Heeling is a structural defect of wood, in which the lower zone of the trunk and branches thicken, and the later annual layers darken. Changes in the structure of the tree occur due to both compression and stretching of the lower section. They represent dark-colored wide-layer areas in the form of an arc or ring and are located at the ends of the material. Dark stripes are visible on the veneer. Such defects are typical for curved or inclined wood. Most often, heeling is observed in spruce.

Trunk shape defects

Distortion of the shape of a tree trunk is a type of natural defect. They increase waste generation and cause radially inclined fibers in lumber and veneer.

Convergence

In woody plants, a decrease in trunk diameter from the butt to the top is natural. This phenomenon is called escape. It is 1 cm for every meter of length.

If the diameter of round timber or the width of lumber decreases by an amount greater than the normal slope, then such a wood defect is called slope.

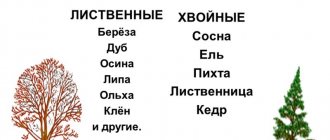

The trunks of coniferous trees are less cambered than those of deciduous trees. Plants grown in a dense forest stand have lower stemness than in open forests. The greatest curvature is characteristic of lumber obtained from the apical zones of trunks.

Growths

These are very common defects in deciduous trees. They represent a sharp increase in trunk thickness. The growths can take on different shapes and sizes and appear in the form of burls or ridges.

They appear under the influence of external factors (radiation, damage, fungi, viruses), leading to disruption of growth processes. The parameters of growths are characterized by length and width. The build-up complicates the use and processing of the assortment.

Zakomelistost

This defect is characterized by a significant (more than 1.2 times) increase in the diameter or width of the assortment in the butt area relative to the zone located at a distance of 1 m from it. The lumps are round or ribbed in shape.

Curvature

A natural type of defect is the curvature of the trunk along its length. Curvature can be caused by the loss of an apical shoot, the tilting of the plant in the direction of better lighting, or the landscape features of the area.

Curvature is a consequence of one or more bends of the trunk; accordingly, it can be simple or complex.

Use of tilted wood

It is undesirable to use timber for the manufacture of building materials and thin boards, furniture pieces and musical instruments. However, small and insignificant zones of local heeling are acceptable if the products during operation are not subject to severe stretching and impact. In addition, they are suitable for producing parts with unstable dimensions.

For the construction of a wooden house or bathhouse, tilting is not allowed. In this case, it is important to choose straight, strong trunks that will not subsequently crack and rot, or become covered with mold or mildew. It is important that the logs and beams retain their natural beneficial qualities, presentable appearance and original color for a long time.

To obtain high-quality and reliable lumber, you need to carefully select raw materials, follow cutting and harvesting technology, storage and transportation rules, and treat products with protective agents. “MariSrub” craftsmen carefully select and process wood, which allows us to obtain only strong and durable products.

We comply with the necessary standards and requirements, we produce logs and beams in accordance with GOST. To protect against the negative effects of moisture and cold, insects and ultraviolet radiation, and temperature changes, each product is antiseptic. In addition, we carry out protective treatment at the stage of assembling the frame and finishing the house.

We offer individual design and modification of a ready-made project, turnkey construction and individual services in this area. The construction of a turnkey wooden house includes the design and production of timber or logs for the project, installation and insulation of the log house, construction of the foundation and roof, installation of communication networks and finishing. You will find many interesting projects of timber and log houses on the pages of the “MariSrub” catalogue.

Wood structural defects

Deviations in the structure of wood tissue are a common defect that disrupts its properties and complicates woodworking operations. The most common defects are shown in the table.

| Vice | Types | Description |

| 1. Cross-layer | tangential | fibers inclined non-parallel to the longitudinal axis, causing warping and shrinkage |

| radial | ||

| 2. Traction wood | characteristic of deciduous trees; manifests itself in an increase in the thickness of growth rings | |

| 3. Curlyness | confusing | tortuosity or randomness in the arrangement of fibers; Helps increase chipping strength |

| wavy | ||

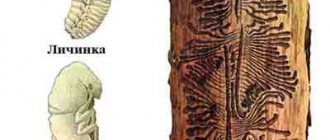

| 4. Kren | local | a sharp apparent thickening of wood inherent in coniferous trees, which leads to the formation of cracks, warping, and a decrease in water absorption and strength properties |

| solid | ||

| 5. Curls | end-to-end | curvature of tree rings |

| unilateral | ||

| 6. Pocket | side | voids in wood filled with resinous substances |

| through | ||

| 7. Core | loose brown or light tubes in the central zones of the trunk | |

| 8. Stepchildren | extended additional peaks that have died out or lagged behind in development; pierce the workpiece at acute angles to the longitudinal axis | |

| 9. Sprouting | open | a gap at the site of healing wounds, filled with bark and other tissues |

| closed | ||

| fused | ||

| 10. Cancer | open | defects in the form of depressions or swellings caused by the activity of fungi or bacteria |

| closed | ||

| 11. Eyes | dispersed | buds underdeveloped into shoots |

| group | ||

| 12. Grinding | parts of wood inherent in coniferous trees, saturated with resin | |

| 13. False core | characteristic only of deciduous trees; looks like a core, different from the rest of the fabric in color; distorts the natural color of wood; characterized by fragility and low strength | |

| 14. Spotting | tangential | a vice often accompanied by rot; manifests itself in the form of spots, similar in color to the core; does not change the strength properties, but may cause cracking of the veneer |

| radial | ||

| vein-shaped | ||

| 15. Water layer | areas of wood with high humidity, leading to the formation of small cracks | |

| 16. Dry sideness | part of the trunk surface that has died due to damage |

Cracks

Cracks are all kinds of wood defects associated with breaks in the direction of fiber growth. All types of assortment are susceptible to cracking.

