How to cut wood with a hacksaw

The saw must be driven, otherwise it will start “walking”. This needs to be realized practically. Wood is a living material, and its behavior is unpredictable. Hard annual rings, knots, cracks, high humidity and high resin levels can seriously complicate sawing.

For this reason, there is no universal tool that could take into account all the vagaries of wood, but there are many different special saws. The shape and order of alternation of their teeth are determined not by the material from which the saw blade is made, but by its purpose. Some equipment can be cut in a straight line, while others, on the contrary, are better able to cut in a circle.

When sawing, only the saw moves; the workpiece must be firmly secured. Therefore, you will need a stable support. For example, a workbench or sawhorses. The workpiece is secured with a clamp or held by hand, and especially large ones - additionally with a knee.

Sawing begins and ends by repeatedly lightly pulling the saw in the opposite direction, in other words, a “trace” is laid. At the end of sawing, you need to hold the remainder firmly so that it does not break off along with a piece of the main wood.

Sawing is one of the most common processes when processing wood. A clean, even cut is not a problem if you choose the right tool and know how to use it.

In the photo (from top to bottom): large and small hacksaws; saw with a “back”; saw with a narrow blade. Next to the left is a saw for finishing cutting.

Tips for use

Like any power tool, a reciprocating saw requires compliance with certain operating rules to ensure safety during use. First of all, you should read the manual that comes with the device. Manufacturers usually fully disclose the main issues in the documentation. In order to avoid injury and prolong the life of the unit, compliance with the rules is a strict necessity.

- During operation, it is imperative to use special protective equipment, because when working with a reciprocating saw, fragments and sparks fly off.

- To prevent the electric hacksaw from damaging the material being cut, you need to protect the surface during finishing work. To do this, put adhesive tape or heat-insulating tape on the sole of the instrument.

- To extend the service life of the saw blade, it must be lubricated. When cutting, the file heats up and becomes dull, quickly becoming unsuitable for work.

- Typically, blades of different lengths are used. This depends on the thickness of the material to be processed. If you choose a blade that is too long, it will make work difficult due to vibrations. Therefore, experts recommend choosing those canvases whose length exceeds the thickness of the material by 3-4 cm.

- Correct placement of the saw handle when cutting is the key to fast work. When cutting material that is too thick, the angle of the tool is alternated, which reduces friction. To prevent vibration, the sole of the reciprocating saw is pressed firmly.

- Dull blades will not be able to cut wood or metal smoothly and accurately. But you shouldn’t throw them away, because they are perfect for working with plastic pipes. New blades usually have sharp teeth that can snag the material.

- If the file is bent, which happens quite often, it can be straightened with a hammer and a wooden block. But when straightening, you should not knock on the teeth of the blade.

- The manufacturer does not recommend repairing broken power tools at home. In case of malfunction, you should take the device to a specialist service center. In addition, manual opening voids the warranty that comes with any model.

An electric hacksaw is suitable for all types of construction and repair work. The universal tool is practical and multifunctional

When choosing, it is important to consider the features of each model, as well as the scope of application. And in order to increase the service life of the reciprocating saw, you must follow simple rules, advice from the manufacturer and experts

article from the Rating section

Power tools Carpentry tools (wood) Garden tools

Save this page on your social media. network and return to it at any time.

ADD A COMMENT

How to saw correctly

You should always cut from the cutting side, close to the marking mowing line. This applies to both rough cuts with a hacksaw and precise cuts with a saw with small teeth. Next, it is very important that the workpiece being processed has a stable support in the form of a workbench tabletop or an ordinary desktop. For large-sized workpieces, it is better to use sawhorses. During the sawing process, the part must always be held firmly with your hand (large-sized workpieces should also be held with your knee) - in other words, only the saw should move.

Sawing begins with the first small movements at an angle of 30 to 45 degrees. Only after the saw blade has entered the wood and is fixed in it, you can start working with the saw along the entire length of the blade.

At the edge of the cut, cut only in small, sharp strokes. This will avoid breakages on the underside of the workpiece.

Cutting along wood fibers is always a “critical” situation, especially if the tree species has a large strand. The saw naturally wants to follow the path of least resistance, and if it is not restrained, it will begin to “walk.” In other words, in such cases you have to press harder on the saw than usual, which, in turn, requires a very stable position of the workpiece.

When making huge cross cuts, an ordinary hacksaw can jam. In such cases, it is better to use a rip saw with very spaced teeth. Honor only needs that the cut strip be significantly thicker than the saw blade.

to saw fresh or damp wood if the saw blade is lubricated with wax or soap.

hacksaw for longitudinal cutting of wood

The workpieces are firmly pressed against the lintel, its right edge guides the saw.

