Wood is an excellent material for construction work. It is environmentally friendly, durable, and retains heat well in the room. But it also has its drawbacks. The main one is poor resistance to external factors. Fungus, moss and wood-boring beetles often settle on its surface. It does not tolerate moisture well and is susceptible to rotting.

Treating wood with antiseptic

All of these problems can be avoided. It is enough to treat the material with an antiseptic. It can be bought at any building materials store. But it is much easier and more economical to prepare it yourself. How to make a wood antiseptic with your own hands and use it correctly - read about it in our article.

The relevance of using antiseptics for wood

After cutting down a tree, its fibers die, which disrupts the exchange of moisture between the tree and the environment. The corresponding imbalance contributes to the spread of multi-colored fungi (saprophytes) outside and inside the wood fibers. If the pathogenic microflora is not stopped in time, the forest will rot and turn into dust.

It is not surprising why sawn wood, being “opened”, quickly deteriorates due to the following negative factors:

- Changeable air humidity (and humidity changes even if there is no precipitation);

- Insect invasion.

Inside the warehouse, the log house also remains unprotected. Therefore, wood must be treated with an antiseptic. This event is especially relevant for hardwoods, which have no resins inside.

Dependence of wood biostability on external factors

The resistance of wood material to biopests depends on many factors; during the construction and operation of a wooden house, it is important to provide optimal conditions for its protection. Putrefactive fungus affects not only lumber with natural moisture content, but also air-dry and semi-dry construction wood with a moisture content of 18 to 22%. To a greater extent, the activity of putrefactive fungus depends on the environment and the influence of external factors. The development of microorganisms is accelerated in conditions of high humidity, in swampy and low-lying areas; favorable factors for the development of fungus include:

- Constant moisture content of lumber exceeding 18%,

- Water flowing into the cracks between the crowns,

- Direct contact of the tree with moist soil,

- Ambient temperature from +5 to +35 degrees.

Rot most often affects walls facing north and lower crowns. The warm and humid climate promotes the activity of wood-boring insects, which use wood as a product for their livelihoods.

Experts note that the conditions for the development of fungus can be the most unexpected. For example, a house surrounded by a solid high fence is more susceptible to rotting due to insufficient ventilation.

How to make an antiseptic

The antiseptics produced at the factory are effective. However, they have to spend a lot of money. If the construction of a large facility or renovation of a finished structure is at stake, then you can save on wood processing by using a homemade antiseptic.

Despite the availability of such a product, the quality of its impregnation is not satisfactory.

Over the centuries, carpenters have developed many recipes for preparing wood antiseptics. Moreover, the most effective processing agents appeared relatively recently.

Conclusions and useful video on the topic

Recipe for preparing wood impregnation:

Detailed instructions for making impregnation for fire-bioprotection at home are in the following video:

Wood has always been in demand and people have invented various ways to protect it from pests and minimize the harmful effects of precipitation, high and low temperatures. You can use both purchased products and make your own using natural ingredients, most of which are available on the farm.

What antiseptic do you use? Share your recipe for the perfect impregnation, which is easy to prepare yourself - the comment form is located below. If you have questions about wood preservatives or application nuances, ask our experts and other site visitors.

Bitumen antiseptic

Impregnation with bitumen is capable of penetrating into the wood structure to a depth of up to 8 mm. In the future, the mixture repels insects and prevents waterlogging. This is quite enough for bitumen-based impregnation to compete with expensive factory-made analogues.

The thematic composition includes bitumen and any substance with a diluting effect - gasoline or diesel fuel. If the latter allows the solution to remain liquid for good impregnation of the array, then gasoline speeds up the processing. The thing is that its flammable mixture quickly evaporates.

The process of preparing bitumen antiseptic occurs carefully and consistently:

- First, bitumen must be melted in a metal container under the influence of fire;

- Next, the main material is cooled and poured into a second container;

- The next stage is the gradual addition of solvent and its subsequent stirring with the base until a homogeneous state is obtained.

Typically, the share of solvent is 20-30 percent of the total mass of the future composition. To make the solution more liquid and volatile, the solvent concentration is increased by 5-10 percent.

A small flame must be used to heat and melt the bitumen. Melting occurs slowly until a certain percentage of the liquid evaporates from the bitumen.

It is recommended to carry out the event in the open air or next to a factory hood (the whole point is that melting bitumen emits toxic fumes). The process must be constantly monitored so that the bitumen, when swelling, does not overflow over the sides of the container. For added fire safety, it is recommended to have a fire extinguisher on hand.