They appear from the side or at the end, coming out onto the face or edge. Cracks can be through and non-through, deep (more than 5-7 mm) and shallow (less than 5-7 mm). Closed (less than 1 mm) and divergent (more than 1 mm) cracks may appear in the veneer.

Types of cracks:

- Methic. These are intermittent cracks that run radially through the core and are directed away from the core. Their length can exceed 10 m. They are characteristic of tree species of various species and arise during the growth process. During drying, cracks enlarge. They can be found in the end part of round timber. In wooden products, parts, and lumber, cracks occur along the ends or side surfaces.

- Fuck off. These are exfoliations passing between the growth rings. Their occurrence is possible in growing trees during a sudden transition from small layers of wood to large ones. At the end of the timber they have the shape of rings or arcs. The snap provokes rot or the formation of water layers.

- Shrinkage cracks When lumber drying technology is violated, defects are formed caused by internal stresses. These are breaks and cracks running from the surface layers to the center, about 1 m long. Beech, birch, and aspen are most susceptible to such defects. At the final stage of the drying process for lumber with a large cross-section, internal cracks can form. They are discovered when cutting blanks.

- From exposure to frost or from a lightning strike. These are long open cracks on the surfaces of the barrel. Their appearance is associated with sudden changes in temperature in winter or a lightning strike on a tree. They are visible on the ends or side surfaces of timber and are directed towards the central part, gradually narrowing. In wooden parts or lumber, cracks take on a radius-rounded appearance, and the growth rings around them are characterized by curvature.

Types of defect

- Local heel - arcuate areas or narrow stripes on the ends and sides of products that capture one or more annual layers. Formed due to temporary bending of the trunk in certain areas of the tree;

- Solid roll - continuous dark-colored areas that cover up to 70% of the cross-sectional area of the material and capture a large number of growth rings. A continuous roll is formed due to prolonged bending of the trunk. It promotes displacement of the core and is accompanied by the formation of curvature of the tree.

Knots on the trunk

The most common defect in wood is knots. This defect should be understood as the bases of living or dead branches remaining in the trunk. This is an inevitable component of the structure of wood, found in every tree.

Their presence is taken into account when assessing the quality indicators of the assortment. Knots negatively affect external characteristics, bend fibers and growth rings, worsening the mechanical characteristics of wood.

They are divided into open and overgrown types of knots.

Open knots

Open knots are round, oval or oblong in shape. They can be located on the plate, edge, rib or at the end of the workpiece. Knots can be scattered over the surface and can have a group or branched arrangement.

Knots may fall out or grow together with the surface. They can come out to the surface in one place or be through.

Healthy knots differ in color from the general color of the wood; they can be light or dark, and may have cracks. Damaged branches have a decaying or rotten appearance.

Open knots are measured using their smaller diameter. Putrefaction is determined by visual signs.

Overgrown knots

Knots of this type are not visible on the surface of trunks. They can be detected by indirect signs. Such signs are represented by wound spots, swellings, and edges.

They are not measured in coniferous trees. In deciduous trees they are determined by the size of the wound spots or by the angle between the tendrils of the edges. Wound spots appear where branches die or fall off.

Edges appear as a result of the pressure of growing branches on the trunk. They look like darkish stripes (whiskers), clearly defined in species with smooth bark (birch, aspen, beech).

Effect of defect on wood

A highly developed heel, which is 15-40% higher than normal, complicates the mechanical processing of wood. Such material is difficult to sand, paint, varnish and antiseptic. Kiln wood is characterized by increased hardness and compressive strength, but at the same time the tensile strength and elasticity along the wood fibers is significantly reduced.

After drying, the wood becomes less durable and resistant to impact. In addition, due to its characteristic high hardness, it is difficult to drive nails into such wood. Shrinkage and shrinkage of a log house made from lumber is much higher than from normal lumber. As a result, this increases the cracking of the timber or log, and warping appears.

Krene easily and quickly absorbs moisture from the air, which contributes to the swelling of the wood. In addition, this defect worsens the appearance of wooden products. Thus, well-developed and widespread maple reduces the quality and grade of lumber, as well as pulpwood, which is used for paper due to its reduced cellulose content.

Fungal lesions

These types of wood defects are caused by the activity of fungi. Mushrooms have a coloring and destructive effect.

Brief characteristics of the types of fungal defects:

- damage by mold fungi;

- acquiring a brownish color;

- mushroom staining of sapwood;

- putrefactive changes;

- core stripes;

- hollow.

Defects that appear during processing and mechanical damage

This type of defects is caused by the mechanical impact of natural factors and technological processing operations on wood. The most common types of these defects, their causes and consequences are shown in the table.

| Type of damage | Kinds | Reasons for appearance | Consequences |

| Natural damage | charring | forest fires, high air temperatures, exposure to animals and insects, natural factors | reduction in wood quality indicators, limitation of the possibility of use |

| tariness | |||

| sections of trunks without bark | |||

| Foreign inclusions | hole | hit by stones, nails, splinters, wire | breakdown of woodworking equipment |

| fold | |||

| dent | |||

| bloating | |||

| Processing defects | waviness | incorrect impact of the processing tool | low quality assortment, limited use |

| flake | |||

| bullies | |||

| burrs | |||

| notches | |||

| gashes | |||

| wane | |||

| Wood warping | longitudinal | change in shape during drying, storage or processing | changes the shape of the product, complicating its use |

| transverse | |||

| screw |

Thus, the study of wood defects, their identification and prevention are important tasks.

Their solution will improve the quality of products, minimize waste generation and increase the rational use of forest resources.