Device, principle of operation

In order to cut the sheet blank into parts of future furniture products, they are placed on the movable table of the machine. It is located on the left side of the structure. The cutting size of the sheets is fixed with an adjustable stop, after which the saw unit is started. When its cutting disk reaches maximum speed, the movable table with the workpiece begins to move forward.

There are three main settings you can set on the machine:

- position of the sheet blank;

- cutting angle;

- depth of cut.

Format cutting machines consist of five main units:

- Beds are the foundations of a structure. More massive beds better absorb equipment vibration during operation, which affects the accuracy of cut dimensions.

- Saw unit . The module consists of two saw blades: slotting and pre-sawing. They ensure cutting of sheet blanks without chipping or uneven edges. Most machine models have a saw angle from 0 to 45°.

- Work tables : fixed and movable. The first one houses the saw unit. The second serves to feed the sheet blank for cutting.

- Carriages – the mechanism guiding the movement of the left table.

- Stops and rulers . They are on the tables. With their help, sheet blanks are placed in the desired position.

Equipment Manufacturers

In order to maintain sales volume, enterprises manufacturing woodworking equipment strive to improve the technical characteristics of machines and at the same time reduce their cost.

Since this is high-precision equipment, its production is carried out by large machine-tool companies known in the world market. When choosing a manufacturer, you need to study the market for maintenance services. Are there centers that service such equipment, what tools they use, who supplies spare parts.

The flagship manufacturers of woodworking equipment from Europe include the German concern Altendorf. The equipment they manufacture is well equipped, which allows for an even cut of the material being processed without much effort. They operate from a 380 V network. They have three switching speeds. The machines quickly pay for their cost if they are well loaded.

The Italian company Griggio has a good lineup. The formatting machine of this company is known all over the world and is represented in three categories - business, standard, budget. It performs many different options for processing materials and has high-quality equipment.

In 2009, to meet the needs of Russian furniture companies of small and medium-sized businesses in woodworking equipment, it was created. Produces models of high-quality design and execution. They are focused on global manufacturers of such equipment, which is confirmed by the components installed on the machines by the company.

There are many equipment manufacturers in the Chinese market. It is better to purchase such equipment from a trusted supplier with a good sales history, who not only sells, but also provides service and has spare parts in stock.

Types of equipment and features

Format cutting machines are professional equipment.

Based on performance, they are divided into three main groups:

- Lungs . The simplest designs with no additional functions. Designed for continuous operation for no more than 5 hours. Designed to equip furniture workshops and small-scale production.

- Average _ The most common type of machine. Designed for continuous operation for 8-10 hours. Designed for small- and medium-scale production.

- Heavy . Multifunctional equipment capable of working without interruption for 16-20 hours. Designed for large-scale production.

Expert opinion

Kokovin Dmitry Vasilievich

Furniture restorer

According to the type of design, machines are: vertical, horizontal and CNC. Vertical models use working space most efficiently. Compared to other equipment, they are smaller in size, can work with large-sized material, and maintain high cutting accuracy.

History of creation

Working with wood with hand tools not only takes a lot of time, but also requires good physical training.

Therefore, in order to improve and speed up the process of wood processing, many craftsmen have tried to create a woodworking machine since ancient times. At the World Exhibition in Paris in 1803, the first circular saw was proposed. It did not have a carriage, and its strength left much to be desired. It is from this moment that we can talk about the worldwide recognition of format cutting machines.

The first formatik with a moving carriage was made in 1906 by German carpenter Wilhelm Altendorf for work in his workshop. A simple carpenter had no idea that in the next century a company called Altdorf would become a world leader in the manufacture and sale of woodworking machines. Every year more than 4,500 machines from this company are sold all over the world .

The best panel saws

Filato FL-3200B

Country of origin: Italy. The model is designed for longitudinal, transverse and angular cutting. It cuts sheet blanks of varying texture densities equally well. The metal frame of the machine is welded from rectangular pipes. It has increased strength and is resistant to deformation.