Other varieties

There are other types of wood hacksaws. Among them there is a garden hand saw, equipped with a narrow blade, for the production of which chromium steel is used. It is armed with widely spaced teeth, inclined towards the handle. It is comfortable to work with such equipment in cases where you have to focus on yourself while cutting.

There is a two-handed saw that can be used to comfortably saw huge logs or cut down trees. Two people should work with it.

A chain hand saw is a short chain with hardened teeth and two handles at the ends. It is compact and suitable for use on backpacking trips. You can work with it either by one person or by two people.

A modern and universal tool is an electric hacksaw, with which you can perform a large volume of various works. In some cases, it completely replaces a circular saw. When changing blades, they use it to saw not only wood , but also plastic and metal.

Sawing circular and oval parts

Before correctly sawing round or oval shaped elements with a jigsaw, markings are applied. Then they make a hole in the material, which will be the starting point for cutting the workpiece. In this case, it should be larger in diameter than the width of the cutting blade. The work itself is done with a narrow file.

The process of cutting out curved parts is carried out slowly. A circle cutter is often used. It is an additional device that allows you to cut out elements of the correct round shape. When using it, first determine the center of the circle. Then an additional device is fixed in this place. After this, a circle of the required diameter is cut out.

During work, only monitor the position of the file. After all, when cutting out curved parts, the front sight or laser of a jigsaw are unnecessary. They are used as a guide when making a straight cut.

Sawing a curved part Source remontik.org

Sometimes a hole in the material is not pre-drilled. It is made using a saw of a power tool. To do this, the edge of the jigsaw sole is placed behind the marking. Then the tool is turned on and carefully tilted until the cutting blade comes into contact with the material. Then the slope is increased to cut through the workpiece. Next, turn off the jigsaw and place the sole on the material. Then it is turned on again and slowly, without excessive pressure, it is moved towards the marking along which the required part is cut out.

When it is necessary to cut a figure of a non-standard shape, the jigsaw, with the sole up, is fixedly fixed on the saw table. Then they take the workpiece and saw the part according to the markings. In this case, it is not the tool that is moved, but the element being cut. This cutting method allows you to clearly control the position of the workpiece.

Main settings

The effectiveness of using a hacksaw for wood largely depends on its technical characteristics. The main ones are:

- the material from which the saw blade is made;

- length of the canvas and its shape;

- tooth size and shape;

- type of handle.

READ Replacing a Black and Decker Circular Saw Blade

When choosing a tool, you need to pay attention to each element of the characteristics. Only in this case you won’t have to regret the purchase.

Handle type

The type of handle and the material from which it is made largely determine the ease of working with a hacksaw on wood. It is best to work with a saw equipped with a solid plastic handle with rubberized finger inserts. The handle, made of two parts, is less comfortable, as it does not have sufficient rigidity.

There are also hacksaws with reversible handles. They are usually equipped with universal and bow saws, in which blades can be changed during operation.

Operating rules

A circular saw is a useful tool. It is necessary to work with it depending on a number of factors:

- When making a cut, the depth should be set 2 mm greater than the thickness of the material.

If the cut size is excessive, the workbench can be seriously damaged. It will no longer be possible to work on it.

- Do not remove the bottom cover. When you try to remove it, the disk penetrates excessively into the part and damages not only it, but also the surface of the workbench. You should first carefully consider how the tool will behave during operation.

- The disc must not touch the workbench. To avoid this, lift the cutting part slightly. Cutting into wood should be done at high speeds. This will prevent the risk of losses and allow you to quickly saw the part.

- The material should be on the work table. It is not allowed to work with it in a suspended state.

- Hold the tool firmly, preventing it from wobbling from side to side.

- Secure the workpiece before starting the operation. If safety rules are not followed, the part moves along with the tool, which is unacceptable.

Before starting work, carefully inspect the workpiece. Make sure that the surface is free of nails, screws and other similar obstructions. If such devices are present on the surface of the part, the saw may break and the disc may jam. This can also lead to injury or other unpleasant situations.

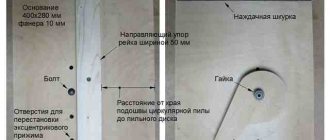

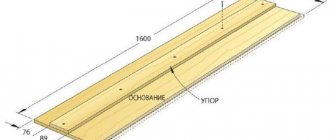

Tsulaga

When processing small workpieces, the tsulaga shown in the pictures below can be of great help.

To make it, you will need a piece of wood slab approximately 20 x 30 cm in size and 2 mm thick, as well as two planed strips, which must be fixed to the slab as shown in the figure. To prevent the slab from bending and breaking, the planks must be positioned transverse to the direction of its core layer.

How to work with a circular saw

The lower bar of the tsulaga rests against the edge of the tabletop and thus sets the correct direction for the cut; the shortened upper bar ensures good centering of the saw.

If you have to saw long boards or planks, then a second tsulaga will not hurt, which will serve as a stop for the other end of the workpiece.

