Articles

Have you decided to build a wooden house on the site? Most developers choose the material as wood. But why? After all, wood has a lot of disadvantages, especially for log houses, which must stand for quite a long time to shrink.

Coniferous forest. Photo: irkutsk.news

Why is wood still a popular material in house construction:

- The financial costs for this material are quite low, as well as for operation, because a wooden house retains heat, therefore it does not require investments in insulation and heating; the costs will be lower than a house built from another material.

- Wood is an environmentally friendly material that is completely harmless. In such a house, evaporation will not accumulate and, accordingly, the microclimate in it will be comfortable for residents.

- The fast construction process is another advantage of a wooden house, because it takes no more than one month.

Pine logs for a log house. Photo: by.all.biz

Choosing the type of wood is much more problematic than the construction itself. Let's figure out which type of coniferous wood to choose for construction.

Softwoods are the choice for construction in harsh climates, and they have their own advantages and disadvantages.

Advantages of coniferous wood

- Easy installation when building walls due to straight shapes.

- Coniferous species are moisture resistant, unlike deciduous species.

- Coniferous species are distinguished by strength and durability and do not have obvious flaws such as cracks and knots. Use the lower part of trunks, such as pine, there are practically no knots on it.

Pine edged timber. Photo: images.by.prom.st

Disadvantages of softwood wood

- The flammability of coniferous wood has a fairly high coefficient because it contains a lot of resin. Usually, before construction, wood is de-tarred and treated with special means, but this increases construction costs.

- Coniferous wood is susceptible to the disease “blueing” - this is the process of the appearance of mold, which has a bluish color. All this happens due to the looseness of the outer layer of wood. It is possible to prevent the process of “blueing” by treating with an antiseptic and drying the wood, but all this depends on the development budget.

Spruce logs. Photo: landscapedizajn.ru

Despite such serious shortcomings, you should not refuse wood for building a house.

What you need to know about wood species

There are a lot of trees growing in nature. Today there are many types of wood, which, naturally, have different properties and their own characteristics.

In order not to make a mistake in choosing a breed specifically for your operational tasks, you need to know its general characteristics and scope of application. We'll talk about this today.

Sapwood and heartwood

The structure of any tree, regardless of its species, consists of core and sapwood. The core is the inner, central part of the trunk, consisting of dead wood. Surrounding the core is a layer of living cells called sapwood.

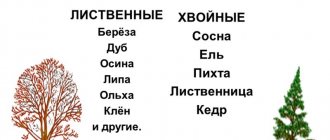

Tree species are generally divided into deciduous and coniferous, as well as:

- sapwood: the core of their trunk does not die (linden, alder, maple, birch);

- sound: the core has a dark shade (oak, ash, pine);

- mature wood: the shade of the core is identical to the color of the sapwood (spruce, aspen).

The color of wood depends not only on the species, but also on other equally important factors, for example, the growth rate of the tree and its age. The heartwood is usually always darker than the sapwood (with the exception of mature wood species).

Hardness

It is quite natural that the harder the tree, the greater wear resistance, practicality and durability the lumber or product made from it will have. The wood hardness coefficient is determined using the Brinnell method.

The method is as follows: a metal ball with a diameter of 10 mm is pressed into the surface of the sample with a force of 100 kg. Depending on the type of deformation and the diameter of the depression formed on the surface, the result is determined - the higher the coefficient obtained, the harder the wood. Each test sample is compared with the hardness of different minerals - from talc to diamond, indicating a hardness coefficient, which, accordingly, varies from 1 to 10.

Dwarf blue spruce

Beloved for its beautiful silver-blue color, dwarf blue spruce is a good choice for small landscapes. Many plants reach no more than 2.5 meters in height and width.

Name: Picea pungens 'Montgomery'

- Growing conditions: full sun and well-drained soil.

- Size: Varieties can grow up to 3 meters.

- Why it's worth growing: blue color and small size

Softwood

They have a fairly light structure, so they can generally be processed without any problems. Coniferous trees are used to produce a variety of lumber, building elements, furniture, and decorative elements.

Coniferous wood is resistant to rotting and has antibacterial properties, which makes it relevant for capital wooden house construction, the construction of log bathhouses or reliable outbuildings.