To dampen equipment vibration during operation, the body of the Filato FL-3200B is reinforced with steel sheets having a thickness of 3-4 mm. The cylindrical type guides are also made of steel. An aluminum carriage moves along them. The machine control buttons are located in the electronic unit, located in a convenient place for access.

Characteristics:

- overall dimensions – 3300x3100x900 mm;

- weight – 1050 kg;

- maximum cutting height – 110 mm.

Advantages:

- the presence of an electronic display and an emergency stop button for the machine;

- reliability;

- durability;

- ease of maintenance and operation.

Flaws:

- high price;

- Difficulties in setting up the carriage.

Bosch GTS 10 XC

Country of origin: China. The model is equipped with a braking function, has a starting current limiter and an overload lock. Designed for small furniture production. The work table has retractable elements that allow you to cut large sheets of material of varying densities.

The design has a well-thought-out slab feeding system, which ensures accuracy and ease of cutting the material. Reliability of sheet fixation is ensured by a parallel stop. The maximum tilt angle is 47 degrees. The machine can produce clean and even longitudinal and transverse cuts. The machine can cut plastic and aluminum profiles.

Characteristics:

- overall dimensions – 635x343x768 mm;

- maximum cutting depth – 79 mm;

- weight – 35 kg.

Advantages:

- smooth start;

- structural strength;

- reliability in operation;

- capacious corner stop;

- the presence of a dust collector and an adapter for connecting a vacuum cleaner;

- ease of setup and maintenance.

Flaws:

- the possibility of backlash;

- high price.

Holzmann TS 315VF-2000

Country of origin: Austria. The model is considered the best professional machine in its class. Designed for longitudinal and cross cutting of slabs. The design of the machine allows you to cut complex configurations from sheets. It features fast, accurate and neat cutting of material.

The machine is intended for equipping furniture and carpentry shops. Can cut chipboard, MDF, fiberboard, plywood, acrylic, composite and other materials. The aluminum carriage has high adjustment accuracy. The stops and marking rulers are made of the same material. The work table is made of vibration-damping cast iron. The body has a welded structure.

Characteristics:

- overall dimensions – 910x741x104 mm;

- maximum cutting depth – 100 mm;

- weight – 263 kg.

Advantages:

- increased security;

- effective cleaning of the working area from dust and chips;

- fine adjustment;

- high quality cut.

Flaws:

- high price;

- Can only saw small slabs.

ZENITECH FR 1800

The country of development is Switzerland, the manufacturer is China. The model is designed for longitudinal, transverse and angular cuts. The machine is professional equipment. Equipped with a powerful three-phase motor. Provides high cutting accuracy. Can cut wood-based materials of various densities, as well as plastic and composite materials.

The desktop has a sliding structure made of cast iron. The frame is made of the same material. Despite the powerful engine, the machine is quiet in operation. The carriage is made of aluminum. The air cooling system prevents equipment from overheating during operation.

Characteristics:

- overall dimensions – 936x756x1040 mm;

- maximum cutting depth – 100 mm;

- weight – 300 kg.

Advantages:

- high power;

- cutting accuracy;

- high quality cut.

Flaws:

- high price;

- You can only cut one slab.

FDB Maschinen MJ 61232Z-B

Country of origin: China. The model is equipped with a powerful three-phase electric motor. Belongs to the group of heavy professional machines. It has a cast iron frame, which dampens even slight vibration during equipment operation. The desktop is made of the same material. Aluminum carriage. The machine can cut large slabs.

Characteristics:

- overall dimensions – 3250x3150x900 mm;

- maximum cutting depth – 80 mm;

- weight – 790 kg.

Advantages:

- high-quality cutting;

- high performance;

- ease of adjustment and maintenance.

Flaws:

- insufficient thickness of the carriage;

- large mass;

- high price.

