The carpentry business will never lose its relevance. Wooden products always remain in fashion. If you approach the matter wisely, you can count on stable profits. A business plan will help organize the process of starting a project from scratch. We’ll look at what a step-by-step guide for a novice entrepreneur includes in this article.

| Starting investment, rub | Revenue per month, rub | Net profit, rub | Payback period |

| from 300,000 | from 300,000 | from 80 000 | 6 - 12 months |

Carpentry as a business - pros and cons

For those who are just trying themselves as the owner of a carpentry company, it is useful to know in advance what advantages and disadvantages the workshop offers.

Pros of the project:

- you can start a business in your garage and not spend money on rent;

- wooden products are always in price and in demand;

- To start a business, you need a minimum of tools. New equipment is purchased gradually - as the business develops;

- a wide range of products - from standard products to unique orders. This helps overcome competition.

Flaws:

- carpentry workshop is passive income;

- without hired workers, it will not be possible to achieve mass production and stable profits;

- The threshold of competition in this area is one of the highest - in order not to go bankrupt, you need to find your advantage. It is difficult to resist large furniture companies;

- the client base is formed slowly, and advertising is expensive;

- work is associated with the danger of occupational injuries;

- the raw material is expensive, which increases the cost of the product. In such conditions it is difficult to maintain a flexible pricing policy.

Construction of houses

0 votes

+

Vote for!

—

Vote against!

All carpentry and improvised tools used by a skilled owner in everyday life should be carefully stored in one place. For these purposes, you need a well-equipped home workshop, where each thing has a strictly designated place, all accessories and tools are laid out on their own shelves. In the workshop it is convenient to make something with your own hands, to repair broken things, but in order for the work to take a minimum of time, it is important to properly arrange this space.

Table of contents:

- Where to set up a home workshop

- How to organize space in the workshop

- Heating and lighting of the workshop

- Necessary home workshop equipment

Where to set up a home workshop

A corner for tools can be allocated anywhere in a house or apartment, but it is much more difficult to attach a small woodworking machine, a workbench with a vice, an electric planer, a grinder and other equipment. With a small amount of available tools, when there is no separate room, you can find a little space in your own apartment. Of course, it is unlikely that it will be possible to equip a full-fledged carpentry workshop in a small apartment with a standard layout if there is no specially designated room for this. Therefore, you will have to find another place to place the machines and tools.

A tool working in a home workshop, being located right in the apartment, will disturb both your family and the neighbors living behind the wall, unless you use it occasionally and for a short time. In addition, the voltage required to operate the tool may cause power outages. When working with wood, sawdust, shavings and fine wood dust are formed, which are difficult to completely remove after working on the machine. The possibility of a short circuit or spark during operation of the machine sometimes creates a fire hazard in the apartment. That is why the workshop and equipment are moved to non-residential premises.

1. If woodworking equipment is used frequently and generates profit, and there is so much of it that it is no longer possible to place it in your home, then you will have to find a separate place for this. This is especially true for machines and other equipment that require sufficient space to operate. It could be:

- an unused summer kitchen or veranda in a private house;

- a small private or rented garage with electricity;

- attic or semi-basement of the house;

- an empty room in the basement of a high-rise building;

- a specially designated extension to the house;

- one of the rooms of a large private house with a separate entrance;

- thorough outbuilding - home workshop: video.

2. If there is no alternative, in the form of an outbuilding or a garage, a small amount of household power tools can be placed in your home. A home workshop in an apartment can be located:

- on a specially equipped glazed balcony (convenient when there are two of them in the apartment);

- on the loggia (equip one side wall with shelves);

- in a well-lit pantry (on shelves);

- in the spacious hallway (dedicate one built-in cabinet for storing tools);

- in the kitchen (pencil case or cabinet only for the master, lockers in the soft kitchen corner);

- in the hallway in built-in wardrobes and on mezzanines (not very convenient, but effective);

- in a niche equipped for storage under the stairs of the first floor (next to the apartment).

Let’s make a reservation that in the indicated places it is only convenient to store the tool, but using it if there is no space will be much more difficult. For any workshop you need at least 2.5 - 5 sq.m of separate premises. For these purposes, it is most advisable to use a loggia, but, again, neighbors will complain about the noise of the instrument. If this is a temporary matter and you don’t have to work for long, then you can refer to repairs, but you will have to simultaneously look for a separate room. For example, if you have friends who have an empty garage next to their house, negotiate an inexpensive rental or for minor repair services.