A piece of wood slab and two pieces of plank are enough to make a practical tsulagi.

Before starting sawing, the saw placed at an angle must be pulled towards you several times.

Adhesive tapes

To protect the back side of the plywood, tape is applied along the cutting line. This method helps prevent large pieces from breaking off, which is especially effective if you decide to use a manual or electric jigsaw. However, not every adhesive tape is suitable for these purposes. For example, masking tape in this case will be completely useless due to its small safety margin.

Before you start sawing , tape with fiberglass or aluminum reinforcement is glued to the surface. The requirements for its width are as follows: there should be a margin of 1.5-2.0 cm on both sides of the cutting line. It is better to paste by pressing the tape with a dry cloth, preventing the formation of wrinkles and gluing.

After the saw blade or electric jigsaw has stopped working, you should remove the tool, first unplugging it from the power supply. Then start peeling off the tape. In this case, great care should be taken so that sudden movements do not cause the tearing of small fragments of the laminated surface that inevitably form during cutting. Therefore, it is necessary to abandon the use of materials with a strong adhesive base. When choosing such a tape, you should take into account its adhesive ability and ease of cleaning from rough surfaces.

How to make a manual template yourself?

Guide bar for a circular saw - this can be made from improvised means by cutting a flat sheet of wood.

When you need to make long cuts with a similar saw, you will need to spend a significant amount of time to make all the measurements necessary to set the mowing line guide and markings exactly to match the width of the base of the structure.

To simplify this procedure, you need to cut a template from fiberboard that is equal to the width from the edge of the tool to the inner edge of the saw blade. The template is then cut to the length of the tool base. To use the template, you need to align its edge with the cutting mark in the product, and on the other side attach a straight guide and secure it with a clamp.

You then need to repeat this procedure on the second cut mark on the other end of the workpiece that is being cut. Such designs can be made for circular saws or electric saw blades.

How to cut plywood without chipping with a circular saw?

It is recommended to cut on a flat floor. The plywood sheet is laid on wooden blocks of equal thickness, placed perpendicular to the cutting line. Full support from below ensures that no corner of the sheet breaks off at the end of the cut. A metal or wooden guide is installed on top, which is fixedly fixed with clamps.

In order to cut laminated plywood accurately and without chipping, you need:

- Setting the minimum cutting depth. On the opposite side of the sheet, the teeth should protrude 2–3 mm. With this setting of the cutting depth, the blade does not chop, but carefully cuts the wood.

- Choosing the right circular saw. For gentle cutting, a blade with a minimum size and a large number of teeth is selected (for example, No. 140).

- Low feed speed of the cutting blade when moving without stopping. In this case, the teeth do not cut, but gently cut the wood without chipping. To properly cut laminated plywood, it is also recommended to adjust the blade speed to maximum. Disadvantage of the method: the carpenter runs the risk of overheating the canvas.

- Laying adhesive tape in place of the cut. To do this, it is recommended to use masking tape that does not leave marks on the surface of the sheet. Upon completion of the work, the tape is removed at an angle of 90°, moving towards the cut.

If you have to process laminated plywood, it is recommended to also tape the sole of the circular saw. This avoids scratches on the front surface of the sheet.

Both an electric jigsaw and a circular saw are suitable for cutting such material. The first option is indispensable in the case of a figured cutting path.

To cut thick plywood without chipping with an electric jigsaw, it is recommended to use any of two types of blades:

- finishing series CleanWood (Bosch);

- on metal.

A regular circular saw is also suitable for even cutting of a sheet of plywood. It is enough to install a blade with a fine tooth (for example, No. 140), adjust the cutting depth within 12–13 mm and lay the sheet on even wooden blocks. It is recommended to make the cut along the guide, with a low tool feed speed and without interruptions.

If the front surface of the sheet is laminated, then the cut area is preliminarily covered with masking tape.

For anyone who doubts which saw is best to cut plywood, we recommend contacting a specialized company with laser cutting and professional cutting equipment.

When producing various finishing works or making furniture, the use of plywood is a common practice. At the same time, home craftsmen are faced with a choice: how to cut plywood and how to achieve a perfect cut without chips. When cutting such material, some difficulties arise: the sheet is large in size, and the structure of its base creates difficulties when sawing. Knowing some features, you can achieve excellent results when working with an electric jigsaw, hand saw or circular saw. The main condition is to ensure reliable fixation of the plywood.

READ What parts does a hacksaw consist of?

Plywood is a material that is practical to use and easy to process.

Hand electric saw

- Saber. It is an alternative to a jigsaw, but is more suitable for quickly cutting off excess without forming an even and precise edge.

- Disk. It is used most often because it allows for large-scale work. The disadvantage of the device is that cutting is only possible in a straight line.

