Metal and plastic are gradually going out of fashion. The modern city dweller prefers to fill his home with products made from natural materials, the most popular of which is wood. Growing demand, combined with the availability of wood processing technology, makes this industry extremely attractive to budding entrepreneurs planning to create a small-scale production facility.

To determine whether such an idea is feasible, you should develop a business plan for a carpentry workshop. As part of the project, it is necessary to identify the market need for a particular product, determine the optimal composition of the production line, consider supply and sales issues, and also calculate the expected payback period for investments. Practice shows that many small businesses close down precisely as a result of erroneous decisions or actions at the initial stage - incorrect choice of niche, underestimating the strategy of competitors or overestimating the possible level of demand.

Business Features

A carpentry workshop is a small specialized enterprise with a team of several people that produces products from natural wood. To open such a production, it is enough to purchase several universal machines, stock up on raw materials and find distribution channels. Therefore, many craftsmen who know how to hold a plane and a hacksaw in their hands create a business in a garage for beginners from scratch with their own hands and turn it into a source of regular income.

Obviously, the garage workshop’s turnover will be quite modest. For this reason, it is advisable to consider ways to organize a medium-sized woodworking shop that can occupy a more prominent place in the market. Why does this idea attract the attention of entrepreneurs:

- The profitability of a home carpentry business reaches 30–35%;

- In the workshop you can simultaneously produce a variety of products aimed at people with different incomes;

- If the initial idea for a carpentry workshop turns out to be unsuccessful, the production line is quickly reconfigured to produce other products;

- A gradual expansion of the workshop is allowed as sales volumes increase.

Before setting up a carpentry workshop, an entrepreneur must choose a basic concept - technical or artistic. The first option is more suitable for people with an engineering education and a technical mindset. In this case, the basis of the workshop’s assortment consists of products for utilitarian purposes - furniture, construction and finishing materials. Business profitability is achieved through the production of products in batches for the mass consumer.

The artistic direction involves the individual production of decorative items and focuses on their exclusivity. Craftsmen can make custom-made carved furniture from valuable wood species, interior elements, patterned frames for paintings and mirrors, and office sets for directors and officials. One of the options for implementing this small business idea in the garage is the production of souvenirs, boxes, panels and other crafts, which does not require complex expensive equipment.

Grinder

Using this tool, the surface of the product is smoothed, rust, scale, chips and burrs are removed. The following grinders are most often used in workshops:

- Belt - for roughing: stripping of rust or old paint

- Eccentric – for fine finishing grinding and polishing of convex, concave or flat parts

- Angle grinder, also known as grinder, is a multifunctional tool for grinding, cleaning and cutting parts.

By the way, the name “grinder” was born in the 70s in the USSR. At this time, the first angle grinders appeared in Soviet stores, which were made in Bulgaria at the Sparky plant.

Workshop assortment

Sometimes it is difficult to determine which products are in demand on the local market. In such cases, it is recommended to use win-win types of carpentry - design and manufacture of furniture, door panels, window blocks or finishing materials: such products are always in demand. Products must be non-standard and original: otherwise the workshop will have to compete with large factories that mass produce standard models.

What you can produce for sale with your own hands in a garage or in a medium-sized workshop:

- Bedroom furniture - wardrobes, chests of drawers, bedside tables, beds;

- Living room furniture - walls, sets, shelving, coffee tables;

- Hallway furniture - cabinets, hangers, shelves;

- Kitchen furniture - sets, dining tables, chairs, stools;

- Furniture for business - display cases, bar counters, tables and chairs;

- Furniture and items for the bath - basins, benches, deck chairs, buckets, tubs;

- Garden furniture - benches, dining sets, armchairs and sun loungers;

- Wooden shutters, carved address signs;

- Prefabricated structures - gazebos, animal booths, swings, fences;

- Staircase structures, railings, fences, balusters, balconies;

- Window frames for conventional glazing and double-glazed windows;

- Doors and door frames;

- Finishing materials - wall panels, baseboards, trim, parquet;

- Kitchen utensils - bread bins, coasters, napkin holders, figured and regular rolling pins, spatulas, bowls, cutlery, cutting boards.