Pine

Features of wood

Pine wood has a sufficient degree of resin, is moisture resistant, not very susceptible to rotting, has high air permeability and ideal sound absorption properties.

The density and specific gravity of wood directly depends on the conditions in which pine grows. Trees grown on dry soils, especially sandy ones, produce dense wood with annual rings as closely spaced as possible - it is very valuable in construction.

Pine, which grew in places with high humidity, most often has a loose woody structure, which means that it is definitely not suitable for the construction of structures with a load-bearing load, but it will definitely find use in the process of construction work.

Pine cut.

Technological properties

Density: 470 kg/m3.

The pine trunk is almost always straight, this ensures comfortable sawing. Freshly cut pine can be sawed without difficulty, but when dried it splits into chips, which can significantly complicate the processing process.

Application

Pine wood glues easily, so it is successfully used in the production of laminated veneer lumber and in the furniture industry. It is used in the process of manufacturing doors, door and window frames, platbands, and is indispensable in the construction of log houses of residential buildings or baths.

Pine window.

Spruce

Features of wood

A low-resinous, mature wood species of light yellow color is inferior to pine wood in terms of moisture resistance and thermal conductivity. Unfortunately, solid spruce logs or spruce-based lumber rot more quickly and are less durable due to the soft structure of the wood.

Spruce cut.

Technological properties

Density: 450 kg/m3.

This wood is not very easy to process, since the spruce trunk has significant knots. However, this disadvantage of spruce wood is fully compensated by its resistance to cracking and deformation, as well as easy gluing, staining and painting.

Application

The main use of spruce wood is the construction of wooden houses and the production of various lumber.

Spruce house.

Cedar

Features of wood

Color - from pink to pink-yellowish, the intensity of the wood tone depends on the age of the tree and changes over time, becoming more impressive, beautiful and noble. High-resin cedar wood does not deform, does not rot, is not affected by wood-boring beetles, and is not afraid of temperature changes and exposure to chemically aggressive environments.

Cedar cut.

Technological properties

Density: from 426 to 455 kg/m3 (depending on the location of the tree).

Due to its plasticity, cedar wood lends itself well to processing, which makes it possible to embody the most daring design ideas in terms of wooden house construction.

Application

Typically, cedar is used as a material for spectacular finishing when creating luxury interiors or as decorative elements of furniture. Despite the ideal heat and sound insulation parameters of cedar wood, it is not always advisable to use it in the construction field, given the significant high cost of the material.

Bathhouse trimmed with cedar.

Larch

Features of wood

It belongs to the heartwood species, it is distinguished by a red-brown core, light-colored sapwood with very contrasting growth rings, which give the wood a versatility of color palette.

Larch wood does not absorb moisture, it is not afraid of attacks by insects and molds, it does not rot and has very high fire resistance.

Larch cut.

Technological properties

Density: 640 kg/m3.

The impressive strength indicators and high resin content of this wood create some difficulties in its processing, especially by machine. An important point: to prevent larch from splitting and suddenly “spreading” with numerous cracks when cutting, scrupulous adherence to a special and rather labor-intensive drying regime is required.

Application

Larch wood is widely and successfully used in construction, in particular for the construction of log buildings of wooden buildings, which will subsequently be operated in conditions of very high humidity or even in direct contact with water.

Floors, solid load-bearing walls, furniture made of larch wood or finishing of any products with larch veneer serve flawlessly for decades without losing their original shape and their original attractiveness.

Larch board.

Fir

Features of wood

Low-resin, light, quite soft and flexible in structure coniferous species. A small amount of resins, unfortunately, gives this wood disadvantages such as warping and rotting at high humidity. However, the incredibly beautiful texture of fir wood and resistance to impact loads smooth out these shortcomings.

Fir cut.

Technological properties

Density: 380 kg/m3.

Fir wood is very easy to process and can be stained, painted and coated with varnish without any problems.

Application

It is relevant in the process of erecting rafters; it can be used for internal wall cladding or to create reliable partitions in a room. Fir wood harmoniously reveals its beauty and grace in decorative elements of furniture or in the openwork nuances of wooden architecture.

