In the production of products from wood material, it is important to take into account the moisture level of the raw materials, which can be determined by a special device - a moisture meter. Such compact devices use a non-contact operating principle.

They give a significant error when measuring hot materials and areas with a resinous surface. To make it easier for you to navigate this area, we have compiled a rating of the TOP 5 best moisture meters for wood: types, characteristics, reviews will be discussed in the article below.

Kinds

The market for such devices is large: from small compact moisture meters to huge devices with many different functions. Let's look at the two most popular types.

- Needle (contact) Designed for extremely accurate measurement of the moisture level of various lumber and wood products. Determination of humidity occurs by measuring and converting the electrical resistance of the material under study into a percentage using the conductometric method.

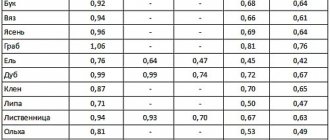

- Contactless. Designed for high-precision determination of the moisture level of wood products using the dielcometric method. The measurement takes place in several stages: the type of species is set on the device, it is leaned against the surface of the wood, a button is pressed and the measurement result is displayed on the indicator.

Equilibrium moisture content of wood

Any wood is capable of absorbing water vapor and water and releasing the resulting moisture. Depending on the moisture content and ambient temperature and the length of time the wood is exposed to air, equilibrium moisture content is established. This concept is associated with the complete uniform distribution of moisture when the drying process of the tree stops and the percentage of moisture in the wood and the environment become equal.

You may be interested in: A lictor is: the essence of the profession and historical facts

It turns out that the hygroscopic equilibrium of a region’s climate can be determined by the equilibrium humidity of a house built from natural wood. The moisture contained in wood, as mentioned earlier, consists of free and component. The boundary of these concepts is the saturation point. This is the state of wood when the free liquid has been completely removed and the cells remain saturated with water. Regardless of the type of wood, the humidity at the saturation point is generally considered to be 23–31%.

Rating TOP 5 best moisture meters for wood

Having analyzed the entire market of available goods, we have compiled the following rating:

- CONDTROL Hydro Pro.

- CONDTROL Hydro-Tec.

- TESTO 606-1.

- CEM DT-125H/G.

- GMH 3830.

Let's consider each model separately.

CONDTROL Hydro Pro

Microprocessor model of a moisture meter designed for measuring temperature and humidity in rooms, as well as monitoring wood moisture content in accordance with GOST. This compact model contains the functions of three different devices, while all sensors are built into the body. The device has two measurement modes: HOLD - fixing a single value, SCAN - for continuous scanning and detection of areas of high moisture content. In addition to measuring wood moisture, the device is suitable for concrete, mortar screed, plaster and brick.

| View | contact |

| Error | 2.5% |

| Operating temperatures | from -5 to +40°С |

| Weight | 200 g |

Price: from 13,900 to 15,999 rubles.

- three operating modes (AUTO, HOLD, SCAN);

- small dimensions (145x60x35 mm);

- wide angle of object capture (up to 110°).

- not detected.

I decided to get into the wood trade and purchased this model to avoid various unpleasant situations. The package included a device passport, a humidity equivalent and a portable bag (convenient and practical). There is an automatic shutdown system, which allows you to significantly save electrical charge and prolong the operation of the equipment. I can't highlight anything else. Simple, outstanding design, compact size. Overall I'm happy with the purchase.

moisture meter CONDTROL Hydro Pro

CONDTROL Hydro-Tec

The model is designed for operational measurements of the moisture level of wood and other building materials. The principle of its operation is based on the correlation dependence of the dielectric constant of a material on its moisture content at positive temperatures. This makes it possible to perfectly accurately determine the moisture content in wood ranging from 2% to 65% at a depth of up to 20 mm. Despite its small size, the device contains a library that includes twenty types of wood: spruce, poplar, aspen, pine, cedar, linden, walnut, elm, maple, beech, pear, oak, cherry and others.

| Error | 2% |

| Operating temperatures | from -5 to +40°С |

| Weight | 75 g |

| View | contactless |

Price: from 4,300 to 5,990 rubles.

- about twenty lumber are stored in memory (oak, birch, maple, etc.);

- optimal error value (up to 2%);

- large display (5.5x12.3 cm).

How to find out the moisture content of wood?

There are several methods for determining wood moisture content. But first you need to find out the type of plant and air moisture, since different trees have their own standards.

In order to measure the moisture of wood raw materials, as a rule, two methods are used: gravimetric or using an electrical device. Their indicators may differ slightly, but not significantly.

Weight

For this method you will need:

- boards;

- very accurate scales;

- saw;

- ruler.

Comparison table of characteristics

For a more clear comparison of the models presented above, we have compiled a comparison table.

| Model | View | Accuracy (%) | Operating temperatures (°C) | Weight, kg) | Price, rub) |

| CONDTROL Hydro Pro | contact | 2.5 | from -5 to +40 | 200 g | from 13,900 to 15,999 |

| CONDTROL Hydro-Tec | contactless | 2 | from -5 to +40 | 75 | from 4,300 to 5,990 |

| TESTO 606-1 | contact | 1 | from -40 to +70 | 230 | from 8,390 to 9,500 |

| CEM DT-125H/G | contact | 0.5 | from -20 to + 40 | 172 | from 4,520 to 5,120 |

| GMH 3830 | contact | 2 | from -25 to +50 | 170 | from 27,800 to 37,200 |

Conductometric method

Rice. 1. Dependence of electrical conductivity on wood moisture content

Wood in a dry state is a dielectric; its electrical conductivity increases sharply with increasing humidity to the limit of hygroscopicity. With a further increase in humidity, the electrical conductivity increases slowly, and at a level of 80-100% it becomes constant (Fig. 1).

