Author: Alexander Lugovoy, timber harvesting specialist

Beech (Fagussylvatica) is a deciduous tree with light grayish bark that grows up to 50 m. The trunk of an adult tree resembles a cylinder and has a girth of 1.5 m. The beech crown resembles an oval or cylinder and is located in the upper part of the trunk. Due to the dense leaf cover, the lower leaves gradually die off, forming a crown on bare branches.

The tree loves shade and loamy soils; grows in the forest or as single specimens.

The growing area of beech covers individual countries of Northern, Central and Southern Europe, covering part of Ukraine. Not found in the wild in Belarus.

Curlyness

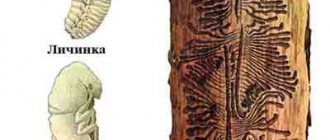

The incorrect location of some of the fibers in the trunk is referred to as curling. This defect is typical for all tree species, but most often it affects deciduous trees. Curliness can cover the entire trunk or be detected only in a small area of the tree. Curlyness negatively affects the strength of wood required during the process of stretching, compressing or bending.

But at the same time, this defect increases the strength of the trunk at the moment of splitting and makes planing more difficult. Curly wood is often used for the manufacture of finishing materials, as it is valued for the expressive pattern on the surface of the produced veneer or plywood.

In the photo - wood graininess

Example No. 1

Example No. 2

Physical properties of beech

Beech has hard and dense wood with streaks of texture, which gradually changes color during storage from yellowish to pink-brown.

Beech is easy to process, easy to sand, chip and bend. Beech wood is suitable for making furniture, musical instruments, veneer, and plywood. Beech is used to make parquet and lumber for construction. Beech processing waste is used to fire stoves and fireplaces.

Beech is susceptible to destruction by fungi, mold and rot in conditions of high humidity and in contact with the ground, therefore, when building outdoors, it requires treatment with special protective compounds. It is recommended to process fallen beech trees immediately after harvesting.

To improve performance characteristics and color correction, beech wood is treated with special protective and tinting compounds.

Common defects of beech wood

False core

Beech is a nuclear-free deciduous tree, which is characterized by an abnormal darkening of the wood in the center of the trunk, resembling a real core in shape.

The appearance and development of a false kernel is associated with infection of the tree by fungi through a damaged trunk and dead branches. Gradually, the cells inside the trunk die and a false nucleus is formed. Intensive growth of hyphal threads leads to the destruction of cell walls and the development of rot.

The structure of the false kernel is determined by the type of fungi that parasitize the tree trunk. When infected with saprophytes (fungi that feed on the contents of cells), the wood is not destroyed: the false core stands out against the background of healthy tissue in a darker color. With such an infection, the performance characteristics of the wood do not deteriorate, and the plant is considered a tree with a “healthy” false core, or a core without rotting (small differences are noticeable in longitudinal stretching, bending upon impact and end hardness).

If the false core appears after infection with wood-destroying fungi, then over time the core of the trunk is affected by rot. Areas of wood with rot are identified by the presence of white discolorations and black sinuous lines.

Choking

Round beech lumber stored in summer, warm spring, or autumn under high humidity conditions exhibits discoloration caused by infestation with wood-decaying fungi.

Choking occurs in two stages:

- Uniform brown-red color (wood browning);

- Striping (gray-brown, violet-brown and dark stripes).

The next stage of structural changes in wood is considered a separate defect, which is called “marble.”

Favorable conditions for the development of wood-decaying fungi:

- Temperature 15-25°C

- Humidity 30-60%

Types of suffocation:

- End choke

develops on the surface of the cut and gradually spreads along the assortment parallel to the direction of the fibers. - Lateral choke

develops on the outer surface of the assortment and gradually moves towards the center.

Due to breathing, the ability of wood to withstand impact bending is reduced by 30%, as well as the ability to be impregnated with antiseptic protective agents.

Marble rot ("marble")

This is the final stage of suffocation, which is identified as a separate wood defect. Marble is identified by discolored spots and stripes on the wood, delimited by dark brown sinuous lines. The last stage of marble is the loosening and softening of wood tissue, accompanied by loss of mass and grinding into dust.

Marble rot is identified by large cracks in the sawn timber and developed fruiting bodies of fungi (the outer surfaces of the lumber do not change). To determine the volume and depth of the lesion, it is recommended to carry out trial sawing or chopping of assortments.

Marble rot worsens the physical and mechanical properties of beech wood. When the first signs of marble appear, the static bending strength is reduced by 30%, and the impact bending resistance by 60%.

At the final stage of development, wood loses its ability to resist mechanical loads and is only suitable for heating (taking into account the reduced thermal output).

Defects in the shape of the barrel

Disadvantages of wood that can be determined by the appearance of the sawlog:

Convergence

Thinning of the trunk from the butt to the top is a natural phenomenon, but if the diameter decreases by more than 1 cm over 1 m, this is already tapered. This defect is typical for plants grown in sparse stands. When processing a tanned trunk, a high amount of waste is generated; wood from such logs is characterized by another disadvantage - the radial inclination of the fibers.