Another production format is a creative workshop. Having an artistic mindset, you can start by making exclusive carpentry products with your own hands at home, and as your client base grows, hire assistants and open a specialized workshop that produces:

- Furniture stylized as antique;

- Carved jewelry boxes;

- Corporate souvenirs, boxes for expensive gifts;

- Photo frames, frames for pictures and mirrors;

- Carved vases and candlesticks;

- Stands for flower pots;

- Carved panels, icons;

- Board games;

- Children's toys, construction sets and puzzles;

- Keychains, talismans, amulets.

Production technology

An entrepreneur who has no experience in the woodworking industry will inevitably have a question: where to start carpentry? Obviously, first of all you need to understand the technology of production of wood products:

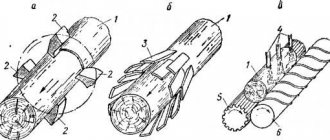

- At the sawmill, the trunks are cleared of branches, cut into boards and sorted. Material with obvious flaws is rejected;

- In drying chambers, the humidity of raw materials is adjusted to 6–8%. After this, the wood is ready for DIY wood carpentry;

- The craftsman cuts the boards into blanks, leaving certain allowances for planing and sanding;

- Future parts are given the required shape by processing them on jointing, planing, milling and thicknessing machines;

- The ends of the boards are cut at specified angles on cross-cutting machines;

- To connect the parts, tenons and corresponding grooves are milled onto them. If necessary, curved edges are made on the same milling machine;

- Next, the surfaces of the elements of the future product are processed on grinding and calibrating grinding machines, bringing their dimensions to the specified ones;

- If the technical specifications provide for veneering, glue is applied to the parts and the veneer is pressed in special hydraulic presses;

- The product is assembled by connecting parts of the structure with fasteners or glue. In the second case, the parts are compressed with clamps until the adhesive mass hardens;

- At the final stage, oil or special impregnations are applied to the surface of the product, and after drying, a paint coating is applied.

Lamellar routers

The best tool for creating a flat, even surface on one side of a board is a router. Perhaps this is also the best tool for processing a second surface strictly perpendicular to the first. There are lamellar cutters of various shapes and sizes. But they all perform the same functions.

We also recommend reading: Details about the lamellar router

Premises requirements

If an entrepreneur decides to start a business on his own or with an assistant, then he can limit himself to arranging a workplace in the garage and purchasing a pair of wood lathes for a home workshop.

However, to achieve more ambitious goals, you will have to choose a warm and dry room of 120–150 m², located at least one hundred meters from the nearest residential and public buildings. Suitable options can be found in industrial zones and on the outskirts of the city, where rent usually does not exceed 180–220 rubles/m² per month. When developing a plan for a carpentry workshop with the arrangement of equipment, it is necessary to divide the workshop premises into zones and separately highlight:

- Section for preliminary cutting of workpieces;

- Area for planing and forming parts;

- Grinding area;

- Assembly and finishing area;

- Isolated painting area;

- Warehouses;

- Administrative premises;

- Domestic premises.

In the process of creating a carpentry workshop with your own hands, you should also take into account the basic requirements and standards for production workshops in order to increase safety and productivity:

- For ease of processing of large parts, ceilings with a height of 4 meters are required;

- Some carpentry workshop equipment is up to 3 meters long, so the room dimensions must allow for their installation;

- To ensure machine stability, a hard, level floor is required. It is better to fill it with concrete;

- The equipment specification for a carpentry workshop should include a heating system - centralized or local. To avoid deformation of the workpieces, it must maintain an optimal temperature at any time of the day;

- The workshop must be connected to the water supply and sewerage networks;

- The power supply power of the workshop is 25–30 kW. Hand tools are connected to a 220 V network, while the operation of industrial equipment in a carpentry workshop requires a three-phase line with a voltage of 380 V;

- To control the microclimate, it is necessary to provide supply and exhaust ventilation with a separate air intake in the painting area. Other workplaces are connected by flexible air ducts to a dust collection unit;

- When setting up a carpentry workshop, artificial lighting is provided using fluorescent or diode lamps.