To measure wood moisture content under industrial conditions, electrical conductometric moisture meters are usually used, in which the measurement is based on the dependence of wood resistance on its moisture content. They are simple in design, quite reliable in operation, and can be portable (with an autonomous power source). The moisture measurement limits for pine wood are 7-22% in the first range and 22-60% in the second. The general view of the conductometric moisture meter is shown in Fig. 2.

When measuring wood moisture content with an EV-2K electric moisture meter, it is necessary to take into account that the measurement result is influenced by the position of the sensor needles in the wood and, most importantly, its temperature. Therefore, in order to determine, for example, the current moisture content of lumber during the drying process, it is necessary to open the chamber, take a pre-laid control sample from the stack and measure the moisture content only after it has cooled to room temperature. It should be noted that modern moisture meters take into account a correction for the temperature of the wood.

Rice. 2. Electric moisture meter EV-2K for determining humidity

Basically, the EV-2K moisture meter is used for manual measurement of the final moisture content of dried lumber, as well as for selecting assortments of approximately the same moisture content, for example, for gluing. The conductometric method for measuring wood moisture is widely used in process control systems in drying chambers. The role of sensors is performed by two-electrode probes (Fig. 3).

Rice. 3. Electrodes for measuring wood moisture content

They are installed directly into the wood in different places in the drying chamber. Humidity values from all sensors enter a single measuring unit, where analysis and further issuance of commands to the central processor for controlling the drying process takes place.

How to use it correctly?

Despite the fact that these devices always come with instructions for proper use, some people cannot always correctly interpret the information described in the instructions for use. Now we will explain everything clearly to you.

Let's say you need to determine the moisture level of a parquet board. In this example, it is better to use a non-contact model; it will not harm the finished product. So, the measurement process goes like this:

- The board itself is prepared (cleaned of debris, it is advisable to ensure a flat surface).

- The device turns on (the button on the device itself).

- The calibration is set (according to the table in the instructions).

- The moisture meter is brought with the sensor side to the surface of the board or inserted into it.

- The display shows the measurement results we need.

Where to look for moisture in wood?

It is known that humidity serves as an indicator of the quality of wood and has a significant impact on its physical and mechanical properties, as well as on the quality of the finished product. The difficulty of measurement lies in the fact that the physical quantity, which is the source of information about moisture, is influenced by many other parameters of wood. This makes it difficult to obtain accurate results. Some of these parameters can be measured and taken into account by introducing corrections. Measuring others: wood density in an absolutely dry state, temperature, fiber orientation, structure is no less difficult than measuring humidity itself.

Existing methods can be divided into direct ones, in which the material is directly separated into dry matter and moisture, and indirect ones - they allow one to measure another quantity functionally related to the moisture content of the material.

What to look for when choosing

Let's consider what criteria should be taken into account in order to make a successful purchase.

- When choosing a moisture meter, the main criterion is the type of unit. There are two types: contact and non-contact.

- Contact (needle). Equipped with small metal needles, which must be immersed in specially prepared holes in the product. After this, the device will begin to create electrical resistance between the needles and the material. Working with this type is quite simple, but the product being tested suffers.

- Non-contact (dielcometric). Created on the basis of a radio frequency generator, which allows you to get a fairly accurate result. The device does not affect the quality of the product being tested.

- Cost of the device. Don't buy an overly expensive model. Their work follows the same principle, which means it makes no sense to overpay for a model whose manufacturers are simply luring buyers.

- Size. The comfort of use depends on the size of the device. Pay attention to the medium-sized model so that it fits easily in your hand. Otherwise, what is the use of a device if it cannot be used?

Weight method

The direct method includes the weight measurement method, or the drying method. It is considered the most accurate in the woodworking industry. Its essence is to directly determine the amount of moisture removed from wood by weighing the sample before and after final drying in a special drying cabinet at a temperature of 103 ± 2 ° C). Measurements are carried out in accordance with GOST 16483.7-71.

Wood moisture content is the percentage ratio of the mass of water mw contained in the sample to its mass in an absolutely dry state m0. It is expressed by the following relationship:

Under certain conditions, this method can provide very high accuracy, but it is not always possible to create them in production. It can be recommended if a wood moisture meter is not available. Along with the advantages, this method also has disadvantages. The main one is the excessive duration of the measurement process, while the use of modern high-performance drying chambers requires fairly efficient control of the drying process. Another disadvantage is the impossibility of continuously measuring the moisture content of the material being dried. In addition, after this, the wood samples become practically unsuitable for further use.

To quickly and continuously measure the moisture content of a material in a process stream, indirect determination methods are used, based on the measurement of a physical parameter dependent on humidity. Electrical measurement methods are the most widely used.