Classification

There is a classification of such means, knowledge of which helps to understand which option should be chosen for a particular situation. The following types of products are distinguished:

- For internal processing, they must be harmless to the body;

- For external coatings, they must be resistant to pests, as well as ultraviolet radiation;

- Water-based, which are most often used for application indoors due to their safety for human health;

- Oil-based, they have an unpleasant odor, so they are applied outside the building, but are environmentally friendly;

- With a wax base;

- Contains solvents.

For external coatings, they must be resistant to pests, as well as ultraviolet radiation.

Salt impregnation

The appropriate composition includes sodium fluoride, which is a white powder. The main advantage of salt impregnation is that the wood does not deform.

Also, sodium fluoride does not change the color of the array in any way. However, the solution is washed off by precipitation, so it is recommended to supplement it with different coatings.

The recipe for making salt impregnation is simple:

- First, sodium fluoride is dissolved in purified water in a ratio of 1:10 (in some cases the ratio is 1:8 or 1:12);

- Next, the resulting concentrate is fed into a device for airless painting;

- The next stage is processing the array under a pressure of about 200 bar.

Subsequently, the impregnation must dry so that the surface can be sanded. After mechanical processing, the lumber is varnished.

Aqueous antiseptic solutions

Aqueous antiseptics are prepared quickly and safely. To make the composition, it is necessary to heat the water, where one of the selected elements will then be dissolved. Next we will look at working with different options.

Aqueous antiseptics are prepared quickly and safely.

Sodium fluoride

For this recipe you need to use 10-40 grams of this ingredient per liter of water. More components are used when they are going to cover an object outside the building. To work inside, you can limit yourself to 5 grams. In order to see which area has been treated during application, they resort to treating the wood with potassium permanganate, which is added in small quantities to the mixture; after drying, the color will disappear.

For this recipe you need to use 10-40 grams of this ingredient per liter of water.

Copper sulfate

This substance is used when dealing with an object buried in the ground. Add 1-2 kg of vitriol to 10 liters of water. You should know that a large amount of the substance will make the solution take a long time to dry, but also be more effective. Vitriol also leads to a change in the shade of the surface.

This substance is used when dealing with an object buried in the ground.

inkstone

This material promotes good pest control; it can remove insects from an already infected tree. But its decorative properties are poor.

For 10 liters, add 50 grams of vitriol, as well as 5 grams of potassium permanganate. Instead of potassium permanganate, a water-based pigment is added for visual perception.

This material promotes good pest control; it can remove insects from an already infected tree.

Wax impregnation

The ecological purity of the wax contributes to the harmlessness of the antiseptic itself. Many ready-made substances lack this quality. But sometimes you have to impregnate wood in a closed space, the ventilation of which leaves much to be desired.

Appropriate conditions welcome the use of wax. After its application, the array acquires an emphasized texture and a slight matte finish.

The wax also gives off a pleasant smell.

For thematic impregnation you need:

- Melt the wax using a steam bath;

- Sequentially add rosin and turpentine to the wax mixture, maintaining a ratio of 3:1:1, 4:1:1 or 4:1:2 (when adding each substance, the solution is thoroughly mixed);

- Pour the finished substance into a metal container.

After cooling, the wax impregnation acquires a paste-like state. This substance can be used to treat wood and even fill various cracks. Wax paste welcomes storage in a closed container at room temperature.

The best homemade impregnation recipes

A worthy alternative to store-bought impregnations is homemade antiseptics. Their effectiveness has been tested by time.

All home-made impregnations have a number of advantages:

- financial savings;

- efficiency, especially if bitumen or vegetable oils are used;

- significantly lower degree of toxicity of the finished product.

Necessary personal protective equipment when preparing homemade antiseptic: rubber gloves, shoes, respirator, robe, apron or special suit, glasses.

When working with a spray gun, a special suit is the most reliable protective clothing that will prevent the product from getting on open areas of the body

No. 1. Oil-based products

Oil-based protective products do not cause allergies when used. When processed internally, they add shine to wood surfaces.

For homemade impregnation, hemp or linseed oils, bitumen, and motor oil (used) are used.

A self-made antiseptic based on oils has proven itself excellent for both external and internal use. To make it, they mainly use technical varieties of linseed oil, which by its natural properties is a water-resistant polymer. To improve the quality and properties of the drug, extracts of burdock, elecampane or galangal are added.