Lighting in workplaces should be:

- At the cutting area - from 300 lux;

- Near processing machines - from 400 lux;

- At the grinding site - from 750 lux;

- At the painting site - from 200 lux.

Changes in temperature and humidity can cause wood to deteriorate and crack. Therefore, the room is constantly maintained at a temperature of 18–22°C and a humidity of 35–40%. The air flow speed should not exceed 0.3–0.5 m/s.

During the production of carpentry, shavings and fine wood dust are formed, which increases the fire hazard of the room. The workshop must have a fire alarm system and install fire extinguishers.

All workshop employees must be provided with special clothing. Workers in sanding and painting areas are provided with eye and respiratory protection.

Main characteristics:

Power

A powerful plane planes deeper. For beginners, a model with a power of up to 600 W will be enough for rough and finishing processing.

Maximum speed

How smoothly the plane will plan the surface depends on the rotation speed of the drum with blades. The optimal indicator for a novice master is no lower than 16,000 rpm.

Maximum planing depth

For small wooden blocks, a depth of 0 to 3 mm is sufficient. If you plan to work with freshly cut wood, choose a larger depth. In this case, the power reserve must be substantial, at least 1000 W.

Planing width

This is the width of the strip that the tool will plan in one pass. The higher this indicator, the higher the productivity of the tool. The most common models of planes are with planing widths of 82, 102 and 110 mm.

Additional details:

- Chip collection bag – prevents wood shavings and sawdust from flying around the workshop

- Coupler for connecting a vacuum cleaner - does the same thing, but for a longer time

- Soft start – adjusts the drum speed to reduce the load on the motor

→ choose an electric planer

Equipment and facilities

What machines are needed for a carpentry workshop? Supplier catalogs present dozens of items with similar functions and price ranges from two hundred thousand to two million rubles: in order to make the right choice and not overpay, it is better for an entrepreneur to consult a professional. In addition, in order to save money, you can buy used machines with a short service life and make some accessories for the carpentry workshop with your own hands.

For a garage workshop with a small production volume, a multifunctional unit is an excellent choice. Such a woodworking machine for a home workshop costs no more than three hundred thousand rubles and performs all the operations necessary for woodworking - sawing, jointing, planing, milling and drilling. However, when organizing production of products at least on a medium scale, the production line is built from highly specialized equipment:

Main characteristics of rotary hammers:

Motor power

The more powerful the motor, the faster the drill moves deeper into the material. The weight of the tool also depends on this parameter. According to power, rotary hammers are divided into three main types:

- Lightweight up to 4 kg – 400–800 W

- Medium up to 8 kg – up to 1,000 W

- Heavy over 8 kg – up to 2,000 W

Light and medium tools are suitable for home use.

Impact energy (force) and rotation speed

Impact energy affects the depth and diameter of the hole. For household work, a hammer drill with an impact force of 1–4 J is sufficient. In terms of engine shaft rotation speed, focus on models with an indicator in the range of 600–1500 rpm. This is quite enough to drill holes for shelves or cables.

Type of cartridge

Determines which shank you need to choose a drill to use with the tool. The most common type of chuck is the quick-release chuck SDS – steck-dreh-sitzt (from German “insert-turn-ready”):

- SDS-plus - for 10 mm shanks with two grooves, more common in lightweight models. A less common analogue of this chuck, SDS-top, is usually used in Bosch tools.

- SDS-max – for 18 mm shanks with three asymmetrical grooves – installed on medium and heavy models.

Operating mode

Rotary hammers with switching between three modes are convenient for the home workshop:

- Hammer drilling (main)

- Drilling

- Impact - turns the rotary hammer into a jackhammer

Some models also have a reverse mode. It makes it easier to remove the drill from the hole.