Features of choice

If the buyer has already decided on the type and configuration of the equipment, then finally he should also pay attention to the following characteristics:

Engine power . Lightweight machines have a motor with a power of 1.5 - 2 kW. This is sufficient for sawing thin plywood and fibreboards. In the case of wood chips, the cutting speed will be low. For cutting a single layer of large format, machines with a power of up to 4 kilowatts are suitable. Industrial units operating from a three-phase power supply allow cutting material in batches and stacks, and their power reaches 6 - 8 kW.- Disk size . The frames and attachment points for the equipment are made in such a way that it is possible to fasten the disk in a certain range of sizes. A 200 mm disc is considered the minimum standard, and 550 mm can be installed in heavy and some medium-sized devices. The maximum thickness of the material being cut depends on this parameter.

- Speed . The cutting speed and equipment performance depend on this number. Some models have speed control. To work with wood and wood-based materials, a frequency of 2500 to 6000 rpm is usually used.

- Carriage mechanism . Can be made using ball bearings or roller rolling devices on aluminum guides. Ball carriages are less susceptible to contamination, but roller carriages are able to withstand greater weight of sheets laid on the cutting table and have a long service life.

A cutting-format machine is a necessary piece of equipment for manufacturers of cabinet furniture and has a high degree of versatility. When choosing and purchasing machines, pay close attention to warranty service and repairs, since any breakdown can lead to downtime.

What to look for when buying a panel saw

The choice of equipment for furniture production depends on the volume of production. It must have sufficient productivity to provide its material.

Other factors determining the choice include:

- length and depth of cutting of the material;

- desktop size.

To cut long workpieces, it is necessary to purchase machines with a carriage stroke that exceeds the planned cutting dimensions. The maximum cutting width of parts is limited by the width of the bed. To work with large-sized material, it is necessary to purchase equipment with a folding frame. Only standard equipment can ensure dimensional accuracy.

What type of bed does your panel saw have?

FoldingMonolithic

For corner cuts, it is necessary to install format-cutting machines with two saw blades in production. High performance can be achieved by models equipped with powerful electric motors. This type of equipment has a large working resource. The evenness of the material cut depends on the rotation speed of the working shaft with sawing discs.

Other factors influencing the choice of machine model include:

- financial opportunities;

- dimensions;

- maintainability.

Before purchasing equipment, it is better to first determine its required technical characteristics, and then conduct a comparative analysis of models of the required class.

Characteristics by type

Enterprises that manufacture small wooden structures with a small load on the equipment purchase machines with horizontal orientation.

They are equipped with a ball carriage with an angular stop. For many, the saw machine is mounted on a bed with a tilt system of up to 45 degrees. Such machines have independent systems for adjusting the height of sawing devices. Vertical roller machines are more precise in operation. They have smaller dimensions, since the processed material is in a vertical position, which helps to save production space. The machines allow you to work with cutting sheets of large sizes. It is not the workpiece that is moved in them, but the saw unit, either manually or using an electromechanical drive.

CNC batch cutting centers are used in large series and mass production. They are easy to operate, and the use of numerical control is a guarantee of the quality and accuracy of the work performed. Depending on the size of the sheets, the saw carriage and pushers are fed automatically. A high speed of movement is achieved by the leveling unit with the constant presence of a pressure roller.

Lifehacks

In order to avoid chipping when cutting chipboard or laminated board, you must first draw a cutting line on the material with a sharp tool. Damage to the decorative layer of the slabs can be minimized by applying paper tape to the surface of the material along the cutting line.

You can reduce the number of chips on the cut edge of material sawed on light machines by reducing the vibration of the equipment during operation. To do this, work tables are additionally attached to the floor using metal corners and dowels.

Format cutting equipment ensures high accuracy of material cutting, which is fundamentally important for furniture production. With their help, angular, transverse and longitudinal cuts are made of particle boards of various densities, as well as solid wood.

Popular models

Popular household machines that are in demand among medium and small furniture manufacturers include Mj 45 kb-2 and JTS-315SP SM. The equipment is convenient to use and has small dimensions.

For Mj 45 kb-2, vibration is reduced due to a powerful welded frame, and for JTS-315SP SM, vibration is reduced due to a cast iron frame and an additional table. The disadvantage of the JTS model is the inconvenience of working with large-area material. Large furniture manufacturers purchase models like Altendjrf F 45. This is high-precision equipment that makes clean transverse, longitudinal and angular cuts of materials. Adjustment of the height and angle of inclination of the main saw is electromechanical. The control system of these machines allows for high-quality cutting.