Attention: If several good machines and expensive power tools are stored in the garage, then it is worth insuring it along with all the equipment. Especially if there is a possibility of fire, flooding, theft and other causes of disappearance and damage to home workshop equipment and stored property! Lightweight, portable power tools that are used periodically are best stored at home - in the pantry or on the mezzanine.

If you are going to earn extra money by renting workshop equipment, strict accounting is important. A special accounting journal must be kept for the instrument being leased, which clearly indicates the date and time of issue, the amount of deposit and rental, the deadline for return, the name of the client (passport details and registration are possible) - so as not to have to search for your property.

How to organize space in the workshop

When choosing a place for a workshop, it is important to take into account the minimum area, without which it is impossible to fully work. The workshop space, ideally, should have several functional areas:

- place for machines near the outlet;

- rack or shelves for accessories and small tools;

- a corner where cleaning tools and a container (box or bucket) for production waste are stored;

- various attachments for the home workshop;

- hanger and shelf for workwear;

- free area for storing finished products;

- wall cabinets for small parts and fixtures;

- a place to store raw materials and materials for work.

There must be enough space in the center of the workshop and at the working surface of the equipment for the free movement of the master and his assistant if help is needed. The area occupied by a machine or workbench is multiplied by 2 - this is the coefficient of the minimum working area. Plus, you need space for free movement, changing working equipment and small tools - this is at least 2-3 sq.m.

Heating and lighting of the workshop

When setting up a home workshop with your own hands in an unheated room, it is important to consider heating in the winter if there is work all year round. Heating appliances will be needed to maintain comfortable working conditions. This is also important in order to periodically warm your hands, especially when working with metal, even if you have work gloves. Heating of the room will be needed when the workshop is located:

- in an unheated garage;

- in the attic;

- in the basement of a private or multi-storey building;

- on a glazed loggia;

- in an attic or attic.

Attention: A room without insulation and proper ventilation, which is heated periodically, results in increased humidity, condensation formation and the creation of conditions for the development of fungi and mold. Dry and fairly warm air is favorable for storing power tools and metal products. Dampness gradually deteriorates instruments and electrical sockets and wiring.

The simplest heating method is to use an electric heater or an oil radiator. It is much more effective to use a fan heater, since it has a directed flow of warm air. A convector or infrared heater is also suitable. But all these devices use a lot of electricity, and it takes time to create the desired microclimate. In an insulated room or with central heating, a working microclimate is stably maintained.

High-quality lighting is not just comfortable conditions for working and making homemade devices for the home workshop. This is also an important safety requirement - with poor visibility or insufficient lighting in the work shop, the likelihood of domestic injuries increases. Troubles from using power tools in insufficient lighting occur approximately 40% more often than under comfortable conditions or with additional illumination of the working plane. The best option is to additionally equip the place near the machine or workbench with a lighting device.

Tip: If you have to work all day in a closed garage or basement without natural light, it is important to provide interior lighting with the right spectrum that is beneficial for vision. Doctors say that combined artificial light is most suitable for the eyes - universal neon (fluorescent) LBU lamps in combination with ordinary incandescent lamps. The flickering light of energy-saving lamps and neon lamps alone is not suitable for constant illumination of the workplace.

When lighting the work area, it is important to provide diffused light so that there are no sharp shadows or distorted proportions and sizes. It is important to consider the total power of electricity consumed so that the machine, air heater and lighting devices do not spontaneously turn off due to overload. It is better to install several sockets to distribute the load.

If connecting electricity to your home workshop is only in your plans, then it is important to consult with a specialist so that such problems do not arise when the operating equipment is fully loaded. To illuminate an ordinary garage, one incandescent light bulb from a manually laid cable is enough, but for a home workshop, the load on it will increase significantly.

Important rules for setting up a home workshop:

1. Each machine and power tool must have its own designated place and free access to the working plane from 2-3 sides.

2. There should be twice as much free space as the space occupied by the equipment.

3. It is better to keep expensive power tools that are not currently in use in a separate cabinet, especially if numerous customers and visitors come into the workshop.

4. The floors in the room must be level and hard for the stability of the equipment.

5. It is important to comply with all fire safety measures, ground machines and equipment, and install a powder fire extinguisher.