→ select a hammer drill

Carpentry workshop equipment

| Equipment | price, rub. | Quantity, pcs. | Amount, rub. |

| Workshop equipment | |||

| Lathe | 65100 | 1 | 65100 |

| Cross-cutting machine | 86500 | 1 | 86500 |

| Thicknesser | 113700 | 1 | 113700 |

| Jointer | 135800 | 1 | 135800 |

| Milling machine with tenon cutter | 125700 | 1 | 125700 |

| Vertical Band Saw Machine | 56200 | 1 | 56200 |

| A circular saw | 132000 | 1 | 132000 |

| Used quadrilateral machine | 250000 | 1 | 250000 |

| Calibrating and grinding machine | 280000 | 1 | 280000 |

| Belt grinding machine | 69500 | 1 | 69500 |

| Drilling and slotting machine | 113700 | 1 | 113700 |

| Drilling and Grooving Machine | 53700 | 1 | 53700 |

| Sharpening machine | 20800 | 1 | 20800 |

| Air compressor | 16000 | 1 | 16000 |

| Mills, drills, saws, knives | – | – | 30000 |

| Hand tools and equipment | |||

| Vise | 4500 | 4 | 18000 |

| Drill | 2800 | 2 | 5600 |

| Screwdriver | 2100 | 2 | 4200 |

| Jigsaw | 2600 | 1 | 2600 |

| Circular Saw | 5200 | 1 | 5200 |

| Miter saw | 10000 | 1 | 10000 |

| Hand router | 4200 | 1 | 4200 |

| Belt sander | 3800 | 2 | 7600 |

| Electric planer | 4900 | 1 | 4900 |

| Angle grinder | 2800 | 1 | 2800 |

| Staple gun | 1500 | 2 | 3000 |

| Spray | 2200 | 1 | 2200 |

| Measuring tool | – | – | 10000 |

| Hand carpentry tools | – | – | 10000 |

| Miter box | 1500 | 2 | 3000 |

| Moisture meter | 3400 | 1 | 3400 |

| Clamps | 300 | 10 | 3000 |

| Angle clamps | 400 | 8 | 3200 |

| Weight clamps | 1500 | 6 | 9000 |

| Crafting table | 15000 | 2 | 30000 |

| Rack | 2200 | 2 | 4400 |

| Assistance systems | |||

| Sawdust removal system | 24600 | 1 | 24600 |

| Fire alarm | 22000 | 1 | 22000 |

| Fluorescent lamps | 1500 | 10 | 15000 |

| Fire extinguishers | 2300 | 4 | 9200 |

| Other equipment | |||

| Computer | 16500 | 3 | 49500 |

| Multifunction device | 9500 | 1 | 9500 |

| Router | 4200 | 1 | 4200 |

| Internet access line | 2000 | 1 | 2000 |

| Office table | 3400 | 3 | 10200 |

| Dining table | 2500 | 2 | 5000 |

| Chair | 850 | 12 | 10200 |

| Lamp | 1000 | 6 | 6000 |

| Bathroom and shower | 26000 | 1 | 26000 |

| Electric kettle | 600 | 1 | 600 |

| Microwave | 3600 | 1 | 3600 |

| Locker for changing room | 2000 | 8 | 16000 |

| Hanger | 1500 | 2 | 3000 |

| Workwear | 1000 | 8 | 8000 |

| First aid kit | 2000 | 1 | 2000 |

| Stationery | – | – | 3000 |

| Total: | 1924600 | ||

Workshop workers

Even when organizing a carpentry workshop in a garage with your own hands, it is difficult to do without an assistant. If we are talking about a larger workshop, then a whole team of specialists will be needed, each of whom will be responsible for a certain stage of the production cycle:

- Woodworking technologist. His tasks include organizing the technological process, developing instructions for processing parts and assembling products;

- Joiners. Industrial machines differ significantly from equipment for a home carpentry workshop, so you need to make sure that your workers have the appropriate skills;

- Support workers. They must also have at least minimal experience working in woodworking enterprises;

- Painter. This employee must be a professional, since the appearance of the finished product directly depends on his skill;

- Accountant. When organizing a carpentry business at home or in a medium-sized workshop, a part-time specialist is sufficient;

- Supervisor. He is the owner of the company. His area of competence includes various administrative issues - searching for suppliers, organizing sales.