Enterprises producing serial furniture use CNC batch cutting centers. A prominent representative is the center for batch and piece cutting Filato FL 3200 V, where 3200 is the length of the cut. On such machines, it is possible to cut large slabs with a saw unit due to the wide table and elongated carriage. The existing scoring disc guarantees the quality of the work performed.

An amateur who knows how to make simple wooden fixtures and simple household furniture can make a formatik with his own hands. To do this, you will need to install a massive table and sawing equipment in your home workshop.

Tools

0 votes

+

Vote for!

—

Vote against!

Many owners are wondering what equipment is required for high-quality production of cabinet furniture. Experts say that these are format-cutting machines, which are popularly called format circular saws or circular saws with a carriage. Each owner can assemble such a device with his own hands.

Purpose of the format-cutting machine

Format cutting equipment is intended for transverse, longitudinal cutting of lumber and cutting at a certain angle, format trimming and cutting of panel blanks, including the removal of overhangs after their cladding, as well as for the purpose of cutting full-size boards into blanks of a given size.

Format-cutting equipment, which is used in the production of cabinet furniture, allows us to produce high-quality finished products. The function of these machines lies in setting the basic parameters of furniture parts for subsequent processing. Such machines are designed for piece and batch cutting of workpieces.

Factory-made and home-made format-cutting machines work with different materials: various types of wood, plywood of any thickness, MDF panels, chipboard, fiberboard, including composite sheet materials lined with plastic, laminated paper and film materials, veneer and melamine. This equipment is usually used for cutting material that has precise geometric dimensions.

Format saws are used in small-scale production, medium- and large-scale furniture factories, as well as in small carpentry workshops. The possibility of preliminary cutting of workpieces with a separate saw directly under the cutting area allows you to cut workpieces lined with natural or artificial material without chipping the lining.

Design of a panel saw

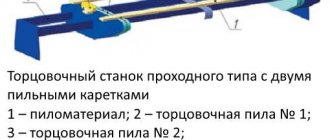

Structurally, format-cutting machines consist of the following elements: a bed, a fixed working table and a movable additional table (carriage, trolley, support frame, separator, ruler), a saw unit consisting of 2 saw blades, guides,

Saw unit

The welded design of the sawing machine guarantees a high level of stability and absence of vibration during sawing. When cutting veneered slabs, the main problem is the formation of chips on the lining in the area where the saw blade tooth comes out. To cope with this problem, the drawings of panel saws provide a saw unit with two saw blades.

The saw unit is a one-piece assembly that is cast from cast iron. Two electric motors are installed on its body, which rotate the scoring and main saw blades using a belt drive. The scoring disc is located closer to the workpiece, its size reaches 120 millimeters, and in the same direction the rotation speed reaches 8000 rpm.

This disk is required for cutting the cladding layer from the side where the teeth of the main disk come out, which rotates in the opposite direction to the workpieces and makes the main cut in the slab, as shown in the video about the sawing machine. This design allows you to get an even and clean cut that is not spoiled by burrs and chips.

On some types of machines, a saw unit is installed using special rotary sectors, which can be adjusted to cut at an angle. In this case, the ratio of the scoring and main saw blades is not violated. The saw unit can be installed on a work table or on a stand.

Founded saw

In format-cutting machines, the rotation speed of the main saw ranges from 4 to 6 thousand revolutions per minute. Continuous speed adjustment allows you to quickly set up the format-cutting machine and accurately select operating modes for different materials being cut. As a rule, the saw drive power is 3-5.5 kilowatts. Remember that high power consumption, which is usually characteristic of a technological process in which sawing a package of sheets or cutting hard wood, is not always appropriate.

The height of the cut or the position of the main saw in format-cutting machines is set by vertical movement of the saw unit. In this case, two methods are used: along vertical guides and by swinging around a horizontal axis. The maximum height to which the saw rises relative to the table must be indicated in the technical specifications of the unit.

