In industrial and home workshops, workers use electrical appliances for different purposes. Various elements are used to process workpieces. They ensure high-quality work.

Circular

Guide bar for circular saw

Thus, the guide bar for a circular saw serves as an additional device for performing smooth, precise cuts.

Sometimes the tool manufacturer sells parts that accompany the main mechanism in a kit. If the tire is missing, it is not difficult to make it with your own hands from available material.

What role does the guide play?

The circular saw guide guides the sliding of the tool along the cutting line and prevents its deflection. The correct design of this part determines the even cut of the workpieces and the absence of defects in the processing areas.

When using a circular saw, the worker controls the movement process.

To comply with safety regulations, he must:

- securely fix the electric saw;

- secure the workpiece.

It is easier to ensure safety and quality of work using the second method. When the parts are not in the package with the saw, you can make them yourself.

How many types of tires does a circular car have?

The circular saw guide not only serves as a safety element, it allows you to increase productivity. Devices of different designs have been developed, they are:

- bilateral;

- one-sided;

- symmetrical;

- asymmetrical.

A universal device is used to process a workpiece of non-standard shape. This guide can be used with a circular saw or a hand saw.

Tires for circular saws

Specialized tires are used when performing professional tasks.

When crossbars are cut at an angle, a textolite or plywood restriction made of bars is installed. Before installing supports, check:

- reliability of clamps;

- tire surfaces for deformation;

- for compliance of the workpiece materials with the guide.

Thrust slats are made of metal or wood. It is important that they are stable under mechanical stress. They did not change their shapes and sizes. Products are used for production from:

- profile;

- rail;

- corners;

- bars.

The structure is attached to the base:

- self-tapping screws;

- screws;

- bolts.

Ruler

There is another stubborn tool - a ruler.

It's quite simple to make from a strip of plywood. The width of the fragment is taken 20 cm more from the working area. And the base is fixed with fastening hardware. Before work you need to check with test cuts:

- tool behavior;

- vibration;

- the level of physical effort required to perform the operation.

Reliable, safe execution of actions depends on the fastenings:

- clamps;

- clamps;

- movable carriage;

- retainers.

These elements fix the workpiece in the required position. The installed limiter prevents the sharp cutting part from deviating from the perpendicular arrangement of the wood fibers.

Technical features of homemade devices

The factory guide for a circular saw does not solve all production problems. The manufacturer sets its dimensions, which often do not suit the master in terms of board length or other technical characteristics.

Guide production procedure

If a homemade stop is installed during work processes, take into account:

- size of the workpiece;

- saw feature;

- how often the tool is used.

Exercise control over operations:

- slice lengths;

- productivity and specifics of technology application;

- groove widths;

- according to the cutting directions;

- density of materials.

The carpenter must correctly evaluate the workpiece in terms of size and material of production.

A properly selected tire will simplify the operation with precise cuts.

Stop ruler

Independent production of devices for circular saws requires strict adherence to safety rules.

The cutting stop is often used when processing material with a circular saw; it is effective only in the case of a jigsaw; problems may arise with cutting: the tire is pressed against the workpiece with a clamp.

The bracket protrudes from the bottom and top of the machine table top. The result is a limiter on the length of the cut, but the saw motor inevitably rests against the clamp, and the cut is performed in two stages. The quality of the edge will be poor and there is a high chance of creating an unwanted step: to ensure a perfect cut, continuous movement of the cutting blade is necessary from the beginning to the end of the lumber. In factory models, the fastener is placed outside the circular saw line and does not interfere with work.

What is the use of stops

A self-made guide for a circular saw will save the craftsman from many problems when operating a complex and dangerous tool. Working with the disc is not always carried out exactly along the marked line and without chipping. Whatever the reason for the defect—lack of plumbing skills or experience in handling a saw—everyone wants a result without damaged materials. Arguments proving the benefits of homemade devices:

- It happens that it is enough to attach the plates with clamps, but not always. The saw will hit the clamps.

- If you need to make a single cut, you can apply a painting rule, but you will have to constantly check it to adjust the position.

- A branded guide is used to accurately set the direction along the cutting line; after aligning the strips, the operation begins immediately. High-quality tires have adhesive tape that protects them from chipping. But factory tires are made to limited sizes.

Guide

The name of the guide indicates its purpose - to move the saw smoothly to a given position.

Regardless of what materials the production will be from:

- channel;

- rectangular pipe;

- laminate - it is necessary to create a geometrically correct structure.

Pressed and wooden stops have a significant drawback:

- absorb moisture;

- swell;

- lose their shape.

If they place a loose stop, they create uncomfortable conditions with simultaneous cutting and control of the position of the rail. You need to monitor the force of pressing on the rule so as not to spoil the base.