To treat log buildings, you can use unrefined linseed oil, for which the most suitable thinner is pine turpentine. This option does not require large financial investments and the polymerization period is much shorter

The protective bitumen agent has several positive properties:

- availability of bitumen;

- Possibility of use in environments with high humidity levels;

- In addition to general biological protection, impregnation gives the wood hydrophobic properties.

Protective properties are maintained for a long period of time. The penetration depth of the impregnation is about 7 millimeters.

The bitumen agent is applied to the surface with a regular paint brush. After complete drying, it is necessary to open the wooden structure with oil paint. Under no circumstances should paint materials containing cellulose nitrate be opened.

Bitumen impregnation No. 1

A bitumen-based antiseptic helps preserve poorly dried wood. Glubokoye penetrates into the thickness of the wood material and at the same time allows it to “breathe”.

The technology for preparing the liquid mixture is simple. In a metal container, 1.5 - 2 kg of bitumen (depending on thickness) is heated to a temperature close to boiling.

Then the heating is stopped, removed from the heat and 1 liter of diesel fuel is added to the bitumen mass, mixed until a liquid consistency is obtained, which will remain fluid even after complete cooling.

Bitumen impregnation No. 2

If it is not possible to produce impregnation using this method, then diesel fuel can be replaced with active solvents - kerosene or high-octane gasoline. During production, the above proportions are observed: for 1.5-2 kg of bitumen, take 1 liter of gasoline/kerosene.

This method of creating a fast-drying, deep-penetration preparation based on bitumen does not require heating - just stir until it is completely dissolved.

After application, the dried surface can be covered with a layer of primer, and then painted or opened with a special varnish. Nitro varnishes and nitro paints cannot be used for coating.

No. 2. Water-based impregnations

The most popular water antiseptics made at home are using sodium fluoride and copper sulfate.

Recipe #1 - antiseptic with sodium fluoride

One of the safest for humans and domestic mammals is a low-toxic antiseptic based on sodium fluoride. The required concentration of the finished solution is from 0.5 to 4%.

The entire manufacturing process of this protective impregnation consists of stirring until the substance is completely dissolved in hot water.

When making impregnation, the following proportion must be observed:

- sodium fluoride - 50–400 grams;

- hot water - 10 liters.

To work indoors, the concentration of the solution should be less saturated, and outside it should be much stronger. To be sure of the accuracy of the concentration, you can use potassium permanganate as a marker, which will act as a litmus test and give a textured, visually visible coloring of the wood, which disappears after the surface dries.

An aqueous solution of sodium fluoride is mainly used to treat exterior wood surfaces that do not touch the ground. The effect will last longer if you open them with varnish. This will prevent protective substances from being washed away by rain, melt water and snow.

Applying an antiseptic to wood with a roller is a faster and more economical method. For a high-quality coating, you need to buy a lint-free roller

To treat monumental wooden structures made of wood that are in direct contact with the ground, you can use an aqueous solution based on copper sulfate.

Recipe #2 - impregnation with copper sulfate

It is safer to prepare impregnation for wood based on copper sulfate in a closed container, as harmful fumes are released.

Required components:

- copper sulfate - 200 milligrams;

- potassium permanganate - 20 grams;

- water - 20 liters.

To prepare this solution, you must thoroughly mix these ingredients. For greater convenience and to obtain a homogeneous consistency, it is better to mix in a plastic canister.

Recipe #3 - antiseptic from vitriol and sodium bichromate

Ingredients:

- copper sulfate powder - 0.5 kg;

- sodium bichromate - 0.5 kg;

- warm water - 9 liters;

- vinegar 9% - 50 grams.

Mix all the ingredients and fill with water heated to 50 °C. Mix everything thoroughly and the solution is ready for use.

No. 3. Wax-based antiseptic

Wax not only protects the surface from moisture penetration into the wood and from possible mechanical damage, but also emphasizes the texture and gives it a lasting, pleasant aroma.

Components:

- wax - 100 grams;

- crushed rosin - 25 grams;

- turpentine - 50 milliliters.

The wax is heated in a water bath, then 25 grams of crushed rosin and 50 grams of turpentine are added. The resulting mass should be brought to a boil, removed from heat and wait until it cools completely.

Dry mint or propolis are good shock absorbers that will give the mastic a pleasant aroma. Rub the product in with a lint-free cloth until a shine appears on the wood.

Impregnation with manganese and vitriol

Copper sulfate has an antiseptic effect, which is important when processing wood. The chemical fungicide is so effective that after its impregnation, the array does not rot even in the ground.