Traditionally, it reaches 80 - 130 millimeters. When the saw is tilted, this figure decreases accordingly. Some models provide automatic raising and lowering of the saw, powered by an electric drive, sometimes even setting the height using the control panel.

The saws of a format-cutting machine usually have an inclination of up to 45 degrees, as in the photo of format-cutting machines. This will cause the entire saw unit to tilt. Thanks to the presence of special trunnions, the horizontal axis of rotation of the machine runs along the line of intersection of the plane of the fixed table and the main saw, which eliminates jamming of the saw in the table slot. This function is necessary in the manufacture of cabinet furniture elements.

Movable and fixed table

The main fixed table, which is cast from cast iron, has an upper milled surface, the dimensions of which can be adjusted by additionally installing extension and expansion tables on it and a parallel stop ruler that can move.

The movable table consists structurally of a carriage, which is made of a multi-chamber aluminum profile, a support frame, an angular stop ruler, which has folding stops and a telescopic extension, a support frame and its support. The carriage, thanks to its own design, is resistant to bending and twisting loads.

Most often in furniture production, format-cutting machines with a carriage length of approximately 3200 millimeters are used. This is the most suitable solution for devices with a movable carriage, because it matches most of the dimensions of the plates that are used by enterprises.

You should not chase the high prices of format cutting machines, believing that they work better. Remember that the longest cutting length will always be less than the carriage stroke if you have a scoring saw. To completely pass the sawing zone, the workpiece requires an additional 200-300 millimeters.

To move the workpiece, a roller carriage is used that moves along steel guides, and a separator with balls or rollers that moves between V-shaped steel guides. To adjust the main table or saw that is movable relative to the plane, the design of format cutting machines, as a rule, provides appropriate compensators or regulators.

Guides and carriages

The movable table of format-cutting machines serves as a base surface intended for laying the slabs to be cut; it must withstand the weight of the material. The load is taken by the carriage itself and its guides. If they are not rigid enough, the carriage guides will be subject to not only vertical loads, but also torque.

Due to the significant length of the lever, the application of load at the contact points of the rollers or balls in linear guides reaches a maximum value. Therefore, special guides are used in machines with a carriage, which ensure ease of movement and eliminate the occurrence of gaps in them, which directly affects the processing accuracy of the workpiece being cut.

Different machines from different manufacturers use guides of different designs using rollers, balls and their combinations. The most common design, regardless of the cost of the saw, is an aluminum carriage that moves along steel guides on linear ball bearings.

The guides are often made in the form of steel strips, which are built into the aluminum carriage body in such a way that two “channels” are formed to accommodate the balls. Such a “prismatic” circuit is capable of absorbing loads in any direction. To increase the service life of the lining, the structure is subjected to thermal hardening before installation. And anodizing, which prevents the appearance of stripes on the workpiece due to aluminum contamination.

There are also guides in which the balls are not steel, but plastic, the rigidity of which is achieved by using an aluminum profile with a large number of internal ribs. Some guides have built-in wear compensators, but this unit usually cannot be repaired at home.

Additional options

Many panel saws are equipped with digital position indicators for stops and rulers, which are mounted directly on them. There are also machines in which the current position of the ruler or stop is set on the monitor screen using a control panel, and then such devices are moved to the specified position automatically by an individual electric drive.

On format-cutting equipment, the following can be used as standard or additional equipment:

- electric braking system for the main saw blade,

- adjusting the speed of movement of the main saw blade,

- system of automatic lubrication and angle adjustment of the saw unit,

- electromechanical drives,

- electric motors with increased power,

- upper protection of saw blades, which is equipped with a pipe for removing sawdust,

- pneumatic or eccentric clamps for holding workpieces,

- additional support frame,

- rotating ruler for cutting blanks and slabs at an indirect angle,

- double corner stop,

- vibration sensor,

- system of protection against ingress of chips and dust.