Consequently, organizing a carpentry workshop will require hiring personnel according to the following staffing schedule:

Carpentry workshop workers

| Job title | Salary, rub. | Qty | Amount, rub. |

| Woodworking technologist | 30000 | 1 | 30000 |

| Carpenter | 23000 | 4 | 92000 |

| Helper worker | 17000 | 2 | 34000 |

| Painting shop worker | 23000 | 1 | 23000 |

| Part-time accountant | 13000 | 1 | 13000 |

| Cleaner | 9000 | 1 | 9000 |

| Insurance premiums | – | – | 60300 |

| Total: | 10 | 261300 | |

We select personnel

A business idea in the form of a carpentry workshop can only be implemented by a knowledgeable person who is capable of performing some types of work himself and understands woodworking. Therefore, you won’t need many employees at first.

To complete the staff you will need:

- Carpenters – 2 people.

- Worker for painting and impregnation of blanks and finished products – 1 person.

- The controller who will check the quality of products and perform a managerial role is 1 person.

- Cleaning lady – 1 person.

The workshop will be open during the day from 10:00 to 19:00. Weekends – Saturday and Sunday. Carpenters can work in pairs or in shifts of 1/1, 2/2 or 3/3. It is worth agreeing with the cleaning lady to work in the evening, for 2 hours.

The project organizer assumes management functions. He also controls each process and checks the quality of blanks and finished products. Employees are paid by the piece - 10-15% of each finished product. But you can offer a salary system. It is less beneficial for this project, since craftsmen need motivation to work.

The cleaning lady is paid once a month with a strictly established salary. Incentive bonuses or rewards are possible at the owner's discretion.

Raw materials

Wood species are divided into three types - soft (linden, pine), medium (ash, beech), and hard (oak, maple). Soft ones are excellent at cutting and processing, and therefore are widely used for making carpentry crafts from wood with your own hands. Hardwoods are characterized by strength and resistance to damage, combined with a pronounced texture, which is why they are used to make furniture, parquet, decorative panels and building structures.

The most common types found in woodworking are:

- Oak. Solid noble breed. Well suited for furniture production;

- Beech. A strong, heavy rock with a light texture. Used to make sturdy furniture, staircases and wall panels;

- Ash. A medium-hard rock with a contrasting texture. Suitable for almost all types of joinery;

- Hazel. A hard rock with a pronounced grain pattern. All varieties of hazel (walnut, American, black) serve as raw materials in the production of expensive furniture;

- Birch. A common breed that combines low price, ease of processing and strength. Paints and tints well;

- Karelian birch. Used to make joinery with a special grain pattern reminiscent of marble;

- Maple. Mainly serves as a raw material for the production of veneer;

- Alder. Characterized by durability and ease of processing. Well suited for elegant figured furniture with decorative elements;

- Linden. Softwood. Carved elements and cutlery are made from linden;

- Pine. It is easy to process, making it ideal for making carpentry products with your own hands;

- Larch. Somewhat more durable than pine. Retains heat well;

- Red tree. A relatively rare and therefore valuable breed. Used to make expensive furniture and interior items.

Personnel search

For the production of carpentry products, at least several assistants are required - subject to the independent organization of the work of the workshop. In the absence of such an opportunity, there is a need to hire a production manager and a foreman.

Additional staff:

- handyman

- sales specialist

- Sales specialist (search and selection of clients)

- accountant

If you want to produce non-standard products, you must additionally use the services of a designer.

Important: the process of manufacturing wood products is accompanied by a risk of injury, which is why employees must be allowed to work after they have been given safety instructions.

It is recommended to develop a job description outlining the rights and responsibilities of workers.

Business registration

As a business in a garage, the production of furniture and other carpentry can do without registration only if it works with private clients.