A reciprocating saw is not designed for precise cutting, so it can only be used for rough cutting of plywood, while a manual circular saw is considered one of the best options for such work

It is better to cut plywood to specified sizes using the latter option, taking into account some application features:

- The ability to adjust the insertion depth minimizes edge damage.

- Small discs made of carbide material with frequently spaced teeth are suitable for the job.

- Ease of use. The tool weighs little and does not require a special installation site.

When choosing a suitable disk, you need to pay attention to the tooth alignment: a slight discrepancy is convenient for thin material, a larger discrepancy is suitable for thick slabs.

Purpose and use of tool elements

Table for circular saw.

Circular saws are equipped with many different elements and additional functions. For example, quite often instruments have an additional handle. There is no point in talking about its purpose - it makes working with the tool more convenient. The only thing that needs to be noted is that this element comes in 2 types. The most convenient, according to user reviews, is the handle mounted on the saw platform. Most often, tools are equipped with an additional handle in the shape of a mushroom.

The circular saw must be equipped with a protective cover. This element consists of two parts. The lower one is movable, the upper one is fixed. There is a special hole in the upper part through which sawdust is removed during operation. The hole can have different shapes. If you do not connect a vacuum cleaner to your saw, then you can not pay attention to the shape of the hole. If the vacuum cleaner will be connected, then it is better to select a tool with a round hole, otherwise you will have to additionally look for a special adapter.

Circular saws must be equipped with a riving knife. It is designed to prevent the disk from being pinched during operation. This element is secured with a pair of bolts. To make it easier to install and remove, there is a special hole in the upper casing of the saw. But there are also models without such a hole. In such a situation, to gain access to the fasteners, the saw must be installed in a position that corresponds to the zero cut. It is quite rare to dismantle the knife. Usually the need for this arises when the workpiece has to be cut from the middle, and not from the edge.

Circular saw device.

It is important to know how to operate the tool's start button. For circular saws it is not entirely simple

This button is associated with a safety mechanism that eliminates the risk of accidentally starting the saw. That is, you will not be able to press this button until you press the unlock button. Thanks to this solution, the circular saw becomes as convenient as possible to use. The button can have different sizes. It is more convenient if it is large.

Another important design element is the spindle locking mechanism. It makes the disk installation process easier. In most cases, it is found exclusively in expensive imported models.

Related article: Roller blinds for the nursery: tips for choosing

It is important to know how to handle the power cord. This seems very simple at first, but if the saw will be used outdoors in cold weather, it is better to have a rubber insulated power cord

This option is preferable to plastic, because... rubber is more flexible and its elasticity does not decrease at low temperatures.

Quite often, modern models of circular saws are equipped with various electronics. It makes the tool easier to use and more convenient. The most common functions are soft start, overload protection, speed control, and maintaining a constant speed level.

How to cut plywood at home

Determining the optimal device for cutting wood panels is not the most difficult task; standard equipment can be used for the process.

Jigsaw

This device is the optimal solution when it is necessary to cut plywood into parts. When choosing such a tool, you need to consider some nuances:

- It is recommended to abandon cheap models, since they do not achieve the desired result and significantly slow down the cutting process.

- A power switch is required. This allows you to adjust the jigsaw to slabs of different densities.

- The ability to adjust the stop plate ensures leveling for an accurate and straight cut. If the device does not have this function, then the sole should not be curved.

The main factor determining the quality of the cut with a jigsaw is considered to be the pitch and size of the tooth, and only then come the local settings of the tool itself, such as turning off the pendulum stroke and adjusting the frequency

The correct choice of file is carried out taking into account the following conditions:

- Preference is given to branded blades designed specifically for sawing plywood. They provide the highest quality results.

- The nozzle may have different tooth directions. Depending on the position of the cutting part, one of the sides of the slab will be completely free of chips.

- An alternative option allows you to use a metal blade. But this solution has disadvantages: the work is carried out very slowly, and small teeth become clogged.

It is with the help of an electric jigsaw that you can quickly and efficiently cut plywood at home. The tool makes it easy to do the process yourself.

Attention! The device is suitable for complex shaped cuts. Difficulties arise when processing thick sheets: the nozzle is quite thin, so it collapses, which requires additional preparation of the fragment.

Features of work

A hand-held circular saw cannot be classified as a carpentry tool that is heavily equipped with electronics. For example, only some models have electronic speed control, since this function is not particularly important for woodworking.

More modern professional tools have a system installed that maintains a constant blade speed during operation. Its task is to maintain speed regardless of the load on the engine.

Models with an overload protection system monitor the temperature of the motor windings and, if necessary, turn off the machine. Expensive professional equipment is equipped with this function.

Almost any saw can be equipped with a guide bar, with which you can achieve high precision in your work. They are supplied by tool manufacturers as additional equipment.