Manufacturing of a panel cutting machine

If you are planning to start making cabinet furniture, then you should ask how to make a format-cutting machine. Its operating principle is simpler than simple, but the price of a factory-made format cutting machine is quite decent. Not every private owner can afford to buy such equipment. But assembling a machine with your own hands is possible for every person who is able to handle tools and is at least a little familiar with technology.

During the work you will need: metal pipes, channels and metal angles, two electric motors, a main dust and scoring disk, shafts from agricultural machinery, fasteners (nuts and bolts), a set of metal tools, a welding machine.

First, you need to make a strong steel frame for the panel saw using metal channels. The dimensions of the blanks for the base should be as follows: length of the machine 6500-6700 millimeters, width 2500 millimeters, height 800-1100 millimeters. Then construct the main and floor guide of the machine and fix them on the bed. For the manufacture of guides, it is customary to use a pipe that has dimensions of 60 by 5 by 6500 millimeters.

The movable work table must be made to move along a guide, because the table will feed the sheet during operation. Provide a cutting line length of 3000-3200 millimeters. If desired, you can increase or decrease this parameter; to do this, you only need to change the length of the guides.

Hang two saws on the machine – a scoring saw and a main saw. The saws should be installed on the saw unit; they rotate towards each other and are driven by two asynchronous motors. Be sure to provide the possibility of tilting the block at an acute angle of up to 45 degrees. For this purpose, equip the saw unit with a special rotating mechanism.

Be careful when choosing motors, because they drive the saws. The motor power must be at least 2.9 kW. The motors must rotate the main saw at a speed of about 5000 rpm, and the scoring saw at 8000 rpm. In the design of the machine, use saw blades with a diameter of 250 millimeters, which allows you to cut laminated chipboards and trim sheets.

To safely use do-it-yourself sizing machines in the production area, provide good exhaust ventilation, because wood particles can ignite from the smallest spark generated when the engines are running. Given the high speed of movement of the saw blades, it is recommended to exercise extreme caution when working on the machine, since disks that rotate at high speed can cause injury to the worker, including loss of the hand and entire limb.

After making a format-cutting machine at home, you can begin to directly process the material. Sheets usually have large dimensions, so before installing the sheet into the mechanism, it is worth making initial markings in the places where the cuts will be made. The size of the workpiece should be larger by at least 7 - 8 millimeters on each side. After creating a small stack of blanks with markings, you can start cutting and trimming the material.

Manual cutting of chipboard parts: Step-by-step instructions

1 Draw out the dimensions of the slab on a piece of paper, preferably to scale. Don't forget to reduce it by 10mm on each side.

2 Sort the list by similarity of required parts. For example, the sides of kitchen cabinets have the same dimensions - 500 x 712 mm.

There are quite a lot of them, write down all such details separately. Continue sorting using the same principle: same width, same structure, and so on.

3 Lay out on a sheet of chipboard first the large parts and those that should have a similar structure. Don't forget about the width of the saw - 4 mm! This is where a calculator will definitely come in handy.

4 Place the remaining parts. You can work through several options until you get the one that is ideal, most economical and profitable.

How to prevent chipping from chipboard

A material such as laminated chipboard has the harmful property of leaving chips on the ends after cutting. The only way to avoid such trouble is to increase the rotation speed of the saw or slowly feed the saw onto the material. However, not all so simple. Chipboard sheets consist of pressed sawdust and a laminating layer. The laminating layer is a thin but very durable material, and the pressed sawdust is a thick and soft layer.

Using a powerful motor, the soft sawdust is cut like butter, causing the hard laminate to simply chip off. The solution is to use 2 saws with different rotation speeds or cut slowly.

Everything is clear with the speed at which the saw feeds onto the material, but using two saws is worth understanding. It is worth noting that here you will need drawings of format cutting machines. To achieve the desired result, the laminate cutting disc is placed so that it cuts no more than 2 mm, and the rotation speed is achieved by reducing the disc or using a more powerful motor.

Cutting part

To cut the base layer, a large disk with a cutting depth of up to 40 mm is used. It is worth noting that this version of the sawing mechanism allows you to achieve a cutting speed of 1 m in 10 seconds.