However, sooner or later, every entrepreneur thinks about selling products through retail chains or his own store: in this case, the official status of the enterprise seems necessary. For a workshop employing 10–15 hired employees, an individual entrepreneur using a simplified taxation system is quite sufficient. If you plan to achieve million-dollar turnover and participate in government tenders, it is recommended to give preference to LLC. The technological equipment itself can be used as authorized capital.

No licenses or certificates are needed not only for mini production in a garage for men, but also for larger enterprises. The only type of product subject to mandatory certification is any product for children. However, permits to conduct activities from Rospotrebnadzor and the Fire Service will have to be obtained.

Market analysis

You need to analyze the market in the area and region where the workshop is opening. To do this, you can attract third-party organizations that will do everything for you and provide the necessary data.

If the budget does not allow this, then you can conduct a market analysis yourself. To do this, you will need to use the Internet, find all the workshops available in the area, ask them for a price list for all products and study the prices in detail. It would be a good idea to study reviews from real customers about competitors. This will allow you to identify their weaknesses and not repeat their mistakes in the future.

Identifying potential clients

To identify the needs of potential buyers for the products you make, go to the search engine, go to Yandex.Wordstat and enter the most common requests for the purchase of handmade furniture. For example, “buy a wooden table”, “buy handmade furniture”, “buy wooden furniture”. This will allow you to estimate the number of requests in a particular city, as a result of which you can identify the level of need.

Another way is to communicate with an employee of a large organization. You don't have to say who you really are. You can come as a buyer. During the conversation, you can sometimes ask leading questions. If you can get the manager to talk, you can find out how many clients they have, how often they purchase products, and what is in greatest demand. Or you can conduct surveys on the streets of the city.

Before you begin your research, you will need to get answers to a number of questions that show the profile of your potential buyer:

- age;

- place of residence - apartment or private house;

- approximate monthly income;

- what products your client requires;

- what primarily influences the purchase;

- what problems the purchased products can solve.

The entrepreneur himself answers these questions. They will help you decide on the choice of potential clients. During the research process, it will become clear which circle of consumers needs to be reached as part of the advertising campaign. Any product has its own value. If he sells at a high price, and in the city in which the workshop is located, the income level of the population is low, then it will be quite difficult to sell.

Promotion and sales

No business aimed at the mass consumer can do without a marketing strategy. In the process of developing it, the entrepreneur must figure out what to call the carpentry workshop. Good name:

- Easily remembered and associated with woodworking;

- Harmonious (no abbreviations or compound words);

- Does not contain terms that are incomprehensible to ordinary people;

- Easily translated into the Latin alphabet for domain name registration.

You should also think in advance about how to interest customers and lure them away from competitors. To do this, it is necessary not only to produce high-quality original products, but also to provide profitable related services:

- Deliver oversized products to the customer;

- Assemble and install structures on the buyer’s premises;

- Repair or restore wood products.

However, all these benefits will be unclaimed if customers do not know about them. Therefore, advertising is what is needed for a carpentry workshop of any size.

To stimulate sales you can:

- Distribute booklets in construction and furniture stores;

- Publish advertisements for carpentry services in local newspapers;

- Post leaflets in cottage villages where construction is underway;

- Send proposals to potential clients of carpentry furniture production - catering establishments, hotels, entertainment establishments;

- Develop your own website with a product catalog and supplement it with a service for placing an order via the Internet;

- Create wood workshop groups on social networks and attract users from your region to them.

There are at least five ways to sell finished products. When considering where to start a carpentry business, you should study these sales channels and choose the most effective ones. So, an entrepreneur can:

- Take part in fairs;

- Deliver products for sale to construction stores;

- Open your own retail outlet;

- Sell products directly from the workshop;

- Organize sales via the Internet.

Electric jigsaw

A tool for sawing wood along a guide or along a width due to the reciprocating movement of the saw blade. There are dozens of models of jigsaws, it is difficult for an untrained user to choose a tool, so let’s listen to the master.

Stanislav Stadnichenko: – The jigsaw is very insidious, it’s the easiest thing for them to ruin a thing. I do not recommend saving on equipment and buying files made by Leroy, Castoram or Obi. Branded items, for example, Bosch, work longer than others, more efficiently, and of better quality. And if you want to minimize mistakes at first, start learning carpentry under the guidance of practicing masters.