The product becomes doubly effective when potassium permanganate is added to the solution:

- First, 100 g of copper sulfate and 10 g of potassium permanganate are added to the water;

- Next, the substances are mixed to obtain a solution;

- The next step is to apply the solution to the surface of the wood using a brush or roller.

Thematic impregnation quickly penetrates into the fibers of the array. Cheap copper sulfate and potassium permanganate make it possible to obtain a large volume of solution for filling deep containers.

The latter are suitable for immersing wood and fully soaking it, respectively (but this measure is used only if necessary).

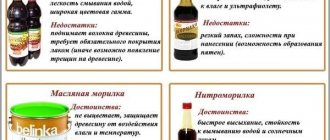

Types of antiseptic compounds

Do-it-yourself antiseptic, or a ready-made one, has the function of protecting against any type of insects; it is advisable to impregnate the wooden material before the construction stage; according to GOST 20022.2, there are 18 types of protective treatment for wood, and antiseptic is one of them.

If necessary, antiseptic agents can get rid of insects that have already settled in the base of the tree. There are 4 types of these solutions:

- With a water base, they are intended for indoor treatment of premises where contact with water is not intended;

- With an oil base, they are used exclusively externally, for example, for impregnating fences and facades. They emit a pungent odor;

- Solvent-soluble, can be used inside and outside the building, petroleum products are used as a base; after impregnating the object with them, a reliable barrier from moisture is obtained;

- Combined, in addition to protecting against insects, they have the function of reducing the flammability of wood.

A do-it-yourself antiseptic, or a ready-made one, has the function of protecting against all types of insects; it is advisable to impregnate the wooden material before the construction stage.

Boric acid impregnation

Boric acid is a substance with a weak corrosive effect. It is mainly used as fertilizer. However, the topical stimulant is also suitable for processing lumber so that the latter is resistant to fungal infection and pests.

The main thing is that the concentration of boron impregnation is balanced:

- In 5 liters of boiling water, 900 g of salt and 50 g of boric acid must be dissolved successively;

- Next, the solution is applied to the surface of the wood until the wood darkens from moisture;

- After a day, the treatment is repeated.

Thematic impregnation extends the service life of wood by 5-10 years. The effect is enhanced after varnishing and painting.

Vegetable oils

You can use vegetable oils for impregnation - flaxseed and hemp. It is important to understand that they will change the color of the surface. The wood will “breathe” and retain its properties. To give the composition the best qualities, it is recommended to add burdock, elecampane, galangal or angelica root to flaxseed oil.

The wood will “breathe” and retain its properties.

Preparing the array for processing

Before using antiseptic impregnation, the surface of the lumber must be prepared.

The corresponding activity is carried out in stages:

- First, the bark and knots are removed and sawed off from the wood;

- Next, the lumber is cleaned of contaminants (this operation occurs first if the lumber has already been used);

- To eliminate irregularities and burrs, the surface is ground;

- The next stage is degreasing the forest area with white spirit or kerosene.

2-3 hours after degreasing, the lumber can be treated with an antiseptic. But if the array was wet, then it must be dried before degreasing.

Nuances of antiseptic “handicrafts”

The quality of impregnation for wood with your own hands depends on the composition; it is also important to understand the features of the manufacture and use of the resulting substance. Therefore, the important points of this process will be described below.

The quality of do-it-yourself wood impregnation depends on the composition.

Pursued goal

Do-it-yourself wood impregnation must meet a number of requirements in order to fulfill its main purpose. There are several main functions required from it to obtain high-quality surface treatment:

- Creating a protective coating from natural influences if the item is used outdoors;

- When used in a humid environment - moisture resistance;

- Wood that will be transported in open transport;

- Wooden material from biological influences and pests.

Do-it-yourself wood impregnation must meet a number of requirements in order to fulfill its main purpose.

Possible ingredients

The result obtained and how well the solution will fulfill its purpose will directly depend on the chosen composition. For independent production of the mixture, the following components are selected as standard:

- Boric acid;

- Gasoline, diesel fuel;

- Bitumen mixture;

- Iodine/green stuff;

- Vitriol with copper or iron;

- Biocidal or clay pastes;

- Salt, soda.

A good and safe option is to prepare a mixture of water and salt; you can safely treat the surface inside a building with it.

A good and safe option is to prepare a mixture of water and salt; you can safely treat the surface inside a building with it.

How to prepare, apply

It is better to prepare an antiseptic at home from safe ingredients. Then the processing and the cooking process itself will be easier. To work you will need containers and mixing tools. If toxic elements will be used, ensure good ventilation in the room.