Some hand saw models can be converted into a permanent installation. To do this, it is enough to screw the protective disk casing to a workbench table or a long board with special clamps.

Features include the presence of a removable network cable, which is convenient not only during transportation, but also in case of damage. It will be more convenient to purchase a new cable rather than contact a service center.

Start with a good drive

For clean cross-cuts in solid wood, decorative plywood and other sheet and plate materials, replace the standard 24-tooth blade found on most models with a 50-60-tooth blade. And for most cuts where quality requirements are not too high, use a 40-tooth blade. And only for longitudinal sawing of solid wood, install a regular 24-tooth blade again.

Get rid of chips in one of three ways

The teeth of the saw blade rotate in a forward and upward direction. The underside of the workpiece, where the teeth enter the material, is almost always left clean, free of chips. In contrast, the top side is usually so defaced with chips that it cannot be used in visible areas of the product (compare three photos with varying degrees of chip severity). Therefore, if possible, always place the sheet or face down for cutting. And if you need to see on the front side, use one of these methods to keep the edges of the cut clean.

READ DIY Circular Saw Drill

How to cut plywood with a hacksaw

Installation of laminated veneer sheets involves varying degrees of processing. The greatest difficulties arise when cutting is necessary; cutting plywood is more labor-intensive due to the layering of the material. To achieve a high-quality result, you need to choose the right device, which will allow you to avoid problems and obtain parts without chips.

Hand saw

When cutting plywood with a hand saw, physical effort is required due to the significant density of the material. This tool is used when it is necessary to cut a sheet of plywood into identical fragments.

A hand jigsaw is considered the best tool and allows you to decide in advance how to cut plywood without chipping, eliminating the need to purchase electric tools. It can be used to produce a small number of elements of complex shapes. Having certain skills in working with a jigsaw, you can make a neat cut, however, due to high labor costs and low productivity, this method cannot be called optimal.

If you don’t have electric tools or a simple jigsaw at hand, you should resort to using a simple hand saw. To make cutting a sheet convenient and to avoid chipping, the tool blade must have a large number of small and well-sharpened teeth. The angle of the saw to the plywood sheet should be sharp. It is recommended to avoid jerking and make even movements with strong pressure.

Tip: The cut of a regular saw is rough, so it is recommended to sand the end parts after finishing the sawing.

How to make a simple guide and removable device with your own hands?

Diagram of the bearings of the circular saw assembly.

It makes sense to make a simple reference book. To make cuts with a portable circular saw, you can purchase an expensive guide at the building's supermarket, or make a few homemade projects in a workshop if you need to cut a large number of sheets. However, you should know that there is a simpler solution - to make a device from scraps that are not used.

A simple homemade miter template for a circular saw

To make your own saw manual, you need to select a factory edge strip of plywood or hardboard 25-30 cm wide. The strip is fixed along the cutting line so that the base of the tool moves along the flat edge. If foam padding is used to protect the saw blade, it must have cutouts for the jaws.

You can also make a cutting device for this type of saw. A clean and even intersection in some cases is quite difficult to do with the introduction of a circular saw. It's almost impossible to fully control the tool, and pieces of material fly off more often than not, leaving behind chips and jagged edges. So it makes sense to try to make a cross-cut design out of a few pieces of wood and an angle of aluminum.

The advantage of sawing logs with a chainsaw

Cutting into boards can be done using tools such as an electric chainsaw and additional accessories designed to simplify the work. When choosing certain products, you need to focus on the amount of work expected. Stationary sawmills are expensive and are purchased only if you plan to organize a business to create boards.

The most accessible tool for the job is a chainsaw. Such devices have several advantages over electric ones:

- the chainsaw can be used anywhere, regardless of the availability of an electrical outlet;

- the tool is suitable for working in conditions of high humidity;

- professional chainsaws are significantly more powerful than electric ones;

- You can use the chainsaw continuously for an hour.

To cut logs into boards, a special frame is used together with a chainsaw, which is attached to the device and allows you to create boards of the same thickness. A device is also needed to secure the log in one position. In addition, you will also need a guide.

READ Miter saw Practyl 1400w 210x30 mm

Since household gasoline saws are not designed for heavy loads, it is worth using professional tools for sawing logs. When choosing, you should pay attention to devices with a power of more than 7 horsepower. Before work, the fixed frame is adjusted in accordance with the selected width of the boards. To create a frame, you can use legs from a school desk or metal corners.

Longitudinal sawing of logs

Before cutting the logs, the optimal method is chosen, which depends on the size of the required lumber, the desired surface quality of the boards, the type of wood and technical capabilities.

They start cutting only after inspecting the log, after which it is freed from bark and branches. If there are no flaws on the log, then processing is faster, and the lumber is of higher quality.

Cut the logs

Depending on the orientation of the growth rings, different types of log cutting are used:

- Radial view - the cut passes along the radius of the growth rings. They obtain high quality lumber that does not deform.

