Since ancient times, wood has been the main material for construction and heating. Vast areas of forests made it possible to choose from a wide variety of wood species suitable for a particular type of use. Today, wood is also the most popular material for use in various industries. Carpentry production, construction of timber houses, roofing, flooring, production of carved sculptures and interior items cannot be done without it.

Tree species

In nature, there are many wood species that have different properties and are used in different industries. To choose the right type of wood, you need to know the characteristics of each of them.

Different types of wood differ from each other in color. The color depends on several factors: the type of wood, age, growth rate, and the brightness of the color depends on the amount of dyes it contains. The sapwood of the tree is a lighter shade than the heartwood. Sapwood is the outer part of a tree containing living cells. The core part of the tree is always darker, where the main amount of tannins and resins is concentrated. Heartwood trees have dark wood, while sapwood trees have light wood. Sound tree species include the following common tree species: larch, pine, ash and others. In sapwood species, the core layer is very narrow and differs little in color from sapwood. These species include birch, pear, linden, beech, hornbeam and alder. Maple, ash and hornbeam have very light wood, while birch has white wood. Parquet boards are mainly made from these species. Boxwood has yellow wood. Used for artistic and decorative purposes. Pine wood acquires a gray tint as it ages.

Coniferous trees are used to make lumber and other building components because they have a light structure that is easy to process. The lightest of them is fir. Most of the coniferous species used grow in our area, so the buyer is provided with a wide selection of wood for various purposes at reasonable prices.

The lightest wood in the world is balsa wood. It grows in the forests of South America. Used by Indians to make rafts. It grows so fast that it has no growth rings. Its structure consists of solid fiber filled with water. After drying, the wood becomes harder than oak, and the weight is 120 g per 1 cubic meter, which is two times lighter than the bark of a cork tree. Balsa is used in aircraft and shipbuilding and is also an excellent insulating material.

Snakewood or snakewood is the heaviest and hardest tree in the world. Grows in Guiana, Guyana and Suriname. Its density is 1300 kg per 1 cubic meter. Snakewood is used to make decorative crafts of the highest quality, handles for knives, umbrellas, bows and bows. The material from this plant is difficult to process due to its hardness, but gives good results when finishing and polishing.

Hardwoods are successfully used to produce various types of furniture. They have darker wood, a wide palette of colors, which are successfully used in the design of furniture and decorative elements.

The quality of any product made from wood depends on the level of hardness of the material used. The harder the material, the higher its wear resistance. The hardness level is determined by the Brinell method. To do this, a metal ball with a diameter of 10 mm is pressed into the surface of the workpiece with a force of 100 kg. The result is determined by the diameter of the recess and the type of deformation. The higher the hardness index, the stronger and harder the wood species.

Softwood

Soft wood varieties with a coefficient of up to 40 MPa have the following well-known deciduous plants: linden, poplar, chestnut. Conifers: spruce, pine, fir. All of them are used in construction, are well processed, they are used to construct rafter structures, make furniture, windows, doors, and small decorative items.

Hardwood

Hardwoods have a hardness coefficient from 40.1 MPa to 80 MPa, and very hard woods have a hardness coefficient above 80 MPa. The pinnacle of hardness among deciduous trees is occupied by the jatobe tree, growing in the forests of South America. The wood has a brick-red color when cut. It is used to produce furniture, parquet, and small interior elements. In terms of hardness, jatobe is followed by sucupira, Amazonian yarra, mutenia, walnut, ash, and oak. And among coniferous species, the record for hardness belongs to larch, products from which are equal to stone ones. Hard varieties of trees have found their application in the manufacture of high-strength structures.

Physical characteristics of wood

Like any building material, wood has a number of physical properties:

Density is measured in g/cm3 and depends on the type of wood and its moisture content. The higher this indicator, the stronger and heavier the material, it is more durable and less susceptible to rotting.

The most dense wood is considered to be oak, ash, maple and larch, and the least dense is aspen, spruce and fir. The moisture content of the wood indicates the degree of its quality and durability. Room-dry has 8 - 12% moisture, air-dry from 12 to 18%, and atmospheric-dry 18 - 23%. If the humidity is even higher, then such wood is called damp. Acoustic conductivity and thermal conductivity are important qualities.

High-quality dry wood perfectly retains heat and sound in the transverse direction. Thermal conductivity along the fibers is reduced, but sound travels perfectly along the trunk. This is even an indicator of quality and dryness. Corrosion resistance, which is higher in coniferous wood, due to the presence of resin in it. Texture, color, smell and shine make it possible to determine the type of wood and determine its decorative value.

