Probably, many have encountered such a problem when, when cutting plywood or chipboard using a jigsaw, chips and burrs remain on the surface of the workpiece.

Of course, this quality of cutting is no good. But what can you do to avoid this?

Alternatively, you can buy a high-quality wood saw with a fine tooth. However, this still does not guarantee a perfect cut.

However, there are four ways to saw off plywood or chipboard without chipping or scuffing. Not perfect, but still as neat as possible.

The author of the YouTube channel The Maker shared his personal experience with us. We recommend you take note!

Method 1: Using masking tape

We glue a strip of masking tape onto the surface of the workpiece (plywood or chipboard). After this, we make a cut using a jigsaw.

But it is advisable to use a file with a fine tooth.

This simple method will significantly reduce chipping and scuffing during the sawing process. You can see the result in the photo below.

Methods for cutting laminated chipboard without chipping

You need to saw a laminated board using a special machine (format cutting machine). But its price is too high (from 50,000 to 100,0000 rubles) when it comes to home use. An alternative could be budget options (hacksaw, jigsaw, etc.), which will take more time to cut but require less investment.

Using a hacksaw

Sawing with a hacksaw at home is quite difficult. First, you need to cut the measurement line with a knife and glue tape along it. This will protect the top layer from damage. Point the tool at an angle of 30 degrees. Carefully move the hacksaw back and forth without pressing hard. To cut laminated chipboard without chipping with a hacksaw at home, choose devices with the finest teeth. In case of damage, the cut area must be passed with a file, directing it from the edge to the center. Finally, rub with sandpaper (fine-grained) and hide the defects under the flexible profile.

Jigsaw

To cut chipboard smoothly with a jigsaw without chipping, you need to choose a device with a minimum tooth size. It is used for small areas of tiles, using smooth movements without pressure at low speed. If you are using a jigsaw for the first time, some cracks may appear on the back of the slab. With further use, the quality of the cut will improve.

Circular saw

The tool is a table with a toothed disk for chipboard. Among craftsmen it is called a circular saw. Cuts through wood better than a jigsaw. A good result without chipping is possible by sketching guide lines and securing the circular saw to the board. Chips should not appear where the saw cut into the slab. But the opposite side can be sawed through with fragments.

Using a router

A router is a power tool for manual wood processing. Suitable for cutting grooves, shaping, edges and drilling. Before using it, a sheet of wood is sawed with a jigsaw, departing 3 mm from the markings. You need to cut with a cutter together with a bearing, which forms the cutting depth to the required level. This is a labor-intensive process that only experienced specialists can do. There is a high probability of cutting the board crookedly.

Sawing with a format saw

The workpiece is placed on the table and fixed in a stationary state. The necessary markings are made on the sheet and the saw unit is turned on. When the disk reaches sufficient speed, the table moves forward along with the wooden slabs and hits the disk.

Equipment setup:

- tile position;

- depth of cut;

- cutting angle.

Chipboard cutting machines are divided into 3 types:

- light – for 5 hours of continuous operation;

- medium – up to 10 hours;

- heavy – up to 20 hours.

What does a cutting machine consist of:

- The bed is the mount on which the entire mechanism rests. A heavy frame will add stability to the device and eliminate vibrations. This is important for quality cutting.

- Saw unit - consists of 2 flat metal discs. The first one pre-saws the slab, and the second one finally cuts through it.

- Work tables. Three people take part in the process. The first is for the location of the unit, the second is for feeding the sawn slabs (movable), the third is for supporting the sawn parts.

- Carriage – allows the movable table to move. In this case, the workpiece is secured using a stop and rulers in the required position.

Sawing with undercut

The process requires a tire - a thrust ruler. It is secured to the board with clamps. Pruning is carried out according to the markings. The tire is installed along the line, and the cut is made 10 mm deep. The second cut is made through. With this method, there will be no chips on both sides, since the laminate is already cut on the bottom side.

Some elements used in design ideas are cut curvilinearly rather than rectilinearly. In this case, a mixed type of chipboard cutting is used.

What not to saw

Due to the combined structure, it is difficult to cut laminate without chipping. But with the right approach, this is possible at home with improvised means.

With a large volume of work, some craftsmen saw laminated boards using a grinder. Nozzles for wood are selected. To make cutting easier, install a bar along the cutting line. It is not recommended to cut laminated boards with a grinder or angle grinder, as this can cause injury.

It is not difficult to cut laminated chipboard yourself. This is a very profitable activity, as the cutting service is very popular. Many construction stores and furniture shops offer cutting chipboard according to markings and fragments. This saves time and effort.

Choose a tool according to your capabilities.

Method 2: using plastic

We cut a piece of plastic of a suitable size and make a cut in it for a jigsaw file. After this, we attach a piece of plastic to the sole of the jigsaw.

We mark the workpiece and then saw it. There will be much less chips and scratches on the surface of plywood or chipboard.

And if you stick a strip of masking tape on the workpiece (that is, combine the first and second methods), the result will be even better.

Tools and accessories

When cutting laminated chipboard at home, both tools and auxiliary devices are used. Auxiliary materials include: tape, masking tape, pencil, sandpaper, measuring tape.

Tools - hacksaw, router, circular saw, jigsaw, formatting and cutting machine.

Method 3: using a utility knife

We apply a square to the workpiece, and using a utility knife, cut a line along the cut site. Then we cut the same line on the other side.

The resulting groove should correspond to the thickness of the saw blade.

Next, using a jigsaw, we make the cut. The result is much better than if you saw without prior preparation.

Method 4: using chipboard

This method is very simple, but also quite effective.

Place a piece of chipboard on top of the workpiece, laminated side down. We fix it with a clamp.

Then use a jigsaw to make a cut. The result can be seen in the photo below.

Let's sum it up

In today's article, we looked at 4 ways to use a jigsaw to cut a piece of plywood or chipboard with a minimum number of chips and burrs. Choose the method that suits you best and try it!

You can also combine several different methods to achieve the best and highest quality results.

Zero gap technique

Carpentry craftsmen most often use the principle of modifying the sole of a cutting tool, which consists in reducing the gap between the working tool and the pressure pad. This is almost guaranteed to eliminate the effect of “breaking” the crust in the top layer of the material.

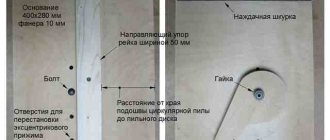

Zero clearance is achieved by securing the cover plate to the tool base. The pad has only one narrow hole (or slot) that fits tightly to the cutting organ. Because of this, even with a high feed force, the teeth are guaranteed to cut off small chips and not turn out the chips in the upper layer of the part.

When using overlays, it is extremely important that they do not scratch or damage the surface of the part. Therefore, they are most often made from a material that is inferior in hardness to the material being processed, for example MDF or plasterboard

Unfortunately, such an overlay does not last long, which is why it has to be changed every 4-5 meters of the cut.

More durable linings can be made from sheet plastic (PVC, fluoroplastic), fiberglass or metal. In the latter case, the surface of the lining must be carefully polished and soft metals such as aluminum or duralumin must be used to reduce vibration.