6. The room must have ventilation and low humidity.

7. It is advisable to have sufficient sound insulation in the workshop.

8. Daily cleaning of the work area is important for health; it is better to use a powerful vacuum cleaner to remove dust and small debris; be sure to have a rag on hand to remove oily contaminants.

9. It is advisable to separate waste containers - for wood scraps and metal waste, and also separately for other waste.

10. It is advisable to have a small supply of drinking water in the workshop in a closed container in a visible place.

11. Paints, varnishes, stains, solvents and other technical liquids should be stored separately. They need to be removed as far as possible from heating sources, places of possible wiring short circuit and open flame.

12. It is important to remove all waste in a timely manner - throw away used containers containing flammable liquids and technical lubricants, hand over scrap metal and throw away unnecessary containers.

13. There should be a bucket of dry sand in the workshop - it will be needed to extinguish the fire of a machine or power tool. For the same purposes, you can use a tarpaulin, a thick blanket or old outerwear to block the access of oxygen to the flame.

14. Upon completion of work, the machine and workbench must be cleaned, since accumulating sawdust and technical oils contribute to the spread of fire.

15. In any workshop, there must be a complete first aid kit in a visible place (bandaging materials, tourniquet, hydrogen peroxide, iodine, brilliant green, painkillers, plaster and medical glue for small cuts).

Remember: Cluttering your home workshop is a potential threat to life, it can cause fire and suffocation! When using chemical components, use a respirator and safety glasses!

Necessary home workshop equipment

If you have a home workshop, DIY equipment can also be added to what you already have. The base is a work table, workbench or other convenient plane where you can attach the necessary devices.

1. Workbench - there is a metalworker's or a carpenter's one, it is twice as long, and you can make it yourself - video.

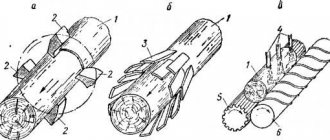

2. A woodworking machine is the basis of a carpentry workshop. Sometimes they are made by hand, but it is easier to purchase a ready-made one inexpensively if it will be used often. For occasional work, it is wise to contact a carpentry shop for product blanks. A lathe is often used.

3. Vices and clamps are the main devices for holding the materials being processed.

4. Required set of hand tools for woodworking:

- set of chisels;

- plane;

- hand drill with drill bits included;

- feathers for making large diameter holes;

- hacksaws;

- square and tape measure;

- hammer and mallet;

- pliers, pliers, etc.

5. The most common power tool:

- drill-driver;

- angle grinder (grinder);

- jigsaw;

- circular saw;

- manual electric router, etc.

6. To work with metal you need:

- hacksaw;

- chisel;

- a set of needle files and files;

- anvil;

- metal scissors;

- a set of taps and dies for the main types of threads plus metal drills.

Nails of different sizes, screws, self-tapping screws and other fastening materials should be sorted in a separate box.

Today, multifunctional universal power tools with removable attachments are quite in demand, which successfully replaces several units of power tools for different purposes. The home craftsman should also always have a stocked portable tool box at hand.

How much money do you need to start a carpentry business?

To assess the economic efficiency of a project, you need to understand what the investments will be.

To start a workshop from scratch, you will need half a million rubles. The main expense item is equipment.

An example of a cost estimate for opening a carpentry shop:

- rental of premises - 25,000 rubles;

- equipment and tools - 250,000;

- raw materials for the first month of work - 50,000;

- utility bills - 5,000;

- wage fund - 120,000;

- advertising at the start - 50,000;

- current promotion costs - 10,000 per month.

Financial section

In any organization there are constant expenses throughout the month. When implementing a business plan for a carpentry workshop, this must also be taken into account. Let's look at the main expenses:

- Payments under the premises rental agreement.

- Payment of utility bills.

- Conducting an advertising campaign.

- Employee compensation and insurance benefits.

- Outsourcing service for accounting issues.

- Transport costs (fuel and lubricants).

- Unforeseen expenses during the work process.

The amount of net profit depends entirely on the direction of the carpentry workshop business plan.

Profitability of a carpentry workshop

Carpentry can hardly be called a highly profitable business. This indicator is tied to the following factors:

- advertising effectiveness;

- individuality of products;

- threshold of competition in the region.

If we talk about average figures, the profitability level in the carpentry business is 10-15%.

Necessary equipment for opening a carpentry workshop

What tools and equipment are required depends on the format of the business.

Basic set of hand tools:

- answers;

- mallets;

- chisels;

- saws;

- vice;

- clamps.