All of the listed physical properties are very important for the use of a particular tree species.

Properties of wood of various species

The structure of wood and the thickness of its layers determines its basic properties.

The properties of wood depend on its structure and thickness of layers. The structure of wood and the thickness of its layers determine its basic physical and mechanical properties. Thus, the strongest wood, resistant to damage and durable, is found in late-forming layers called sapwood. This statement does not apply to larch, whose core is twice as strong as sapwood. Builders of houses made of rounded logs need to be aware of this property when choosing the type of wood, since in the process of processing logs on a machine, the strongest outer part is cut off, leaving the inner, softer part. It is the wrong choice of wood in construction that can ruin the work and significantly reduce the service life of the facility.

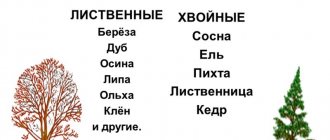

There are two main groups of tree species: coniferous and deciduous. Let's look at the characteristics of some of them.

The most famous domestic conifers are pine, cedar, and spruce. Pine wood is very popular and easily available. It has a smooth trunk, which is convenient for cutting. It also has greater density and strength, and is impregnated with resin, which protects it from rotting. Pine is mainly cut into boards. It is easy to saw when freshly cut, but when dry, it pricks and makes processing difficult. Pine is a raw material for the production of cellulose and feed yeast. Fiberboards are made from it, medicinal resin and biologically active substances are extracted.

Cedar is quite a bit weaker in quality than pine. But it is more resistant to rotting and does not crack when dry. The texture is very delicate, young – pink, late – pink-yellow, indispensable in the production of carved products. Valuable cedar oil and turpentine are extracted from pine nuts, and medicinal balms are made.

Larch is the standard of strength among conifers. This is an excellent material for construction. Larch is three times stronger than pine. Floors, furniture, and veneer are made from it. Larch is very resistant to rot. In Siberia, larch is used to build log houses (log houses) that are resistant to adverse weather conditions that last for many decades. The texture of larch is attractive, the color is brownish, it looks very good when varnished and lends itself well to processing.

In deciduous species, oak takes precedence in value and quality of material. Oak material is stronger and denser than pine, and is more resistant to decay from pine. It has an attractive texture and good bite. Amenable to the most complex processing. Durable and reliable parquet, window frames and doors are made from oak. After painting and polishing it acquires unique beauty. Bog oak is a tree that has been in water for a long period of time and has a dark green, almost black color. It also has many tanning-extractive substances used in medicine for the treatment and prevention of various inflammatory diseases, as well as for the preparation of edges and leather.

Birch wood, which is white in color, is used mainly to make small items. It is very easy to process in its raw form, but usually warps when dried. Staining and polishing give birch a special beauty.

Rowan is a high-strength and fire-resistant working material. Craftsmen use rowan sapwood to make handles for hammers and axes, stools, benches and other durable household items.

Aspen is easy to process and has white or slightly greenish wood. The level of strength is almost like oak. Aspen wood is used to produce matches, toys and all kinds of necessary little things.

Linden is a good material for decorative crafts. Drawing and school boards, office furniture, desks and even pencils are made from linden wood. Linden wood is pinkish-white, very soft, resistant to cracking and deformation. Very easy to process.

Pear is a very durable and reliable material for processing and polishing, but it chips if not handled carefully. Pear is often used as an imitation of mahogany. Has a heavy structure. Various small appliances are made from pear, as it does not deform when dried.

The wood of the apple tree has an original yellow-pink color. It is used only in a dry state, as otherwise it will warp very much. Apple trees make high-quality carpentry, the wooden parts of musical instruments and various small souvenirs are made from it.

Ash is similar in structure to oak, but a little lighter. Impact resistant, flexible and does not splinter. These qualities have made it indispensable in the manufacture of hockey sticks and tennis rackets.

Walnut is a very durable and reliable material. It is often the choice when making furniture. This is due to the beautiful texture pattern. Walnut is used to make plywood, wooden components for hunting tools, and carved finishing components for furniture. Old walnut wood, which has unique beauty, deserves due attention.

Treatment

Although birch wood is dense, it can be easily processed with any tool, both manual and mechanized. Processing on planing machines, manual milling machines, turning on lathes allows us to obtain clean surfaces of a high class of cleanliness. At the same time, the likelihood of chipping on products is very low, and with certain skills it is reduced to zero.