If toxic elements will be used, ensure good ventilation in the room.

Surface preparation

The item must be cleaned and degreased in advance (alcohol can be used, vodka will also work, but it is better to choose White Spirit). To clean particularly difficult stains, you can try using hydrogen peroxide; glycerin can also be used.

If the appearance of the item is important, then it is necessary to sand the wood for an even coating. It is also necessary to prime the surface; you can use a prepared antiseptic for this purpose, diluting it with a solvent - White Spirit, which can also be used for the degreasing stage.

If the appearance of the item is important, then it is necessary to sand the wood for an even coating.

Relevance of ready-made impregnations

Lumber differs depending on the type of tree. Unlike deciduous trees, needles are more resistant to fungi and pests. At the same time, deciduous crops can be stronger. A striking example is oak.

Therefore, in some cases it is better to use ready-made, highly targeted impregnations, the composition and effectiveness of which have been thoroughly studied:

- Acrylic composition – environmentally friendly, suitable for indoor and outdoor use;

- Salt base - in addition to antiseptic properties, reduces the risk of ignition, suitable primarily for treating rafter systems;

- Oil antiseptic – protects against exposure to ultraviolet radiation, which means it is relevant when treating garden furniture and gazebos;

- Alkyd resin – emits a chemical odor, but emphasizes the texture of the solid well in the presence of wax and oil;

- Bitumen base - has a strong chemical odor, perfectly prevents moisture, but increases the risk of fire (therefore, a fire retardant must be used together with bitumen);

- Silicone antiseptic - covers the wood with a protective film, and the latter does not interfere with ventilation.

As a result, individual antiseptics serve not only as a fungicide, but also as a frost-resistant sealant or fire-resistant fire retardant. For example, salt impregnation reduces the risk of fire, while bitumen creates an airtight layer.

Tips for applying impregnation

Before starting work, it is advisable to more thoroughly prepare the surface on which the composition will be applied. Clean from dust and other contaminants and sand. Pre-treat existing cracks with white spirit and prime with alkyd primer.

Long-handled synthetic brushes or felt rollers are ideal for applying oil liquid. Excess must be removed with a soft, lint-free cloth. Repeat the manipulation in 1-2 steps.

Thick antiseptics are applied with a regular paint brush, sponge or soft rag, or a lint-free roller, while liquid ones are best applied with a spray gun.

When performing work on impregnating wood with an antiseptic outdoors, it is necessary to take into account external factors. It is better to choose dry, calm weather for applying the product.

Designate a special area for work. Prepare in advance all the tools, personal protective equipment and buy the missing items.

Internal wood impregnation work is permissible in well-ventilated areas.

When purchasing lumber, give preference to wood species that are most resistant to the destructive effects of external factors. These include: ash, pine, oak, Siberian larch

If desired, you can also use an old method to protect wood, which practically eliminates costs - roasting or boiling in a saline solution .

You can also impregnate wood using traditional methods - birch tar, flax oil, pine resin mixed with crushed coal and salt.

What is tinting

An antiseptic can give wood a specific color. The corresponding effect is called tinting. To give the impregnating substance a specific color, you must use a tint dye (color, toner). Usually it has a liquid state and is diluted in a ready-made antiseptic solution.

To obtain colored impregnation you have to use a little dye. Therefore, purchasing a ready-made color scheme does not portend large expenses.

The main thing is that it is intended specifically for wood. After impregnation with a colored antiseptic, the array gets a noble appearance.

General rules for application and processing

To obtain an even distribution of the composition, the application itself should be carried out correctly. Experts recommend adhering to the following operating rules:

- If liquid antiseptics are made, then spray with a spray gun; for thicker ones, choose brushes, rollers, or a sponge;

- For safety, the master must wear a respirator and protective clothing, gloves;

- Good ventilation is created inside the room.

For safety, the master must wear a respirator and protective clothing and gloves.

It is possible to make an antiseptic for wood yourself. The main thing is to decide on the components and carry out the process in compliance with safety measures. This is an economical option if large areas will be impregnated.

Photo of homemade antiseptic for wood

Why do you need to process wood?

Treating wood with antiseptics is necessary to protect against pests, bacteria, and mold. Putrefactive microorganisms can change the natural structure of wood fibers in a short time, and fungal spores leave dark stains that cannot be removed.

