Wood is an affordable, environmentally friendly building material with a beautiful appearance. Modern materials (expanded clay concrete, foam concrete) have recently become often used for the construction of walls and partitions, but their popularity in the construction of small houses is still inferior to wood.

However, being an organic material, wood is too hygroscopic and is an excellent breeding ground for mold and microorganisms. Therefore, when using this material, you should pay special attention to its protection from external factors.

Causes of wood rotting

The development of mold fungi is the main factor that destroys wood. Mold development (rotting) occurs under certain conditions:

- air humidity 80–100%;

- material humidity above 15%;

- temperature below 50 and above 0 C0

Additional reasons for rotting may include freezing of the material, stagnation of air, and contact with the soil.

Factors favorable to the decay process are quite common. Therefore, you need to know how to treat wood to protect it from mold.

When is the use of impregnations especially necessary?

Since wood is subject to the greatest damage in conditions of high humidity, the use of antiseptics is especially important in areas where moisture has the maximum destructive effect. These include basements, baths and saunas, outdoor gazebos, garden furniture, as well as those parts of wooden structures that have close contact with the ground.

Treatment of such a surface can be carried out both at the construction stage and on finished structures. Using a wood stain to protect against moisture and rot, you can minimize the appearance of fungus and mold stains, avoid rot and protect wood materials from the destructive power of water.

Drying wood

You should start with preventive measures. To prevent the development of mold, the wood must be dry. There are four methods for drying timber or boards:

- Natural drying in dry rooms with good ventilation. This is the longest method (drying time is up to 1 year).

- Drying in a chamber using superheated steam and hot air. This is a more expensive, but fast and effective method.

- Paraffinization. The tree is immersed in liquid paraffin and placed in an oven for several hours.

- Steaming in linseed oil. Suitable for small wooden products. The tree is immersed in oil and boiled over low heat.

How to prepare bioprotection for wood at home

You can make an antiseptic for a wooden surface with your own hands. A popular recipe is the use of bitumen and gasoline (diesel fuel). It is also necessary to prepare a metal container, a metal spatula and support elements for fixing the container above the fire.

It is advisable to work outside, it will be safer. Perform the following steps:

- Bitumen is placed in a prepared container.

- She is transferred to the fire.

- The bitumen is heated until completely dissolved; with a spatula, mix it well until it has an even consistency.

- Continue the process until a weak viscosity is obtained, then remove the containers from the heat.

- When the bitumen has cooled, gasoline is added to it in small portions to make it easier to mix.

- Apply the product with a brush or roller.

Differences between hand-made antiseptics and ready-made ones from the factory

Self-prepared compositions have a number of positive aspects when compared with purchased impregnations: inexpensive, oil and bitumen compositions have a good degree of efficiency, less toxicity.

Factory ones are better in quality. They are easy to use and do not require long cooking. They selectively affect the tree.

A popular recipe is the use of bitumen and gasoline.

Protecting wooden elements from moisture

Modern waterproofing allows you to protect timber from capillary moisture. A high-quality roof and the application of special paints and coatings protect the structure from atmospheric moisture.

Protection against condensation accumulation is provided by thermal and vapor barrier. The heat-insulating layer is placed closer to the outer surface, and a vapor barrier is placed between it and the wooden wall. The timber of the roofing elements is protected from rain and snow by waterproofing films.

Wooden houses and structures must be located above ground level, on a foundation. For effective protection from water, it is worth taking care of the presence of a blind area and an effective drainage system. Of great importance for the biostability of a wooden building is the possibility of natural drying of the walls. Therefore, trees should not be planted near wooden buildings.

Antiseptic impregnations for processing logs

The choice of antiseptic impregnations must be approached responsibly; the safety of the home depends on them. It is important that they are of high quality, their composition is effective for quite a long time and, most importantly, environmentally friendly. Neomid 440 Eco fits these criteria perfectly. It is created in order to protect wood from various types of fungi and mold, prevent and destroy the processes of decay that have begun. Thanks to its unique and safe composition, it can be used to treat log structures both outside and inside.