The expert's choice is the Bosch PST 650 jigsaw. Indispensable for straight and shaped cuts. Advantages: low vibration system; durable metal sole with adjustable angle of inclination made of aluminum alloy; the ability to blow away sawdust during the process, which improves visibility of the working area.

The weight of the model is 1.6 kg, and the ergonomic handle with a soft anti-slip pad allows you to control it as precisely as possible during operation.

A high-quality tool saves time, increases productivity, and protects the craftsman’s mood. When choosing a jigsaw, remember the Russian proverb - “The miser pays twice.”

Investments in business

After analyzing the equipment specifications, you can understand that the costs of creating a manufacturing enterprise are several times higher than the costs of organizing a small business in a garage in 2022. To determine the final amount of initial investment, other organizational costs should be taken into account:

Initial costs

| Type of expenses | Amount, rub. |

| Individual entrepreneur registration | 800 |

| Production of IP seal | 1200 |

| Opening an account | 2300 |

| Workshop equipment | 1924600 |

| Renovation of premises 120 m² | 50000 |

| Rent for the period of repair and installation, 200 rub./m² per month | 24000 |

| Advertising expenses | 40000 |

| Consumables for a month | 20000 |

| Raw materials for a month | 120000 |

| Administrative costs | 15000 |

| Total: | 2197900 |

In addition to the typical costs for any enterprise, the business plan of a carpentry shop must provide for a monthly allocation of funds for the purchase of quality wood and various consumables, the list of which includes:

- Wood glue;

- Antiseptic and fire-resistant impregnations;

- Paints, varnishes, impregnating oils;

- Fasteners - nails, screws;

- Paint brushes and rollers;

- Sanding belts and sheets.

The required amount of raw materials and consumables is determined according to industry standards or empirically - based on the results of assembling one product. Then the indicators are adjusted taking into account the expected output volumes. Accordingly, the structure of regular costs of carpentry production takes the following form:

Monthly expenses

| Type of expenses | Amount, rub. |

| Rent 200 rub./m² per month, 120 m² | 24000 |

| Payroll | 261300 |

| Communal payments | 20000 |

| Advertising expenses | 10000 |

| Insurance premiums | 2700 |

| Fare | 10000 |

| Maintaining a bank account | 2300 |

| Connection | 4000 |

| Garbage removal | 4000 |

| Raw materials | 120000 |

| Consumables | 20000 |

| General expenses: | 478300 |

Profit and profitability

To calculate the profit of a small business, you need to figure out how to calculate the cost of carpentry. The initial data for the calculation are provided by the same industry standards that regulate the time spent on each operation, from cutting blanks to assembling the finished product. Material cost is the sum of the costs of raw materials, consumables and finishing materials. Finally, the selling price is determined by the market. Suppose a carpentry shop produces doors made of solid pine:

Income calculation

| Index | Meaning |

| Standard time for door assembly, h | 2,0 |

| Lumber consumption per product including waste, m³ | 0,2 |

| Cost of lumber, rub./m³ | 6000 |

| Material cost of the product, rub. | 1200 |

| Number of doors per month, pcs. | 100 |

| Material consumption per month, rub. | 120000 |

| Selling price of the product, rub. | 6000 |

| Gross income per month, rub. | 600000 |

It remains to be determined how profitable a carpentry workshop is as a business. If the enterprise’s source of income is only production (excluding earnings from the assembly and installation of structures), then the profitability indicator will exceed 20%, and the payback period will be 1.8 years:

Calculation of business payback

| Index | Meaning |

| Gross income, rub. | 600000 |

| Expenses per month, rub. | 478300 |

| Profit before tax, rub. | 121700 |

| Tax simplified tax system 15%, rub. | 18200 |

| Net profit, rub. | 103500 |

| Profitability, % | 21,6 |

| Investments, rub. | 2197900 |

| Payback period, months | 21,2 |