- Tangential view - the log is sawn tangentially to the growth rings. The lumber is of low strength.

- Parallel view - the cut runs parallel to the grain of the wood.

For sawing in the direction of the grain, the simplest method is a circular cut. First of all, the croaker is cut off. After this, the log is turned 180 degrees, and then the second slab is cut off. To obtain boards, the log is constantly turned.

For high-quality sawing of logs in different ways, the following general rules are used:

so that the log does not move during processing, it is securely fixed; if sawing is done with a chainsaw, then use a chain for longitudinal processing

In order for the cut to be smooth and the saw not to be pulled to the side, the chain must be well sharpened and not sag; for sawing by hand, they try to select logs of short length; before sawing, the log is marked for a certain type of cut; sawing logs into boards begins with cutting the slab; special attention is paid to safety measures at all stages of sawing logs. Sawing of logs is carried out on their own using various cutting tools

Sawing logs is done on your own using various cutting tools.

Electric or gasoline saws

A gasoline saw has advantages over an electric model:

- the workplace is not connected to a power source;

- higher power;

- thanks to soft start and speed control, the risk of saw chain breakage is reduced;

- continuous operation for up to an hour, there is no need to interrupt the cut to allow the saw to cool down;

- You can work in any humidity, for example during rain.

Mini disc sawmill

One or two disks separated by an insert are used as a cutting element.

This sawing machine is widely used because of its advantages:

- simple design, equipped with an electric or gasoline engine;

- easy to use;

- accuracy of cutting logs according to marks;

- high productivity when sawing logs.

The main requirement for a circular saw is a durable frame and a powerful engine.

The peculiarity of independent longitudinal cutting of a log is clearly visible in four simple methods.

Hacksaw - simplicity and safety

A hacksaw is a simple tool that is quite suitable for the job. And although the cutting speed is low and considerable physical effort is required, such a saw is the most acceptable option for home use.

to cut wood correctly The main condition for a high-quality cut of the material is to make the cut correctly. To simplify the task, you can use a regular flat block, which is used as a guide.

The question often arises of how smoothly with a hacksaw at an angle. For this purpose, a special carpentry device is used - a miter box. Moreover, it will help not only to make a cut at the desired angle, but will also allow any beginner smoothly .

You can also saw off the timber with a hacksaw. The only problem when working with such a workpiece is that you have to put in a lot of effort.

The last option is to use an angle grinder with a wheel with teeth installed for the work. But since the “grinder” is not intended for cutting wood, this method can only be used as a last resort: attempts to cut a board can result in serious consequences. It’s better to use a hacksaw - it’s labor-intensive, but safe.

All my life will now take place in my VKontakte group, https://vk.com/club37090442 here I only post videos, without discussions or comments.

Serge_msv:

Well damn…

Mila Solovyova:

exciting film. Myocardial infarction!!)))) (according to TO) And so - super!! Thank you!

First stage

First you need to prepare the necessary tools:

- clamps;

- pencil;

- bar or beam for guide;

- jigsaw;

- measuring tool.

When starting work, you should secure the workpiece as firmly as possible. It is not at all advisable to use a jigsaw to cut along the fiber, because in this case it will not be possible to cut straightly. But if such a need still exists, then you can use a parallel stop, one end of which is attached to the jigsaw, and the second rests against the edge of the workpiece material. In this way it will be possible to saw off extremely smoothly.

If you need to cut with a jigsaw in the inside of the workpiece, you should first drill a hole in it. After this, a saw blade is inserted into the drilled hole, and the jigsaw is moved exactly along the marking line. Once the cut is complete, adjust the corners on each side of the workpiece.

To cut as smoothly as possible, it is recommended to use a jigsaw with a blade that has a good moving speed. The saw blade should be wide and designed for working with wood materials.

It is necessary to place something under the workpiece so as not to rest when working with a jigsaw. Next, using a measuring tool, measure the width of the area that needs to be cut.

Then a line is drawn along the ruler connecting the marks. After this, the guide is secured with clamps at the required distance from the edge of the cutting line.

Then the jigsaw is placed with the blade against the cutting line. The guide is pressed against it and also secured with a clamp.

You need to fix it motionless, but you shouldn’t clamp it too hard. Next, everything is done in the same form on the opposite side.

So, the measures necessary to make the cut smoothly have been taken.

Next, after turning on the jigsaw, you need to set the speed to the maximum and adjust the movement of the pendulum, setting it to one. The jigsaw is placed with the blade against the cutting line, the platform is pressed sideways against the guide, and you can start sawing.

Second phase

When working with a jigsaw, you should avoid applying excessive pressure on the tool. The device is pushed forward with a slight movement, also exercising control over the platform.