This antiseptic is colorless, so the appearance of the log will remain the same, and its structure will not change either. After treating a wooden house with Neomid 440 Eco, various biological pests will not disturb it for 25 years. Before applying this impregnation, it is necessary to examine the logs for the presence of dirt and dust; if any, remove them. 440 eco-manufacturers Neomid is available in concentrated form. And before using it, you should not forget to dilute it in water, in a ratio of 1 to 9. Logs can be treated by applying or immersing in the composition. For the first method, you can use rollers, brushes with bristles made from synthetic materials, or use a spray device. Impregnation must be applied in at least 2 layers. The second method is great if you need to process a large number of logs. To do this, they need to be immersed in a container with Neomid 440 Eco for several minutes. After treatment, the wooden material must be protected from moisture for 24 hours.

What to do if the timber begins to rot

Rotting greatly deteriorates the physical parameters of the tree. Its density drops by 2–3 times and its strength by 20–30 times. It is impossible to restore a rotten tree. Therefore, the element affected by rot should be replaced.

If the mold infestation is minor, you can try to stop the process. To do this, the rotten area is completely removed (including part of the healthy wood). The removed part is replaced with steel reinforcing rods, which must go deep enough into the healthy part of the element. After reinforcement, the area is puttied with epoxy or acrylic putty.

This is a labor-intensive and complex procedure, after which it is not always possible to achieve the previous strength of the structure. The problem is easier to prevent by treating the wood to prevent rotting.

Features of fence processing

Processing wood for a fence begins from the moment the material is purchased. For a number of reasons, applying protective agents to an already installed fence is less effective. Some areas of the finished fence, for example, the side parts of the board, will become difficult to access, and those that go underground will be completely out of reach.

The method of application depends on the type of impregnation, but, as a rule, better protection from external factors can be achieved when the material is kept in baths of solutions for a long time. Obviously, this can only be done before installation.

Processing sequence

- To deprive bark beetles of their natural habitat, the fence tree must be cleared of bark.

- If the boards are planed, this will provide additional protection from moisture.

- Parts of the boards that will be in a state of greatest interaction with an aggressive environment, with high humidity, go underground, it is better to additionally treat them with tar.

- Antiseptic agents are reapplied some time after installation.

Preparing and drying wood

If the boards are not sufficiently dried, you can dry them yourself. It is necessary to stack the boards, placing supports made of logs, beams or bricks under the bottom layer. The rows are laid with a gap of 2-3 cm. Between the layers of lumber, spacers from slats or cuttings of boards are placed in increments of 1-1.5 m. The stack laid in this way is covered on top to protect it from moisture. The ends of the boards are covered with waste machine oil or oil paint. Drying can last from several weeks to months, depending on the thickness of the material.

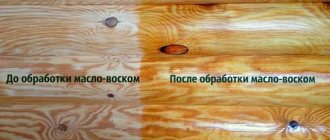

Impregnation and patination of wood

In its original meaning, patina is an oxide film that forms on the surface of copper and gives it a more “decrepit” appearance. Now the concept of patination is used when it comes to applying compounds that create an aging effect not only on the designated metal, but also, for example, on a wooden surface. This type of processing can be a successful design solution in a number of cases. Patination compositions, in addition to the decorative effect, perform the function of protecting wood from external influences.

Protecting a tree with folk remedies

The problem of protection against rotting has been relevant since the time when wood was first used as a material. Over the course of a long time, many effective folk recipes have accumulated that are still successfully used today:

- Coating wooden structures with silicate glue.

- Treatment of walls and soil (up to 50 cm depth) with a solution of potassium dichromate in sulfuric acid. 5% solutions of acid and potassium dichromate are mixed 1:1.

- Treatment with vinegar and soda. The affected areas are sprinkled with baking soda and sprayed with vinegar from a spray bottle.

- Treating wood with a 1% solution of copper sulfate.

- Hot resin impregnation. A very effective method for treating logs, fence stakes, benches in contact with the soil.

- Using salt with boric acid. A mixture of 50 g of boric acid and 1 kg of salt per liter of water should be treated several times, at intervals of 2 hours.

All these methods are only suitable for healthy wood or when the tree has small lesions.

Where can I buy these quality products?

Photo: the most popular antiseptic and decorative impregnations of the Neomid brand.

You can buy high-quality wood preservatives for processing wooden log houses, high-quality sealants for wood, from our company, which is the official dealer of effective impregnations Neomid and Prosept.