Power tools:

- jigsaw;

- grinding apparatus;

- screwdriver;

- drill.

To manufacture complex and large products you need:

- lathe and grinder;

- spray gun;

- compressor;

- circular;

- surface planer

You can reduce costs by purchasing new equipment.

Vocational training, production technology, work skills

Work in a carpentry shop is impossible without a master. The price of finished wooden products depends on its quality. A craftsman with golden hands can earn a stable income, making do with a plane and an awl. And vice versa. Even having purchased the latest high-tech equipment and top-class raw materials, you can burn out if you don’t know how to handle a hacksaw and hold a chisel in your hands. Much depends on the desire to learn, improve yourself and earn money. When making wood crafts has become a favorite hobby, but you lack professional skills, you can complete accelerated courses and master the skill. Knowledge of computer programs CorelDRAW and PowerShape will be useful for visualizing projects in 3D format.

Joiners

How to select personnel

The selection of staff is approached responsibly. A company's reputation has a direct connection with the quality of their work. Hire candidates who have specialized education and work experience in their specialty.

In order for the workshop to function fully and without interruptions, you will need:

- production technologist - will control the process and participate in its organization;

- carpenter - 2 people;

- assistant carpenter - 2 people. They will take over small operations and assemble finished products. Their labor is valued cheaper than the services of a carpenter;

- general workers - 2-3 people. Their responsibilities: pack the goods, clean the hall, perform loading and unloading;

- Sales Manager;

- accountant - alternative - an outsourcing agreement with a company.

For staffing, the cost estimate includes 120,000 - 140,000 rubles every month.

Note ! At the stage of project promotion, you can take on part of the operations yourself or work in one shift. This will reduce payroll costs. As orders appear, additional personnel are recruited.

Market analysis

You need to analyze the market in the area and region where the workshop is opening. To do this, you can attract third-party organizations that will do everything for you and provide the necessary data.

If the budget does not allow this, then you can conduct a market analysis yourself. To do this, you will need to use the Internet, find all the workshops available in the area, ask them for a price list for all products and study the prices in detail. It would be a good idea to study reviews from real customers about competitors. This will allow you to identify their weaknesses and not repeat their mistakes in the future.

Identifying potential clients

To identify the needs of potential buyers for the products you make, go to the search engine, go to Yandex.Wordstat and enter the most common requests for the purchase of handmade furniture. For example, “buy a wooden table”, “buy handmade furniture”, “buy wooden furniture”. This will allow you to estimate the number of requests in a particular city, as a result of which you can identify the level of need.

Another way is to communicate with an employee of a large organization. You don't have to say who you really are. You can come as a buyer. During the conversation, you can sometimes ask leading questions. If you can get the manager to talk, you can find out how many clients they have, how often they purchase products, and what is in greatest demand. Or you can conduct surveys on the streets of the city.

Before you begin your research, you will need to get answers to a number of questions that show the profile of your potential buyer:

- age;

- place of residence - apartment or private house;

- approximate monthly income;

- what products your client requires;

- what primarily influences the purchase;

- what problems the purchased products can solve.

The entrepreneur himself answers these questions. They will help you decide on the choice of potential clients. During the research process, it will become clear which circle of consumers needs to be reached as part of the advertising campaign. Any product has its own value. If he sells at a high price, and in the city in which the workshop is located, the income level of the population is low, then it will be quite difficult to sell.

We recommend reading:

- laminate production

- how to open a sawmill from scratch

- how to open a framing workshop

- laminated timber manufacturing business

- wooden staircase manufacturing business

What products and services will the carpentry shop produce?

A small carpentry company can produce:

- home interior items - stairs, doors, windows, frames, finishing panels;

- decorative elements - wooden partitions, screens, columns;

- building materials - parquet, timber;

- country interior - benches, gazebos;

- furniture;

- small accessories - souvenirs, toys, bath products.

Depending on the material, these will be budget products or exclusive products. For small production, it is better to work with individual orders. Author's solutions cost 3-4 times more than serial models. The main thing is to have a high-class master.

Material selection

Before you start making furniture, you need to decide on the raw materials to be used. Let's consider which species are the most popular and what they are used for: Deciduous:

- Oak – massive furniture.

- Alder is light and elegant furniture.

- Beech – bent products, stairs.

- Ash – for interior decoration and carving.

- Walnut is predominantly expensive furniture.

- Maple - veneer.