With constant exposure to moisture, mold appears on wooden objects, which leads to their destruction. Molds have a detrimental effect on human health, and when harmful ergot is first detected, radical measures must be taken.

This is what wood affected by fungus looks like. If proper measures are not taken in time and the harmful spores are completely destroyed, then in a short time mold will cover the entire wooden surface

Antiseptic agents have a general toxic effect on wood borers, putrefactive microflora and cause their death.

When exposed to an antiseptic, a protective anaerobic film is formed on the wood, which is unfavorable for the life of parasites, which also becomes a barrier to the penetration of moisture and oxygen. Therefore, a wooden product (chair, bed, bath, etc.), building (house, bathhouse) or structure (gazebo, summer bathhouse) will last longer.

There are different types of antiseptic impregnations for wood processing:

- Oil-based products are ideal for impregnating wooden facades, outbuildings, garden gazebos, fences, benches and more. These products prevent moisture from seeping into the wood and are excellent pest control. Oil solutions have a specific odor, are toxic, flammable and are not recommended for use in enclosed spaces.

- Wax . The direct purpose of wax-based protective mastic is to protect decorative wooden surfaces and products. The shelf life of the wax antiseptic reaches one year.

- Water based . Excellent for processing interior wooden building structures and facades. The advantage is the absence of toxicity, absolute safety, and the absence of a pungent odor. If the composition contains fire retardants, then this treatment gives the wood fire-resistant properties.

- Based on organic compounds . Organic non-oil products contain isotopes of sodium and phenol. When dry, they form a thin protective layer that protects the wood from the destructive effects of moisture and scorching sun.

Organic antiseptics can also be used outside buildings. After complete drying, it is necessary to open the surface with varnish or apply a layer of paint.

According to the type of protection, antiseptics can be used against rot and mold , and fire-bioprotection (with fire retardants).

Impregnations for interior and exterior use .

You can apply the antiseptic with a brush, but your hand movements must follow exactly the location of the wood fibers

Comprehensive protection of wood is provided by combined antiseptics . These products protect it from inflammation and moisture, and from damage by putrefactive microorganisms.

They contain copper sulfate, which helps disinfect wood, but at the same time changes its natural color.

When choosing organic means of protection, you must remember that they give the wood a dirty greenish tint, and rust forms when it comes into contact with metal.

Processing using the Finnish method

For the Finnish method of wood processing, you will need salt, water, iron sulfate, slaked lime, and flour. Mix the ingredients thoroughly until smooth. Most of the mixture should be water and flour.

Heat the mixture over low heat and immediately apply it to the wooden surface. This composition is not washed off with water and stays on the wood for a long time.

The method is safe, but it is recommended to use it for treating barriers and roofing. After the first layer has dried, repeat the treatment. If the composition has cooled down, it must be reheated.

inkstone

It is produced, according to GOST, under number 6981, developed in 1994 (one thousand nine hundred and ninety-four), where it is called ferrous heptahydrate sulfate (20 percent (twenty percent) is usually found in stores). It is practically non-toxic, however, compliance with safety measures is a prerequisite for using vitriol. Also, according to some data, ferrous sulfate is explosive. Therefore, it must be stored in an airtight container in a dry place. And, of course, if it gets on your skin or eyes, rinse with plenty of water, and after work, wash your face and hands with soap.

So, to treat the ceiling, a 5-7 percent (five to seven percent) solution is enough (500-700 (five hundred to seven hundred) grams per 10 (ten) liters of water), and to get rid of the fungus on the walls, 1 (one) solution is enough. 150 (one hundred and fifty) grams of powder are dissolved in a liter of water. To prevent iron sulfate from oxidizing, add a little citric acid. For the walls of the cellar, prepare a 10 percent (ten percent) solution: mix vitriol with clay to the consistency of sour cream and apply with a brush twice in the fall, but always before storing vegetables.

In order to prepare a waterproof solution, which in most cases is used to cover a storage facility, the roof of a dugout, or a swimming pool, then it is worth preparing a solution consisting of 7-10 (seven to ten) kilograms of lime, 3.5-8 (three and a half to eight) kilograms iron sulfate, and everything is diluted with water to the consistency of sour cream:

- To begin with, lime is diluted in cold water (a small amount), obtaining the so-called milk of lime. It is necessary to stir thoroughly so that there are no lumps.

- Separately, iron sulfate is diluted in hot water and poured into the milk of lime in a thin stream with continuous stirring.

By the way, the color after painting becomes soft brown. Those who have experienced it advise adding a little more salt to this solution - this will protect against staining with lime.