Fir board.

Weeping white pine

An absolutely graceful tree, the Weeping White Pine looks like a waterfall of beautiful blue-green needles. It is especially effective when grown near a pergola or other structure to create a curtain effect. Additionally, this tree is highly adaptable and grows in many areas.

Name: Pinus strobus 'Pendula'

- Growing conditions: full sun and moist, well-drained soil.

- Size: As tall as it can be supported, but grows as a ground cover without support

- Why it's worth growing: For its long, soft needles as well as its ground cover.

Hardwood

The wood of deciduous trees is used both in construction and in the production of furniture or in creating spectacular and extraordinary decorative elements.

The variability of the palette of shades of hardwood and a wide range of tensile strength (from 40 MPa for soft species (linden, chestnut, poplar) and up to 80 MPa for hard species) allows you to competently select and use wood for its intended purpose, taking into account its features and technological characteristics.

Linden

Features of wood

The diameter of the trunks of 40-year-old linden trees can reach two meters. The color of the wood is uniform and can vary from white and cream to yellowish and light brown. Linden wood does not warp or crack during use.

Linden cut.

Technological properties

Density: after drying 535 kg/m3.

End surface hardness: 448 kgf/cm2.

It is very easy to process and is extremely flexible, which is why it is incredibly popular among wood carvers.

Application

Of course, excessively soft linden wood is not suitable for capital construction, but it is no coincidence that it is in impressive demand in the furniture industry (veneer, plywood), the manufacture of musical instruments, wood carving and the production of original decorative items.

Linden casing.

Oak

Features of wood

The sapwood is slightly lighter than the yellow-brown heartwood; a spectacular pattern of silvery “rays” is clearly visible on the cut. The wood is dense and durable, but under conditions of slow tree growth in an unfavorable climate it can be more loose and soft.

Oak slice.

Technological properties

Density: after drying 690 kg/m3.

End surface hardness: 622 kgf/cm2.

Oak wood is not poorly processed. Oak can be painted, polished, bleached and glued well; there are no problems with staining this wood either.

Application

Oak wood is an excellent material for making parquet, paving stairs or making reliable railings. Solid oak or veneer made from this wood is indispensable in furniture production - the result is solid, exclusive, solid and timeless products.

Oak board.

Beech

Features of wood

Freshly cut beech has a wood with an even texture of a light brown hue; when dry, it acquires a red-brown tone. Raw beech has approximately the same parameters as oak wood. By the way, after drying, beech wood becomes much stiffer and stronger, better able to withstand impact loads, surpassing oak in these indicators by 20%.

Beech cut.

Technological properties

Density: after drying 690 kg/m3.

End surface hardness: 622 kgf/cm2.

The wood is easy to process; beech lumber is easily glued, painted, varnished and polished. Keep one thing in mind: beech wood is highly hygroscopic, so it is definitely not suitable for use where there is excessive humidity.

Application

Beech is used in the furniture industry (after steam treatment it acquires good flexibility), parquet boards are made from it, exclusive stairs and all kinds of interior items with a claim to originality are made.

Beech board.

Ash

Features of wood

During the drying process, ash wood acquires a slightly yellowish tone. There may be specimens in which the core zone has almost black strokes - this gives the wood decorative exclusivity; this option is usually called “olive ash”.

In terms of its technical parameters, ash is almost similar to oak wood, but has more impressive resistance to splitting.

Ash cut.

Technological properties

Density: after drying 710 kg/m3.

End surface hardness: 400 kgf/cm2.

The increased viscosity of ash wood does not interfere with its manual or machine processing. The resulting material has a smooth surface, adheres perfectly, and can be easily polished and painted with all kinds of paint and varnish products.

Application

Ash wood is in demand in the production of veneer and durable plywood, and is used for the manufacture of furniture, sports equipment, and handles for various tools.

Ash plywood.

Maple

Features of wood

Maple wood is dense, quite hard, light yellow in color, with a slight shine. When impregnated with special compounds, it acquires quite high strength indicators.

Maple slice.

Technological properties

Density: after drying 630 kg/m3.

End surface hardness: 470 kgf/cm2.