Trunk rootiness

A variation in camber, in which there is a significant increase in the diameter of the trunk at the butt (an increase of 20% or more in the diameter of the trunk at a distance of 1 m from the expansion).

Curvature

Curvature of the trunk is possible for a number of reasons: due to the loss of the top and its replacement by a side branch, due to changes in lighting, when growing on hills and mountain slopes, etc. The percentage of curvature is calculated as an indicator of the arrow deflection of the trunk at the point of curvature.

Ovality

If the shape of the end of the round timber is elliptical, it is likely that heel and tension wood will be found when cutting.

Growths

Local thickenings of the trunk, which are formed as a result of damage to the tree by fungi, bacteria, chemical and radiation reagents, and mechanical damage. The plant's growth processes are disrupted, which naturally affects the quality and structure of the wood: the annual layers bend, repeating the outlines of the growth.

This material is difficult to process, has high hardness and low elasticity. Wood from growths (burl, suvel) is valued as a raw material for artistic products and facing material (veneer).

Consequences of mechanical damage

Sprouting

Sprout is an overgrown wound containing dead wood. Recent damage can be easily detected by visual inspection of the side surface of the trunk of a growing tree. But when completely overgrown, only a gap filled with bark remains is visible.

Tree cancer

Tree cancer is the result of the activity of fungi and bacteria - an open or closed wound with abnormal thickenings and swellings near the affected areas. With this defect, the correct round shape of the log is disrupted, and in coniferous species it is accompanied by increased resin content.

Dry-sidedness

Dry sidedness is one-sided necrosis of a trunk that has been deprived of bark due to burns, abrasions, bruises, etc. The defect causes increased resinity, the formation of curls and sagging, disrupts the strength qualities of the wood and increases the amount of waste during processing.

Grade of beech lumber in accordance with GOST

The grade of beech lumber is determined by the presence and degree of manifestation of the following defects and processing defects:

- Dimensional accuracy;

- Humidity;

- Rot;

- Cracks;

- Knots;

- Mold damage;

- Breakouts, etc.

First grade (Grade A)

Does not allow:

- fused healthy knots with a diameter of more than 1 cm; knots on faces more than 10 cm wide; knots on the edges (more than 1/3 of the thickness for a single and paired knot), as well as more than 20 partially fused and unfused knots;

- falling out and rotten knots, cracks, porosity, mushroom spots and rot;

- acute wane

Allows:

- individual stripes and spots of mold and fungal stains on the sapwood;

- mechanical damage and processing defects within 5 mm;

- slope of the cut within 5% of the thickness and width of the lumber;

- blunt wane (up to 1/5 of the width of the lumber);

- longitudinal winging of the face and edge (up to 0.5% of the length);

- transverse winging (up to 1% of the width of the lumber).

Second grade (Grade B)

Does not allow:

- fused healthy knots with a diameter of more than 2 cm; knots on faces more than 20 cm wide; knots on the edges (more than 1/2 thickness for single and paired knots), as well as more than 40 partially fused and unfused knots;

- falling out and rotten knots, cracks, porosity, mushroom spots and rot - more than 10 pcs.;

- sharp wane more than ¼ of the width of the edge.

Allows:

- mold damage;

- wormholes (but no more than 3);

- mechanical damage and processing defects within 5 mm;

- slope of the cut within 5% of the thickness and width of the lumber;

- blunt wane (up to 1/3 of the width of the lumber);

- longitudinal winging of the face and edge (up to 1% of the length);

- transverse winging (up to 2% of the width of the lumber).

Third grade (Grade C)

Does not allow:

- fused healthy knots with a diameter of more than 5 cm; knots on faces more than 50 cm wide; partially fused and unfused knots more than 30 pieces;

- falling out and rotten knots, cracks, porosity, mushroom spots and rot - more than 25 pcs.;

- sharp wane more than 1/2 of the width of the edge.

Allows:

- knots on the edges;

- mold damage;

- wormholes (no more than 5);

- mechanical damage, processing defects and minor deformations;

- slope of the cut within 5% of the thickness and width of the lumber;

- blunt wane (up to 1/2 of the width of the lumber);

- longitudinal winging of the face and edge (up to 2% of the length);

- transverse winging (up to 3% of the width of the lumber).

Tree species with the least chance of rotting

Larch practically does not rot, so it is often used for log houses and bathhouses. Also, fungi and microorganisms do not multiply in sequoia and yew. The wood of the Marbau tree is not afraid of water. The natural antiseptics contained in oak wood also reduce the possibility of rotting of this tree.

Wood defects are important in the manufacture of various lumber. There are techniques that allow you to identify hidden defects even before cutting down the tree. Their use helps to increase the efficiency of all work. Detection of defects always determines the type of lumber and the possibility of its further use and processing.