Conifers:

- Pine – window frames, door panels.

- Spruce – doors with good thermal insulation.

Exotic wood species:

- Red – decor, musical instruments.

- Black – used for small items, such as boxes. Furniture made from this type is the most expensive.

Production plan

To set up a workshop for the production of wood products, you must rent a premises with an area of at least 150 square meters.

Carpentry workshop layout:

- production workshop - 75-80 square meters;

- warehouse No. 1 - wood storage;

- warehouse No. 2 - finished products;

- staff room;

- bathroom, shower.

Premises requirements:

- water pipes;

- heating system;

- electricity;

- sewerage;

- ventilation system.

The room must be dry - wood easily absorbs moisture. The properties of the material deteriorate. Temperature range: 18-22 degrees.

Workshop lighting plays an important role. Windows should occupy at least a quarter of the entire area. If you plan to release doors or windows, consider the height of the ceilings. Minimum - 4 meters.

Advice! Choose a location away from residential premises and the center - this way you will save on rent and not violate sanitary standards.

Project implementation planning

It is planned to launch the carpentry workshop within three months, from March 1 to May 31, in time for the start of construction work. In summer, the workshop receives more orders, as seasonality affects.

| Stagedness | March | April | May |

| Registration of a legal entity, selection and transition to the simplified tax system | + | ||

| Finding suitable premises | + | ||

| Approval of documents and installation of electrical wiring | + | ||

| Selecting a machine, purchasing it, installing it | + | + | |

| Tool selection and purchase | + | ||

| Arrangement of carpentry tables, installation | + | ||

| Installation of fire sensor system | + | ||

| Purchasing a kettle and cooler for workers | + | ||

| Staff Recruitment | + | ||

| Purchase of lumber for the manufacture of wooden products and furniture, glue, adhesives, antiseptics, paints and varnishes | + | ||

| Promotions | + | ||

| Launch | + |

The phasing is scheduled according to certain dates, from which it is not recommended to deviate. The owner can delegate some of the responsibilities to a legal company, for example, registration of individual entrepreneurs. But this entails additional expenses.

How to advertise a carpentry workshop

A competent advertising company will help you express yourself and find new clients. Effective ways to promote a product or service:

- submit a free ad on the regional administration website;

- Post advertisements at wholesale warehouses of building materials;

- install an advertising stand near a supermarket or shopping center;

- create your own website on the Internet - fill the page with a product catalog, price list, and useful articles on the topic. Provide the opportunity to place an order directly from the site;

- distributing leaflets and business cards - this method of promoting a service cannot be called effective. It is not advisable to use it as the main method of advertising, but it is quite possible as an additional method. The advantage of this method is its low cost compared to other marketing methods.

Marketing strategy

There is no need to organize complex marketing campaigns to promote your workshop. It is proposed to use the following methods of advertising and promoting your product:

- Creation of a special group on social networks. Promoting it through communities of bathhouse and wooden house-building lovers.

- Placing advertisements for sale in periodicals in your region.

- Printing color booklets with price lists and distributing them to construction stores and companies that perform finishing of houses and baths.

- Creation of an online store where all products will be presented not only for one region, but also for buyers from neighboring cities.

- Offer entrepreneurs who have construction stores to list your product and pay for it after the sale.

If wooden products have an original design and differ from other analogues, then regular customers will appear very quickly.

Paperwork

To register a company, you should contact the tax service at the location of the legal address of the object.

Package of documents for registration of individual entrepreneur:

- passport - original and a copy of all pages;

- TIN - if available;

- written application of the established form P21001;

- check for transfer of duty - 800 rubles;

- tax form statement.

Documents for LLC:

- application for registration, sample P11001;

- passports of those who will become founders, plus copies of all pages;

- fee payment receipt;

- minutes of the founders' meeting. If the founder is one person - his decision to form an LLC;

- articles of association;

- application for the tax form chosen by the founder.

Tile

One of the most durable materials, not subject to destruction and changes in quality when interacting with water.

Tiles are easy to use and allow for creativity, coming in many varieties and designs.

Disadvantages include the risk of breakage, acoustic effect, hardness and smoothness.

Considering all the variety of modern models, this flooring option can satisfy almost anyone. This example uses wood grain tiles.

This option is suitable for use in public places, due to its wear resistance, as well as in places with high humidity. However, in music studios and where people are forced to stand for a long time, its use is inappropriate.