The edge of the sole should be pressed against the guide so that it does not move. At the end of the cut, when a couple of centimeters remain to the edge, it is necessary to hold the sawn fragment to avoid breaking.

To improve the quality of movement of the saw on the workpiece, you can use an auxiliary device in the form of a replaceable plate, which can be made of various materials. The plate is attached to the main support platform of the jigsaw. The adapter and guide bar allow you to cut more evenly.

When cutting some materials with a jigsaw, there is a need to cool them. Therefore, before you start cutting, you need to install a container with cold liquid on the support platform, designed specifically for this.

Before sawing metal, the file must be lubricated with machine oil, and the cutting line area must be cooled.

It is recommended to cut curved shapes using files with a narrow blade. When cutting out a round part, a special circle cutter is used, which is installed in the center of the circle.

That's all for a simple description of how to cut smoothly with a jigsaw.

How to cut a board lengthwise

For carpenters, boards and beams are the most common blanks, from which crafts and wood products are subsequently produced. And the first thing the material undergoes is sawing into pieces of the required length. At the same time, you should know how to evenly , because performing this operation incorrectly can ruin the workpiece or significantly affect the appearance, and not for the better.

At large enterprises, the problem of how to saw off a beam or board evenly Any serious production facility has high-precision equipment that performs this type of work. At home you have to make do with what you have on hand. At the same time, you still need to be able to use the tool or equipment correctly in order to saw off the board correctly, and the cut turns out without flaws.

Note that many enterprises that sell boards and timber provide cutting services. And for this they use the same specialized equipment, so the purchased material will be cut with high quality. But it is not always possible to use such a service, and it often happens that only one piece needs to be cut.

Why does it cut crookedly?

The disc cuts the line it is directed towards. In this case, the tool should be held or pressed against the guide firmly enough so that it does not move to the side.

If, despite all efforts, the cut turns out to be crooked, the reason is a waste disc. A scorched disc with blue spots on both sides may begin to wobble at the slightest heat. If the teeth on one side are normal, but on the other they are knocked out or blunted, dust may be introduced in one direction, no matter how hard you try to hold it.

Sources:

https://stroyvolga.ru/%D0%BA%D0%B0%D0%BA-%D1%80%D0%B0%D1%81%D0%BF%D0%B8%D0%BB%D0%B8% D1% 82% D1% 8C-% D0% B4% D0% BE% D1% 81% D0% BA% D1% 83-% D0% B2% D0% B4% D0% BE% D0% BB% D1% 8C / https://dnipro-m.ua/news/pravilnaya-rabota-czirkulyarnoj-piloj/ https://benzopilok.ru/rabota/kak-rovno-pilit-tsirkulyarnoj-piloj.html

Circular saw – high performance and ease of use

A circular saw is the best option for performing the work. It has excellent productivity and allows you to cut a considerable number of workpieces in a relatively short time, and with high quality. In addition, such a saw allows you to make a longitudinal cut of the material, but you need to know how to cut the board straight along .

One of the most important criteria when choosing a circular saw is the maximum depth of cut. There are devices on the market that cut materials with a thickness of 30 to 130 mm. That is, you can choose a machine both for cutting only thin boards and for sawing bars.

Recipe. how to cut straight with a simple hacksaw

It is also worth paying attention to the cutting tool itself. Discs with a large number of teeth will provide a neat, high-quality cut, while the cutting speed will be low.

How to adjust the dust for an even cut?

The saw blade must stand strictly perpendicular to the support platform. This can be seen both in the position of the disk and in the degree scale on the adjusting arc. If the disk is at an angle:

- The locking screw is released.

- The platform tilts to the desired position.

- The screw is fixed.

You should be more careful with tightening. On some models, if it is too heavy, the thread can be stripped or the head can break off.

Then it depends on how and what generates dust.

How to cut an unedged board?

Trimming the wane of a board a manual circular saw can be done in two ways:

How to trim a hand-held circular saw quickly and accurately

- By marking with a pencil (marker, sharp tool, etc.).

- Along the guide. To do this, a block, corner or factory guide rail is attached to the board with clamps or self-tapping screws. Dust, presses the edge of the saw platform to the guide.

Cutting along a guide usually produces a smoother cut.

We also recommend reading a useful article with reviews of the most popular and best circular dusts for the home.

Cutting boards at home

You can cut a board at home using the following tools and equipment:

- a circular saw;

- hand saw ;

- angle grinder (“grinder”).

Each of these options has its own specifics, which are important to consider before starting work, that is, you need to know how to cut a beam or board with one or another tool so that the quality of the cut is acceptable.

Lightweight nozzle

Such devices are often used, but they should only be used when creating boards for fences or sheds. This is due to the fact that the attachment is secured to the tire only on one side.