DIY remote guide bar for a circular saw

Despite many advantages, the previous design has a significant drawback. It is necessary to constantly monitor the lateral pressure of the circular body to the ruler. If the width of the workpiece cut during cutting is too large, the arms may simply not be long enough.

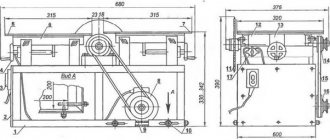

The solution is to use a carriage on ball bearings. The design is not so budget-friendly (at a minimum you need to buy bearings), but its capabilities cover all costs. The operating principle is visible in the illustration:

The carriage is made from metal plates and a corner. To adjust the width, you can use wing clamps installed in movable grooves. A profile of complex shape can be purchased from an aluminum structural materials store. There are many options, the main thing is to provide support with bearings on the top and sides. For example, one of these options.

The profile should provide fastening of the C-shaped clamp inside the tire. You can purchase a ready-made design from a selected pair of carriage and guide.

It all depends on the budget of the event. The sole of the manual circular saw is firmly attached to the carriage.

IMPORTANT! It is necessary to ensure strict parallelism of the movement of the circular saw along the profile, otherwise the cut will be a loose cut.

This self-made tire allows you to cut large-area workpieces. At the same time, the movement of the saw is light and smooth; feeding can be done either by hand or by a guide rod.

Preparatory activities

To work, you will need a tool kit with components for assembling and cutting a persistent product. You need to prepare:

- wood blanks for processing;

- solid wood from blocks, dense plywood, laminate boards;

- fasteners made of screws, self-tapping screws;

- electrical appliances – circular saw, jigsaw, drill, screwdriver;

- clamps.

If production is carried out in a home carpentry workshop, there should be a primitive furnishings of a table, cabinets, and electricity.

Instructions for production

Different materials for the production of guides require the same attitude. When laminate is being created:

- cut off 2 parts according to the size marks;

- mill the edge;

- fixed to the base with a self-tapping screw;

- Use a sheet of paper to measure the groove in width and screw it to the device;

- A tire is attached to the sole of the saw; it will serve as a side support;

- the guide is extended to the maximum so that the sole steps on it;

- saw off the laminate according to the edge markings.

The circular saw can be equipped with an external carriage

DIY guide

Such a device is not difficult to create, but it absorbs the depth of the cut.

Limiters are also made from the painting rule. A design with grooves and handles is suitable for this:

- The handles are removed from the construction model to install spring clamps in these places; after removing them, the clamp is fixed on the rule;

- propylene is used for adapters, parts are cut out in a special shape to be inserted into the grooves of the handles;

- Hollow recesses are cut out at the base of the adapter for screwing in screws;

- Place the stop on the surface and secure it firmly with a fastening element.

Fixation is carried out to the sheet with grooves located below, so as not to create obstacles for the saw to slide; only the size of the rule can limit the work.

The production of a rail miter box will allow you to cut:

- boards;

- bars;

- small workpieces.

You need to prepare:

- metal corner;

- board or plywood base;

- hardware.

Make markings along the length of the tire with places of fixation. For sizes you need to provide the following conditions:

- free movement of the board under the tire;

- not high arrangement of saw blades.

The structure is secured with bolts with parallel angles so that the sole of the circular can slide freely. This is achieved by gluing fluoroplastic strips, which reduce friction and reduce the force acting on the saw.

Create a device from a finished aluminum profile

Metal lasts much longer than wooden products. In addition, it holds steadily without distortion. For installation you will need:

- profile fragment;

- fasteners;

- plywood sheet.

Additional tools you will need to prepare:

- electric drills, metal drills;

- wrench;

- measuring items.

During production:

- take 2 profiles;

- Aluminum is attached to the plywood on both sides; chipboard is used for rigidity;

- the excess is cut off.

When combining all the work carried out, the following settings are carried out:

- a profile with a smaller cross-section is installed in the rail, the height of which should not absorb the main profile;

- fix the structure with wing screws to the sole of the circular saw parallel to the disk circle;

- the saw should be on top of the guide;

- The edges of the tire are directed to the marking line and secured.

Such limiters ensure smooth sliding of the cutting device and make it easy to operate the saw.

The simplest device can be made from plywood

For proper production, you need to make markings and strictly follow the dimensions without deviations. For this:

- measure the gap between the inner edge of the saw and the guide groove in the longitudinal cut; it is located on the supporting base of the mechanism;

- cut the plywood strip to a width less than the measured distance with the fibers on the material arranged in the longitudinal direction;

- use self-tapping screws to secure the resulting segment to the base, aligning the ends to form the working edge of the guide;

- take a caliper to determine the width in the longitudinal section; the remaining strip should fit here, parallel to the first plate, ensuring a gap between the 2 sheets.