Maple wood tends to crack, so when drying it, you need to strictly follow all the nuances of the regime. It is easy to process and after it takes on a very impressive look.

Application

It is used for the manufacture of natural veneer in the production of musical instruments, furniture, as well as a variety of carpentry and turning products.

Maple veneer.

Birch

Features of wood

This wood does not have a clearly defined core. The color of fine-grained wood generally varies from cloudy white and pinkish to light brown. When dried, birch wood is very similar in mechanical parameters to beech wood, although it exceeds its technical characteristics in terms of strength and rigidity.

Birch cut.

Technological properties

Density: after drying 670 kg/m3.

End surface hardness: 392 kgf/cm2.

Birch can be easily planed, machined, profiled, painted, glued, and polished.

Application

Birch wood is used to make plywood and veneer, produce furniture and a variety of decorative fittings, make original carvings and even firearm butts.

Birch edged board.

White pine

One of the most unique pines in the landscape, white pine has twisted branches and needles that give a distinct silhouette.

It also has a small area, growing approximately 3 meters at maturity. It is one of the most popular types of coniferous trees.

Name: Pinus strobus 'Contorta'

- Growing conditions: full sun and well-drained soil.

- Size: up to 15 meters or more

- Why it’s worth growing: the interesting effect that the branches and needles give.

Japanese white pine

A tree of exceptional beauty, Japanese white pine has clusters of silver-blue needles and beautiful vegetation that looks especially good in winter.

Name: Pinus parviflora

- Growing conditions: full sun and moist, well-drained soil.

- Size: Varieties can grow up to 25 meters.

- Why it's worth growing: Blue-green needles and unique tree shape.

Juniper Blue Star

Among thousands of junipers, Blue Star stands out for its silvery color and dense, ground-hugging vegetation.

Name: Juniperus squamata 'Blue Star'.

- Growing conditions: full sun and well-drained soil.

- Size: up to 40 centimeters in height

- Why it's worth growing: A beautiful silver-blue groundcover.

Types of lumber

By shape and type of processing

Wood lumber is divided into several types:

- unedged board.

It is obtained by one-time sawing of a log lengthwise. In dry form, it is a blank for the production of joinery; - edged board

. It is obtained by sawing the log lengthwise twice. Widely used in roof and building structures. After drying, up to 18-20% is used in the construction of frame houses. In dry form (with a humidity of 12-14%) it is a raw material for the production of planed products (lining, imitation timber, floor boards, etc.); - bar.

Used to create frames. In dry form, it is also the starting material for the production of load-bearing beams and furniture panels.

Dwarf Albert spruce

Known for its dense growth, small needles and near-perfect conical shape, dwarf Alberta spruce is easy to grow.

- Growing conditions: full sun and moist, well-drained soil.

- Size: Varieties can grow up to 6 meters in height.

- Why it’s worth growing: beautiful small needles, easy to care for.

Fir - a tree with purple cones

An evergreen representative of the Pine genus. It differs from its close relatives in the characteristics of its needles:

- softness;

- shine;

- flat shape.

White stripes are visible on the underside of each needle, which gives the plant a festive look. The fir tree is decorated with purple cones, which is its main highlight. It grows slowly for 10 years, after which growth accelerates. Lives about 400 years. Breeders have developed decorative varieties that are used to decorate urban and suburban areas.

Since the needles of the tree have healing properties, growing fir in your summer cottage is a great idea. It helps in the fight against colds, radiculitis and wound healing.

Why is it profitable to buy lumber from us?

In the Klisko online store you can buy boards in Kaliningrad and other lumber online and with a guarantee of shipment the next day of order. We have a wide selection of products from different types of coniferous wood and favorable order conditions:

- You can buy everything you need and pay by card directly through the website, with a 3% discount (except for edged products);

- delivery in Kaliningrad and the region is carried out by the company’s transport, pickup is also possible;

- all coniferous planed and laminated lumber that we sell are dried in special chambers at the manufacturing plant;

- storage rules at the Kaliningrad warehouse also exclude dampening of products.

For a manager to advise you on product selection and help you place an order, contact him by phone. At the same time, you can find out from a Klisko employee what advantageous package deal the online store can make for you.