Call, check the availability and cost of wood protection products for wooden log and timber frame houses.

Modern methods of combating rotting

There are two ways to reliably protect wood: conservation and antiseptic treatment.

When preserving, a product with a long-lasting toxic effect is applied to the timber or board. To do this, the wood is soaked in cold or hot baths, or the preservative penetrates into it using diffusion or autoclave impregnation. The method is applicable only in factory conditions.

Antiseptic treatment involves self-impregnation of the material by applying chemicals with a spray bottle or roller. The antiseptic agent must be selected in accordance with the operating conditions of the wooden structure. For example, impregnations based on water and white spirit are safe and inexpensive, but are easily washed off. Therefore, only water-repellent antiseptics are suitable for elements in contact with moisture or soil.

Classification of antiseptics

When choosing a product to treat timber, it is worth understanding the main categories and types of protective compounds. There are three categories of compositions for protecting wood: paints, varnishes, and antiseptics.

Paints perform both protective and aesthetic functions. For interior work it is better to choose water-soluble paints, and for exterior paints - based on an organic solvent.

Varnishes form a protective film on the surface without changing its appearance. For exterior work, varnishes with fungicides are used that kill mold and prevent cracking and fading of wood.

Antiseptics work great when mold has already infected the tree. There are 5 types of them:

- Water soluble. Odorless, non-toxic, dry quickly. They are made on the basis of fluorides, silicofluorides, a mixture of boric acid, borax or zinc chloride. Not recommended for treating surfaces frequently in contact with moisture.

- Water repellent. They are distinguished by deeper penetration into the tree. Suitable for processing bath structures, cellars and basements.

- On organic solvents. Allowed for use in external and internal work. Forms a thick film that dries up to 12 hours.

- Oily. They form a thick, durable coating that is insoluble in water. However, they should only be used with dry wood. When applied to damp wood, oil antiseptics do not prevent the proliferation of fungal spores inside the material.

- Combined. Suitable for any wood and additionally have anti-flammable properties.

Basic methods

First of all, let's look at the factory processing method:

Method No. 1: heat treatment

Heat-treated pine timber is practically free of the problems inherent in conventional wood

How to treat timber so that it does not crack, rot, become moldy and is not susceptible to insect attack? Fifteen years ago the Finns came up with a very interesting process, which is as follows:

| Operation | Effect |

| Exposure of bars to water vapor under pressure | The wood structure changes at the cellular level, getting rid of hydrophobicity |

| Subsequent careful drying of samples in special chambers | Allows you to remove residual moisture |

Of course, such a task can only be accomplished using factory equipment, and the price of finished products increases noticeably as a result.

But after this level of drainage and elimination of resins, the timber acquires the following advantages:

- Immunity to dampness. That is, rotting and the spread of mold can already be excluded;

- Increasing strength qualities. This will make the building even more reliable;

- Eliminates the possibility of cracking. After all, the material is already completely dried;

- Lack of attractiveness to pests.

Method No. 2: antiseptics

An example of an impregnating non-washable antiseptic

How to treat the timber to prevent it from rotting if you purchased regular samples? To do this, it is worth using antiseptics, which are divided into two types:

| Species name | Description |

| Impregnating | May have an organic or chemical basis. In the case of coating wooden surfaces, as a rule, aqueous compositions are used to preserve the environmental friendliness of the material. Penetrates into wood pores, blocking the path of moisture. They do not wash out and are more reliable, but also more expensive. |

| Film-forming | In turn, they are divided into two types:

|

Decorative film-forming antiseptic

Advice: if you plan to treat timber with natural humidity with an antiseptic, it is recommended to wait a few weeks until it dries. Otherwise, the moisture contained in it will prevent the normal penetration of the composition.

What antiseptic to treat the timber with should be decided after answering the following questions:

- What kind of finishing do you plan to do?

- What kind of finances do you operate?

- Are you treating the outside or inside of the house?

Advice: for the external facade it is worth using chemical-based compounds. Although they are toxic, they are more resistant to precipitation. And harmful fumes from outside quickly disappear.

