriage

Smooth interior walls make the interior of a Scandinavian home very stylish.

Canadian bowl

Canadian bowl

Canadian log cutting is a technology similar to the Scandinavian one: the corner connection is made like a Norwegian castle with a wedge-shaped tenon. Round logs are used and a trapezoidal cup is cut into them. When laying, the insulation is immediately cut off so that water does not get into it. The result is walls without gaps and cracks, which look like a solid mass.

Canadian log house

A simplified version of the Canadian log house is a “saddle” log house. Due to the absence of a tenon and a groove for it (a distinctive feature of this type of felling), the tightness of the corner is significantly reduced, which makes the log house short-lived.

Canadian bowl, tongue-and-groove connection

Log house “into the pillar” (“into the fence”)

Log house in the fence

This ancient technology of wooden construction is used quite rarely today. Log houses for commercial buildings were cut in this way. The principle of construction of this type of log house is radically different from all traditional ones. Logs with spikes at the ends are laid between vertically dug posts with grooves cut out. Making a log house “into a pillar” does not require much time or special skill of builders.

So, we looked at the features of making log houses. In addition to logs, another type of lumber is used in wooden house construction - timber. Houses made of timber, like log houses, have a frame as a base, but the corner connections are made slightly differently.

Butt connection

For beginners, the easiest option is to connect profiled timber using the butt method. The ends of the beams are cut evenly and fixed at the corners using steel brackets or plates with spikes.

However, this method of joining timber cannot be called very durable and airtight. Therefore, it is better to use it for non-residential outbuildings.

Butt connection of beams

To strengthen corners assembled end-to-end, dowels are often used - vertical rods made of hard wood (oak, birch, hornbeam).

We invite you to familiarize yourself with: Standard sizes of plastic panels

Joining timber on a straight flat key (dowel)

The optimal joining option is the “warm corner” method, also called the “root tenon” connection. At the end of the beam, an internal protrusion-spike is cut out, which protects the seam from blowing and increases the strength of the corner.

A common corner joint method is the dovetail. It differs from the root tenon in its trapezoidal shape, which makes the contact area of the beams denser and more rigid.

Jaw connection methods

Cutting in the paw (without residue) is characterized by the fact that the ends of the logs or beams are not carried beyond the wall. In this case, the strength of the log house suffers, but the crowns are reinforced with wooden nails (dowels) and tongue-and-groove joints of complex design. These are, for example, trapezoidal cuts, which evolved from rectangular ones with a dovetail joint. Straight paw is the simplest method of cutting without leaving any residue - half of the upper beam (log) at the corner is inserted into half of the lower one.

Varieties of cutting technology without residue:

- Cutting in the paw - end-to-end joint. It is considered the lightest but most fragile knot;

- Keyed connection;

- Logging with a root tenon implies that there will be a tenon in the lower load-bearing element of the log house, and a groove at the top, the corner is reinforced with dowels;

- Joining in a block - cutting down two, three or four longitudinal locks;

- Is it worth starting construction of a stone house in the fall?

Half swallowtail

With this connection, the tenon is sawed down into a cone. The characteristics of the half dovetail connection do not differ from the knot described earlier. But the strength indicator increases. The conical cut securely holds the beams and prevents them from moving apart. This connection is used in the construction of walls with a length greater than the length of the beam.

There is no difference in the complexity of manufacturing when joining a half dovetail and a straight tenon. Both methods are performed with or without a template. For an experienced professional, the difference in the labor intensity of making these joints is almost imperceptible.

The half dovetail tenon should not be more than 5cm at its widest point. Otherwise, a crack will appear in the timber with the groove. This happens due to uneven shrinkage. The picture shows this place.