Cutting with chisels or knives both along and across the grain allows you to get very clean cuts. The main condition for this is a sharp tool. According to these characteristics, birch wood is superior even to linden wood.

Due to the fact that birch is very finely porous and dense, it lends itself well to grinding operations. The resulting surfaces are very smooth and have a silky soft shine.

Treated birch wood surface

The process of gluing birch wood blanks does not cause any difficulties; the glue adheres tightly to the wood, forming strong joints.

Mordants and stains perfectly color wood, and an imitation of mahogany or walnut is easily obtained. Varnishes and polishes easily adhere to birch wood, forming high-quality external coatings.

Valuable wood species

Valuable breeds have a wider purpose than ordinary ones. They have an interesting, beautiful texture, a wide range of colors, original patterns, and high density. The color range of wood is used by building designers to create decorative interior items. Valuable rocks are much more expensive than construction rocks due to the listed artistic qualities.

A rare and valuable species of wood is boxwood, which has a pleasant yellow-gray wood color. It has great strength, which can be compared to the strength of bone. Wooden parts of musical instruments, engraving boards, carvings, and buttons are made from boxwood. Engraving on boxwood turns out elegant and smooth, which has a positive effect on its quality.

In the distant 18th century, wood began to be imported to Russia from distant subtropical countries. The height of fashion was furniture made from mahogany mahogany, and the work was carried out by master cabinetmakers. The chambers of the royal palaces, and later the homes of the rich nobility, were furnished with such furniture. Mahogany wood has white sapwood and a contrasting red-brown core, which creates a very interesting combination and fertile ground for the manifestation of the artistic imagination of craftsmen.

Equally popular was black ebony, which had white sapwood and a glossy black core. These colors of wood created a unique artistic contrast, which greatly attracted master artists who made souvenirs and all kinds of decorative items. It was also used to produce piano keys, woodwind instruments, and inlays. The density of wood is 1000 kg per 1 cubic meter.

Valuable breeds also include domestic breeds. These are walnut, ash, oak, alder, cherry and others. The list can be continued with rare tree species growing in remote areas. These are sequoia, eucalyptus, yew, rosewood and others.

All these breeds are used for making interior items, works of art, and designer jewelry, which allows us to fill our lives with positive energy, positive emotions and a sense of peace.

Mechanical characteristics of wood

The mechanical properties of different types of wood are more important. After all, they influence the strength and durability of buildings or wood products. Mechanical strength is the ability to resist various static and dynamic influences from the outside.

The strength of a material depends on the direction of the load. In this regard, it is customary to distinguish between shear or shear strength, bending strength and compression strength. Any wood has greater strength along the grain than across it.

Testing the strength of a wooden block in the direction of load

It is worth noting that damp wood becomes less durable. The same is observed in light and loose breeds.

Plasticity is the property that allows you to create bent parts from wood. More plastic rocks retain the shape obtained under a certain long-term exposure.

Humidity and temperature greatly increase this indicator, so to make curved parts, wood is exposed to hot water or steam. Beech, elm, oak, and ash boast high plasticity. This cannot be said about conifers, since the structure of their fibers is too linear.

The hardness of wood is the ability to resist various penetrations of foreign bodies into it. There are hard tree species, such as: beech, maple, larch, oak, ash, elm (the hardest are boxwood and acacia) and soft ones, such as: linden, alder, spruce, pine. The level of wear resistance of wood directly depends on its hardness.

Deciduous hardwoods

These include trees such as oak, maple, birch or ash. They are used less frequently in construction. Birch has greater bending strength compared to pine (99 MPa). Additionally, birch wood is lighter and more resistant to various damage. Birch bars are often used to make the handles of various tools. It has also found its application in the construction of frames for upholstered furniture. Birch lumber has a light white hue.

Oak wood is very dense (800 kg/m3) and hard compared to other species. Due to these characteristics, oak is often used in industry. Oak wood is actively used to create decorative interior elements, a variety of musical instruments, as well as luxury expensive furniture.

Oak lumber comes in a variety of colors - from dark brown to light shades. The cost of such wood is higher compared to pine, since the growth period of oak is much longer (forest resources are renewed much longer), and it also has unique performance characteristics.

Definition

Deciduous wood species grow in temperate climates, with standard seasonal alternation - spring, summer, autumn, winter.

Trees in deciduous forests reach a height of 25-30 meters. They are predominantly distributed in the northern hemisphere of the planet (North America, western and eastern Europe, eastern regions of Asia), but are also found in the southern hemisphere (Chile, Argentina).

Deciduous forests can grow separately, or they can be part of mixed forests.