The instructions suggest applying the protective solution using a brush or spray, which is much more convenient, in several layers. And it’s worth starting even before installing the bars, paying special attention to the lower crown and joists, since they are located near the ground and are thus most susceptible to the harmful effects of dampness.

Processing of the first crown of a timber house should be carried out at the installation stage

The base of a wooden building can even be coated with waste motor oils to increase its moisture insulation.

Method No. 3: end protection

Treating the ends of the timber will prevent cracking

How to treat the ends of the timber to prevent cracking? In this case, for example, a special product “Neomid Thor Plus”, which contains synthetic copolymers, will help.

In the photo - “Neomid Thor Plus” for processing ends

This composition, applied by hand, prevents uneven drying and protects the end parts from dampness, which are the most hygroscopic.

How to apply a protective coating to wood

Applying antiseptics, varnishes and paints is not difficult. However, carrying out such work requires compliance with certain rules.

- Before handling, wear gloves, a protective mask and goggles.

- Clean the surface to be painted from dirt, grease and old paint with a scraper.

- Clean the board or beam with an old brush or sandpaper.

- Wash the surface with water and detergent.

- Wait until the wood is completely dry.

- Read the instructions for instructions on how to apply the product.

- Start processing wooden structures from the ends, cuts, and damaged areas.

- If it is necessary to apply several layers of coating, you should pause 2-3 hours between applying each layer.

We increase fire resistance

Protecting wood from moisture and rot is not the entire range of work that must be performed before use. One of the weak points of wooden structures is their rapid flammability. Therefore, we pay attention to solutions that can slightly increase the degree of fire resistance of wood, the so-called fire retardants. This is especially true in residential buildings.

The essence of fire retardants is that under the influence of high temperature they form a film that can delay the ignition of wood material for some time.

With the help of additional treatments against the influence of all negative factors, the reliability of a wooden structure can be significantly increased. The best treatment is up to consumers to decide depending on individual preferences and conditions.

How to protect wood from moisture (2 videos)

Different types of protective equipment (26 photos)

What you need to know about mold protection

The protective composition should be selected based on the operating characteristics of the surface being protected. Only hard-to-wash coatings are suitable for outdoor use. Such products will reliably protect wood for 30 years.

For wet rooms (basements, baths) special products are needed that can withstand sudden temperature changes.

Changes in the color of the wood, the appearance of chips and cracks are a signal that the protective coating should be urgently renewed. It is recommended to alternate antiseptic compounds without treating the wood with the same compound again.

Comparison of brands: which manufacturer to choose?

There are a large number of antiseptic protective agents on the market, and choosing among manufacturers can be very difficult. Funds can be divided into 3 categories:

- Budget ones are “Senezh”, “Aquatex”;

- Middle class – “Tikkurila”, “Belinka”;

- Professional – “Dulux”, “Teknos”, “Woodworks” and others.

According to the rating, they are placed this way: the more expensive the product, the higher quality it will be and will last longer.

There are a large number of antiseptic protective agents on the market, and choosing among manufacturers can be very difficult.

An antiseptic for wood is a mandatory element of the coating so that it lasts longer and biological formations harmful to health do not appear on it. You need to choose a product based on the stage of work, budget, and operating conditions. Having made the right choice, you can be confident in the safety of the surface.

What is the danger of rot?

The most obvious answer is that the structure of the wood is destroyed, delaminates, and falls into pieces in the shortest possible time. Elements of the porch, fence, and building will have to be changed. The consequence is moral discomfort, an unfavorable indoor microclimate, and additional costs for repair work.

The main reason that forces a person to fight mold and rot on wood is the spread of numerous respiratory diseases, including asthma. It is easier to eliminate putrefactive stains than to spend years on treatment.

How to correctly calculate the cost of funds

Industrially made impregnations for log houses are usually sold in the form of a powder or concentrate, which are then diluted with water. The diluted solution is 5-10 times the original volume of the product. For example, from a 5-liter canister you can get about 50 liters of ready-made antiseptic.

The calculation of the product required for treatment is based on a standard consumption of 0.3 liters per 1 m2 for one treatment layer. If you perform a simple calculation, you can calculate that 1 liter of concentrate will be used for a single treatment of an area of 60 m2. Thus, one five-liter canister will be enough for three-layer treatment of a house with an area of 100 m2.