A soft cloth is glued onto the finished tires to protect the working material from damage.

Useful tricks and tips

There are such small devices that it is shameful to even consider them a tool. At the same time, they are great for cutting. These are the tricks of experienced masters.

Blank template

When cutting a large number of identical parts, you can use the first of them as a template for cutting subsequent copies. You just need to fasten a thrust piece on one side of the first sample with a width corresponding to the distance from the edge of the slab to the cutting disc. By installing such a template on the material to be cut, you can make many identical parts without markings.

Installation bars

The simplest part that makes it easier to install any stop and guide along the markings is a small cross-section block. There are cuts on it, the distance between which is equal to the segment from the end of the saw sole to the saw blade. Two such bars will help you install any guides quickly and accurately at the required distance from the marking line. All that remains is to secure the guide.

Pull-out protection

The protection can be any block whose width corresponds to the thickness of the workpiece being cut. If it is secured at the point where the saw blade exits the material being processed, it will act as a limiter and serve as protection against tearing out and chipping.

These devices are not limited to the range of useful homemade products that make working with a hand-held circular saw easier. These are the easiest to make. Others require time and skill. But craftsmen even make such a device as a protractor for a circular saw with their own hands. There would be a desire.

Operation of plywood tire

In addition to the guide, preparation of the saw for work is required. You need to saw off durable material with dimensions:

- height exceeding the depth of the groove;

- equal in width;

- longer than the sole.

Fastening is carried out with the restriction protruding from under the edges of the sole. To carry out the work, you need to take 2 clamps with two flat bars, but larger in thickness than the part prepared for processing. The ends of the tire are installed on the limiter so that they protrude beyond the tabletop. In areas of contact with wooden blocks, the guide is attached to the base of the table.

On the workpiece to be cut, markings are made along the cutting line. It is placed under the guide, the cutting direction and the working edge are aligned. A circular saw with a fixed limit strip is placed on the guide in such a position that the stop on the sole is aligned with the prepared gap. They saw the part, slightly guiding the part, and at the same time press the tool.

The design has proven in practice the high stability of a high-quality cut. For production, a metal I-beam is taken, which is attached to the lower plane of the workbench. The platform moves along the surface on bearings with the lower edges curved into a profile. The outrigger carriage slides freely thanks to bearings, which, due to tight pressing, relieve the structure from lateral play. The extension guide is held by the sole of the cutting tool.

Parallel angles and pipes are used to make a tire. When the sole moves, the cut is adjusted to size. Thanks to the support platform, which fits tightly to the workpiece, the stability of the cutting depth is not compromised.

The manufacturer of circular saw bars must take into account the working conditions, where the rules of use must comply with:

- the mode of use of the saw - the more often the tool is used, the stronger the raw materials for making the guide should be;

- processing parameters - you need to make sure that the disk completely cuts the thickness of the workpiece;

- technical capabilities of the mechanism.

In addition to the guide, quality cutting is affected by:

- condition of the saw and discs;

- position of the support platform.

Blunt disc teeth leave chips on the material. Tires significantly expand the functions of a circular saw, but poor care of the tool nullifies all the capabilities provided by the manufacturer.

Summary

Article Name

Guide bar for circular saw

Description

DIY guide bar for a circular saw

Author

Sarychev Alexander Viktorovich - forensic construction and technical expert, candidate of technical sciences

Publisher Name

Wikipedia of construction tools

Publisher Logo

- Related Posts

- Rating of miter saws 2022 based on customer reviews

- Reciprocating Saw Rating

- Rating of hand-held circular saws 2021

« Previous entry

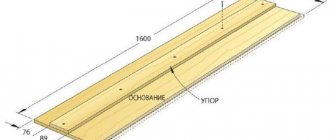

Making a laminate tire

This method of making a carriage for a circular saw with your own hands is the easiest to implement; it uses readily available raw materials.

Required:

- laminate sheet;

- several screws;

- A4 piece of paper.

Three blanks are made from the laminate. One of them will serve as the basis for the guide. The other two are cut in the shape of two strips, each about half a meter long. For both, the edges are aligned on one side using a milling cutter. Using self-tapping screws, the strips are attached to each other parallel to the straight edges. The width of the groove between them is checked using an A4 piece of paper, inserting it into the device and scrolling.

The tire is secured to the base of the circular saw using side support fasteners. If the warranty period of the saw has already expired, for greater reliability of fastening you can use the body of the circular saw by making an additional hole in it.

Before starting work, the homemade guide must be extended in front of the circular saw handle. In this case, it is necessary that the guide is covered by the nose of the sole by several centimeters. For perfect compatibility of the edges of the guide strips with the marks on the material, you need to carefully saw off the uneven strips with a laminate cutting disc.