Attachment for longitudinal sawing

When using this attachment, sawing occurs in a horizontal direction. It is fixed to the rail using special clamps and allows you to create boards of equal thickness. After the work is completed, the boards are dried and can then be used in construction.

Sources:

https://ingener-pto.ru/2019/12/12/kak-pilit-faneru-nozhovkoj/ https://stroyvoLGa.ru/%D0%BA%D0%B0%D0%BA-%D1%80% D0%B0%D1%81%D0%BF%D0%B8%D0%BB%D0%B8%D1%82%D1%8C-%D0%B4%D0%BE%D1%81%D0%BA%D1 %83-%D0%B2%D0%B4%D0%BE%D0%BB%D1%8C/

The importance of following safety precautions

When working with a circular saw, you need to be careful. Carefully tuck in the garment by tucking in any overhanging parts and tying the belt and laces.

Hold the instrument well. If it wobbles during operation, such a situation can lead to a number of troubles: damage to equipment, the desktop and cause injury.

Use a saw to cut dry wood. If the rules are not followed, the tool can quickly be damaged. The motor of the circular machine will burn out.

After finishing the work, you can put the saw on the workbench. She must stop completely.

Do not touch the exposed wire or use a damaged tool to avoid injury.

If you follow the rules, working with a hand-held circular saw will be easy and safe.

Technology and equipment for trimming lumber

Work pages

The content of the work

TECHNOLOGY AND EQUIPMENT FOR TIMBER CUTTING

Trimming (trimming) – the formation of the end surfaces (ends) of lumber by dividing them transversely for the purpose of:

-removal of defective areas;

- obtaining a given length of pm.

In this regard, a distinction is made between preliminary and final trimming.

Preliminary trimming

carried out with the aim of removing obvious defects and defects of wood on the surface of the pm (pf). These are, as a rule, pointed (pintail), curved and facet boards.

Final trimming

performed to form specified (standard) dimensions of PM along the length. The final formation of the length is carried out, as a rule, after drying.

Cleaning the butt ends is also practiced.

pm. When the operator (end-cutter) doubts the depth of the spread of a processing defect or a defect in the wood from the butt end of the board, he “cleans” it: he saws off a piece of board 3...5 cm long, assesses the condition of the “opened” end and makes a decision on the final trimming of the butt end. end of the board.

Nominal length dimensions pm:

– 1. 6.5 m with a gradation of 0.25 m – for the domestic market;

– 1.5...6.3 m with a gradation of 0.3 m.

Maximum deviations from the nominal dimensions of lumber along the length are +50 mm; – 25 mm.

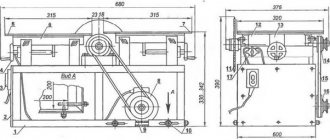

In sawmill production, single-saw cross-cutting machines and multi-saw cross-cutting units are used for cross-cutting lumber. Single-saw cross-cutting machines can be divided into four types: with a fixed support, pendulum, balancing and with linear movement of the saw. (Fig. 13.1). The classification of machines according to their design allows us to distinguish two main types among them: with a movable and a fixed support. In machines with a movable support, designed for precision and preliminary trimming, the feed is carried out by the support onto a stationary workpiece.

The boards are trimmed using positional and passing methods. In the first case, when performing a technological operation, the material being processed is motionless, and the cutting tool is fed. In the second case, the transverse division of lumber occurs during their movement.

Positional cross-cutting machines

Fig. 13.1. Schemes of machines for positional trimming of lumber and blanks:

a- pendulum; b and d - with straight forward extension of the saw; c-balanced.

Single-saw cross-cutting machines with a fixed caliper are part of the cross-cutting units and lines. Pendulum cross-cutting machines and machines with linear movement of the saw are rarely used in sawmills; they are widely used in cutting and woodworking shops.

Balancing cross-cutting machines are most widely used in the production of lumber.

Position type installations

are equipped with single-saw circular saws of various models: balancing (type TsKB), pendulum (type TsME), with straight-line saw extension (type TsPA and ST), the technical specifications of which are given in Table 1.

Fig. 13.2. Balanced cross-cutting machine TsKB40-01:

A

-general form;

b

- hydrokinematic scheme; 1-fence; 2-table; 3-guide ruler; 4-bed; 5.6-electric motors; 7-pedal control; 8-board; 9-saw; 10,14-hydraulic distributors; 11-frame; 12,16-hydraulic cylinders; 13-hydraulic pump; 15-throttle; 17-guide; 18-shaft; 19 V-belt transmission.

TsKB type machines with pedal operation of the saw and its movement during the cutting process using a hydraulic drive are designed for sawing boards up to 300...400 mm wide with a saw diameter of 500...700 mm. They are most widespread in sawmills that practice the positional method of trimming.

Fig. 13.3. Cross-cutting machine with straight saw motion:

1-bed; 2saw; 3-clip; 4-hydraulic cylinder; 5-pedal.